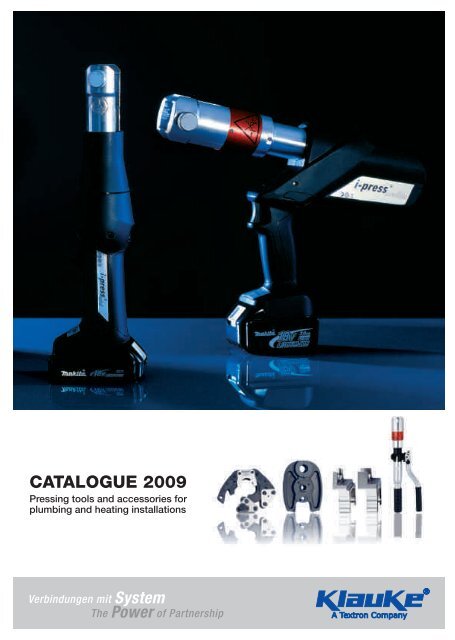

CATALOGUE 2009 - Gustav Klauke GmbH

CATALOGUE 2009 - Gustav Klauke GmbH

CATALOGUE 2009 - Gustav Klauke GmbH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Dear business friend,Time and time again, people ask us how our tools have become so widespread on the marketand how our developments sit so close to the pulse of time. The answer is easy:3 Because we work closely with the system suppliers.3 Because we have gained immense expertise over some 130 years.3 And because we see your requirements as first priority.All this makes us who we are today: A worldwide leading manufacturer of pressing tools inthe plumbing and heating technology sector.You will find our new products in this catalogue. It also contains valuable information onpressing machines, jaws and chains for diverse connection systems.And there's more: The following pages will show you what the <strong>Klauke</strong> company stands forand describes the benefits of our high product quality.Enjoy reading your <strong>Klauke</strong> catalogue of plumbing products.Yours sincerely<strong>Klauke</strong> Plumbing Team<strong>Gustav</strong> <strong>Klauke</strong> <strong>GmbH</strong>Auf dem Knapp 46 · D-42855 RemscheidP.O. Box 10 05 22 · D-42805 RemscheidPhone: +49 (0) 2191 / 907 442 · Fax: +49 (0) 2191 / 907 - 251E-mail: tools@klauke.textron.com · Internet: www.klauke.com

<strong>Klauke</strong>, a Textron Group Company –and your partner.We use best matched products and services to create pioneering solutions fortrade and industry all over the world. Both as <strong>Klauke</strong> in its own right, as well as incollaboration with the technology Group Textron.Familiar with the market for 130 years.Since being established in 1879, we have been committed tosystematically developing and producing innovative, user-orientedsolutions. Our origin lies in the traditions of tool production in ourregion; the focus being on watch-making tools. By the end of the1950s, we were specialising in cable lugs for the electrical industryand tools for solderless pressing technology.Since 1994, we have also been applying our knowledge toplumbing and heating technology and are the world's leadingmanufacturer of pressing tools.We meet your requirements backed by our 600-strong highlytrained team. Every year, over 30 hours of training and developmentper worker qualify our team to apply rationalisation potentials usingSIX SIGMA and Lean Management methodologies.Our consistent progress is set apart by future-oriented investmentin personnel, production, development and service.This guarantees first-class processes, professional quality andunprecedented customer-satisfaction.4

Certified for qualityand the environment.<strong>Klauke</strong> for enhanced safety andoptimised standards.For us, just meeting the standard is not enough.In terms of safety, user friendly application androbustness, all <strong>Klauke</strong> products comply with thehighest specifications and perform in excess ofthe standards required. We are certified to DINISO 9001. Our products comply with internationalapprovals.We purchase only raw materials and componentsthat guarantee first-class quality. And to guaranteethat, we work long-term with carefully chosensuppliers. Stringent monitoring proceduresand thorough quality inspections atevery stepof the manufacturing process ensure ourhigh standards are consistently maintained.Our customers depend on it – and so theyshould: We guarantee maximum safety andoptimised comfort in the application of ourproducts.Environmental issues also playa crucial role. Our company isEcoprofit (“ECOlogical PROjectFor Integrated EnvironmentalTechnology”) certified andexcels through its especiallypro-environmental processes.5

In touch with your requirements.<strong>Klauke</strong>: Your partner in all phases.As a partner to the system suppliers, as well asto the installer, <strong>Klauke</strong> offers an unrivalled servicepackage: Advising customers on the market launchof new systems, developing, manufacturing andmaintaining the tools concerned, testing connections- everything under one-roof. Become a <strong>Klauke</strong>partner and benefit from unparalleled expertise in thefield of solderless connection technology for heatingand plumbing installations.We integrate closely with the market to make surewe can react swiftly to changes and influencethese changes wherever we can. With <strong>Klauke</strong> asyour partner, you will always have state-of-the-arttechnology, guaranteeing optimised safety for boththe planning and use of the system.6

Always in good hands.Our sales force at your service.Some 50 years of experience in solder-free connection systems and closepartnerships with over 150 system suppliers have made us a force to bereckoned with all over the world in the pressing tool and accessory sector.Our plumbing team is close to our products' users and keeps abreastof both market developments and the needs of system suppliers andinstallation engineers. Skilled employees offer you the advice you need overthe phone or on-site. We also develop solutions for specific enquiries fromsystem suppliers and continuously improve our products in discussion withusers.Individual development and design.In parallel with the development projects for system suppliers, we designprototypes of the pressing tools concerned and test them together withthe system suppliers in our own test laboratories. This ensures that<strong>Klauke</strong> tools are also available for use by professionals as soon as thenew systems are ready for market launch.7

The latest technologyfor top quality.State-of-the-art production.As well as carefully selecting top-quality raw materials and components,we take care to ensure optimised precision in the manufacturing processes.The latest CNC machines guarantee precision manufacturing for all toolcomponents. Our facility in Germany enables great production depth,offering our customers the benefit of swift modification in line with need orproduct changes.Using the latest methods in manufacture and logistics guarantees anoptimised added-value process. This ensures top quality, low costs andadequate availability.Our application engineers are at your service.Our proprietary application systems and test laboratory leave no stoneunturned. We are able to conduct country-specific system pre-tests for thesystem suppliers. We are your competent partner, from sectional images,material analyses on pressings through to high-temperature tests (VP614).At your service - by telephone or on the spot. Either way, you can dependon the experience of our application engineers.8

