Power and Performance - Tsubaki Europe

Power and Performance - Tsubaki Europe

Power and Performance - Tsubaki Europe

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

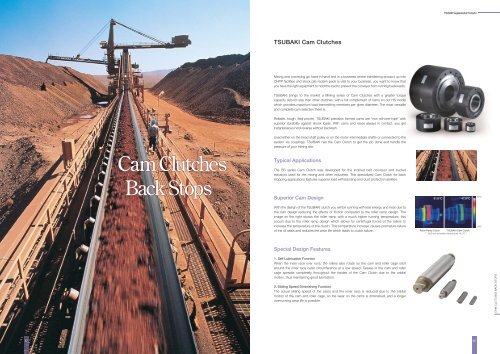

TSUBAKI Supplemental ProductsTSUBAKI Cam ClutchesMining <strong>and</strong> conveying go h<strong>and</strong> in h<strong>and</strong> <strong>and</strong> in a business where transferring product up intoCHPP facilities <strong>and</strong> stock pile reclaim pads is vital to your business, you want to know thatyou have the right equipment to hold the load to prevent the conveyor from running backwards.TSUBAKI brings to the market a Mining series of Cam Clutches with a greater torquecapacity size-for-size than other clutches, with a full complement of cams on our HS modelwhich provides maximum load transmitting members per given diameter. The most versatile<strong>and</strong> complete cam selection there is.Reliable, tough, field-proven. TSUBAKI precision formed cams are “non roll-over-type” withsuperior durability against shock loads. With cams <strong>and</strong> races always in contact, you getinstantaneous hold reverse without backlash.Used either on the head shaft pulley or on the motor intermediate shafts or connected to thesystem via couplings, TSUBAKI has the Cam Clutch to get the job done <strong>and</strong> h<strong>and</strong>le thepressure of your mining site.Cam ClutchesTypical ApplicationsThe BS series Cam Clutch was developed for the inclined belt conveyor <strong>and</strong> bucketelevators used for the mining <strong>and</strong> other industries. This specialized Cam Clutch for backstopping applications features superior load withst<strong>and</strong>ing <strong>and</strong> dust protection abilities.Back StopsSuperior Cam Design81.8ºC47.8ºC95ºCWith the design of the TSUBAKI clutch you will be running with less energy <strong>and</strong> heat due tothe cam design reducing the effects of friction compared to the roller ramp design. Theimage on the right shows the roller ramp with a much higher running temperature, thisoccurs due to the roller ramp design which allows for centrifugal forces of the rollers toincrease the temperature of the clutch. This temperature increase causes premature failureof the oil seals <strong>and</strong> reduces the wear life which leads to clutch failure.Roller Ramp Clutch TSUBAKI Cam Clutch** 1600 rpm at ambient temperature 19.2ºC **18ºCSpecial Design Features1. Self Lubrication FunctionWhen the inner race over runs, the rollers also rotate so the cam <strong>and</strong> roller cage orbitaround the inner race outer circumference at a low speed. Grease in the cam <strong>and</strong> rollercage spreads completely throughout the insides of the Cam Clutch due to the orbitalmotion, thus maintaining good lubrication.2. Sliding Speed Diminishing FunctionThe actual sliding speed of the cams <strong>and</strong> the inner race is reduced due to the orbitalmotion of the cam <strong>and</strong> roller cage, so the wear on the cams is diminished, <strong>and</strong> a longeroverrunning wear life is possible.CAM CLUTCHES BACK STOPS4748