You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

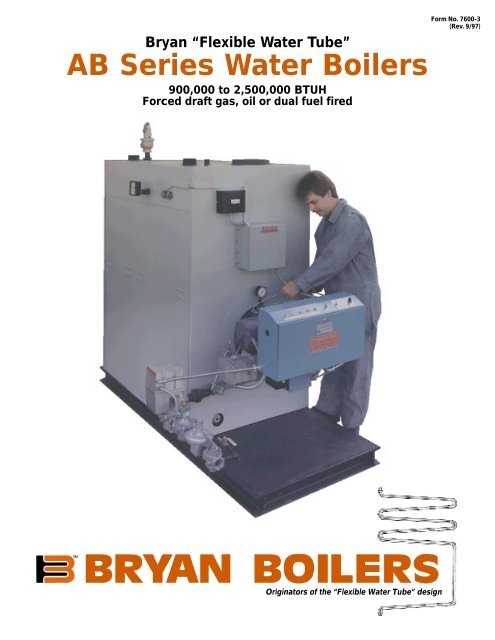

Bryan “Flexible <strong>Water</strong> Tube”<strong>AB</strong> <strong>Series</strong> <strong>Water</strong> <strong>Boilers</strong>900,000 to 2,500,000 BTUHForced draft gas, oil or dual fuel firedForm No. 7600-3(Rev. 9/97)Originators of the “Flexible <strong>Water</strong> Tube” design

Performance efficiency breakthrough for commercial/industrial applicationsHigh efficiency hot water heat guaranteedFeaturing Bryan’s “flexible water tube” design· True bent water tubedesign guaranteedshock freeE· 83.5% efficiencyguaranteedL· Full 5 sq ft per BHPheating surface areaAQualityConstructionFeaturesA Heavy steel boiler frame,built and stamped in accordancewith the appropriateASME Boiler Code.B Large volume water legdowncomers promote rapidinternal circulation and temperatureequalization.C Bryan bent water tubesare flexible, individually replaceablewithout weldingor rolling.D <strong>Water</strong> cooled furnace withlow heat release.E <strong>Water</strong> side interior accessiblefor cleanout and inspection,front and rearopenings, upper and lowerdrum.F Pressurized design: Innerfireside casing constructedof heavy gauge steel, completelyseal welded, linedwith high temperature insulationand refractory.BGKHG Boiler tube and furnacearea access panels; Heavygauge steel lined with hightemperature insulation andrefractory, bolted and tightlysealed to boiler frame.H Access panel: Front panelsprovide easy access forinspection, cleaning and accessto burner head.INMI Single side access: Combustionchamber, tubes andburner head are completelyaccessible from one side,simplifying maintenance,minimizing floor space.J Heavy gauge steel boilerjacket with rust resistant zinccoating and enamel finish.Insulated with fiberglass toensure exceptionally coolouter surface.JDCK Rear flame observationport.L Minimum sized flue vent.M Forced draft, flame retentionhead type burner. Efficientcombustion of oil orgas, quiet operation.N Control panel: All controlsinstalled and connected toterminal strip (optional).FIBryan <strong>AB</strong> <strong>Series</strong> Boiler SpecificationsBOILER NOMINAL NOMINAL HEATING APPROXIMATEMODELINPUT OUTPUT BOILER SURFACE SHIPPING WT.NUMBER MBH (kW) MBH (kW)* HORSEPOWER SQ. FT. (m 2 ) LBS (KG)A B 9 0 -W 900 (263.7) 720 (211.0) 21 113 (10.5) 2000 ( 907 )<strong>AB</strong>120-W 1200 (351.6) 960 (281.3) 29 148 (13.8) 2250 (1020)<strong>AB</strong>150-W 1500 (439.5) 1200 (351.6) 36 184 (17.1) 2550 (1157)<strong>AB</strong>200-W 2000 (586.0) 1600 (468.8) 48 244 (22.6) 3050 (1383)<strong>AB</strong>250-W 2500 (732.5) 2000 (586.0) 60 303 (28.2) 3500 (1588)* NOTE: Nominal output based on boiler industry standard of 80% of input. Actual combustion efficiencies will be higher and fuel dependent.

