WholesalerIs an importer/stockist who imports, completes all the import and custom formalities <strong>in</strong> his/herimport<strong>in</strong>g country and sells to various retailers, retail organisations, <strong>in</strong>dependent retailer or aretail cha<strong>in</strong> <strong>in</strong> his own country. A wholesaler may be a contact through the sales agent or canalso be a direct customer of the factoryBuy<strong>in</strong>g agentA buy<strong>in</strong>g agent is like a buy<strong>in</strong>g house and is usually based <strong>in</strong> the country or <strong>in</strong> the region of theexporter. He/she represents the buyer’s <strong>in</strong>terest and takes commission from the buyer forrepresent<strong>in</strong>g the buyer. <strong>The</strong> function of a buy<strong>in</strong>g agent is to <strong>in</strong>troduce the buyer to variousfactories for a k<strong>in</strong>d of product and get the best product at the best price for the buyer. In mostof the cases, the buy<strong>in</strong>g agent adm<strong>in</strong>isters the shipment and gives all the logistic <strong>in</strong>formationabout shipments to the buyer.Sales agent<strong>The</strong> sales agent is an <strong>in</strong>dependent <strong>in</strong>termediary between the (foreign) producer and the retaileror retail organisation, receiv<strong>in</strong>g a commission from the former. <strong>The</strong> agent (or salesrepresentative) covers a limited geographical area. <strong>The</strong> level of commission depends on anumber of factors, <strong>in</strong>clud<strong>in</strong>g the turnover rate of the product concerned, but it averages anestimated 6-10% of turnover. Most agents represent more than one producer, althoughcompetition is avoided. More and more agents are start<strong>in</strong>g to sell from stock, to meet theirclients' short-term demands. Stock is often held on a consignment basis. If the agent builds uphis own stock, he is <strong>in</strong> fact function<strong>in</strong>g as a wholesaler. <strong>The</strong> role of agents as described above,they are often used as sell<strong>in</strong>g agents. <strong>The</strong>y operate ma<strong>in</strong>ly <strong>in</strong> the segments of high price/qualityand <strong>in</strong> the middle/high price, classical and branded fashion footwear. Another type of agent isthe so-called buy<strong>in</strong>g agent located <strong>in</strong> the supply<strong>in</strong>g country, settles bus<strong>in</strong>ess on the <strong>in</strong>structionsof his pr<strong>in</strong>cipals, ma<strong>in</strong>ly retail organisations and works on a commission basis too.Contacts with sales <strong>in</strong>termediaries can be made <strong>in</strong> several ways, such as consult<strong>in</strong>g traderepresentatives' associations, chambers of commerce, fashion centres, trade publications, tradedirectories, etc.2.1.2 Availability, quality and price of raw materialsIn the last two to three years, the price of leather has gone up and there is a persistent shortageas well. Dur<strong>in</strong>g the October 2005 earthquake, the footwear sector suffered a loss of livestockand cattle, which was not reported, but the follow<strong>in</strong>g season experienced a further raw materialshortage and pressure on prices. Likewise, <strong>in</strong> the case of f<strong>in</strong>ished shoe production, the costs of<strong>in</strong>puts for all raw materials are go<strong>in</strong>g up, e.g. electricity, wages, local tariffs and federalgovernment’s taxes, while the quality available is of medium grade. However, our qualitystandards meet <strong>in</strong>ternational specifications, but the feel of f<strong>in</strong>ished product lacks far beh<strong>in</strong>d. Asthere exists an upward pressure on raw material, the end consumer is always pressuris<strong>in</strong>g forprice discounts. <strong>The</strong>refore, profitability is under a constant pressure.Furthermore, it must be noted that petrochemical prices have <strong>in</strong>creased very steeply <strong>in</strong> the lastfew years, i.e. all chemicals and sol<strong>in</strong>g material have also become very expensive.16 International Trade Centre

