OSHA's Flame-Resistant Clothing Policy - ASSE Members

OSHA's Flame-Resistant Clothing Policy - ASSE Members

OSHA's Flame-Resistant Clothing Policy - ASSE Members

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

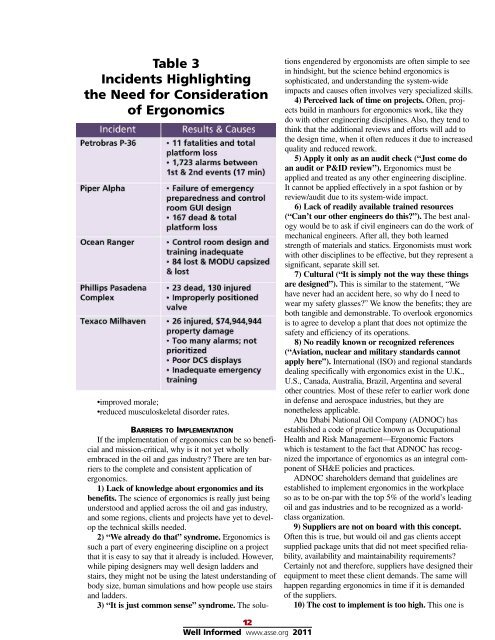

Table 3Incidents Highlightingthe Need for Considerationof Ergonomics•improved morale;•reduced musculoskeletal disorder rates.BARRIERS TO IMPLEMENTATIONIf the implementation of ergonomics can be so beneficialand mission-critical, why is it not yet whollyembraced in the oil and gas industry? There are ten barriersto the complete and consistent application ofergonomics.1) Lack of knowledge about ergonomics and itsbenefits. The science of ergonomics is really just beingunderstood and applied across the oil and gas industry,and some regions, clients and projects have yet to developthe technical skills needed.2) “We already do that” syndrome. Ergonomics issuch a part of every engineering discipline on a projectthat it is easy to say that it already is included. However,while piping designers may well design ladders andstairs, they might not be using the latest understanding ofbody size, human simulations and how people use stairsand ladders.3) “It is just common sense” syndrome. The solutionsengendered by ergonomists are often simple to seein hindsight, but the science behind ergonomics issophisticated, and understanding the system-wideimpacts and causes often involves very specialized skills.4) Perceived lack of time on projects. Often, projectsbuild in manhours for ergonomics work, like theydo with other engineering disciplines. Also, they tend tothink that the additional reviews and efforts will add tothe design time, when it often reduces it due to increasedquality and reduced rework.5) Apply it only as an audit check (“Just come doan audit or P&ID review”). Ergonomics must beapplied and treated as any other engineering discipline.It cannot be applied effectively in a spot fashion or byreview/audit due to its system-wide impact.6) Lack of readily available trained resources(“Can’t our other engineers do this?”). The best analogywould be to ask if civil engineers can do the work ofmechanical engineers. After all, they both learnedstrength of materials and statics. Ergonomists must workwith other disciplines to be effective, but they represent asignificant, separate skill set.7) Cultural (“It is simply not the way these thingsare designed”). This is similar to the statement, “Wehave never had an accident here, so why do I need towear my safety glasses?” We know the benefits; they areboth tangible and demonstrable. To overlook ergonomicsis to agree to develop a plant that does not optimize thesafety and efficiency of its operations.8) No readily known or recognized references(“Aviation, nuclear and military standards cannotapply here”). International (ISO) and regional standardsdealing specifically with ergonomics exist in the U.K.,U.S., Canada, Australia, Brazil, Argentina and severalother countries. Most of these refer to earlier work donein defense and aerospace industries, but they arenonetheless applicable.Abu Dhabi National Oil Company (ADNOC) hasestablished a code of practice known as OccupationalHealth and Risk Management—Ergonomic Factorswhich is testament to the fact that ADNOC has recognizedthe importance of ergonomics as an integral componentof SH&E policies and practices.ADNOC shareholders demand that guidelines areestablished to implement ergonomics in the workplaceso as to be on-par with the top 5% of the world’s leadingoil and gas industries and to be recognized as a worldclassorganization.9) Suppliers are not on board with this concept.Often this is true, but would oil and gas clients acceptsupplied package units that did not meet specified reliability,availability and maintainability requirements?Certainly not and therefore, suppliers have designed theirequipment to meet these client demands. The same willhappen regarding ergonomics in time if it is demandedof the suppliers.10) The cost to implement is too high. This one is12Well Informed www.asse.org 2011