Download Premium Catalog Ch1-9 - Schneider Electric

Download Premium Catalog Ch1-9 - Schneider Electric

Download Premium Catalog Ch1-9 - Schneider Electric

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Automation platformModicon <strong>Premium</strong><strong>Catalog</strong>ue2008

. . . . all Automation & Control functionsMotor controlMachine safetyInterfaces and I/OPower suppliesSystems & architectures&Motor starter solutionsControl and protectioncomponentsn° 814711MKTED205103ENContactorsCircuit-breakers, fuse carriersThermal relaysCombinations, motor controllersMounting solutionsMotor starter mounting kitsThis catalogue containsAutomation and Control functionproducts relating to machinesSafety&Safety functions andsolutions using Preventan° 960260MKTED208051ENSafety PLCsSafety controllersSafety monitorsSafety solutions on AS-Interfacecabling systemSafety switchesSafety light curtainsSafety matsEmergency stopsControl stationsEnabling switchesFoot switchesBeacons & indicator banksSwitch disconnectorsThermal-magnetic motor circuitbreakersEnclosed D.O.L. startersSoftwareXPSMFWIN configurationsoftwareXPSMCWIN configurationsoftware&Interfaces, I/O splitter boxesand power suppliesn° 70263MKTED203113ENDiscrete interfacesPre-wired interfacesIP 67 Splitter boxes&Terminal blocksn° 960151MKTED207011ENTerminal blocksCable ends&IP 20 distributedinputs/outputs Advantys STBn° 960266MKTED208053ENModules for automation islandNetwork interfacesPower distributionDigital I/O, analogs andapplication-specificSoftwareSTB configuration software&Power supplies andtransformers Phaseon° 822591DIA3ED2061209ENSwitch mode power suppliesFiltered rectified power suppliesTransformersThis catalogue containsAutomation and Control functionproducts relating toCommunication&Machine & Installations withindustrial communicationn° 960153MKTED207012ENPreferred implementationsEthernet TCP/IP, the universalcommunication standardCANopen for machines andinstallationsAS-interface, simple and safeProductsHuman-Machine interfaceControllers and PLCsField devicesInfrastructure and wiringGatewaysSoftware and toolsCollaborative AutomationPartner Program & Partners

General ContentsModicon <strong>Premium</strong>automation platform1231 – <strong>Premium</strong> processorsUnity selection guide ........................................ page 1/2Unity processors ........................................... page 1/4Unity slot-PLCs ........................................... page 1/14PL7 selection guide ........................................ page 1/24PL7 processors ........................................... page 1/262 – Racks, I/O architectures and power suppliesPower supply and fan modules ................................ page 2/2Single rack configuration .................................... page 2/6Multi-racks configuration without remote module ................ page 2/8Multi-racks configuration with remote module .................. page 2/12453 – Discrete and analog I/ODiscrete I/O modules ........................................ p age 3/2Analog I/O modules ........................................ page 3/20Distributed I/O modules ..................................... page 3/28TeSys Quickfit for motor starter components ................... page 3/42674 – Application-specific modules and solutionsPreventa safety modules ..................................... page 4/2Counter and electronic cam modules .......................... page 4/18Motion control modules ..................................... page 4/32MFB, Motion Function Blocks ..............................see page 9/20Integrated weighing system ................................. page 4/56Hot Standby redundancy (Unity) . ............................. page 4/62Warm Standby redundancy (PL7) ............................. page 4/72895 – CommunicationSelection guides ............................................ page 5/2Ethernet network - Transparent Ready ......................... page 5/12CANopen machine bus ..................................... page 5/62AS-Interface sensor/actuators bus ............................ page 5/68X-Way bus and network ..................................... page 5/74Modbus Plus network and Profibus DP/INTERBUS buses ........... page 5/90Modbus, Uni-Telway and asynchronous serial links ............. page 5/100102

Selection guideModicon <strong>Premium</strong> automationplatform<strong>Premium</strong> processors and Atrium slot PLCsUnity1<strong>Premium</strong>/Atrium platforms for Unity Pro software offer TSX 57 0p processor TSX 57 1p processors2gNumber of racks (according to rack type) 1 with 4, 6, 8 or 12 slots 4 with 4, 6, or 8 slots or 2 with 12 slots345678910In-rack I/O (1) Discrete I/O 256 channels (8-, 16-, 32- or 64-channelmodule)In-rack applicationspecificchannelsSerial linkconnectionsBus connections512 channels (8-, 16-, 32- or 64-channelmodule)Analog I/O 12 channels (4-, 8- or 16-channel module) 24 channels (4-, 8- or 16-channel module)Max. no. of channels 4 8Integrated counter (max. 40 kHz) –CounterModules with 2/4 counter channels 1 MHz max., single-channel electronic cam moduleMotion (2)Modules with 1/2 axes for stepper motors, 2/3/4 axes for analog control servo motors, 8/16 axeswith SERCOS digital linkWeighingModule for 8 load cells (2 application-specific channels)Serial linksTSX SCY in-rack communication modules (1 application-specific channel)ModbusRS 232, RS 485 or current loop (3) (4) master/slave PCMCIA modules and RS 485 master/slave in-rack communication modulesUni-Telway1 integrated RS 485 master/slave channel, RS 232, RS 485 or current loop (3) (4) master/slavePCMCIA modules and RS 485 master/slave in-rack communication modulesCharacter mode 1 integrated RS 485 channel, RS 232, RS 485 or current loop PCMCIA modules (3) (4)and RS 485 in-rack communication modulesAS-Interface actuator/sensor 1 in-rack module 2 in-rack modulesbus master V2CANopen machine bus1 integrated PCMCIA module 1 PCMCIA module (3)master V4.02INTERBUS fieldbus master V2 (5) or –Profibus DP fieldbus master V0Class 1 and 2 (5)Network connections Max. no. of networks 1Integrated processcontrolEthernetFipway/Ethway/Modbus PlusmodulesConfigurable loops –Programmable loopsProcess control EFB libraryHot Standby availability –Multiprotocol in-rack modules (Modbus /TCP, Uni-TE, Global Data, I/O Scanning, TCP Open),Web server, FactoryCast server or FactoryCast HMI serverFipway module (4), Ethway in-rack modules Modbus Plus (3), Fipway (3)(4) modules,Ethway in-rack modulesMemory capacity Without PCMCIA extension 96 Kb program and data 96 Kb program and dataWith PCMCIA extension128 Kb program96 Kb data224 Kb program96 Kb dataData storage256 Kb (PCMCIA extension in upper slot (0) on processor)USB programming port –Power supply100…240 V a, 24 c non-isolated and 24…48 V c isolated power supply. A power supply isrequired for each rack.<strong>Premium</strong> processor Standard TSX P57 104MIntegrated EthernetTSX P57 1634 g(9)Integrated CANopenTSX P57 0244MIntegrated Fipio TSX P57 154M (11)Atrium slot PLC StandardIntegrated FipioPages 1/12(1) The maximum values for the numbers of discrete and analog I/O are cumulative (with the exception of TSX H57 24M/44M Hot Standby processors).(2) 1 axis = 1 application-specific channel, except for SERCOS modules where, depending on the configuration, the module = 2…32 channels.(3) Module to be inserted into the lower PCMCIA slot (no. 1) on a <strong>Premium</strong> processor or into the external PCMCIA slot (no. 1) on an Atrium slot PLC.(4) Module to be inserted into the TSX SCY 21 601 in-rack communication module slot.(5) The INTERBUS and Profibus DP limits are not cumulative.(11) The TSX P57 154M processor does not support the CANopen bus PCMCIA module.1/2

TSX 57 2p processors and slot PLCs TSX 57 3p processors and slotPLCsTSX 57 4p processorsTSX 57 5pprocessorsTSX 57 6pprocessors1n n n21 with 6, 8 or 12slots512 channels (64-channel modules)80 channels (16-channel modules)16 with 4, 6, or 8 slots or 8 with 12 slots 1 with 6, 8 or 12slots1024 channels (8-, 16-, 32- or 64-channel modules) 512 channels (64-channel modules)80 channels (4-, 8- or16-channel modules)128 channels (4-, 8- or 16-channelmodules)128 channels (16-channel modules)18 24 32 18 64–– Modules with 2/4 counter channels, single-channelelectronic cam– Modules with 1/2 axes for stepper motors, 2/3/4 axes forservo motors, 8/16 axes with SERCOS digital link16 with 4, 6, or 8 slots or 8 with 12 slots2048 channels (8-, 16-, 32- or 64-channel modules)256 channels (4-, 8- or16-channel modules)512 channels (4-, 8- or 16-channelmodules)– Modules with 2/4 counter channels, single-channel electroniccam– Modules with 1/2 axes for stepper motors, 2/3/4 axes forservo motors, 8/16 axes with SERCOS digital link– Module for 8 load cells (2 application-specific channels) – Module for 8 load cells (2 application-specific channels)TSX SCY in-rack communication modules (1 application-specific channel)RS 232, RS 485 or current loop (3) (4) master/slave PCMCIA modules and RS 485 master/slave in-rack communication modules1 integrated RS 485 master/slave channel, RS 232, RS 485 or current loop (3) (4) master/slave PCMCIA modules and RS 485 master/slave in-rackcommunication modules1 integrated RS 485 channel, RS 232, RS 485 or current loop PCMCIA modules (3) (4) and RS 485 in-rack communication modules– 4 in-rack modules 8 in-rack modules – 8 in-rack modules345– 1 PCMCIA module (3) – 1 PCMCIA module (3)– 1 in-rack module 3 in-rack modules – 4 in-rack modules 5 in-rack modules2 1 + for Atrium,1 software gateway3 3 + 1 softwaregatewayMultiprotocol in-rack modules (Modbus/TCP, Uni-TE, Global Data, I/O Scanning (6), TCP Open), Web server, FactoryCast server or FactoryCast HMI server andvia software gateway with Atrium slot PLCs– Modbus Plus (3), Fipway (3)(4) module,Ethway in-rack modules4– Modbus Plus (3), Fipway (3) (4) (7) module,Ethway in-rack modules10 channels with 3 loops max. 15 channels with 3 loops max. 20 channels with 3 loops max. 30 channels with 3 loops max.Process control EFB libraryYes – Yes –67160/192 Kb program and data (8) 192/208 Kb program and data (8) 440 Kb program and data 1 Mb program anddata768 Kb program1.75 Mb program2 Mb program7 Mb program160/192 Kb data (8)192/208 Kb data (8)440 Kb data1 Mb data8 Mb (PCMCIA extension in upper or lower slot (0 or 1) on processor)– 1100…240 V a, 24 V c non-isolated and 24…48 V c isolated power supply. A power supply is required for each rack.2 Mb program anddata7 Mb program2 Mb data8TSX H57 24M(10)TSX P57 204M TSX P57 304MTSX P57 2634M TSX P57 3634M TSX H57 44M(10)TSX P57 4634MTSX P57 5634M TSX P57 6634M9TSX P57 254M TSX P57 354M TSX P57 454M TSX P57 554MTSX PCI 57 204MTSX PCI 57 354M4/69 1/12 1/12 1/21 1/13 4/69 1/13(6) TSX H57 24M/44M Hot Standby processors do not support the Ethernet I/O Scanning service.(7) TSX P57 4634M/5634M/6634M processors with integrated Ethernet port do not support the PCMCIA Fipway card.(8) The second value applies to TSX P57 254M/354M processors with integrated Fipio link and to the TSX H57 24M Hot Standby processor.(9) The integrated Ethernet port requires one of the available network connections.(10) The integrated Ethernet port is dedicated to Hot Standby communication (CPU Sync link between “Primary” and “Redundant” processors).n New feature101/3