Optimised worldwideservice.Your tool is in good hands.The Service Center in Remscheid and the authorisedService Centers (ASC) offer you comprehensive technicalsupport for our tools.Starting with a tool hotline for maintenance and repairservice through to a hire service.We provide this service all over the world.We do everything we can to make sure your tools remainfully functional – or, upon request, provide you withalternatives.Our national and international partners‘ expertise andequipment always conform to the latest standards. Contactdata for all our national and international service partnerscan be found in the annexe on page 44. Repair and maintenance service through theService Centers. Complete maintenance with annual inspection. Fast, uncomplicated tool hire service for all standardtools.International phone+49 (0) 21 91 / 907 - 242Fax Service Center+49 (0) 21 91 / 907 - 243E-mailservice@klauke.textron.com9

ntelligenttechnologyThe new generation of <strong>Klauke</strong> pressing tools.10

Intelligent solutions for efficient pressingtechnology.How the new innovations of thetool generation benefit you.Improved ergonomics and comfort.The newly designed tools of the machine generation havebeen completely revised, both technically and ergonomically. The2-component plastic housing with soft inlay gives the feeling ofa pleasant, secure grip, prevents slipping and avoids pressurepoints in the grip area. The optimised centre of gravity makeswork effortless - even when continuously assembling overhead.Optimum illumination.The new, integrated workplace illumination for tools makesit easier to identify the pressing location and mount the pressingjaw on the correct fittings in difficult light conditions. This meansguaranteed reliable pressing and higher efficiency at all times,even under difficult conditions.Reliably monitored pressing: Hydraulic Pressure Check.Hydraulic Pressure Check, HPC for short, monitors the oil pressurein the tool's oil circuit, hence ensuring a continuous, consistentpress quality.During each pressing cycle, the achieved pressing pressure isdetermined by a pressure sensor and compared to the requiredminimum value. An audible warning signal sounds if the achievedpressure differs from the specified working pressure. The user willknow immediately that the corresponding pressing location must bechecked and repressed or replaced as required. If three consecutivepressings occur outside the required pressure range, the toolsswitch off automatically and must be sent in for service. Thisadditional safety function has been requested by our customersand system partners, offering more safety as you work.11

Immediate stop as required and after use.Should unclear situations occur during a pressing operation, useof an incorrect fitting or incorrect pressing jaw for example, theimmediate “Quickstop” function on the motor permits a swiftreaction. As soon as the push button is released, the tool comesto an immediate standstill – without even the slightest follow-upmovement – so that the user can make the necessary correctionswithout delay.The “Autostop” after pressing tells the user that the pressingoperation has finished. This function also reduces tool wear andprolongs battery life.Electronic control for optimum benefit.The machine generation is equipped with a robust,construction site standard electronic system. This system providesthe user with all important information on machine status, pressingresult and battery power.The information is output via a light diode or an audible signal:When 20% battery power remains:Service notification:Pressure deviation:visual LED signalvisual LED signalaudible signal, buzzerKey data such as the tool's year of manufacture, serial number,revision status of the integrated machine parts, number of pressingcycles and the last or next service are also evident for our ServiceCenter, hence guaranteeing the best possible service result.Pro-environmental high-quality synthetic oils for optimumfunctionality.And not only have technology and electronics been completelyrevised - closer attention has also been paid to environmentalissues: <strong>Klauke</strong> uses exclusively synthetic hydraulic oils in its newtools. These oils are highly bio-degradable and harmless to water.Furthermore, these hydraulic oils are tested to the most stringentstandards and are available worldwide.12

Our new tools:MAP2LUAP3LUAP4LUAP100LMAPAXL13

Hydraulic pressing toolsRadialFlexible andcost-effectivethanks to interchangeable<strong>Klauke</strong> Mini pressingjawsMAP2LBattery-powered pressing tool18 V/1.5 Ah with constant thrust forsystem-related nominal sizes to 32 mmCompact design foroptimum access to theinstallationEffortless workingthanks to low weight andergonomic designSecure grip due to innovative2-component housingTool information shownvia LED displayEasy 1-handedoperationIllumination forworking safelyHigh-quality, powerfulMakita Li-Ion technology forlasting, battery-poweredpressingSpecial features and benefits Very quick pressing thanks toshort pressing cycle of3-4 seconds Very high safety factor based on“Quickstop” function Precise pressing force thanks toHPC pressure monitoring withaudible signal Extremely short charging timeof just 15 minutes (1.5 Ah) Time saved when multiplepressing by means of automaticpiston return Pressing jaws compatible withMAP1 tool Makita batteries andchargers available worldwide Long battery and tool servicelifethanks to “Autostop” afterthe pressing operation

Hydraulic pressing toolsRadialMAP2LApplicationsStainless steel, steelCopper, copper alloysmax. NS22* (NS28 upon request)max. NS28*32 NW 15 kNLi-Ion 350°2KMulti-layer composite pipemax. NS32*PEX pipemax. NS32**These values are system-related.Please contact your system supplier for binding information.Technical dataMachine weight:without jaw 1.7 kgincl. jaw 2.3 kgmm15 min350°Li-Ion15 kNDimensions (L x W x H): 377 x 75 x 116 mmPressings per battery charge:Charging time: 1.5 Ah 15 min.3.0 Ah 22 min.approx. 350° rotating pressing jaw holder1.5 Ah approx. 150 (for NS20)3.0 Ah approx. 300 (for NS20)High-power Makita 1.5 Ah Li-Ion battery (3.0 Ah optional)Linear thrust of approx. 15 kNScope of supplyRigid plastic case with battery and chargerTool and case available with customised labelling (optional extra)Country-specific chargers availableAccessoriesPressing jaws Page 343.0 Ah battery Page 43Country-specific power packsavailable Page 43Application examples15

Hydraulic pressing toolsRadialFlexible andcost-effectivethanks to interchangeable<strong>Klauke</strong> Mini pressing jawsMAP1Battery-powered pressing tool9.6 V/2.0 Ah with constant thrust forsystem-related nominal sizes to 32 mmEffortless workingthanks to low weightand ergonomic designPrized at the Mostra ConvegnoExpocomfort international trade fair held inMilan for functionality, ergonomics andtechnical handlingEasy 1-handedoperationWork independent ofmains powerwith battery operationSpecial features and benefits Quick pressing thanks to shortpressing cycle of 5-6 seconds High safety factor thanks to“Quickstop” function Long tool and battery servicelife due to quality components Time saved when multiplepressing by means of automaticpiston return Pressing jaws compatible withMAP2 tool16

