RO06 PLUS Brochure - Sinerji Grup

RO06 PLUS Brochure - Sinerji Grup

RO06 PLUS Brochure - Sinerji Grup

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

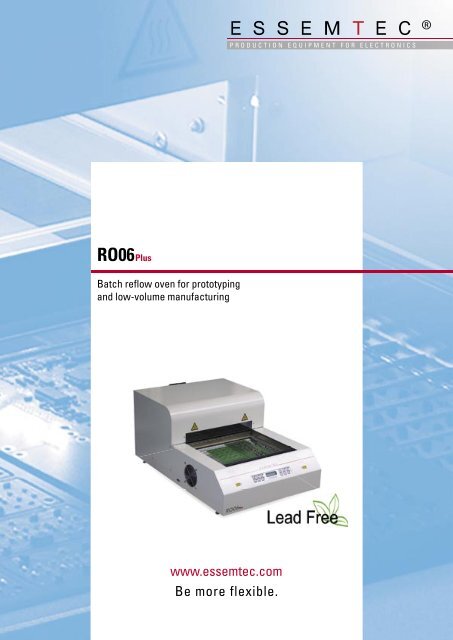

E S S E M T E C P R O D U C T I O N E Q U I P M E N T F O R E L E C T R O N I C S<strong>RO06</strong>PlusBatch reflow oven for prototypingand low-volume manufacturingwww.essemtec.comBe more flexible.

<strong>RO06</strong>PlusDrawer-type reflow oven for low-volume manufacturingHomogeneous convection heaterQuartz lamp supports quick heatingLead-free or standard solderingprofilesMotor-driven drawer for automatedprocess flowT1 °StandbyT2 °/SecPreheatT3 °/SecSolderT4 °CoolingIntegrated microprocessorcontrol permits theprogramming of abasic temperature (T1),the desired pre-heattemperature and time (T2),as well as the requiredsoldering temperature andtime (T3). After coolingdown to T4, the drawerautomatically moves out ofthe heat chamber.Microprocessor control with largememoryLarge viewing window for processmonitoringUnique pause function for processevaluationExternal sensors for in-boardmeasurementsThe large viewing windowenables visual monitoring ofthe process running insidethe sealed heat chamber.Using the unique pausefunction, a given solderprofile can be extendedmanually. This ensures thata new product is correctlysoldered in the first pass.In regard to component type, componentdensity and board complexity,the soldering of state-of-the-artPCB requires professional productionequipment, especially inlow-volume manufacturing. Solderquality equal to that in high-volumeenvironments must be ensured.To meet these requirements, the<strong>RO06</strong> reflow oven is the ideal solution.The integrated convectionheater with quartz lamp support forsteep ramping, an automated processflow and the feasibility of storingvarious profiles have made the<strong>RO06</strong> the preferred solution in thelab and in low-volume manufacturingall over the world.Two external temperaturesensors allow themeasuring of profilesdirectly in the circuitboard. The integrated LCDpanel directly indicatesthe measured temperaturevalues.

E S S E M T E C P R O D U C T I O N E Q U I P M E N T F O R E L E C T R O N I C SFumes from the heatchamber can be exhausteddirectly by a fumeextraction system.The motor-driven drawerautomatically moves backand forth between heatchamber and forced aircooling zone.Integrated microprocessorcontrol sets exact values fortemperature and time andprovides a comprehensiveprogram library. In addition,it can store customprograms as well.The temperature profilesmeasured can begraphically displayed on aPC, connecting via RS-232interface.

<strong>RO06</strong>PlusE S S E M T E C P R O D U C T I O N E Q U I P M E N T F O R E L E C T R O N I C SOptions• Temperature sensor set• Windows-compatible RO-SOFT softwarewith RS-232 interface• Exhaust fume flangeThe Windows-compatibleRO-SOFT software recordsthe measured temperatureprofiles as well as thecontrolled temperaturewithin the heat zone.These curves can bestored and graphicallysuperimposed for processcontrol.Other Soldering Solutions From ESSEMTEC• Inline reflow ovens• Wave soldering machines• Nitrogen inert atmosphere• Reflow profile simulationsoftwareConveyor ovens feature ahigher productivity and offermore process stability forcomplex PCB.Wave Soldering MachineWS330Soldering width 330 mmReflow Oven RO300FCSoldering width300 mm (11,8“ )Reflow Oven RO400FCSoldering width400 mm (15,7“ )Complete production equipment line from one source• Printers• Dispensers• Placement systems• Solder systems• Handlers• PPS software• Process know-howESSEMTEC deliverscomplete SMDmanufacturing lines alongwith the necessary processknow-how – all from onesource. Worldwide supportand a high innovationpotential lay the foundationfor a strong and futureorientedpartnership withour cutomers.HeadquartersESSEMTEC AGMosenstrasse 20CH-6287 Aesch/LUSwitzerlandPhone +41 (0)41 919 60 60Fax +41 (0)41 919 60 50info@essemtec.comNorth AmericaESSEMTEC (USA) LLC816N. Delsea Drive #308Glassboro, NJ 08028-1499USAPhone +1 856 218 1131Fax +1 856 218 1134sales@essemtec-usa.comGermanyESSEMTEC DeutschlandHerzog-Arnulf-Strasse 20D-85604 Zorneding/MünchenGermanyPhone +49 (0)8106 24 86 22Fax +49 (0)8106 24 86 23germany@essemtec.com<strong>RO06</strong>_e_06BBe more flexible.www.essemtec.com