Mining Pumps - Putzmeister Solid Pumps

Mining Pumps - Putzmeister Solid Pumps

Mining Pumps - Putzmeister Solid Pumps

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

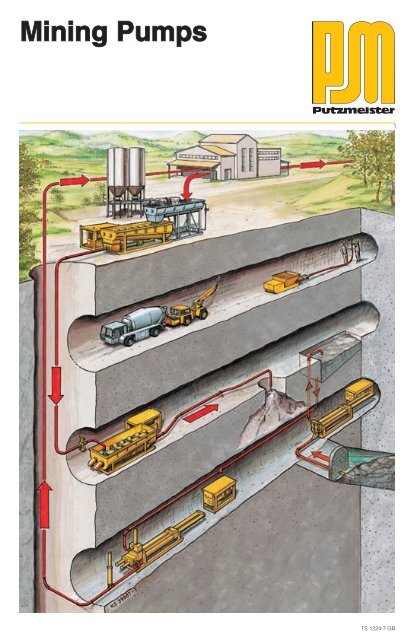

<strong>Mining</strong> <strong>Pumps</strong>1TS 1224-7 GB

2 5Mine Dewatering Backfilling Packing and Injection9File under: A 1.00, TS 1.10, IP 1.05, A 4.00, TS 4.10, IP 4.05, A 5.00Mine dewatering requires thatmine sludge loaded with sand beconveyed to the surface. The<strong>Putzmeister</strong> HSP seat valve pumpis a particularly cost-effectiive andhigh performance solution to thisquestion. The case study below ofa mine in Alsace-Lorraine is anexample of the economic andtechnical benefits.The French mining companyHouillères de Bassin de Lorraine(HBL) was looking for a bettersolution for bringing their miningsludge, with a sand loading of720 g per litre, up to the surfacefrom a depth of 1250 m . The 43centrifugal pumps used for thispurpose had reached their performancelimits as mining depthsincreased. Furthermore, the additionof further pumps had led to adrastic dilution of the solids contentover the full height. The systemsengineers at <strong>Putzmeister</strong> used twodouble-piston seat valve pumpsmodel HSP 3080) to solve this problem.Using the largest pump ofits kind in the world, powered byits 320 kW hydraulic power packproduced the following benefits.■ Greater volumes, ie 90 m 3 /h areconveyed at a flow velocity of2.7 m/s against a pressure of100 bar.■ The solids concentrationremains constant.■ The power consumption hasbeen reduced by 75%.■ The long 3 m stroke guaranteeslow wear and smooth operation.■ The reliable technology enhancesavailability and considerablyreduces maintenancecosts.0 m315 m545 m686 m826 m1.036 m1.250 mSystematic illustration of the old conveying plant consistingof 43 centrifugal pumpsHSP 3080HSP 3080System of the new pump circle43High production costs, safety considerations,ecological restraints,etc, are forcing comprehensiverestructuring of operating methodson mine owners. Backfilling usingmine and power plant tailings isan important part of this. At theheart of any backfill system is the<strong>Putzmeister</strong> double piston pumpwith S-transfer tube (type KOS) orwith seat valves (type HSP) pumpwith ZX conveying pipelinesystems. For paste backfilling projectsthe HSP-pump with poppetvalves allow high pressures in thepipeline system and therefore longconveying distances.Up to 500 m 3 /h and 150 barConveying distances up to 11 kmfrom the central surface mixingplant to the underground backfillingarea, without intermediatepump.Conveying capacities up to500 m 3 /h.Operating pressures in the conveyedmedium of up to 150 bar.Permissible pressure in the200 mm internal diameter pipelineof up to 250 bar because of thehigh static pressure elements.Suitable for abrasive material.The advantages of the method:■ Closed fine tailing circuit ‘mine -preparation - mine’.■ Better mechanical control ofmine excavation openings.■ More selective excavation andincrease of cut-off-grade.■ Hermetically sealed conveyingpath for material within the pipeline.■ Increased working and operationsafety.■ Lower wear costs.■ Less specific energy requirement.■ Only little residue water inthe mines.Process illustration of coal-mine backfillingKOS-<strong>Pumps</strong> 3080 at Walsum colliery6(Source: German Montan Technologie DMT)78The manual construction of rockfilldams prevent water infiltration andconsiderably reduce the cost ofmaintaining the gallerie. Control ofthe point where face and gallerymeet is improved and a higherspeed of mining achieved.In hydro-mechanical backifllingtechnology a concrete mixed withwater to a pumpable consistencyis placed by the machine.This method achieves a high qualityof placement and a high levelof backfill placed (80 – 100 %). Ithas advantages from the point ofview of rock mechanics and processingtechnique and is thereforethe most widely used.For this kind of work werecommend our BSM 1002 E andBSM 1400 E double piston pumpswith S-transfer tube or ourRMP 1000 worm pump, dependingon the output, grain size andpressure which is needed.For mortar and cement injectionwe recommend <strong>Putzmeister</strong> pressurecontrolled mixing and pumpingstations.11Universal spraying and injection equipment1012High density solids pump HSP 30802 HSP 25 100 pumps for Bulyanhulu gold mineIntroducing the hose into the liningBSM 1401 with Contimix CMH 1240 in a German collieryTS 1224-7 GB 23 TS 1224-7 GB 4TS 1224-7 GB