Hydraulic pressing toolsRadialMAP1ApplicationsStainless steel, steelmax. NS22* (NS28 upon request)32 NW15 kN 350°Copper, copper alloysmax. NS28*Multi-layer composite pipemax. NS32*PEX pipemax. NS32**These values are system-related.Please contact your system supplier for binding information.Technical datamm40 min350°Machine weight:without jaw 1.9 kgincl. jaw 2.5 kgDimensions (L x W x H): 415 x 55 x 80 mmPressings per battery charge:Charging time:1.5 Ah 40 min.3.0 Ah 60 min.approx. 350° rotating pressing jaw holder2.0 Ah approx. 100 (for NS20)3.0 Ah approx. 150 (for NS20)High-power 2.0 Ah NiMH battery (3.0 Ah optional)15 kNLinear thrust of approx. 15 kNScope of supplyRigid plastic case with battery and chargerCountry-specific chargers availableAccessoriesPressing jaws Page 343.0 Ah battery Page 43Application examples17

Hydraulic pressing toolsRadialFlexible and costeffectivethanks tointerchangeablestandard pressing jawsUAP3LBattery-powered pressing tool18 V/3.0 Ah with constant shear force forsystem-related nominal sizes to 110 1 mmEffortless workingthanks to low weight andergonomic designIllumination forworking safelyTool information shownvia LED displayEasy 1-handedoperationSecure grip due toinnovative 2-componenthousingHigh-quality, powerfulMakita Li-Ion technology forlasting, battery-poweredpressingSpecial features and benefits Quick pressing due to shortpressing cycle Very high safety factor based on“Quickstop” function Precise pressing force thanks toHPC pressure monitoring withaudible signal Extremely short charging time ofjust 22 minutes Time saved when multiplepressing by means of automaticpiston return18 Worldwide availability ofMakita batteries andchargers Long battery and tool servicelifethanks to “Autostop” afterthe pressing operation

Hydraulic pressing toolsRadialUAP3LApplicationsStainless steel, steelCopper, copper alloysmax. NS54*max. NS54/108/4"*110 NW 32 kNLi-Ion 350°2KMulti-layer composite pipemax. NS75/110*PEX pipemax. NS75**These values are system-related.Please contact your system supplier for binding information.Technical dataMachine weight: 3.5 kgmmDimensions (L x W x H): 366 x 81 x 317 mmPressings per battery charge: approx. 300 (for NS20)22 min350°Li-Ion32 kNCharging time: 22 min.approx. 350° rotating pressing jaw holderHigh-power Makita 3.0 Ah Li-Ion batteryLinear thrust of approx. 32 kNScope of supplyRigid plastic case with battery and chargerTool and case available with customised labelling (optional extra)Country-specific chargers availableAccessoriesPressing jaws Page 34Pressing chains Page 36Country-specific power packsavailable Page 43Application examples19

Hydraulic pressing toolsRadialUAP2Flexible andcost-effectivethanks to interchangeablestandard pressing jawsBattery-powered pressing tool12 V/3.0 Ah with constant thrust forsystem-related nominal sizes to 110 mmTool information shownvia LED displayEasy 1-handedoperationWork independentof mains power withbattery operationSpecial features and benefits Quick pressing thanks to shortpressing cycle of 5-7 seconds Time saved when multiplepressing by means of automaticpiston return Long battery and tool servicelifethanks to “Autostop” afterthe pressing operation High safety factor thanks to“Quickstop” function20

Hydraulic pressing toolsRadialUAP2ApplicationsStainless steel, steelmax. NS54*110 NW 32 kN350°Copper, copper alloysmax. NS54/108/4"*Multi-layer composite pipemax. NS75/110*PEX pipemax. NS75**These values are system-related.Please contact your system supplier for binding information.Technical dataMachine weight: 3.9 kgmmDimensions (L x W x H): 350 x 95 x 300 mmPressings per battery charge: approx. 220 (for NS20)45 min350°Charging time: 45 min.approx. 350° rotating pressing jaw holderHigh-performance 3.0 Ah NiMH battery32 kNLinear thrust of approx. 32 kNScope of supplyRigid steel case with battery and chargerTool and case available with customised labelling (optional extra)Country-specific chargers availableAccessoriesPressing jaws Page 34Pressing chains Page 36Country-specific power packsavailable Page 43Application examples21

Hydraulic pressing toolsRadialFlexible andcost-effectivethanks to interchangeablestandard pressing jawsUNP2Mains operated pressing tool230 V with constant thrust for systemrelatednominal sizes to 110 mmEffortless workingthanks to low weightEasy 1-handedoperationMains operation with230 V / 110 V, optionalSpecial features and benefits Quick pressing thanks to shortpressing cycle Time saved when multiplepressing by means of automaticpiston return High safety factor based on“Quickstop” function22

Hydraulic pressing toolsRadialUNP2ApplicationsStainless steel, steelCopper, copper alloysMulti-layer composite pipePEX pipe*These values are system-related.Please contact your system supplier for binding information.max. NS54*max. NS54/108/4"*max. NS75/110*max. NS75*110 NW 32 kN 350°Technical dataMachine weight: 3.5 kgmm350°32 kNDimensions (L x W x H): 350 x 81 x 260 mmapprox. 350° rotating pressing jaw holderLinear thrust of approx. 32 kNScope of supplyTool, including rigid steel caseTool and case available with customised labelling (optional extra)Country-specific version possibleAccessoriesPressing jaws Page 34Pressing chains Page 36Application examples23

Hydraulic pressing toolsRadialFlexible andcost-effectivethanks to interchangeablestandard pressing jawsUAP4LBattery-powered pressing tool18 V 3.0 Ah with constant thrust forsystem-related nominal sizes to 110 mmEffortless workingthanks to low weight andergonomic designIllumination forworking safelyTool information shownvia LED displaySecure grip due toinnovative 2-componenthousingHigh-quality, powerfulMakita Li-Ion technology forlasting, battery-poweredpressingSpecial features and benefits24 Time saved when multiplepressing by means of automaticpiston return Very high safety factor based on“Quickstop” function Makita batteries andchargers available worldwide Precise pressing force thanks toHPC pressure monitoring withaudible signal Long battery and tool servicelifethanks to “Autostop” afterthe pressing operation Broad application range fromNS12 to NS110 (4") includingsteel and stainless steel systems Quick change from pressingjaws to chains with adapter jaw

Hydraulic pressing toolsRadialUAP100LReliable pressingchain adaptationthanks to new pressinghead conceptBattery-powered pressing tool18 V/3.0 Ah with constant thrust forsystem-related nominal sizes from76.1 mm to 108 mm, PN16 approvedIllumination forworking safelyTool information shownvia LED displayComfortable operationhandleSecure gripdue toinnovative2-componenthousingHigh-quality, powerfulMakita Li-Ion technology forlasting, battery-poweredpressingSpecial features and benefits Extremely short charging time ofjust 22 minutes Very high safety factor based on“Quickstop” function Precise pressing force thanks toHPC pressure monitoring withaudible signal Time saved when multiplepressing by means of automaticpiston return Makita batteries andchargers available worldwide Long batteryand tool service-lifethanks to “Autostop” after thepressing operation26