PresentationModicon <strong>Premium</strong>automation platformUnity processors123456789PresentationModicon <strong>Premium</strong> TSX P57 pp4M, TSX P57 pp34M and TSX Hp4M automationplatform processors manage the entire PLC station comprising:bbbbDiscrete I/O modulesPreventa safety modulesAnalog I/O modulesApplication-specific modules (counter, motion, weighing, communication)n The <strong>Premium</strong> processor offer has seen the addition of three new references:b TSX P57 6634M, high-end processor with 1 integrated Ethernet Modbus/TCP portand an internal 2 Mb RAMb TSX H57 24M/44M, which support the Hot Standby system (with "Primary" and"Secondary" PLCs), see pages 4/60 to 4/69The processors differ in terms of their memory capacities, processing speeds, thenumber of I/O and the number of communication ports.Depending on the model, they include:b 1 to 16 racks interconnected by means of Bus X (max. distance: 700 m)b 192 to 2040 discrete I/Ob 12 to 512 analog I/Ob 4 to 64 application-specific channels. Each application-specific module (countermotion control, communication or weighing) accounts for one or more applicationspecificchannels.b 1 to 4 networks (Ethernet Modbus/TCP, Fipway, Modbus Plus, Ethway), 1 to 8AS-Interface busesb 0 or 1 Fipio bus, 0 or 1 CANopen or Modbus Plus bus and 0 to 5 INTERBUS orProfibus DP (1) fieldbusesb 0 to 30 process control channels, with each channel capable of supporting up to3 loopsDepending on the model, <strong>Premium</strong> processors also feature:b A 10BASE-T/100BASE-TX Ethernet Modbus/TCP port (RJ45 connector)b A 1 Mbit/s Fipio bus link (bus manager)b Communication via 2 terminal ports (TER and AUX) using Uni-Telway or charactermode protocol (typically a 19 or 115 Kbit/s programming terminal and an operatordialogue terminal)b A USB type TER port (for connecting a programming terminal)Each processor has two slots for a PCMCIA card:b An upper slot (no. 0) for battery-backed memory extension cards (program,symbols, constants and/or data files)b A lower slot (no. 1) for (1) a network card (Fipway, Modbus Plus) or bus(CANopen, Fipio Agent, Modbus, Uni-Telway and serial links). Memory extensioncards intended specifically for storing data can also be inserted into this slot.Treatment for harsh environmentsn If the Modicon <strong>Premium</strong> automation platform is destined for use in extremelyharsh environments, the "conformal coating" offer is available. This involves applyinga coat of "humiseal 1A33" varnish to the electronic cards of the processor and powersupply modules, I/O modules on Bus X and the racks. See page 9/2.<strong>Premium</strong> application design and installationThe installation of these <strong>Premium</strong> processors requires:b Unity Pro Medium, Large or Extra Large programming software. This is the sameas the software for installing the Modicon M340 and Modicon Quantum platforms.b Optionally, depending on requirements:v The Unity Application Generator (UAG) specialist software for modelling andgenerating process applicationsv Unity EFB toolkit software for developing EF and EFB libraries in C languagev Unity SFC View software for visualizing and diagnosing applications written inSequential Function Chart (SFC) or Grafcet language10___________________________________________________________________________(1) TSX H57 24M/44M Hot Standby processors do not support the following buses or networks:Fipio, CANopen, Modbus Plus, INTERBUS and Profibus DP.n New featureDescription:pages 1/5 …Memory structure:pages 1/8…Characteristics:pages 1/10 …References:pages 1/12…PCMCIA references:pages 1/22 …1/4

DescriptionModicon <strong>Premium</strong>automation platformUnity processorsDescriptionTSX P57 104MTSX P57 204M/304M812345671234567TSX P57 154MTSX P57 254M/354M/454MTSX P57pp4M processors without integrated Ethernet portTSX P57 1p4M single-format processors and TSX P57 2p4/3p4M double-formatprocessors feature the following on the front panel:1 A display block with 5 LEDs:v RUN LED (green): Processor in operation (program running)v ERR LED (red): Fault on the processor or its on-board devices (PCMCIA memorycard and PCMCIA communication card)v I/O LED (red): Faults occurring on another station module or configuration faultv TER LED (yellow): Activity on TER or AUX terminal portv FIP LED (red): Activity on integrated Fipio bus (depending on model)2 RESET button causing a cold restart of the PLC when it is activated3 An 8-way female mini-DIN connector marked TER for connecting a programmingor adjustment terminal (RS 485)4 An 8-way female mini-DIN connector marked AUX for connecting a programming,adjustment or operator dialogue terminal (RS 485)5 A PCMCIA slot (no. 0) for a memory card6 A PCMCIA slot (no. 1) for a communication card or memory extension card forstoring additional data7 A 9-way SUB-D connector (on TSX P57 154/254/354M models) for Fipio buscommunication (Fipio manager port)8 An air recirculating heatsink (on TSX P57 0244/1p4M models)1234TSX P57 0244M7123456Processor with integrated CANopen portThe TSX P57 0244M processor feature all or some of the following:1 A display block with 4 LEDs:v RUN LED (green): Processor in operation (program running)v ERR LED (red): Fault on the processor or its on-board devices (PCMCIA memorycard and PCMCIA communication card)v I/O LED (red): Faults occurring on another station module or configuration faultv TER LED (yellow): Activity on TER or AUX terminal port2 RESET button causing a cold restart of the PLC when it is activated3 An 8-way female mini-DIN connector marked TER for connecting a programmingor adjustment terminal (RS 485)4 An 8-way female mini-DIN connector marked AUX for connecting a programming,adjustment or operator dialogue terminal (RS 485)5 A PCMCIA slot (no. 0) for a memory card6 A PCMCIA slot (no. 1) equipped with PCMCIA CANopen master V4.02 card,complete with cordset and tap junction (see page 5/65)7 An air recirculating heatsink.5678910Presentation:page 1/4Memory structure:pages 1/8 …Characteristics:pages 1/10 …References:pages 1/12 …PCMCIA references:pages 1/22 …1/5

Description (continued)Modicon <strong>Premium</strong>automation platformUnity processorsDescription12341 3 245678TSX P57 1634M/2634M/3634MTSX P57 pp34M processors with integrated Ethernet portTSX P57 1634M/2634M/2834M double-format processors with integratedEthernet Modbus/TCP port feature, on the front panel:1 A display block with 5 LEDs:v RUN LED (green): Processor in operation (program running)v ERR LED (red): Fault on the processor or its on-board devices (PCMCIA memorycard and PCMCIA communication card)v I/O LED (red): Faults occurring on another station module or configuration faultv TER LED (yellow): Activity on TER or AUX terminal port2 A display block relating to the integrated Ethernet port featuring 5 LEDs:v RUN LED (green): Ethernet port readyv ERR LED (red): Ethernet port faultv COL LED (red): Collision detectionv STS LED (yellow): Ethernet link diagnosticsv Two TX and RX LEDs (yellow): Transmission/reception activity3 RESET button causing a cold restart of the PLC when it is activated4 An 8-way female mini-DIN connector marked TER for connecting a programmingor adjustment terminal (RS 485)5 An 8-way female mini-DIN connector marked AUX for connecting a programming,adjustment or operator dialogue terminal (RS 485)6 An RJ45 connector for connection to theEthernet Modbus/TCP 10BASE-T/100BASE-TX network7 A PCMCIA slot (no. 0) for a memory card8 A PCMCIA slot (no. 1) for a communication card or memory extension card forstoring additional data5678910Presentation:page 1/4Memory structure:pages 1/8 …Characteristics:pages 1/10 …References:pages 1/12…PCMCIA references:pages 1/22 …1/6

