Fed-Batch Sorbose Fermentation Using Pulse and Multiple Feeding ...

Fed-Batch Sorbose Fermentation Using Pulse and Multiple Feeding ...

Fed-Batch Sorbose Fermentation Using Pulse and Multiple Feeding ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

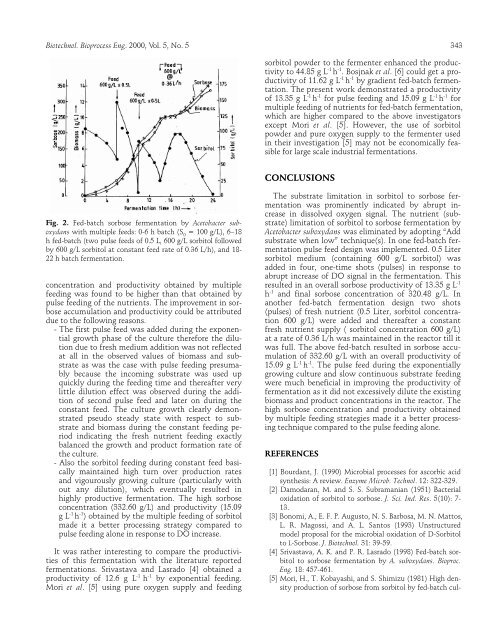

Biotechnol. Bioprocess Eng. 2000, Vol. 5, No. 5 343sorbitol powder to the fermenter enhanced the productivityto 44.85 g L -1 h -1 . Bosjnak et al. [6] could get a productivityof 11.62 g L -1 h -1 by gradient fed-batch fermentation.The present work demonstrated a productivityof 13.35 g L -1 h -1 for pulse feeding <strong>and</strong> 15.09 g L -1 h -1 formultiple feeding of nutrients for fed-batch fermentation,which are higher compared to the above investigatorsexcept Mori et al. [5]. However, the use of sorbitolpowder <strong>and</strong> pure oxygen supply to the fermenter usedin their investigation [5] may not be economically feasiblefor large scale industrial fermentations.CONCLUSIONSFig. 2. <strong>Fed</strong>-batch sorbose fermentation by Acetobacter suboxydanswith multiple feeds: 0-6 h batch (S 0= 100 g/L), 6–18h fed-batch (two pulse feeds of 0.5 L, 600 g/L sorbitol followedby 600 g/L sorbitol at constant feed rate of 0.36 L/h), <strong>and</strong> 18-22 h batch fermentation.concentration <strong>and</strong> productivity obtained by multiplefeeding was found to be higher than that obtained bypulse feeding of the nutrients. The improvement in sorboseaccumulation <strong>and</strong> productivity could be attributeddue to the following reasons.- The first pulse feed was added during the exponentialgrowth phase of the culture therefore the dilutiondue to fresh medium addition was not reflectedat all in the observed values of biomass <strong>and</strong> substrateas was the case with pulse feeding presumablybecause the incoming substrate was used upquickly during the feeding time <strong>and</strong> thereafter verylittle dilution effect was observed during the additionof second pulse feed <strong>and</strong> later on during theconstant feed. The culture growth clearly demonstratedpseudo steady state with respect to substrate<strong>and</strong> biomass during the constant feeding periodindicating the fresh nutrient feeding exactlybalanced the growth <strong>and</strong> product formation rate ofthe culture.- Also the sorbitol feeding during constant feed basicallymaintained high turn over production rates<strong>and</strong> vigourously growing culture (particularly without any dilution), which eventually resulted inhighly productive fermentation. The high sorboseconcentration (332.60 g/L) <strong>and</strong> productivity (15.09g L -1 h -1 ) obtained by the multiple feeding of sorbitolmade it a better processing strategy compared topulse feeding alone in response to DO increase.It was rather interesting to compare the productivitiesof this fermentation with the literature reportedfermentations. Srivastava <strong>and</strong> Lasrado [4] obtained aproductivity of 12.6 g L -1 h -1 by exponential feeding.Mori et al. [5] using pure oxygen supply <strong>and</strong> feedingThe substrate limitation in sorbitol to sorbose fermentationwas prominently indicated by abrupt increasein dissolved oxygen signal. The nutrient (substrate)limitation of sorbitol to sorbose fermentation byAcetobacter suboxydans was eliminated by adopting “Addsubstrate when low” technique(s). In one fed-batch fermentationpulse feed design was implemented. 0.5 Litersorbitol medium (containing 600 g/L sorbitol) wasadded in four, one-time shots (pulses) in response toabrupt increase of DO signal in the fermentation. Thisresulted in an overall sorbose productivity of 13.35 g L -1h -1 <strong>and</strong> final sorbose concentration of 320.48 g/L. Inanother fed-batch fermentation design two shots(pulses) of fresh nutrient (0.5 Liter, sorbitol concentration600 g/L) were added <strong>and</strong> thereafter a constantfresh nutrient supply ( sorbitol concentration 600 g/L)at a rate of 0.36 L/h was maintained in the reactor till itwas full. The above fed-batch resulted in sorbose accumulationof 332.60 g/L with an overall productivity of15.09 g L -1 h -1 . The pulse feed during the exponentiallygrowing culture <strong>and</strong> slow continuous substrate feedingwere much beneficial in improving the productivity offermentation as it did not excessively dilute the existingbiomass <strong>and</strong> product concentrations in the reactor. Thehigh sorbose concentration <strong>and</strong> productivity obtainedby multiple feeding strategies made it a better processingtechnique compared to the pulse feeding alone.REFERENCES[1] Bourdant, J. (1990) Microbial processes for ascorbic acidsynthesis: A review. Enzyme Microb. Technol. 12: 322-329.[2] Damodaran, M. <strong>and</strong> S. S. Subramanian (1951) Bacterialoxidation of sorbitol to sorbose. J. Sci. Ind. Res. 5(10): 7-13.[3] Bonomi, A., E. F. P. Augusto, N. S. Barbosa, M. N. Mattos,L. R. Magossi, <strong>and</strong> A. L. Santos (1993) Unstructuredmodel proposal for the microbial oxidation of D-Sorbitolto L-<strong>Sorbose</strong>. J. Biotechnol. 31: 39-59.[4] Srivastava, A. K. <strong>and</strong> P. R. Lasrado (1998) <strong>Fed</strong>-batch sorbitolto sorbose fermentation by A. suboxydans. Bioproc.Eng. 18: 457-461.[5] Mori, H., T. Kobayashi, <strong>and</strong> S. Shimizu (1981) High densityproduction of sorbose from sorbitol by fed-batch cul-