Hydraulic pressing toolsRadialUAP100LApplicationsStainless steel, steel NS76.1; 88.9; 108; 2.1/2"; 3", 4"Copper, copper alloys NS76.1; 88.9; 108; 2.1/2"; 3", 4"*These values are system-related.Please contact your system supplier for binding information.108 NW 120 kNLi-Ion 350°2KTechnical dataMachine weight: 12.7 kgmmDimensions (L x W x H): 567 x 81 x 359 mmPressings per battery charge: approx. 20 (for NS108)22 min350°Li-Ion120 kNCharging time: 22 min.approx. 350° rotating pressing jaw holderHigh-power Makita 3.0 Ah Li-Ion batteryLinear thrust of approx. 120 kNScope of supplyRigid sheet steel case with 1 battery, charger and mains adapterTool and case available with customised labelling (optional extra)Country-specific chargers and mains adapters availableAccessoriesPressing chains Page 36Synchronised pressing thanksto 4-segment technologyApplication examples27

Hydraulic pressing toolsRadialHPU2Manual hydraulic pressing tool forsystem-related nominal sizes to 110 mmFlexible andcost-effectivethanks tointerchangeablestandard pressingjawsOptimum pump leverposition for all requirementsthanks to approx.350° rotating headSecure grip due toergonomic handlesCompact design thanksto the integrated oil tankin the handleSpecial features and benefits Quick infeed of the piston dueto 2-stage hydraulics With manual/hydraulic forcetransmission, it also meetsfire and explosion protectionrequirements Time saved when multiplepressing by means of automaticpiston return Effortless working thanks to lowweight Broad application range fromNS12 to NS108 (4") Forced pressing cycle thanks tovalve control28

Hydraulic pressing toolsRadialHPU2ApplicationsStainless steel, steelmax. NS54110 NW 32 kN350°Copper, copper alloysmax. NS54/108/4"Multi-layer composite pipemax. NS75/110PEX pipemax. NS75*These values are system-related.Please contact your system supplier for binding information.Technical dataWeight: only approx. 3.1 kgmm350°32 kNDimensions (L x W x H): 500 x 81 x 125 mmapprox. 350° rotating pressing jaw holderLinear thrust of approx. 32 kNScope of supplyPressing tool, including fabric bagAccessoriesPressing jaws Page 34Pressing chains Page 36Application examples29

Pressing profilesThe usages for which dimensions, profiles and machine types are relevant can be foundin the application and assembly instructions from the system supplier.KSP 0Machine and system-related forUponorDimension-related forPressing jaws Interchangeable dies ÆPressing chains ÆUponor UNIPIPEKSP 1BDimension-related forPressing jaws Interchangeable dies Pressing chains ÆMachine and system-related forALPHATECH F.I.V. Fivpress MegaroBegetube Fränkische Ibérica PipelifeEmmeti GerpexIvarKSP 2Dimension-related forPressing jaws Interchangeable dies Pressing chains ÆMachine and system-related for Fränkische Rohrwerke alpex-duoKSP 3FMDimension-related forPressing jaws Interchangeable dies Pressing chains Machine and system-related forBelair Sertinox Filtube Instalpres NirotecChibro HSF Raccorderie Metalliche InoxPresComap Inoxpres Seppelfricke <strong>GmbH</strong>Comisa Isotubi SimplexEmcal PRESSO NOX Kohler InoxPres VSHEsta Simplesta Lombarda Raccordi InoxPres Pegler YorkshireEurotubi EuropaMainpexKSP 4VDimension-related forPressing jaws Interchangeable dies Pressing chains Machine and system-related forABM Kupral Frabo Metallwerke Möllersdorf B-PressComap Sudopress CU IBP B-Press NibcoComisa LK Systems B-Press Tzanos B-PressEmmetiMegaro30

Pressing profilesThe usages for which dimensions, profiles and machine types are relevant can be foundin the application and assembly instructions from the system supplier.KSP 5UDimension-related forPressing jaws Interchangeable dies Pressing chains Machine and system-related forAquatecnic Jupiter Heizsysteme Polytherm EspanolaCO.E.S Coesclima Mr. Pex RifengFAR Nikkai Industries Saneper SaperXPress / MultisaperFränkische Rohrwerke Nupi Wavin Future K1-K2IntermaliaPipelifeKSP 6Machine and system-related forHTHDimension-related forPressing jaws Interchangeable dies Pressing chains ÆThermtecKSP 7HDimension-related forPressing jaws Interchangeable dies Pressing chains ÆMachine and system-related forBlansol / Barbi Haka HAKAPRESS SimplexFAR Mair M-Press /Gomafix TzanosFriatec Prandelli Multyrama Wefa Plastic WEFATHERM-PRESSKSP 7AMachine and system-related forHRDimension-related forPressing jaws Interchangeable dies Pressing chains ÆRothKSP 8THHDimension-related forPressing jaws Interchangeable dies Pressing chains Machine and system-related for HENCO NS32-4031

Pressing profilesThe usages for which dimensions, profiles and machine types are relevant can be foundin the application and assembly instructions from the system supplier.KSP 11Machine and system-related forTHDimension-related forPressing jawsInterchangeable diesPressing chainsABM Kupral Golan PipelifeAPE Henco PolysanAuspex Duopes Herz IPANAPRESS Fränkische RohrwerkeBecker Plastics Industrielle du Plastique & Accessoires RifengChibro IP Produkter RofixComap SudoPress Multiskin IPA IPANAPRESS Schlösser EuroPressSystermComisa Kermi X-Press Schütz EHTDalpex Klimit Seppelfricke DistribuzioneDiwa Rohrsysteme LK Systems PressPex SestaEgoplast MA.S.TER SYSTEM SSt RolltecEmcal PRESSO Megaro StelbiFAR Nicoll Tiba abitFränkische Ibérica Nikkai Industries Tiemme Racorderie CobrapressGabo Systemtechnik PB Tub Watts MTRGeneral FittingsPedothermGiacominiPinto & CruzKSP 12Machine and system-related forHODimension-related forPressing jaws Interchangeable dies Pressing chains ÆOventrop Cofit-P Polytherm Polyfix / Polyfix MT Systerm WELCOFLEXKSP 13MEDimension-related forPressing jaws Interchangeable dies ÆPressing chains ÆMachine and system-related for J.O.B. Heating MetzerplasKSP 15Machine and system-related forFG InoxFilpresFILDimension-related forPressing jaws Interchangeable dies ÆPressing chains ÆFiltubeJäger SystermvertriebKSP 16RRBDimension-related forPressing jaws Interchangeable dies ÆPressing chains ÆMachine and system-related for Rehau Raubasic32