Description (continued)Modicon <strong>Premium</strong>automation platformUnity processorsDescription1 2TSX P57 454M/554M34567891 2TSX P57 4634M/5634MTSX P57 6634MTSX P57 4p4/5p4/6634M and TSX H57 p4Mhigh-performance processors (1)<strong>Premium</strong> (numbers) double-format high-performance processorsTSX P57 454/554M/4634M/5634M/6634M and TSX H57 24M/44M (1) feature thefollowing on the front panel:1 A display block with 5 LEDs:v RUN LED (green): Processor in operation (program running)v ERR LED (red): Fault on the processor or its on-board devices (PCMCIA memorycard and PCMCIA communication card)vvvI/O LED (red): Faults occurring on another station module or configuration faultTER LED (yellow): Activity on the AUX terminal portFIP LED (red): Activity on integrated Fipio bus (TSX P57 454/554M model)In the case of models with an integrated Ethernet port(TSX P57 4634M/5634M/6634M), this display block features 6 additional LEDs:v RUN LED (green): Ethernet port readyv ERR LED (red): Ethernet port faultv COL LED (red): Collision detectionv STS LED (yellow): Ethernet link diagnosticsTwo TX and RX LEDs (yellow): Transmission/reception activity2 A "Memory extract" button for extracting the PCMCIA memory extension card.The associated "Memory extract ready" LED indicates that this card can beextracted safely.3 RESET button causing a cold restart of the PLC when it is activated4 An 8-way female mini-DIN connector marked AUX for connecting a programming,adjustment or operator dialogue terminal5 A USB type connector marked TER for connecting a programming terminal(requires the PC-compatible 3 m connection cable, referenceUNY XCA USB 033, to be ordered separately)6 A PCMCIA slot (no. 0) for a memory extension card7 A PCMCIA slot (no. 1) for a communication card or memory extension card forstoring additional data8 A 9-way SUB-D connector (on TSX P57 454M/554M models) for Fipio buscommunication (Fipio manager port)9 An RJ45 connector (on TSX P57 4634M/5634M/6634M models) for connection tothe Ethernet Modbus/TCP 10BASE-T/100BASE-TX networkUSB portThe USB port 5 boasts a faster useful data rate (12 Mbit/s) than the Uni-Telwayterminal port available on <strong>Premium</strong> processors. The USB port is compatible withUnity Pro programming software and the OPC Factory Server (OFS).123456TSX P57 4p4M/5p4M/6634M processors can be connected to a USB buscomprising several peripheral devices. However:b Only one processor must be connected to the USB busb No device on the USB bus (modem, printer) can be controlled by the PLC.7__________________________________________________________________(1) TSX H57 24M/44M Hot Standby processor, see description on page 4/61.8910Presentation:page 1/4Memory structure:pages 1/8 …Characteristics:pages 1/10 …References:pages 1/12 …PCMCIA references:pages 1/22 …1/7

Memory structureModicon <strong>Premium</strong>automation platformUnity processors1234567Processor without PCMCIA memory cardInternal RAM96 to 2048 KbLocated dataGlobal and DFBunlocated dataProgram, symbols andarea for online programmodificationConstantsProcessor with PCMCIA memory card in slot no. 0Internal RAMPCMCIA card(slot no. 0)96 to 2048 Ko128 to 7168 KoLocated dataGlobal unlocated dataDFB unlocated dataDFB unlocated dataProgram and symbolsConstantsAdditional data storageProcessor with data storage type memory card in slot no. 0Internal RAM96 to 2048 KbLocated dataUnlocated dataProgram, symbols andarea for online programmodification1123111234112Memory structureThe application memory is divided into memory areas, which are physicallydistributed across the internal RAM and 0, 1 or 2 PCMCIA memory extension cards:1 The application data, which is always found in the internal RAM, is divided intotwo possible types:v Located data, corresponding to data defined by an address (e.g. %MW237),which can have a symbol linked to it (e.g. Counter_rejects).v Unlocated data, corresponding to data defined only by a symbol. This type ofaddressing eliminates the problems of memory mapping management, becauseaddresses are assigned automatically. It also facilitates data structuring.v DFB unlocated data, corresponding to DFB user function block data. The size ofthis area (which is determined by the physical size of the available internal RAM)depends on the processor model, see pages 1/12 and 1/13.2 Area in internal RAM or PCMCIA memory card for the program and symbols. Ifthis area happens to be inside the internal RAM, it also contains the area formodifying the program in online mode (1).This area contains the program's executable binary code and IEC source code.The user selects the type of information to be stored in the PLC memory.3 Constants area in the internal RAM or the PCMCIA memory card (slot no. 0)4 Area for storing additional data (slot no. 0 or no. 1), e.g. for production data andmanufacturing recipesMemory organizationThe memory will be organized in one of two ways, depending on whether the<strong>Premium</strong> processor is fitted with 0, 1 or 2 memory extension cards:b Application in internal RAM: In this case, the application is completely loaded intothe processor's internal battery-backed RAM (2), the capacity of which depends onthe processor model (96 Kb to 2 Mb).b Application in PCMCIA card: In this case, the internal RAM is reserved for theapplication data. The PCMCIA memory card (slot no. 1) contains the program space(program, symbols and constants areas) (128 Kb to 2 Mb). Certain types of PCMCIAmemory card also host the data storage area (max. 6976 Kb).Symbols areasHaving the symbols area in the same place as the program area is optional.However, if the application symbols database is available on the PLC, it means that,when an empty programming terminal is connected to the PLC, all the elementsneeded to debug or upgrade this PLC can be transferred to the terminal.Constants389PCMCIA datastorage card(slot no. 0)4096 or 8192 KoAdditional data storage4__________________________________________________________________(1) If a PCMCIA card has been inserted, it is the memory on this memory card that will be usedfor the purpose of modifying the program in online mode (outside areas 2, 3 and 4 opposite).(2) The internal RAM is backed up by an optional battery (with a service life of 3 years), which islocated in the power supply module (see page 2/4).1011Presentation:page 1/421/8Description:pages 1/5 …Characteristics:pages 1/10 …References:pages 1/12 …PCMCIA references:pages 1/22 …

Memory structure (continued)Modicon <strong>Premium</strong>automation platformUnity processorsProcessor with mixed type memory card in slot no. 0 and datastorage type memory card in slot no. 1 (1)Internal RAMPCMCIA card(slot no. 0)96 to 2048 Ko128 to 7168 KoLocated dataGlobal and DFBunlocated dataProgram andsymbolsConstants1123Memory structure (continued)Extension of the data storage areaMemory cards reserved for data storage (4096 or 8192 Kb) are used to:b Access the data storage area in cases where the application is fully loaded into theinternal RAM. In this case, the data storage memory card is inserted into PCMCIAslot no. 0.b Free up memory to serve as additional program space when the application is onthe PCMCIA card (slot no. 0). In this case, the data storage memory card is insertedinto PCMCIA slot no. 1 (although the memory card in slot no. 0 can still be used forsome of the data).Unity Pro programming software helps the application designer to manage thestructure and organize how the memory space on the <strong>Premium</strong> PLC is occupied.12PCMCIA datastorage card(slot no. 1)4096 or 8192 Ko(1) TSX P57 20 processors and higherAdditional datastorage (zone A)Additional datastorage (zone B)44Protecting the applicationRegardless of the PLC memory structure (whether the application is located in theinternal RAM or on the PCMCIA card), it is possible to prevent the application frombeing accessed (for the purpose of reading or modifying the program) by onlyloading the executable code into the PLC.A memory protection bit, set in configuration mode, is also available to prevent anyprogram modification (via the programming terminal or downloads).Program modification in online modeThis function is different from previous versions of <strong>Premium</strong> PLCs (with PL7 software)in that it now allows program code and data from different parts of the application tobe added or modified in a single modification session (thus making modificationunified and consistent with regard to the controlled process).This increased flexibility comes at a cost in terms of the amount of program memoryrequired. In order for the program to be modified in online mode, the amount ofprogram memory space available must be at least equal to the combined size of allsections of the Unity Pro program affected by the single modification sessionconcerned.345Depending on circumstances:b In the case of a processor with a memory extension card, there will be sufficientmemory left on the card for online modification, provided that the recommendationson page 1/22 are observed.b In the case of a processor without a memory extension card, if the user wants tobe able to make modifications in online mode, he or she must select a processor onthe basis of the following:v The anticipated size of the applicationv The number and size of the program sections to be modified in online mode67Note: A memory extension card based exclusively on Flash EPROM technology (withoutadditional SRAM) is clearly incapable of supporting online program modifications.8910Presentation:page 1/4Description:pages 1/5 …Characteristics:pages 1/10 …References:pages 1/12 …PCMCIA references:pages 1/22 …1/9

CharacteristicsModicon <strong>Premium</strong> automationplatformUnity processors12345678910<strong>Premium</strong> PLCs have been developed to comply with major national and international standards on electronic industrial automation equipment.See pages 9/8 to 9/19 "Standards, certification and environmental conditions".Characteristics and performanceTypes of processorMaximumconfigurationFunctionsMemoriesApplicationstructureExecution timefor oneinstructionNo. ofKinstructionsexecutedevery msSystemoverheadTSX P570244MTSX P57104MTSX P571634MTSX P57154MNo. of racks 4/6/8 slots 1 4 1612 slots 1 2 8Max. no. of slots for modules 12 32 128Max. no in-rack(3)IntegratedconnectionsMax. no. ofconnectionsMaximumcapacityMaximum sizeof object zonesTSX P57204MDiscrete I/O 192/256 (2) 512 1024Analog I/O 12 24 80Process controlchannelsApplication-specificchannels, numberApplication-specificchannels, typeTSX P572634M (1)TSX P57254M– 10 (up to 30 parameterizable simpleloops)Programmable loops via EFB control blocks (with Unity Pro Large and Extra Large)4 8 24Counter, axis control, weighing and serial links (Modbus, Uni-Telway and asynchronous)Ethernet – 1 – 1 –Fipio manager – 1(63 agents)Serial link1 link with 2 connectors (TER and AUX) 19.2 Kbit/sNetwork (Ethernet,Fipway, Ethway,Modbus Plus)1 1 integratedEthernetportAS-Interface bus 1 2 4CANopen or1 integrated 1 1 Modbus 1Modbus Plus busCANopenPlus only– 1(127 agents)1 1 integratedEthernetportINTERBUS orProfibus DP bus– 1Without PCMCIA card Kb 96160prog. + dataprog. + dataWith PCMCIA card Kb 128 prog.96 data224 prog.96 data768 prog.160 data1192 prog.+data768 prog.192 dataData storage Kb 256 16,384 (limited to 8192 with currentPCMCIA cards)Located internal bits bits 4096 8132(%Mi)Located internal data Kb 64 for internal words %Mpi64 for constant words %KpiUnlocated internaldataKb Elementary EDT and derived DDT data: 32 Kb Elementary EDT and derived DDT data:64 KbDFB and EFB function blocks: Size per instance: 64 Kb, unlimited number of instances (7)Tasks Master 1 1 1Fast 1 1 1Auxiliary – – –Event-triggered 32 (1 of which has priority) 64 (1 of which has priority)WithoutPCMCIA cardWith PCMCIAcardWithoutPCMCIA cardWith PCMCIAcardBoolean ms 0.19 0.19 0.19On word or fixed-point ms 0.25 0.25 0.25arithmeticOn floating points ms 1.75…2.60(7)1.75…2.60 (7) 1.75…2.60 (7)Boolean ms 0.25 0.25 0.21On word or fixed-point ms 0.50 0.50 0.42arithmeticOn floating points ms 1.75…2.60 1.75…2.60 (7) 1.75…2.60 (7)(7)100% Boolean Kinst/ 4.76 4.76 4.76ms65% Boolean and Kinst/ 3.71 3.71 3.7135% fixed arithmetic ms100% Boolean Kinst/ 3.10 3.10 3.70ms65% Boolean and35% fixed arithmeticKinst/ms2.10 2.10 2.53Tasks Master ms 1.00 1.00 1.00Fast ms 0.30 0.30 0.30(1) For details of TSX H57 p4M processor characteristics and performance, see page 4/68.(2) The first value applies to the TSX P57 Cp 0204M configuration and the second to the TSX P57 0244M processor.(3) Only affects in-rack modules. The maximum values for the number of discrete I/O, analog I/O, application-specific channels and process control channels arecumulative. The remote I/O on the bus or network (Ethernet, CANopen, AS-Interface, Uni-Telway, Fipio, Modbus Plus, etc.) or third-party bus (INTERBUS orProfibus DP) are not included in these maximum numbers.1/10

