mechanised and orbital tig

mechanised and orbital tig

mechanised and orbital tig

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

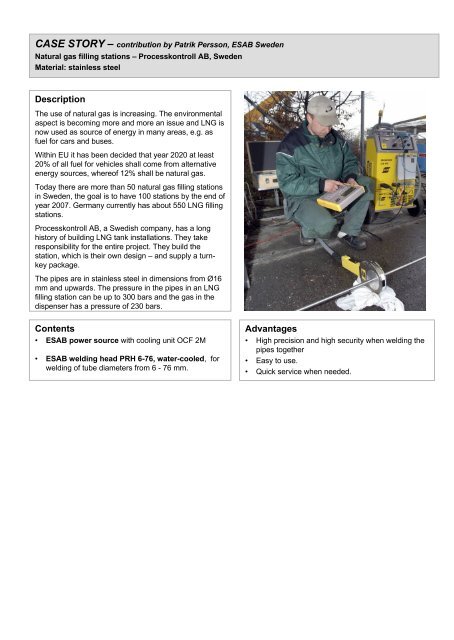

CASE STORY – contribution by Patrik Persson, ESAB SwedenNatural gas filling stations – Processkontroll AB, SwedenMaterial: stainless steelDescriptionThe use of natural gas is increasing. The environmentalaspect is becoming more <strong>and</strong> more an issue <strong>and</strong> LNG isnow used as source of energy in many areas, e.g. asfuel for cars <strong>and</strong> buses.Within EU it has been decided that year 2020 at least20% of all fuel for vehicles shall come from alternativeenergy sources, whereof 12% shall be natural gas.Today there are more than 50 natural gas filling stationsin Sweden, the goal is to have 100 stations by the end ofyear 2007. Germany currently has about 550 LNG fillingstations.Processkontroll AB, a Swedish company, has a longhistory of building LNG tank installations. They takeresponsibility for the entire project. They build thestation, which is their own design – <strong>and</strong> supply a turnkeypackage.The pipes are in stainless steel in dimensions from Ø16mm <strong>and</strong> upwards. The pressure in the pipes in an LNGfilling station can be up to 300 bars <strong>and</strong> the gas in thedispenser has a pressure of 230 bars.Contents• ESAB power source with cooling unit OCF 2M• ESAB welding head PRH 6-76, water-cooled, forwelding of tube diameters from 6 - 76 mm.Advantages• High precision <strong>and</strong> high security when welding thepipes together• Easy to use.• Quick service when needed.