KSP 17Machine and system-related forIDimension-related forPressing jaws Interchangeable dies Pressing chains ÆIplexPressing profilesThe usages for which dimensions, profiles and machine types are relevant can be foundin the application and assembly instructions from the system supplier.KSP 18Machine and system-related forMPDimension-related forPressing jaws Interchangeable dies ÆPressing chains ÆPoliedraKSP 19VALDimension-related forPressing jawsInterchangeable diesPressing chainsMachine and system-related for Valsir PexalKSP 20RFDimension-related forPressing jaws Interchangeable dies Pressing chains ÆMachine and system-related forBlansol / Barbi Ingenieria Plastica del Sur PipelifeGlobal Piping System AC-FIX Intermalia SaneperKSP 24Machine and system-related forCHEDimension-related forPressing jaws Interchangeable dies ÆPressing chains ÆChemidroKSP 25RRMDimension-related forPressing jaws Interchangeable dies ÆPressing chains ÆMachine and system-related for Rehau RaumultiKSP 28 (ABC)PEXDimension-related forPressing jaws Interchangeable dies ÆPressing chains ÆMachine and system-related for Auspex KSP28 Mr. Pex KSP28BTransmatic KSP28A Nibco KSP28B Ditron KSP28CKSP 33MADimension-related forPressing jaws Interchangeable dies ÆPressing chains Machine and system-related for Samyong EQJOINT33

Pressing jaws, universal jaws, interchangeable diesPressing jawsProfile codingto verify the used systempressing jaw on request<strong>Klauke</strong> pressing jaws with approvalfrom over 150 system suppliers for theapplications concernedEasy assignment ofpressing jaws and profilesthanks to coding withnominal size, profile andproduction dataMinimum wearthanks to additionalinduction-hardening ofthe wear points at infeedchamfers and profilegeometrySpecial features and benefits Compatible with all pressingtools approved by the systemsupplier Easy to differentiate betweenthe system-related profiles dueto different surface colours Better corrosion protectionthanks to special surface finish Optimised safety based on theuse of high-resilience tool steelThe additional jaw size coded onthe small face allows the user topick the jaw quickly from a full box.34

Pressing jaws, universal jaws, interchangeable diesPressing jaw MiniUniversal jaw Mini Pressing jaw, Size 1Stainless steel/steel(NS28 upon request) max. NS22Copper/alloysmax. NS28Multi-layer composite/PEXmax. NS32Copper/alloysMulti-layer composite/PEXmax. NS28max. NS32Stainless steel/steelCopper/alloysMulti-layer composite/PEXmax. NS18max. NS18max. NS20Pressing jaw, Size 2Pressing jaw, Size 3Universal jaw StandardStainless steel/steelCopper/alloysMulti-layer composite/PEXmax. NS35max. NS35max. NS40Stainless steel/steelCopper/alloysmax. NS54max. NS54CopperMulti-layer composite/PEXmax. NS28max. NS32Interchangeable dies, Size 1Interchangeable dies, Size 2Axial jawMulti-layer composite/PEXmax. NS20Copper/alloysmax. NS28Multi-layer composite/PEX max. NS32 Multi-layer composite/PEX max. NS32Suitable pressing toolsUAP3 Page 18UAP2 Page 20 UNP2 Page 22 HPU2 Page 28 UAP4 Page 24MAP2 Page 14MAP1 Page 16 MP32 Page 40MP20 Page 4135

Pressing chainsPressing chainsSynchronised pressing thanks tofour-segment technologySynchronised pressing thanksto 4-segment technologyReliable form fitthanks to forced segmentguidanceSolid chain lockallows strong forces to beabsorbed and preventsthe slipping off the fittingFirm positioningof the adapter jaw thanksto optimised design Simple chain changeover evenwhen “working overhead” byseparating the chain from themachine Optimum force transmissionthanks to the toggle actionprinciple The pressing chains can bechanged by one personSpecial features and benefits Simultaneous constriction of thefitting and deformation of thesealing element thanks to foursegmenttechnology Easy chain removal after thepressing operation due to polishedprofile surfaces Optimised safety based on theuse of high-resilience tool steel International approvals,including for special systemtests with large dimensions(PN12, 48 bar; PN16, 64 bar) Profile coding to verify theused system pressing chain onrequest36

Pressing chainsPressing chain HP (to 64 bar)Pressing chain LP (to 48 bar)System tests PN 16 to 64 bar bursting pressureStainless steel/steel max. NS108 – 4"Copper/copper alloys max. NS108 – 4"Multi-layer composite/PEXmax. NS110Compatible only with adapter jaw SBKUAP4(to be ordered separately)Stainless steel/steel max. NS108 – 4"Copper/copper alloys max. NS108 – 4"Multi-layer composite/PEXmax. NS110Pressing chain 42-54Pressing element for interchangeable diesCompatible only with adapter jaw SBK42-54(to be ordered separately)Stainless steel/steel max. NS54 – 2"Copper/copper alloys max. NS54 – 2"Multi-layer composite/PEXmax. NS75Interchangeable dies to be ordered separatelyStainless steel/steel max. NS54 – 2"Copper/copper alloys max. NS54 – 2"Multi-layer composite/PEXmax. NS63Suitable pressing toolsUAP3 Page 18UAP2 Page 20 UNP2 Page 22 HPU2 Page 28 UAP4 Page 24UAP100 Page 2637

Hydraulic pressing toolsAxialMAPAXLQuick-change systemfor sliding forksBattery-powered pressing tool18 V/1.5 Ah with constant thrust forsystem-related sliding connections to32 mmEffortless workingthanks to low weightand ergonomic designCompact design foroptimum accessto the installationTool information shownvia LED displaySecure grip due toinnovative 2-componenthousingEasy 1-handedoperationIlluminationfor working safelyHigh-quality, powerfulMakita Li-Ion technology forlasting, battery-poweredpressingSpecial features and benefits Very quick assembly thanks toshort pressing cycle of3-4 seconds Extremely short charging timeof just 15 minutes (1.5 Ah) Very high safety factor based on“Quickstop” function Makita batteries andchargers available worldwide Long battery and tool servicelifethanks to “Autostop” afterthe pressing operation Multi-use thanks to mountingexpanding heads Time saved when multiplepressing by means of automaticpiston return38 Precise pressing force thanks toHPC pressure monitoring withaudible signal