Characteristics (continued)Modicon <strong>Premium</strong> automationplatformUnity processors<strong>Premium</strong> PLCs have been developed to comply with major national and international standards on electronic industrial automation equipment.See pages 9/8 to 9/19 "Standards, certification and environmental conditions".Characteristics and performance (continued)Types of processorTSX P57304MTSX P573634MTSX P57354MTSX P57454MTSX P574634M (1)Maximum No. of racks 4/6/8 slots 16 16 16configuration12 slots 8 8 8Max. no. of slots for modules 128 128 128FunctionsMemoriesApplicationstructureExecutiontime for oneinstructionTypicalprogramcodeexecutiontime for 1KinstructionMax. no in-rack(3)IntegratedconnectionsMax. no. ofconnectionsMaximumcapacityTSX P57554MDiscrete I/O 1024 2040 2040Analog I/O 128 256 512Process controlchannelsApplication-specificchannels, numberApplication-specificchannels, type15 (up to 45 parameterizable simpleloops)20 (up to 60 parameterizablesimple loops)Programmable loops via EFB control blocks (with Unity Pro Large and Extra Large)32 64 64TSX P575634M6634M30 (up to 90 parameterizablesimple loops)Counter, axis control, weighing and serial links (Modbus, Uni-Telway and asynchronous)Ethernet – 1 – 1 – 1Fipio manager – 1 (127 agents) – 1–(127 agents)Serial link1 link with 2 connectors (TER andAUX) 19.2 or 115 Kbit/s1 x 12 Mbit/s USB link (TER),1 x 19.2 Kbit/s (AUX) linkNetwork (Ethernet,Fipway, Ethway,Modbus Plus)3 3 including 1integratedEthernet port3 4 4 including 1integratedEthernet port (4)AS-Interface bus 8 8 8CANopen or1Modbus Plus busINTERBUS orProfibus DP bus3 4 5Without PCMCIA card Kb 192 prog. + data 208 prog.+ dataWith PCMCIA card Kb 1792 prog.192 data1792 prog.208 data440prog. + data2048 prog.440 dataData storage Kb 16,384 (limited to 8192 with current PCMCIA cards)Maximum size Located internal bits bits 16,384 32,768 32,768of object zones (%Mi)Located internal data Kb 64 for internal words %Mpi64 for constant words %KpiUnlocated internaldataKbElementary EDT and derived DDTdata: 64 KbDFB and EFB function blocks:- Size per instance: 64 Kb- Unlimited number of instances (6)4 4 including 1integratedEthernet port (4)1024/2048 (5)prog. + data7168 prog.1024/2048 data (5)128 for int. words %Mpi64 for const. words %KpiElementary EDT and derived DDT data: Unlimited (6)DFB and EFB function blocks:- Size per instance: unlimited (6),- Unlimited number of instances (6)Tasks Master 1 1 1Fast 1 1 1Auxiliary – – 4Event-triggered 64 (1 of which has priority) 64 (1 of which has priority) 128 (1 of which has priority)32 (timers)WithoutPCMCIA cardWith PCMCIAcardWithoutPCMCIA cardWith PCMCIAcardBoolean ms 0.12 0.039…0.057 (7) 0.0375...0.045 (7)On word or fixed-point ms 0.17 0.054…0.073 (7) 0.045...0.060 (7)arithmeticOn floating points ms 1.75...3.00 (7) 0.55…0.63 (7) 0.48...0.56 (7)Boolean ms 0.17 0.048…0.057 (7) 0.0375...0.045 (7)On word or fixed-point ms 0.32 0.054…0.073 (7) 0.045...0.060 (7)arithmeticOn floating points ms 1.75...3.00 (7) 0.55…0.63 (7) 0.48...0.56 (7)100% Boolean Kinst/ 6.72 15.75 20.26ms65% Boolean and Kinst/ 5.11 11.40 14.0035% fixed arithmetic ms100% Boolean Kinst/ms65% Boolean and35% fixed arithmeticKinst/ms4.59 15.75 20.263.11 11.40 14.00System overhead Master task ms 1.00 1.00 1.00Fast task ms 0.35 0.08 0.07(4) TSX FPP 20 PCMCIA Fipway card not supported.(5) The first value applies to TSX P57 554M/5634M processors and the second to the TSX P57 6634M processor.(6) Within the limits of the processor's data memory capacity(7) Values limited according to type of instruction.123456789101/11

ReferencesModicon <strong>Premium</strong>automation platformUnity processors123TSX P57 0244MTSX 57 processorsI/O capacity (2) Capacity Maximum numberTSX 57 0p 1 rack256 discrete I/O12 analog I/O4 applicationspecificchannelsTSX 57 1p 4 racks (4)512 discrete I/O24 analog I/O8 applicationspecificchannelsMemory96 Kbintegrated128 Kb onPCMCIAControlchannelsof bus/networkmodules0 1 network1 AS-Interface busIntegratedportReference(3)WeightkgCANopen TSX P57 0244M 0.32096 Kb 0 1 network– TSX P57 104M 0.380integrated224 Kb max. onPCMCIA2 AS-Interface buses1 CANopen bus2 AS-Interface buses Ethernet TSX P57 1634M –1 CANopen bus1 network2 AS-Interface busesFipio TSX P57 154M 0.4204TSX 57 2p 16 racks (4)1024 discrete I/O80 analog I/O24 applicationspecificchannels160 Kbintegrated768 Kb max. onPCMCIA10 1 network4 AS-Interface buses1 CANopen bus (5)1 fieldbus (5)4 AS-Interface buses1 CANopen bus (5)1 fieldbus (5)– TSX P57 204M 0.520Ethernet TSX P57 2634M –5TSX P57 1634M192 Kb 10 2 Ethernet networks Ethernet TSX H57 24M 0.560integrated768 Kb max. onPCMCIAdedicated toHot Standby1 network4 AS-Interface buses1 CANopen bus (5)1 fieldbus (5)Fipio TSX P57 254M –67TSX P57 2634M/3634MTSX 57 3p 16 racks (4)1024 discrete I/O128 analog I/O32 applicationspecificchannels192 Kbintegrated1792 Kb max.on PCMCIA208 Kbintegrated1792 Kb max.on PCMCIA15 3 networks – TSX P57 304M 0.5208 AS-Interface buses1 CANopen bus (5)3 fieldbuses (5)2 networks8 AS-Interface buses1 CANopen bus (5)3 fieldbuses (5)Ethernet TSX P57 3634M –15 3 networksFipio TSX P57 354M 0.5608 AS-Interface buses1 CANopen bus (5)3 fieldbuses (5)8TSX P57 154M/254M/354M(1) Two of these channels are used by the TSX CTY 2A 2-channel 40 kHz counter module integrated into the configuration.(2) Cumulative maximum values. The number of remote I/O on the various buses is not taken into account.(3) Product supplied with multilingual Quick Reference Guide: English, French, German, Spanish and Italian.(4) Maximum number of TSX RKY 4EX/6EX/8EX racks (4, 6 or 8 slots). Using the TSX RKY 12 EX rack (12 slots) is the sameas using 2 racks with 4, 6 or 8 slots.(5) Fieldbus: INTERBUS or Profibus DP.910Presentation:page 1/4Description:pages 1/5 …Memory structure:pages 1/8 …Characteristics:pages 1/10 …PCMCIA references:pages 1/22…1/12

References (continued)Modicon <strong>Premium</strong>automation platformUnity processorsTSX 57 processor (continued)I/O capacity (1) Capacity Maximum numberTSX 57 4p 16 racks (3)2040 discrete I/O256 analog I/O64 application-specificchannelsMemory440 Kbintegrated2048 Kb max.on PCMCIAControlchannelsof bus/networkmodulesIntegratedportReference(2)Weightkg20 3 networks8 AS-Interface buses1 CANopen bus (4)4 fieldbuses (4)Ethernet TSX P57 4634M 0.6104 networksEthernetEthernet TSX H57 44M 0.610dedicated toHot Standby12TSX P57 454M/554MTSX 57 5p 16 racks (3)2040 discrete I/O512 analog I/O64 application-specificchannels1 Mb integrated7168 Kb max.on PCMCIA4 networks8 AS-Interface buses1 CANopen bus4 fieldbuses (4)Fipio TSX P57 454M 0.56030 3 networks Ethernet TSX P57 5634M 0.6108 AS-Interface buses1 CANopen bus5 fieldbuses (4)4 networks8 AS-Interface buses1 CANopen bus5 fieldbuses (4)Fipio TSX P57 554M 0.56034TSX P57 4634M/5634M/6634MTSX 57 6p 16 racks (3)2040 discrete I/O512 analog I/O64 application-specificchannels2 Mb integrated7168 Kb max.on PCMCIA30 3 networks8 AS-Interface buses1 CANopen bus5 fieldbuses (4)Ethernet TSX P57 6634M 0.6105TSX PCX 1031PCMCIA memory extension cards<strong>Premium</strong> processors can support up to 2 memory extension cards. However, useful memory capacity is limited to themaximum size defined for the processor model. See pages1/22 and 1/23Connection cables for PC programming terminalDescriptionUseFrom terminal port To PCUniversal cable forterminal port/RS 232 portCable for terminal port/USB portMini-DIN (TER or AUX) on:TSX Micro<strong>Premium</strong> TSX P57 0p/1p<strong>Premium</strong> TSX P57 2p/3pAtrium TSX PCI 57 20/35Tap junction TSX P ACC 01Mini-DIN (TER or AUX) on:TSX Micro<strong>Premium</strong> TSX P57 0p/1p<strong>Premium</strong> TSX P57 2p/3pAtrium TSX PCI 57 20/35Tap junction TSX P ACC 01RS 232D port(9-way SUB-D)USB port(USB/RS 485converter)USB port(mini-DIN/RJ45cable)Length Reference Weightkg2.5 m TSX PCX 1031 0.1700.4 m TSX CUSB 485(5)2.5 m TSX CRJMD 25(5)0.1440.150678TSX CUSB 485USB (TER) on:<strong>Premium</strong> TSX 57 4p/5pQuantum 140 CPU 6p1USB port on a PCterminal3.3 m UNY XCA USB 033 –9(1) Cumulative maximum values. The number of remote I/O on the bus is not included.(2) Product supplied with a multilingual Quick Reference Guide.(3) Maximum number of TSX RKY 4EX/6EX/8EX racks (4, 6 or 8 slots). Using the TSX RKY 12 EX rack (12 slots) is the sameas using 2 racks with 4, 6 or 8 slots.(4) Fieldbus: INTERBUS or Profibus DP.(5) The TSX CUSB485 converter requires the use of cable TSX CRJMD 25 (length 2.5 m, equipped with1 mini-DIN connectorand 1 RJ45 connector).10Presentation:page 1/4Description:pages 1/5 …Memory structure:pages 1/8 …Characteristics:pages 1/10…PCMCIA references:pages 1/22 …1/13

