mechanised and orbital tig

mechanised and orbital tig

mechanised and orbital tig

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

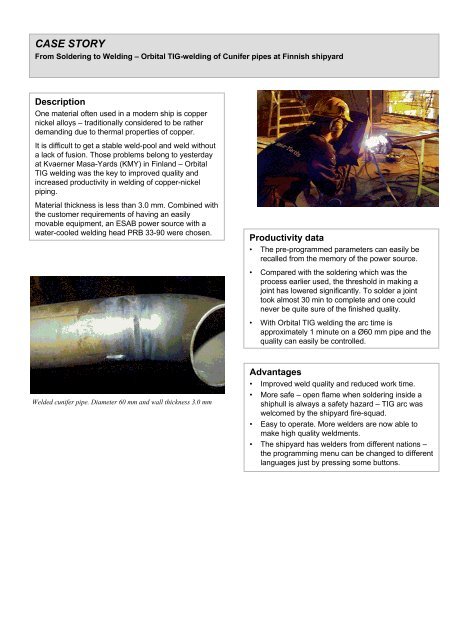

CASE STORYFrom Soldering to Welding – Orbital TIG-welding of Cunifer pipes at Finnish shipyardDescriptionOne material often used in a modern ship is coppernickel alloys – traditionally considered to be ratherdem<strong>and</strong>ing due to thermal properties of copper.It is difficult to get a stable weld-pool <strong>and</strong> weld withouta lack of fusion. Those problems belong to yesterdayat Kvaerner Masa-Yards (KMY) in Finl<strong>and</strong> – OrbitalTIG welding was the key to improved quality <strong>and</strong>increased productivity in welding of copper-nickelpiping.Material thickness is less than 3.0 mm. Combined withthe customer requirements of having an easilymovable equipment, an ESAB power source with awater-cooled welding head PRB 33-90 were chosen.Productivity data• The pre-programmed parameters can easily berecalled from the memory of the power source.• Compared with the soldering which was theprocess earlier used, the threshold in making ajoint has lowered significantly. To solder a jointtook almost 30 min to complete <strong>and</strong> one couldnever be quite sure of the finished quality.• With Orbital TIG welding the arc time isapproximately 1 minute on a Ø60 mm pipe <strong>and</strong> thequality can easily be controlled.Welded cunifer pipe. Diameter 60 mm <strong>and</strong> wall thickness 3.0 mmAdvantages• Improved weld quality <strong>and</strong> reduced work time.• More safe – open flame when soldering inside ashiphull is always a safety hazard – TIG arc waswelcomed by the shipyard fire-squad.• Easy to operate. More welders are now able tomake high quality weldments.• The shipyard has welders from different nations –the programming menu can be changed to differentlanguages just by pressing some buttons.