Hydraulic pressing toolsAxialMAPAXLApplicationsMulti-layer composite pipePEX pipemax. NS32*max. NS32*32 NW 13 kN2KLi-Ion*These values are system-related.Please contact your system supplier for binding information.Technical dataMachine weight: 2.2 kgmm15 minLi-Ion13 kNDimensions (L x W x H): 170 x 81 x 300 mmPressings per battery charge:Charging time: 1.5 Ah 15 min.3.0 Ah 22 min.1.5 Ah approx. 150 (for NS20)3.0 Ah approx. 300 (for NS20)High-power Makita 1.5 Ah Li-Ion battery (3.0 Ah optional)Linear thrust of approx. 13 kNScope of supplyRigid plastic case with battery and chargerTool and case available with customised labelling (optional extra)Country-specific chargers and mains adapters availableAccessoriesSliding forksExpanding adapterExpanding crownsupon requestupon requestupon requestApplication examples39

Manual pressing toolsRadial32 NW 55 kN360°MP32Manual pressing tool for system-relatednominal sizes to 32 mmPressing headmade of forgedspecial steelApplicationsStainless steel, steel max. NS22Copper alloyMulti-layercomposite pipePEX pipemax. NS28max. NS32max. NS32*These values are system-related. Pleasecontact your system supplier for bindinginformation.Technical dataWeight: approx. 2.7 kgmm360°55 kNDimensions (L x W x H):570 x 55 x 115 mmapprox. 360° rotatingpressing jaw holderLinear thrust of approx.55 kNScope of supplyPressing tool, including fabric bagSpecial features and benefits With manual force transmission,it also meets fire and explosionprotection requirements Less force required thanksto toggle action transmissionand continuously-adjustabletelescopic handles Quick-change mounting forsimple die changing Optimum positioning for allrequirements thanks to 360°rotating head40

Manual pressing toolsRadialMP2020 NWManual pressing tool for system-relatednominal sizes to 20 mmCompact head designpermits assembly inconstricted spacesApplicationsMulti-layercomposite pipePEX pipemax. NS20max. NS20*These values are system-related. Pleasecontact your system supplier for bindinginformation.Technical dataWeight: approx. 1.6 kgmmDimensions (L x W x H):500 x 25 x 100 mmScope of supplyPressing tool, including fabric bagSpecial features and benefits Optimum pressing forcedistribution thanks to the 5-levelfunction of the pressing lever Neutral position possible due tosafety function Quick-change mounting forsimple die changing Easy access to skirting boardinstallations thanks to one-sided90° handle opening Forced pressing cycle thanks tobar ratchet41

AccessoriesUncoiler/pipe dressing toolRR2KPLKLVersionUncoiler and pipe dressing device for multi-layer composite pipe toNS26Pipe dresser continuously adjustableCoiler weight: approx. 12.5 kgPipe dresser weight: approx. 4.3 kgConnection piece weight: approx. 2.0 kgScope of supplyUncoiler, pipe dresser, connector pieceAlso available as separate items.RAH2RR2KLStepped de-burrerVersionFor all standard multi-layer composite and PEX pipes to NS40Customised NSDeburring set with interchangeable headsInternal and external de-burrers made for multi-layer composite and PEX pipesVersiond de-burring and calibration toolfor multi-layer composite and PEX pipes to NS 63.Reliable de-burring and calibration of pipe ends thanks tocalibration mandrel and three-edged de-burring blade formachining the internal, end and external surfaces of the pipe.De-burring heads can be used with handle or cordless screwdriver.NS and version upon request42

AccessoriesChargers and spare batteries for 18 V pressing machinesLGL1 RAL1 RAL2Versionwith Makstar chargingLGL1technology from Makita18 V / 1.5 Ah / Li-Ion onlyRAL1 to be used formini and axialRAL2 18 V / 3.0 Ah / Li-IonChargers and spare batteries for 9.6 V MAP1 pressing machinesLG4F RAM2 RAM3VersionCharger for all <strong>Klauke</strong>LG4F9.6 V and 12 V batteriesRAM2 9.6 V / 2.0 Ah / NiMHRAM3 9.6 V / 3.0 Ah / NiMHChargers and spare batteries for 18 V pressing machinesLG4FRA5VersionLG4FRA5Charger for all9.6 V and 12 V batteries12 V / 3.0 Ah / NiMHMains units for 12 V and 18 V pressing machinesNG1-12VNG2-18VVersionMains unit suitable forall <strong>Klauke</strong> 12 V pressingNG1machines, 240 V and120 V availableMains unit suitable forall <strong>Klauke</strong> 18 V pressingNG2machines, 240 V and120 V availableMains adapter not to be usedfor 9.6 V pressing machines43

44Notes

Notes45

For secure connections worldwide.<strong>Gustav</strong> <strong>Klauke</strong> <strong>GmbH</strong>Auf dem Knapp 46 · D-42855 RemscheidP.O. Box 10 05 22 · D-42805 RemscheidPhone: +49 (0) 2191 / 907 - 442Fax: +49 (0) 2191 / 907 - 251E-mail: info@klauke.textron.comInternet: www.klauke.com46 AUSTRALIAForcorp PTY Ltd.Ellenbrook Western Australia 6069Phone: +61-92969090Fax: +61-92969080bill@forcorp.com.auThe Energy Network PTY LTGeebung QLD 4034Phone: +61-7321288999Fax: +61-7321288998repair@the energynetwork.com.au AUSTRIA<strong>Klauke</strong> Handelsgesellschaft mbH2544 LeobersdorfPhone: +43-2256-62925Fax: +43-2256-62930office@klauke.at BELGIUMNBR Nussbaumer & Cie1500 HallePhone: +32-23570940Fax: +32-23549679info@nussbaumer.be PEOPLE'S REPUBLIC OF CHINAHangzhou XianhenHangzhou, 31009Phone: +86-571-87813666Fax: +86-571-56180991Xianhenguoji-lml@hotmail.comShanghai Feng Ye Trading Co. LtdShanghai, 200233Phone: +86-21-5265 8823Fax: +86-21 5265 8829fengyemaoyi@sohu.comfengye@fengye-sh.comGuangzhou Xueqin ElectricalGuangdong, 510095Phone: +86-20-37589535* 3068Fax: +86-20-87327792xueqin-electric@tom.comBeijing Black Eagle HydraulicBeijing, 100028Phone: +86-10-64924396Fax: +86-10-58220595service@bjbsn.comChengdu Taili Industry & Trade Co. LtdChengdu, 100028 (China)Phone: +86-28-85592749Fax: +86-28-85594507taili@mail.sc.cninfo.net CROATIAKonekt d.o.o.HR-10000 ZagrebPhone: +385-12361890Fax: +385-12361882konekt@konekt.hr CZECH REPUBLIC/SLOVAKIA<strong>Klauke</strong> z. Nitsch s.r.o.14000 Praha 4 - PankracPhone: +420-261213229Fax: +420-261213218<strong>Klauke</strong>@<strong>Klauke</strong>.cz DENMARK<strong>Klauke</strong> Remscheid42855 Remscheid (Germany)Phone: +49 - 2191/907-168Fax: +49 - 2191/907-243service@klauke.textron.com FRANCEKLAUKE FRANCE57150 CreutzwaldPhone: +33-3-87298470Fax: +33-3-87298479s.weiten@klaukefrance.fr FINLANDOY Elteosähkö AB20360 TurkuPhone: +358-2-4100200Fax: +358-2-4100230info@elteo.fiCableX oy20360 TurkuPhone: +358-2-8800020Fax: +358-2-8800021reijo.karlsson@cablex.fi GREAT BRITAINNorwich Instrument ServicesNorwich NR6 5DRPhone: +44-1603-416900Fax: +44-1603-416902norman@nisltd.co.uk