PresentationModicon <strong>Premium</strong>automation platformAtrium slot PLCsUnity12345678TSX PCI 57 pp4MPresentationAtrium TSX PCI 57 204M/354M slot PLCs are PC format cards (PCI 32-bit/25…33MHz bus) to be integrated into a PC running under Windows 2000 or Windows XP.This combination of PLC and PC optimizes performance in applications requiring, forexample, a higher level of communication, control or supervision functions. The slotPLC manages the entire PLC station, which comprises the same I/O modules as<strong>Premium</strong> processors (discrete, analog, application-specific and communication):b Locally, in one or more racks connected to bus X on the Atrium slot PLCb Using remote I/O via the same fieldbusesTwo types of Atrium slot PLC are available. They can both accommodate:b A maximum of 16 extendable TSX RKY ppEX racksb A CANopen master bus function in their external PCMCIA slotBoth have:b An internal PCMCIA slot (no. 0) to accommodate all types of memory extensioncard: program and symbols only, or mixed (program, symbols and data storage)b An external PCMCIA slot (no. 1) to accommodate the network card (Fipway,Modbus Plus) or bus (CANopen, Modbus, Uni-Telway, Fipio Agent and serial link)This slot can also accommodate the 4 or 8 Mb SRAM memory extension card usedto store additional data (see page 1/22).Their distinguishing characteristics are:b The short application program execution timeb The program memory and data memory capacityb 80 or 128 “in-rack” analog I/Ob 24 or 32 application-specific channels: Each application-specific module (counter,motion control, serial link, or weighing) accounts for 1 or a number of applicationspecificchannels.b 1 or 3 networks (Ethernet Modbus/TCP, Fipway, Modbus Plus, Ethway types),1 Ethernet Modbus/TCP network, 4 or 8 AS-Interface buses V2.1, 1 CANopen busand 1 or 3 third-party fieldbuses (INTERBUS, Profibus DP)b 10 or 15 process control channelsIntegrated communicationSix means of integrated communication (communication that does not require theexternal rack to be connected on the slot PLC bus X) are possible:b CANopen master, via a PCMCIA card that is inserted into the external slot on theslot PLCb Fipio manager, via a 9-way SUB-D type connector on the faceplate of theTSX PCI 57 354M slot PLCb Ethernet Modbus/TCP, via the TCP/X-Way Windows-compatible gatewaysoftware, which communicates with the slot PLC via the PCI bus on the host PC (thissoftware is either connected to an Ethernet port in the host PC, integrated into themotherboard or supplied on a PC format card)b INTERBUS master generation 4, via an additional PC format card, occupying an ISAbus slot and connected to the slot PLC via a ribbon cable that includes bus Xb Modbus Plus or Fipway, via a PCMCIA card that is inserted into the external slot(no. 1) on the slot PLCb Communication via a terminal port (TER) using Uni-Telway or character modeprotocol, 19.2 or 115 Kbit/s (typically a programming terminal or an HMI terminal)910Description:pages 1/16 …Memory structure:pages 1/18 …Characteristics:pages 1/20 …References:pages 1/21 …PCMCIA references:pages 1/22 …1/14

Presentation (continued)Modicon <strong>Premium</strong>automation platformAtrium slot PLCsUnityPresentation (continued)TSX PSI 2010 standalone power supplyIn order to enable standalone operation in the event of a PC power outage, astandalone c 24 V TSX PSI 2010 power supply can be connected to a PCI or ISAbus slot to ensure continuity of service for the automation part of the system (onlyfunctions managed by the PC are disabled).Design and installation of Atrium applicationsInstallation of these new Atrium slot PLCs requires:b Unity Pro Medium, Large, Extra Large or XL Safety programming software. This isthe same as the software used on the Modicon M340 and Modicon Quantumplatforms.b Optionally, depending on requirements:v Unity Application Generator (UAG) specialist software for modeling andgenerating process applicationsv Unity EFB toolkit software for developing EF and EFB function block libraries inC languagev Unity SFC View software for displaying and diagnosing applications written inSequential Function Chart (SFC) languageThe Atrium slot PLC is not supplied with any Windows driver or application typesoftware programs. These are supplied with the Unity Pro, Vijeo Designer,Vijeo Citect, OFS (OPC Factory Server), etc. software.They enable connection to the slot PLC via:bbbUni-Telway and the TER port on the front panelPCIway and the PC host’s PCI busEthernet Modbus/TCP (XIP)1234Ethernet Modbus/TCPPC Panel Magelis iPCfitted with, for example:- Atrium TSX PCI slot PLC- Vijeo Designer and Unity Pro software- TCP/X-Way gateway software- c 24 V standalone power supply<strong>Premium</strong> I/O extension racksAltivarMomentumEthernet, CANopen, Fipio, Modbus Plus, INTERBUSTypical architectureBy integrating an Atrium slot PLC card, the architecture shown opposite can becreated using any compatible PC (equipped with PCI bus slots) and PC PanelMagelis iPCThis solution can provide a PLC architecture in which the I/O are:b Remotely located close to the machine or process via the fieldbus (1):v Ethernet Modbus/TCP via the TLX CD GTW 10M gateway softwarev CANopen with TSX CPP 110 PCMCIA cardv Fipio with the integrated port on the TSX PCI 57 354M slot PLCv Modbus Plus with TSX MBP 100 PCMCIA cardv INTERBUS with PC format slot PLC card, TSX IBX 100 ISA bus (link toTSX PCI 57 204M/354M slot PLC via ribbon cable)b And/or centralized in TSX RKY ppEX extendable racks. TSX RKY ppEXextendable racks connected on bus X permit the use of application-specific modulesand the setting up of AS-Interface bus segments. For example:v TSX ETY 4103 or TSX ETY 5103 Ethernet Modbus/TCP module (with Webserver, FactoryCast server or TSX WMY 100 module (FactoryCast HMI server)v INTERBUS TSX IBY 100 or Profibus DP TSX PBY 100 master modulev TSX SAY 1000 AS-Interface V2.1 master modulev TSX CAY, TSX CFY or TSX CSY 84 (SERCOS) motion control modules._________________________________________________________________(1) Corresponding to an integrated module solution on the host PC, without having to usemodules on extension racks on bus X.5678910Description:pages 1/16 …Memory structure:pages 1/18…Characteristics:pages 1/20 …References:pages 1/21 …PCMCIA references:pages 1/22 …1/15

DescriptionModicon <strong>Premium</strong>automation platformAtrium slot PLCsUnity1234TSX PCI 57 354M123564DescriptionAtriul slot PLCsTSX PCI 57 204M/354M slot PLCs mechanically occupy two consecutive slots onthe PCI bus, but only use one electrically (1). They feature:b On the faceplate:1 A PCMCIA slot (no.1) for a communication card or memory extension card forstoring additional data2 A 9-way female SUB-D connector for connecting bus X to the first extendable racksupporting the I/O modules and application-specific modules3 An 8-way female mini-DIN connector marked TER for connecting a programmingterminal4 A RESET button causing a cold restart of the slot PLC when it is activated5 An ERR lamp (red); fault on the slot PLC or its on-board devices (PCMCIAmemory or communication cards)6 A 9-pin male SUB-D connector (on TSX PCI 57 354M model) for Fipio busmanager communication.b On the components side of the card:v 4 or 5 LEDs indicating the operating status (RUN, TER, BAT, I/O and FIP on theTSX PCI 57 354M)vvvvA slot for a backup battery for the slot PLC internal RAM memoryA slot (no. 0) for a PCMCIA format memory extension cardA bus X line terminator circuit (type A)A PCI bus connector for connection to the host PCSupplied with the slot PLC1 bus X line terminator (type B) to be installed at the end of the last of the I/O andapplication-specific module support racks.57Description of the additional TSX PCI ACC1 remote bus X faceplate7 An additional faceplate, TSX PCI ACC1, fitted with a 9-way male SUB-Dconnector, enabling the slot PLC Atrium to be located in the middle of its extensionracks rather than at one end of them.67TSX PCI ACC189Description of the c 24 V TSX PSI 2010 power supplyThe c 24 V TSX PSI 2010 power supply is inserted into a PCI bus slot located nextto the TSX PCI 57 204M/354M slot PLC. It occupies one slot mechanically but noslots electrically. It can provide the power supply for one slot PLC.It features the following on the front panel:8 A 9-way female SUB-D connector enabling a second remote bus X to beconnected (instead of using the TSX PCI ACC1 faceplate)9 A 3-way female SUB-D connector for connection to the c 24 V power supply(male connector supplied)TSX PSI 2010This power supply includes two ribbon cables for connection to the slot PLC, one forthe power supply to the slot PLC and the other to ensure bus X continuity.8__________________________________________________________________(1) Atrium slot PLCs can also operate using just one PC slot: For this purpose, carefully unscrewand remove the external PCMCIA slot.910Presentation:pages 1/14…Memory structure:pages 1/18 …Characteristics:pages 1/20…References:pages 1/21 …PCMCIA references:pages 1/22 …1/16