Shotcreting13Wet shotcreting is a recognizedand succesful method in tunnellingand mining. Being a pioneerin the spraying of plaster, mortarand concrete, <strong>Putzmeister</strong> canoffer complete, customer-specificsystems and accessories forunderground use.14<strong>Putzmeister</strong> equipment is availablemounted on mine carriers withAWD and articulated- or 4-wheelsteering-chasis.For hand held operations smalland versatile pumps such asBST 501 E give best results inplacing wet shotcrete in a mineenvironment.The advantages of the wet shotcretingmethod:Concrete pumps for standard Shotcreting work15■ High performance, more than20 m 3 shotcrete per hour.■ Reduces shotcreting timeby 50%.■ Reduces rebound by 30%- 50%.■ Lower compressed airconsumption.■ Uniform concrete due to homogeneousdistribution.■ Better working environment.■ Lower wear costs.Shotcrete Buffalo WETKRET in action, with a performance of 30 m 3 /h16Schot crete pump BST 501 E5TS 1224-7 GB

The right pump for every application.Pump type Field of application Output PressureS-tube pump KOS-Series Backfilling and Muck pumping 10 to 500 m 3 /h up to 150 barof coarse grainedsludges with particles of up to 80 mm17Seat-valve pump HSP-Series Mine dewatering for finely grained 10-250 m 3 /h up to 150 barhigh density solids18Ball-valve pump KOV-Series High pressure pumping of fine slurries 0-50 m 3 /h up to 130 barlike waste coal, concentrated tailings,packing concrete, sump sludge.19Eccentric worm pumps Smooth and uniform conveying of vicous 0-20m 3 /h up to 25 barmedia directly from the delivery line, containeror mixer, etc. Simple reliable design.2320Differential Injection of cement, lime mortars, up to 6 m3/h up to 80 barpiston pumpsgypsum, anhydrite and other mortar-21like materials.KK 139 models Pumping without pulsation 0-6 m 3 /h up to 60 barand interruption with mechanicalcompensation piston drive.22Mixokret-pneumatic conveyers For conveying sand, gravel, earth, and 2-8 m 3 /h up to 25 barfine concrete mixes which are not pumpable.III: 1/KS 39987-1, 2/KS 69818-f, 3/KS 69950, 4/10396, 5/KS 39918, 6/60118, 7/60119, 8/14794-12A, 9/KS69869, 10/137804-3, 11/12783, 12/9964-3, 13/KS 39756, 14/54406, 15/14438-10,16/–, 17/KS 39918, 18/KS 69818-f, 19/KS 69869, 20/KS 69953, 21/KS 69951, 22/KS 69952, 23/KS 39648-2<strong>Putzmeister</strong> Products and Services:PM-Concrete <strong>Pumps</strong>PM-Systems Engineering PATPM-TelebeltPM-Mortar Machines GmbHPM-Aqua Pressure System A/SPM-ServicesPM-Concrete Project Division CPDPM-Consulting und Data Technology PCDPM-Academy GmbH<strong>Putzmeister</strong> AGMax-Eyth-Str. 10 · D-72631 AichtalP.O. Box 2152 · D-72629 AichtalTel. +49 (71 27) 599-0Fax +49 (71 27) 599-520Internet: http://www.putzmeister.deE-mail: pmw@pmw.deTS 1224-7 GBRight to make technical amendments reserved. · © by <strong>Putzmeister</strong> 2001 · All rights reserved · Printed in Germany (20103 Pe)