GREECEKalamarakis Sapounas SAAthensPhone: +30-210-240-6000Fax: +30-210-240-6007dtzanes@ksa.gr HUNGARYTrend ElektroH-1117 BudapestPhone: +36-1-464-3118Fax: +36-1-464-3119trendelektro@freemail.hu INDIASTI IndustriesMumbai 400058Phone: +91-22-26744096Fax: +91-22-26744044supriti@calter.comBishop ElectricalsBangalore 560064Phone: +91-9886115506Fax: +91-8026914568servicecentre@bishopelectricals.com INDONESIAPT. Aura Sinarindo AbadiKelapa Gading, Jakarta 14240Phone: +62-214534237Fax: +62-214534238rifkiyadi@aurasinarindo.com IRELANDPressure Hydraulic LtdRathcoole, Co, DublinPhone: +353-1-4588880Fax: +353-1-4588940nfallon@pressure-hydraulics.com ISRAELShay A.U., Ltd.49222 Petach TikvaPhone: +972-3-9233601Phone: +972-3-9234601ilans@uriel-shay.com ITALYWAB40121 BolognaPhone: +39-051-522308Phone: +39-051-522761info@wab-aleotti.com JAPANGoodman IncYokohama, Kanagawa 236-0037Phone: +81-45-701-5680Fax: +81-45-701-4302kazu@goodman-inc.co.jp KOREAKESCO CO., LTD.2-1608, ACE HITECH CITY,Phone: +82-22-6140989Fax: +82-22-6140966tsoh@ikesco.com LEBANONAl-Bonian Group6470 BeirutPhone: +961-1-385 708Fax: +961-1-385 714zokhrof.sleiman@al-boniangroup.com LITHUANIATechnikos MeistraiVilnius 03154Phone: +370 -5-2311564info@technikosm.com NEW ZEALANDJonel Hydraulics Ltd.East Tamaki AuklandPhone: +64-9-2749294Fax: +64-9-2748231enerpac@jonelhydraulics.co.nz The NETHERLANDSH.K. Electric B.V.5320 AB HedelPhone: +31-73-5997599Phone: +31-73-5997590f.jansen@hkelectric.nl NORWAYMiltronic ASN-3421 LierskogenPhone: +47-32226610Fax: +47-32226656hans.petter.selbo@miltronic.no POLANDRB Brexim S.A.05-825 Grodzisk MazowieckiPhone: +48-22-7344380Fax: +48-22-7344381rboffice@brexim.pl PORTUGALPalissy Galvani Electricidade S.A.1200-433 LisbonPhone: +351-21-3223400Phone: +351-21-3223410ana.pereira@palissygalvani.pt ROMANIAGerkon Electro S.R.L.Miercurea Ciuc,Phone: +40-266-372108Fax: +40-266-312238office@gerconelectro.ro RUSSIAUnit Mark Pro109147 MoscowPhone: +7-495-7480907Fax: +7-495-7483735service-pro@unit.ruOrionkommash620046 EkaterinburgPhone: +7-343-3531153Fax: +7-343-3539396 SINGAPOREGrace Electrical Engineering PTE LTDSingapore 349185Phone: +65-6741-3423Fax: +65-6741-7506geepl@singnet.com.sg SLOVENIAIsaria d. o.o.1420 TrbovljePhone: +386-356-31800Fax: +386-356-31802isaria.trbovlje@siol.net SPAIN/ANDORRAGave Electro s.l.BarcelonaPhone: +34-93-8424887Fax: +34-93-8422755gsalmeron@gave.com SOUTH AFRICAEberhardt Martin CCNewlands JohannesburgPhone: +27-11-2880000Fax: +27-11-6732043ebm@ebm.co.za SWEDENAGB Service AB39241 KalmarPhone: +46-480-28122Fax: +46-480-28165anders@agbservice.se SWITZERLANDFerratec AG8964 RudolfstettenPhone: +41-56-6492121Fax: +41-56-6492141info@ferratec.ch TAIWANPo Charng Co.LtdSun Yi Dist, Taipei 110Phone: +84-886227631623Fax: +84-886227667492vincent.cn@msa.hinet.net TURKEYÜnal Kardes Tic A.S.34630 Besyol-Sefaköy / IstanbulPhone: +90-212-6249204Fax: +90-212-5924810sdiricanli@unalkardes.com.tr UKRAINETechlight LTD36002 PoltavaPhone: +38-0532-500970Fax: +38-050-5242646Y.Tsilyuryk@techlight.com.ua USAGreenlee TextronRockford, IL 61109-2932Phone: +1-800-435-0786Fax: +1-815-kdrews@greenlee.textron.comA & A Hydraulic Repair Co.Cleveland, OH 44142Phone: +1-216-362-4000Fax: +1-216-362-4020dan@hydraulicparts.comQUEST IncBrighton, CO 80601Phone: +1-720-685-9091Fax: +1-303-655-8143bobquest@prodigy.net VIETNAMHuu Hong Machinery Co., LtdHo Chi Minh CityPhone: +84-8-8117454Fax: +84-8-8116338sales@huuhong.com.vn47