Gateway,setupModicon <strong>Premium</strong>automation platformAtrium slot PLCsUnityPCSCADAOFS serverEthernet Modbus/TCP1 23Uni-TE<strong>Premium</strong>QuantumModbus1 Atrium slot PLC2 Ethernet Modbus/TCP card or integrated port3 TCP/X-Way software gatewayMagelis iPC or PC with:- 1 Atrium slot PLC- and TSX PCI ACC1faceplate or TSX PSI 2010power supplyTCP/X-Way gatewayThe TCP/X-Way software gateway performs 2 main functions for Atrium slot PLCs:b Communication using the Modbus or Uni-TE protocol via the EthernetModbus/TCP card integrated in the PCb Data exchange in both directions with remote stations via the telephone modem inthe PCThis software interfaces with the Atrium slot PLC PCIway driver and automaticallyroutes messages. The most common configurations are:v Via Ethernet network (diagram opposite). Access is made secure by checkingincoming IP addresses, in a similar way to the <strong>Premium</strong> PLC Ethernet TSX ETY 4103module. The Global Data and I/O Scanning services are not supported.v Via modem link. Incoming calls are checked via the standard Windows passwordchecking mechanisms. In addition to remote access with Unity Pro software, theTCP/IP gateway enables communication with other stations that can be connectedto a local Ethernet network (RAS (Remote Access Server) function).SetupIntegration into the host PCTo receive a TSX PCI 57 204M/354M Atrium slot PLC, the host PC must:b Run under Windows 2000 or Windows XPb Have a 33-bit 33 MHz (c 5 V or c 3.3 V) PCI busb Have two consecutive slots available on the PCI bus (of which at least one mustbe a PCI type slot)The maximum number of slot PLCs per PC depends on the number of availablePCI/ISA slots, the PC power supply rating (when the TSX PSI 2010 power supplyoption is not used) and whether or not PCMCIA cards have been inserted into theslot PLC.The slot PLC is completely independent of the application running on the PC, inparticular:b The standard PC command “Restart” (1) has no effect on the slot PLC operatingmodes (2).b Switching the PC off and then on again causes a warm restart of the applicationbeing managed by the slot PLC (restart without loss of application context).b The TSX PSI 2010 c 24 V standalone power supply allows the slot PLC tooperate even in the event of a PC power supply outage.The host PC, equipped with Unity Pro software, can be used as a programming andsetup terminal for the TSX PCI 57 Atrium slot PLC.Logical location on bus XThe Atrium TSX PCI 57 204M/354M slot PLC logically occupies the same 2 slots asa <strong>Premium</strong> TSX 57 processor of the same type. The 2 slots in the TSX RKY ppEXrack with address 0 next to the TSX PSY ppp0M power supply module musttherefore remain unoccupied.1234567TSX RKY ppEX rackTSX RKY ppEX rackThe TSX PCI ACC1 faceplate or TSX PSI 2010 c 24 V power supply enables asecond bus X to be connected from PC Panel Magelis iPC industrial PCs, thusforming a Y structure (see the diagram opposite, where the maximum length of eachbus X segment is 100 m).8__________________________________________________________________(1) “Ctrl-Alt-Del” command, followed by “Restart” or pressing the “Reset” button on the PC (ifthere is one).(2) Causes the loss of the PCI bus connection.910Presentation:pages 1/14 …Memory structure:pages 1/18 …Characteristics:pages 1/20 …References:pages 1/21…PCMCIA references:pages 1/22 …1/17

Memory structureModicon <strong>Premium</strong>automation platformAtrium slot PLCsUnity12Slot PLC without PCMCIA memory cardLocated dataGlobal and DFBunlocated dataInternal RAM160 to 208 KbProgram, symbols andarea for online programmodificationConstants1123Memory structureThe application memory is divided into memory areas physically distributed in theinternal RAM memory and on 0, 1 or 2 PCMCIA memory extension cards:1 The application data area, which may be one of 2 possible types, is always in theinternal RAM:v Located data corresponding to data defined by an address (e.g. %MW237) towhich a symbol may be associated (e.g. Counting_rejects).v Global unlocated data corresponding to data defined only by a symbol. This typeof addressing removes memory “mapping” management constraints, as address areassigned automatically, and enables data to be structured.v DFB unlocated data, corresponding to data from DFB user function blocks. Thesize of this object zone is only limited by the size of the physical internal RAMmemory available 1 (160 Kb or 208 Kb).34Slot PLC with PCMCIA memory card in slot no. 0Located dataInternal RAM160 or 208 KbGlobal unlocated dataDFB unlocated data1112 Area in internal RAM or PCMCIA memory card for the program and symbols. Inthe event of this area being in internal RAM, it also supports the area for modifyingthe program in online mode (1).This area contains the program’s executable binary code and IEC source code.The user selects the type of information to be stored in the slot PLC memory.3 Constants area in the internal RAM or the PCMCIA memory card (slot no. 0)4 Storage area for additional data (slot no. 0 or no. 1), e.g. for production data andmanufacturing recipes567PCMCIA cardslot no. 0128 to 7168 KbProgram and symbolsConstantsStorage of additionaldata234Memory organizationTwo memory structures are possible depending on whether the Atrium slot PLC isfitted with 0, 1 or 2 memory extension cards:b Application in internal RAM. In this case, the application is entirely loaded in thePLC slot’s internal battery-backed RAM (2), the capacity of which depends on thePLC slot model (160 Kb or 208 Kb).b Application in PCMCIA card. In this case, the internal RAM is reserved forapplication data. The PCMCIA memory card (slot no. 1) contains the program space(program, symbols and constants areas) (768 Kb or 1792 Kb).Certain types of PCMCIA memory card host the data storage area (max. 6976 Kb).Symbols areasThe presence of the symbols area with the program area is optional. Having theapplication symbols database on the memory of the slot PLC means that, whenconnected to a programming terminal not containing any applications all theelements needed to debug or upgrade this PLC are available within the PLC.__________________________________________________________________(1) If a PCMCIA card has been inserted, the memory used by program modification in onlinemode is located in this memory card (outside zones 2, 3 and 4 opposite).(2) The internal RAM memory is backed up by an optional battery (3 years’ battery life) located inthe power supply module (see page 2/2).8910112Presentation:pages 1/14…Description:pages 1/16 …Characteristics:pages 1/20…References:pages 1/21 …PCMCIA references:pages 1/22 …1/183

Memory structure (continued)Modicon <strong>Premium</strong>automation platformAtrium slot PLCsUnitySlot PLC with data storage memory card in slot no. 0Located dataInternal RAMGlobal and DFBunlocated dataProgram, symbols andarea for online programmodificationConstantsPCMCIA datastorage card (slotno. 0)Storage of additionaldata160 or 208 Kb4096 or 8192 Kb11234Memory structure (continued)Extension of the data storage areaMemory cards reserved for data storage (4096 or 8192 Kb) are used to:b Access the data storage area when the application is entirely supported by theinternal RAM. In this case, the data storage memory card is inserted into PCMCIAslot no. 0.b Free up memory space to provide additional program space when the applicationis in the PCMCIA card (slot no. 0). In this case, the data storage memory card isinserted into PCMCIA slot no. 1 (a part of it can be supported by the memory card inthe slot).Unity Pro programming software assists the application designer with themanagement of the structure and the occupation of memory space on theAtrium slot PLC.Protecting the applicationRegardless of the slot PLC memory structure (whether the application is located in theinternal RAM or in the PCMCIA memory card), it is possible to protect this in order toprevent it being accessed (read or modify program) by only loading the executablecode on the slot PLC.123Slot PLC with mixed type memory cards in slot no. 0 and datastorage type memory cards in slot no. 1Internal RAMPCMCIA card (slotno. 0)PCMCIA datastorage card (slotno. 1)160 or 208 Kb128 to 7168 Kb4096 or 8192 KbLocated data1Global unlocated data1Unlocated DFB data1Program and symbols2Constants3Additional data storage(zone A)4Additional data storage4(zone B)A memory protection bit, set in configuration mode, is also available to prevent anyprogram modification (via the programming terminal or downloads).Program modification in online modeThis function is different from previous versions of <strong>Premium</strong> PLCs (with PL7software) and now allows program code and data in different parts of the applicationto be added or modified in a single modification session (thus making modificationunified and consistent with regard to the controlled process).This increased flexibility comes at a cost in terms of the program memory volumerequired. Any program modifications made in online mode require available programmemory space at least equal in size to the combined size of all sections of theUnity Pro program affected by the same modification session.Depending on circumstances:b For a slot PLC with memory extension card, the memory volume remainingavailable in the card for online modification is sufficient if the recommendations onpage 1/22 are observed.b For a slot PLC without memory extension card, users wishing to have the option ofmaking modifications in online mode may select a processor according to:v The anticipated size of the applicationv The number and size of the program sections to be modified in online modeNote: A memory extension card that only uses Flash Eprom technology (without additionalSRAM) cannot provide the function of program modification in online mode.45678910Presentation:pages 1/14 …Description:pages 1/16 …Characteristics:pages 1/20 …References:pages 1/21 …PCMCIA references:pages 1/22 …1/19