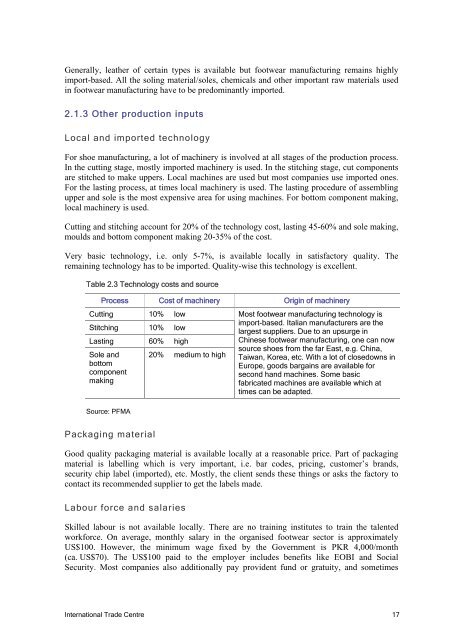

Generally, leather of certa<strong>in</strong> types is available but footwear manufactur<strong>in</strong>g rema<strong>in</strong>s highlyimport-based. All the sol<strong>in</strong>g material/soles, chemicals and other important raw materials used<strong>in</strong> footwear manufactur<strong>in</strong>g have to be predom<strong>in</strong>antly imported.2.1.3 Other production <strong>in</strong>putsLocal and imported technologyFor shoe manufactur<strong>in</strong>g, a lot of mach<strong>in</strong>ery is <strong>in</strong>volved at all stages of the production process.In the cutt<strong>in</strong>g stage, mostly imported mach<strong>in</strong>ery is used. In the stitch<strong>in</strong>g stage, cut componentsare stitched to make uppers. Local mach<strong>in</strong>es are used but most companies use imported ones.For the last<strong>in</strong>g process, at times local mach<strong>in</strong>ery is used. <strong>The</strong> last<strong>in</strong>g procedure of assembl<strong>in</strong>gupper and sole is the most expensive area for us<strong>in</strong>g mach<strong>in</strong>es. For bottom component mak<strong>in</strong>g,local mach<strong>in</strong>ery is used.Cutt<strong>in</strong>g and stitch<strong>in</strong>g account for 20% of the technology cost, last<strong>in</strong>g 45-60% and sole mak<strong>in</strong>g,moulds and bottom component mak<strong>in</strong>g 20-35% of the cost.Very basic technology, i.e. only 5-7%, is available locally <strong>in</strong> satisfactory quality. <strong>The</strong>rema<strong>in</strong><strong>in</strong>g technology has to be imported. Quality-wise this technology is excellent.Table 2.3 Technology costs and sourceProcess Cost of mach<strong>in</strong>ery Orig<strong>in</strong> of mach<strong>in</strong>eryCutt<strong>in</strong>g 10% lowStitch<strong>in</strong>g 10% lowLast<strong>in</strong>g 60% highSole andbottomcomponentmak<strong>in</strong>gSource: PFMA20% medium to highMost footwear manufactur<strong>in</strong>g technology isimport-based. Italian manufacturers are thelargest suppliers. Due to an upsurge <strong>in</strong>Ch<strong>in</strong>ese footwear manufactur<strong>in</strong>g, one can nowsource shoes from the far East, e.g. Ch<strong>in</strong>a,Taiwan, Korea, etc. With a lot of closedowns <strong>in</strong>Europe, goods barga<strong>in</strong>s are available forsecond hand mach<strong>in</strong>es. Some basicfabricated mach<strong>in</strong>es are available which attimes can be adapted.Packag<strong>in</strong>g materialGood quality packag<strong>in</strong>g material is available locally at a reasonable price. Part of packag<strong>in</strong>gmaterial is labell<strong>in</strong>g which is very important, i.e. bar codes, pric<strong>in</strong>g, customer’s brands,security chip label (imported), etc. Mostly, the client sends these th<strong>in</strong>gs or asks the factory tocontact its recommended supplier to get the labels made.Labour force and salariesSkilled labour is not available locally. <strong>The</strong>re are no tra<strong>in</strong><strong>in</strong>g <strong>in</strong>stitutes to tra<strong>in</strong> the talentedworkforce. On average, monthly salary <strong>in</strong> the organised footwear sector is approximatelyUS$100. However, the m<strong>in</strong>imum wage fixed by the Government is PKR 4,000/month(ca. US$70). <strong>The</strong> US$100 paid to the employer <strong>in</strong>cludes benefits like EOBI and SocialSecurity. Most companies also additionally pay provident fund or gratuity, and sometimesInternational Trade Centre 17