mechanised and orbital tig

mechanised and orbital tig

mechanised and orbital tig

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

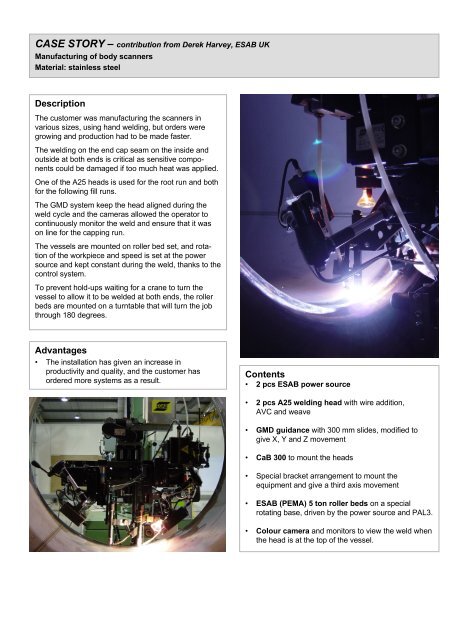

CASE STORY – contribution from Derek Harvey, ESAB UKManufacturing of body scannersMaterial: stainless steelDescriptionThe customer was manufacturing the scanners invarious sizes, using h<strong>and</strong> welding, but orders weregrowing <strong>and</strong> production had to be made faster.The welding on the end cap seam on the inside <strong>and</strong>outside at both ends is critical as sensitive componentscould be damaged if too much heat was applied.One of the A25 heads is used for the root run <strong>and</strong> bothfor the following fill runs.The GMD system keep the head aligned during theweld cycle <strong>and</strong> the cameras allowed the operator tocontinuously monitor the weld <strong>and</strong> ensure that it wason line for the capping run.The vessels are mounted on roller bed set, <strong>and</strong> rotationof the workpiece <strong>and</strong> speed is set at the powersource <strong>and</strong> kept constant during the weld, thanks to thecontrol system.To prevent hold-ups waiting for a crane to turn thevessel to allow it to be welded at both ends, the rollerbeds are mounted on a turntable that will turn the jobthrough 180 degrees.Advantages• The installation has given an increase inproductivity <strong>and</strong> quality, <strong>and</strong> the customer hasordered more systems as a result.Contents• 2 pcs ESAB power source• 2 pcs A25 welding head with wire addition,AVC <strong>and</strong> weave• GMD guidance with 300 mm slides, modified togive X, Y <strong>and</strong> Z movement• CaB 300 to mount the heads• Special bracket arrangement to mount theequipment <strong>and</strong> give a third axis movement• ESAB (PEMA) 5 ton roller beds on a specialrotating base, driven by the power source <strong>and</strong> PAL3.• Colour camera <strong>and</strong> monitors to view the weld whenthe head is at the top of the vessel.