CharacteristicsModicon <strong>Premium</strong>automation platformAtrium slot PLCsUnity12345678910Characteristics and performanceType of processor TSX PCI P57 204M TSX PCI P57 354MMaximum No. of racks 4/6/8 slots 16configuration12 slots 8Max. no. of slots for modules 128FunctionsMemoriesApplicationstructureExecutiontime for oneinstructionMax. no. “inrack” of (1)Integrated EthernetconnectionsMaximumno. ofconnectionsMaximumcapacityMaximumsize ofobjectzonesDiscrete I/O 1024Analog I/O 80 128Process control channels 10 (up to 30 simple loops) 15 (up to 60 simple loops)Programmable loops via EFB control blocks (with Unity Pro Large and Extra Large)No. of applic.-specific ch. 24 32Type of applic.-specific ch.Counter, axis, weighing and serial links (Modbus, Uni-Telway and asynchronous)1 (uses the Ethernet Modbus/TCP port integrated in the host PC via the TLX CD GTW 10Mgateway software)Fipio manager – 1 (127 agents)Serial link1 link with 2 connectors (TER and AUX) 1 link with 2 connectors (TER and AUX),19.2 Kbit/s19.2 or 115 Kbit/sNetwork(Ethernet, Fipway, Ethway,Modbus Plus)2 (including 1 Ethernet Modbus/TCPintegrated into host PC)4 (including 1 Ethernet Modbus/TCPintegrated into host PC)AS-Interface bus 4 8CANopen or Modbus Plus bus 1INTERBUS or Profibus DP bus 1, none if CANopen is used 3, 2 if CANopen is usedWithout PCMCIA card Kb 160 program + data 208 program + dataWith PCMCIA card Kb 768 program160 data1792 program208 dataData storage Kb 16,384 (limited to 8192 with current PCMCIA cards)Located internal bits (% Mi) bit/s 8132 16,384Located internal data Kb 64 for internal words %MpWi, 64 for constant words %KpWiGlobal unlocated internal data Kb Elementary EDT and derived DDT data: 64 KbDFB and EFB function blocks: size per instance 64 Kb, unlimited number of instance (within thelimits of slot PLC’s data memory capacity)Tasks Master 1Fast 1Auxiliary –Evens64 (1 of which has priority)WithoutPCMCIAcardWithPCMCIAcardTypical program codeexecution time for1 KinstructionSystemoverheadBoolean ms 0.19 0.12On word or fixed-point ms 0.25 0.17arithmeticOn floating points ms 1.75...2.60 (2)Boolean ms 0.21 0.17On word or fixed-point ms 0.42 0.32arithmeticOn floating points ms 1.75...2.60 (2)100% Boolean Kinst/ 4.76/ 3.70 (3) 6.72/4.59 (3)ms65% Boolean and 35% fixed Kinst/ 3.71/2.53 (3) 5.11/3.12 (3)arithmeticmsTasks Master ms 1.00 1.00Fast ms 0.30 0.25(1) Only affects “in-rack” modules. The maximum values for the number of discrete I/O, analog I/O and application-specific channels are cumulative. The remote I/Oon the bus or network (CANopen, AS-Interface/Uni-Telway/Fipio/Modbus Plus, etc.) or third-party bus (INTERBUS or Profibus DP) are not included in thismaximum number.(2)Values limited according to the type of instruction(3)The first value corresponds to execution time without PCMCIA card and the second value with PCMCIA card.Standalone power supply characteristicsType of power supply module TSX PSI 2010Primary Voltage Nominal V c 24Limits (including ripple) V c 19.2 … 30 (possible up to 36 V)Current Nominal input value 1 rms A y 1.1 at c 24 VInitial powerupat 25°C1 inrush A 100 at c 24 VI 2 t on triggering A 2 3It on triggering As 0.04Power line disturbance period ms y 7 at 24 V, y 1 at 19.2 VBuilt-in protectionVia a 2 A time-delay fuse (complying with standards)Conformity to standards IEC 1131-2InsulationDielectricstrengthPrimary/secondary andprimary/earthV rmsNon-isolated, internal 0 V connected to PC ground1/20

ReferencesModicon <strong>Premium</strong>automation platformAtrium slot PLCsUnityTSX PCI 57 204MAtrium slot PLCsI/O capacity (1) Capacities Maximum numberMemoryProcess controlchannelsof bus/networkmodulesTSX PCI 57 20 16 racks (2)1024 discrete I/O80 analog I/O24 application-specificchannels160 Kb integratedMax. 768 Kb onPCMCIA10 1 network all types1 Ethernet network4 AS-Interfacebuses1 CANopen bus (3)1 fieldbus (3)ReferenceWeightkgTSX PCI 57 204M 0.31012TSX PCI 57 35 16 racks (2)1024 discrete I/O128 analog I/O32 application-specificchannels208 Kb integratedMax. 1792 Kb onPCMCIA15 1 integrated Fipio3 networks all types1 Ethernet network8 AS-Interfacebuses1 CANopen bus (3)3 third-party buses(3)TSX PCI 57 354M 0.3403TSX PCI 57 354MPCMCIA memory extension cardsAtrium slot PLCs can support up to 2 memory extension cards. However, useful memory capacity is limited to the maximumsize defined for the slot PLC model.References, see pages 1/22 and 1/23.4TSX PCI ACC1Software options (4)When connected to an Atrium slot PLC, the TCP/X-Way gateway software offer (supplied on CD-ROM) enablescommunication under the Modbus or Uni-TE protocol using the Ethernet Modbus/TCP port integrated into the host PC.Description Use Site license Reference WeightkgTCP/X-Way gatewaysoftwareCompatible with Windows 2000 or XP Single-station TLX CD GTW 10M –Separate partsDescription Use Sold in lots of Reference WeightkgFaceplate for remote bus X Enables a second remotebus X connection (9-way SUB-Dconnector)– TSX PCI ACC1 –c 24 V standalone powersupplyEnables the TSX PCI slot PLC to operate inthe event of a PC power supply outageEnables a second remote bus X connection(9-way SUB-D connector)– TSX PSI 2010 –Batteries Internal RAM memory of slot PLC backup 1 TSX PLP 01 0.01010 TSX PLP 101 0.1005678TSX PSI 2010(1) Cumulative maximum values. The number of remote I/O on the bus is not counted.(2) Maximum number of TSX RKY 4EX/6EX/8EX racks (4, 6 or 8 slots). Using the TSX RKY 12 EX rack with 12 slots is thesame as using 2 racks with 4, 6 or 8 slots.(3) Fieldbus: INTERBUS or Profibus DP.(4) Other software compatible with Atrium slot PLCs: OFS data server software, see page 6/105;Vijeo Designer/Vijeo Citect supervisory software, see our catalog “Human/Machine Interfaces”.910Presentation:pages 1/14 …Description:pages 1/16 …Memory structure:pages 1/18 …Characteristics:pages 1/20 …PCMCIA references:pages 1/22 …1/21

PresentationModicon <strong>Premium</strong> automationplatformPCMCIA memory extension cardsUnity12345678910PCMCIA SRAM memory cardPCMCIA SRAM memory card<strong>Premium</strong> processorsAtrium slot PLCsCards recommended for program modificationin online modeTSX P57 CpTSX P57 0pAllTSX MRP PpppKand TSX MRPCpppK/M/7PresentationPCMCIA memory extension cards are used to extend the internal RAM capacity of<strong>Premium</strong> processors and Atrium slot PLCs.Some of the cards can also be used on Quantum and Micro processors. Dependingon the model, these cards can host:bbbApplication program, symbols and constantsAdditional application dataOr bothPCMCIA memory extension cardsAll the cards are inserted into PCMCIA slot no. 0 on <strong>Premium</strong> processors and Atriumslot PLCs, i.e.:bbThe upper slot on processorsThe internal slot on slot PLCsTwo of these SRAM data storage memory cards can also be inserted into slot no. 1,i.e.:b The lower slot on processorsb The external slot on slot PLCsThese cards support three types of data storage:b Application storage: Program, symbols and constants in a common space (128 Kbto 7168 Kb, depending on the card model):v TSX MRP PpppK for SRAM memoriesv TSX MFP PpppK/M for Flash EPROM memoriesb Storage of the application and additional data, with 192 Kb to 7 Mb of applicationspace and 7 Mb to 0 Kb of data storage space for additional data. The limit betweenthese 2 spaces is configurable. The configurable cards are:v TSX MRP CpppK/M for SRAM memoriesv TSX MCP CpppK/M for Flash EPROM and SRAM memoriesb Storage of additional data, provided by 4 Mb or 8 Mb TSX MRP F00pM SRAMmemory cardsThese cards use 2 technologies:b Battery-backed SRAMUsed in particular in the creation and debugging phases for the application program.These cards support:v All of the application’s transfer and modification services in online modev Additional data storageThe memory is backed up by a removable battery integrated into the PCMCIA card.A second auxiliary battery is present to enable the main battery to be replacedwithout loss of data.b Flash EPROMUsed once debugging of the application program is complete. It enables:v Backup battery life restrictions to be overcomev A global application transfer to be performedIf it is used, the application cannot be modified in online mode.Program modification in online modeOnly extension cards on which the program is stored in SRAM memory(TSX MRP PpppK/M. and TSX MRP CpppK/M) support online programmodification.Users of processors fitted with memory extension cards who wish to modify or addprogram data in online mode must follow the two recommendations below:b Structure the application program in a number of sections of a reasonable sizeb Where possible, select one of the two extension cards recommended in the tablebelow:TSX P57 1pTSX MRPP224K/P384K,all TSX MRPCpppK/M/7TSX P57 2pTSX PCI 57 2pTSX P57 3pTSX PCI 57 3pAll TSX MRP CpppK/M/7TSX P57 4p TSX P57 5p TSX P57 6pTSX MRP C002M, TSX MRP C003M,TSX MRP C007M1/22