Trusting in <strong>Klauke</strong>:Our system partners. <strong>Klauke</strong> pressing tools ols and jaws are tested and approved for specific systems by all the system stsuppliers pllisted below. Contact your system supplier for other approved systems or information on potential presessingdimimensions for specifiificsystems. <strong>Klauke</strong> System components can be obtained from our partners below.A&O Johansenwww.ao.dkFiltubewww.inoxidables.s.cocomABM Kupralwww.abmkupral.huFittings Specialistenwww.fittings.dkAdrien Riquierwww.riquier.frFra.Bowww.frabo.netAFLwww.blockfitting.itFränkische Ibéricawww.w.frfraeaenknkische.comAlphatechalphatech@magnet.grFränkische Rohrwerkewww.fraenknkische.e.deAquatech. Distributionwww.aquatech.ieFriatecwww. w.friatec.deAPEwww.ape-raccorderie.comGabowww. w.gabosysys.deAquatecnicwww.aquatecnic.esGalprowww. w.galprostylex.co. o.nzAuspexwww.auspex.com.auGas Pexwww.gaspex.comom.a.auBecker Plasticswww.becker-plastics.deGattringerwww.gattringer.atBegetubewww.begetubeb .comGeneral Fittingswww.w.gegeneneralfiittings.itBelairwww.belair.frGeneral Fittings GIBACOwww.generalfiittings.nlBlansolwww.blansol.esGeorg Fischerwww. w.gegeorgfischer.itCentral Heatingwww. w.centralheating.co.o.nzGiacominiwww.giacomini.comChemidrowww.w.chemidro.comGlobal Piping SystemAC-FIX www. w ac-fix.comChibrowww. w chibro.comGolanwww.pexgol.co.ilCO.E.Swww.coes.itHakawww. w.hakagerodur.chComapwww. w.comamap-group.comHencowww.henco.beComisawww. w.comisasa.itHerotecwww.herotec.deDalpexwww. w dalpexgroup.comHerzwww.herz-armaturen.comDasungwww.w.spjoint.comHidrotecwww.coes.itDiwawww.diwafleex.deHSFwww.hsfbv.nlEgoplastwww.egoplalast.ruIBPwww.baenninger.infoEmcalwww.emcal.deIndustrie du Plastique et Accessoires www.ipa-tn.comEmmetiwww.emmeti.comIngenieria Plastica del Surwww.plomyplas.comEstawww.esta-rohr.deInoxwww. w.inox.dkEurotubiwww.eurotubieuropa.itInoxpreswww.inoxpres.netF.I.V.www.fiv.itIntermaliawww. w.intermrmalia.comFARwww.far-spa.itIP Produkterwww.ip-produktkter.fiFG Inoxwww.fginox.comIPAwww.ipa-fitting.comFilpreswww.filpres.ptIsotubiwww.isotubi.com48

IvaruPurmowww.purmo.deIVT Würthwww.rohreausrohr.deR.B.M.www.rbmspa.itJ.O.B. Heatingwww.jobco.ieRaccorderie Metallichewww.racmet.comJägerwww.jaeger-aquatec.atRehauwww.rehau.comJupiterwww.fussbodenheizung.deRifengwww.rifeng.comKanwww.kan.plRofixwww.rofix.comKekelitwww.kekelit.comRotexwww.rotex.deKermiwww.kermi.deRothwww.roth-industries.comKohlerwww.kohler.chSamyongwww.eqjoint.comLK Systemswww.lksystems.seSaneperwww.saneper.comLogstorwww.logstor.comSchlösserwww.schloesser-armaturen.deLombarda Raccordiwww.lombardaraccordi.itSchütz EHTwww.schuetz.netMainpexwww.mainpex.deSeppelfricke <strong>GmbH</strong>www.seppelfricke.deMair Heiztechnikwww.mair-heiztechnik.deSeppelfricke SDwww.seppelfricke.itMapresswww.mapress.deSestawww.sestasrl.itMarkwww.mark-kg.deSimplexwww.simplex-fit.deMA.S.TER SYSTEMwww.w.master-system.itSST Rolltecwww.sst-rolltec.itMegarowww. w.megagaro.deStelbiwww.stelbi.comMetallwerke Möllersdorfwww. w.mmhg.a.atSystermwww.systerm.itMetzerplaswww.memetzerplas.comTECEwww.tece.frNibcowww.nibcbco.comTersiawww.tersia.nlNicollwww.nicoll-italia.comThermtecwww.thermtec.deNikkaiwww.kombi-3.comoTibawww.tiba.ptNirotec Aschlwww.nirotec.auTiemme Raccorderiewww.tiemme.comNupigecowww.nupinet.comTransmaticwww.transmatic.comOetikerwww.oetiker.comTzanoswww.tzanos.grOteraccordiwww.oterspa.itUnideltawww.unidelta.itOventropwww.oventrop.deUponorwww.uponor.comP. Henning Jensen www.phj.dkValsirwww.valsir.comPB Tubwww.pbtub.frVediswww.fonditalgroup.itPedothermwww.pedotherm.deViegawww.viega.comPegler Yorkshirewww.yorkshirefittings.co.ukVSHwww.vsh-fittings.comPinto & Cruzwww.pintocruz.ptVulkan Lokringwww.vulkan-lokring.dePipelifewww.pipelife.comWatts Industrieswww.wattsindustries.comPoliedrawww.poliedra.comWavinwww.wavin.comPolysanwww.polysan.atWefa Plasticwww.wefaplastic.comPolytherm Espaňolawww.polytherm.esWinklerwww.winkler-heizung.atPrandelliwww.prandelli.comWirsbo Veltawww.velta.de49

Your partner for electrical connectors.<strong>Klauke</strong> expertise beyond the world of heating and plumbing.ElectricalSanitaryOver the company's long history, <strong>Klauke</strong> has developed broadexpertise in the field of solderless connection technology. Notonly in the fields of plumbing and heating technology, but alsoevery aspect of electrical connections. <strong>Klauke</strong> ranks among theworld's leading technical innovators in this sector too.Textron's strategic alliance with Greenlee enables us to offercomplementary and matched product ranges for professionals. Thisinternational alignment highlights “The Power of Partnership”– and gives our customers the opportunity to focus on a partner forsolderless connection technology. For both electrical connectionsand connections for plumbing and heating installations.

www.klauke.comYour <strong>Klauke</strong> catalogue forelectrical connection technology.<strong>Klauke</strong> products forthe electrical industryare available only fromspecialist dealers. Therelevant sales addresses– as well asthe link to order your<strong>Klauke</strong> catalogueof electrical products– can be foundon the Internet atwww.klauke.comHAUPTKATALOGElektrische VerbindungstechnikWerkzeuge und Messgeräte<strong>Klauke</strong> sets benchmarks.Weight32 NWNominal sizeAutostopmmDimensions15 kNLinear thrust2K2-component housingPressings per battery chargeLi-IonLi-Ion batteryWorkplace illumination40 minCharging timeNiMH batteryLED maintenance indicator2-segment pressing350°Rotating pressing jaw holderAudible signal4-segment pressingAutomatic retractionHydraulic Pressure CheckQuick stop

Strong brands for your success:<strong>Gustav</strong> <strong>Klauke</strong> <strong>GmbH</strong>Auf dem Knapp 46D-42855 RemscheidPhone: +49 (0) 2191 / 907 - 442Fax: +49 (0) 2191 / 907 - 251E-mail: tools@klauke.textron.comInternet: www.klauke.comSubject to change without prior notice. KATHAUPTSAN09GB 500 05/09 I