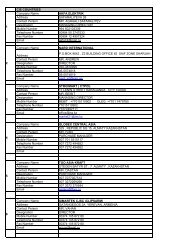

ReferencesModicon <strong>Premium</strong> automationplatformPCMCIA memory extension cardsUnityReminder of the memory capacities of processors and slot PLCsMemory capacities without PCMCIA extension card (data, program, symbols, and constants in internal RAM memory):<strong>Premium</strong> processorsAtrium slot PLCsTSX P57Cp0244/0244MTSX P57104/154M/1634MTSX 57204/2634MTSX PCI57 204MTSX P57254TSX P57304/3634MTSX P57354MTSX PCI57 354MTSX P57454/4634MTSX P57554/5634MTSX P576634MIn internal RAM 96 Kb 160 Kb 192 Kb 208 Kb 440 Kb 1024 Kb 2048 KbMemory capacities with PCMCIA extension card(s) (data in internal RAM memory; program, symbols, constants, and data storage on PCMCIA card):<strong>Premium</strong> processorsAtrium slot PLCsTSX P570244MTSX PCI57 204MTSX P57254TSX P57354MTSX PCI57 354MTSX P576634MTSX P57104/154M/1634MTSX 57204/2634MTSX P57304/3634MTSX P57454/4634MTSX P57554/5634MData in internal RAM 96 Kb 160 Kb 192 Kb 208 Kb 440 Kb 1024 Kb 2048 KbPCMCIA extension (progr., 128 Kb 224 Kb 768 Kb 768 Kb 1792 Kb 1792 Kb 2048 Kb 7168 Kb 7168 Kbsymbols and constants)Data storage on PCMCIA (1) 256 Kb16,384 Kb, limited to 8192 Kb if the TSX MRP F008M PCMCIA card is usedPCMCIA memory extension cards<strong>Premium</strong> TSX P57 Cp/0p/1p/2p/3p/4p/5p/6p processors and Atrium TSX PCI 57 2p/3p slot PLCs support the memory extensioncards listed below. There are two types of memory limit:- One associated with the type of processor or slot PLC (see above)- One associated with the model of PCMCIA memory card selectedThe lowest of these two limits defines the memory capacity available to the user for his/her application.Use on processor Slot Memory size Reference WeightApplicationAdditional datakgSRAM application memory extensionsTSX 57 Cp, TSX 57 0p…57 4p Slot 0 128 Kb – TSX MRP P128K 0,076TSX PCI 57 2p/3p224 Kb – TSX MRP P224K 0,076384 Kb – TSX MRP P384K 0,076Configurable SRAM application/additional data memory extensionsTSX 57 Cp, TSX 57 0p…57 4pTSX PCI 57 2p/3pSlot 0 96…448 Kb 352…0 Kb TSX MRP C448K 0,076TSX 57 Cp TSX 57 0p…57 6p Slot 0 192…768 Kb 576…0 Kb TSX MRP C768K 0,076TSX PCI 57 2p/3p192…1024 Kb 832…0 Kb TSX MRP C001M 0,076192…1792 Kb 1600…0 Kb TSX MRP C01M7 0,076192…2048 Kb 1856…0 Kb TSX MRP C002M 0,076192…3072 Kb 2880…0 Kb TSX MRP C003M 0,076192…7168 Kb 6976…0 Kb TSX MRP C007M 0,076Flash EPROM application memory extensionsTSX 57 Cp, TSX 57 0p…57 4pTSX PCI 57 2p/3pTSX 57 Cp, TSX 57 0p…57 6pTSX PCI 57 2p/3pSlot 0 128 Kb – TSX MFP P128K 0,044224 Kb – TSX MFP P224K 0,044384 Kb – TSX MFP P384K 0,044Slot 0 512 Kb – TSX MFP P512K 0,0441024 Kb – TSX MFP P001M 0,044TSX 57 2p…57 6pSlot 0 2048 Kb – TSX MFP P002M 0,044TSX PCI 57 2p/3p4096 Kb – TSX MFP P004M 0,044Flash EPROM and SRAM application/additional data memory extensionsTSX 57 0p…57 4pTSX PCI 57 2p/3pSlot 0 224 Kb 256 Kb TSX MCP C224K 0,076TSX 57 CpTSX 57 0p…57 6pTSX PCI 57 2p/3pSRAM additional data memory extensionsTSX 57 2p…57 6pTSX PCI 57 2p/3pSlot 0 512 Kb 512 Kb TSX MCP C512K 0,0762048 Kb 1024 Kb TSX MCP C002M 0,076Slot 0 or 1(2)– 4096 Kb TSX MRP F004M 0,0768192 Kb TSX MRP F008M 0,076Flash EPROM backup card (3)TSX 57 Cp Slot 0 96 Kb – TSX MFP B096K –TSX 57 0p/1pReplacement partsDescription Use Type Reference WeightkgBackup batteries PCMCIA SRAM memory card Main TSX BAT M02 (4) 0.010Auxiliary TSX BAT M03 0 005HandleRemove PCMCIA memory card – TSX P CAP 0.010(provided with the memory card)(1) Intended for the storage of manufacturing recipes and production data. Capacity depending on PCMCIA card model.(2) Memory extension card for file storage to be inserted into slot no. 0 if free, otherwise into slot no. 1. In the latter case, anapplication memory type or application memory and file storage type memory extension card is inserted into slot no. 0.(3) This card is pre-loaded and can be used to update the application program on a <strong>Premium</strong> PLC without having to use aprogramming terminal (the entire program must be located in the internal RAM).(4) TSX BAT M02 with PCMCIA card PV u 04 (blue), for PCMCIA card PV < 04, please order TSX BAT 01 reference.123456789101/23

TSX 57 3p processorsTSX 57 4p processors12n16 with 4, 6, or 8 slots or 8 with 12 slots31024 channels (8-, 16-, 32- or 64-channel modules)128 channels (4-, 8- or 16- channel modules)Configurable loops (15 channels with 3 loops max.)32 64Modules with 2/4 counter channels 1 MHz max., single-channel electronic cam moduleModules with 1/2 axes for stepper motors, 2/3/4 axes for analog control servo motors, 8/16 axes with SERCOS digital linkModule for 8 load cells (2 application-specific channels)In-rack communication modules (1 application-specific channel)RS 232, RS 485 or current loop (3) (4) master/slave PCMCIA modules and RS 485 master/slave in-rack communication modules1 integrated RS 485 master/slave channel, RS 232, RS 485 or current loop (3) (4) master/slave PCMCIA modules and RS 485 master/slave in-rackcommunication modules1 integrated RS 485 channel, RS 232, RS 485 or current loop (3) (4) PCMCIA modules and RS 485 in-rack communication modules458 in-rack modules1 PCMCIA module (3)62 in-rack modules3 4Multiprotocol in-rack modules (Modbus/TCP, Uni-TE, Global Data, I/O Scanning, TCP Open), Web server, FactoryCast service and FactoryCast HMI servicesFipway (3) (4) and Modbus Plus (3) PCMCIA modules, Ethway in-rack modules64/80 Kwords program and data (6) 96 Kwords program and data80/96 Kwords data (6)384 Kwords program176 Kwords data512 Kwords program (992 Kwords with PL7 V4.4 or higher)640 Kwords + 2048 Kwords 2048 Kwords (640 Kwords + 2048 Kwords with PL7 V4.4 or higher)128 Kwords 256 Kwords (384 Kwords with PL7 V4.4 or higher)100…240 V a, 24 V c non-isolated and 24…48 V c isolated power supply modules. A power supply is required for each rack.78TSX P57 303AM QTSX P57 3623AM Q (8)TSX P57 353LAM (9) TSX P57 353AM Q TSX P57 453AM1/31(7) The TSX P57 153M processor does not support the CANopen bus PCMCIA module.(8) The integrated Ethernet port requires one of the available network connections.(9) Processor reserved for updating configuration with TSX P57351M/352M PL7 processor (old version)TSX P57 4823AM (8)9Q Processor can be migrated from PL7 to Unity Pro by means of a simple update of the processor's operating system (included on the Unity Pro softwareCD-ROM).n New feature101/25

PresentationModicon <strong>Premium</strong>automation platformPL7 processors1Presentation<strong>Premium</strong> TSX P57 pp3M/3AM and TSX P57 pp23M/23AM automation platformprocessors manage the entire PLC station comprising discrete I/O modules,Preventa safety modules, analog I/O modules, and application-specific modules,which can be distributed over one or more racks connected via Bus X or a fieldbus.TSX P57 processors23The types of processor available are divided into different capacities according tomemory, in-rack I/O, communication, and processing speed. According to the model:b 4 to 16 racksb 512 to 2040 discrete I/Ob 24 to 256 analog I/Ob 8 to 64 application-specific channels: Each application-specific module (counter,motion control, serial link or weighing) accounts for 1 or a number of applicationspecificchannels.b 1 to 4 networks (Ethernet, Fipway, Ethway, Modbus Plus), 2 to 8 AS-Interfacesensor/actuator buses, 1 to 2 fieldbuses (CANopen, INTERBUS, Profibus DP), 0 or 1Fipio fieldbus, serial links (Modbus, Uni-Telway)b 10 to 20 process control channelsIntegrated communication456According to the model, <strong>Premium</strong> processors include:b A 10 or 100 Mbit/s Ethernet Modbus/TCP port (RJ45 connection)b A 1 Mbit/s Fipio bus link (bus manager)b Communication via 2 terminal ports (TER and AUX) using Uni-Telway or charactermode protocol (typically a 19 or 115 Kbit/s programming terminal and an operatordialogue terminal)Each processor has a slot for a type III PCMCIA card, which can accommodate anetwork card (Fipway, Modbus Plus), bus (CANopen (1), Fipio Agent) or serial links(Modbus, Uni-Telway, character mode).Application design and installationDifferent software licences are available for PL7 Junior/Pro version V4.5 dependingon requirements:b Single-stationb Multistation in the form of independent local stations (Junior/Pro), remote stationsconnected to a server via a network (Pro OpenTeam for 3 to10 stations orPro OpenSite for more than 10 stations).These licences are compatible with PC terminals running Windows 2000Professional or Windows XP operating systems.Configurations with TSX P57 351/352M processor or Atrium slot PLC7The TSX P57 353LAM single-format processor is intended as a replacement for theold version TSX P57 351M/352M processors and for T PCX 57 203/353M Atriumslot PLCs. The latter also only occupy one slot; hence there is no need forreconfiguration when they are replaced.Migration of <strong>Premium</strong> processors89Some <strong>Premium</strong> TSX P57 pp3M/3AM processors that are compatible with PL7software can be migrated for compatibility with the Unity Pro software without theneed for hardware modifications. This migration from PL7 to Unity Pro is achieved bymeans of the following software updates:bProcessor operating systemIntegrated Ethernet port operating systembThis update is carried out using the OS-Loader tool, included in Unity Pro (see page6/27). Once migrated, PL7 processors are equivalent to corresponding Unityprocessors.The following PL7 processors can be migrated to Unity Pro (software migration):b TSX 57 2p: TSX P57 203/253/2623M becomeTSX P57 204/254/2634M respectively.b TSX 57 3p: TSX P57 303/353/3623AM becomeTSX P7 304/354/3634M respectively (migration supported by Unity Pro version u 3.0).10Note: Processor migration requires the use of new PCMCIA TSX MRP P/C, TSX MFP P/Cmemory references. See the equivalence table on page 1/32.___________________________________________________________________________(1) Not with TSX P57 153M processor.Description:page 1/27Characteristics:pages 1/28 ...Functions:page 1/30References:pages 1/30 ...1/26