These unique features are availableonly on Bryan <strong>AB</strong> <strong>Series</strong> water boilersThe Bryan Flexible TubeBryan’s exclusive “flexible tube” design eliminates the possibilityof damage from “thermal shock.”Tubes are easily removable and replaceable,without welding or rolling, eliminatinglong, expensive downtime shouldrepairs ever be required. A 20-year non prorated warrantyagainst pressure vessel damagedue to thermal shock protectsevery Bryan water boiler.Compact design, minimum floorspaceWith our compact water tubedesign, the overall size of theunit is less than most othertypes of boilers, yet maintainsa full five sq ft per HPheating surface area. Needingonly 24 inches for tube removal,and only on one side of the boiler,the <strong>AB</strong> <strong>Series</strong> boiler occupies verysmall space in the boiler room.This can result in considerablesavings in building costs. Pressurizedfiring permits minimum sized breechingand vent.Positive internal circulationEach pass of the Bryan water tube slopes upward. Thisconfiguration, along with the large volume downcomer waterlegs, provides extremely rapid natural thermal internal circulation,promoting both high efficiency of heat transfer anduniform temperature throughout the boiler. Eliminating stressdamage caused by unequal temperature distribution is especiallyimportant for hot water heating systems, particularlywhere intermittent or continuous low temperature water returnsmay be encountered.Multi-pass flue gas travelHigh velocity four pass flue gas travel is obtained by aunique baffling system. This contributes to maximum fireside heat transfer and overall high boiler efficiencies.Accessibility of furnace and tube areaBolted inner panel provides easy and completeaccess to furnace andboiler tube area, as well as toburner head. Tube side panelsare all removable and heavilyinsulated and sealed to boilerframe. All access is from onlyone side.Thermal blend water returnBryan’s unique “thermal blend”return blends cold or cooler returnwater with warmer boilerwater, bringing it to design operatingtemperatures.An injector tube directs the“mixed” water flow through thedowncomer to the lower headerand heating surfaces at a temperatureabove possiblecondensing conditions. Thisreduces the possibility of“cold spots” and damagefrom corrosive condensation.<strong>Water</strong> cooled furnaceThe configuration of the water tubes provides a water cooledcombustion chamber. A high percentage of the heatingsurface is exposed to direct radiant heat, increasing watervelocities and heat transfer.Bryan <strong>AB</strong> <strong>Series</strong> <strong>Boilers</strong>Standard and OptionalEquipmentSTANDARD EQUIPMENTFURNISHEDGas fired, forced draftCombination thermometer and altitude gauge, ASMECode rated boiler relief valve, water temperaturecontrol (240°F Max. Std.), high limit control, probeLWCO, electronic combustion safety control, automaticoperating gas valve, safety gas valve, pilotsolenoid valve, pilot ignition assembly, main manualgas shut-off valve, pilot cock, pilot and main gaspressure regulators, air safety switch, electrical box,all controls installed and wired.Oil fired, forced draftCombination thermometer and altitude gauge, ASMECode rated boiler relief valve, water temperaturecontrol (240°F Max. Std.), high limit control, probeLWCO, electronic combustion safety control, oilvalve, oil ignition transformer, two-stage fuel unit,gas pilot, oil nozzle assembly, electrical box, allcontrols installed and wired.Combination gas-oil forced draftCombination thermometer and altitude gauge, ASMECode rated boiler relief valve, water temperaturecontrol (240°F Max. Std.), high limit control, probeLWCO, automatic motorized gas valve, safety gasvalve, pilot solenoid valve, pilot ignition assembly,main manual gas shut-off valve, pilot cock, pilot andmain gas pressure regulators, air safety switch,manual fuel selector switch, electronic combustionsafety control, oil valve, oil ignition transformer,two-state fuel unit, oil ignition and nozzle assembly,electrical box, all controls installed and wired.OPTIONAL EQUIPMENT,EXTRA COST[1] Manual reset high limit control, installed[2] Manual reset low water cutoff[3] Auxiliary low water cutoff[4] Combination low water cutoff and feeder[5] Alarm bells or horns[6] FM, IRI, CSD-1 or other insurance approvedcontrol systems[7] Indicating lights, as desired[8] Control panel mounted on boiler[9] Lead-lag systems for two or more boilerswith or without outdoor reset control[10] Draft control systemOptional construction,high temperature hot waterOptional construction to ASME Power Boiler Coderequirements for temperatures exceeding 250°Fand/or pressure exceeding 150 psi to maximum of350°F and 300 psi, high temperature gauge andoperating controls included.When ordering, please specify:[1] Boiler size[2] Supply and return temperatures required[3] Boiler relief valve setting[4] Type of fuel: natural, LP or other gas and/orNo. 2 oil[5] If gas, type, BTU content, specific gravityand pressure available[6] Electric power voltage, phase and frequency[7] Optional extra equipment or construction[8] Special approvals required (FM, IRI or other)

Bryan <strong>AB</strong> <strong>Series</strong> Hot <strong>Water</strong> Heating <strong>Boilers</strong>DIMENSIONS in inches (cm)A B C D E F G H I J K LBoiler Length Width Min. Tube Clearance for Height Floor toModel ofFlue Flue Overall Gas Train Supply ReturnOutside Removal Servicing Over FlowNumber JacketLocation Size Length Connection Connection ConnectionJacket Clearance Burner Jacket Nozzle<strong>AB</strong>90-W 4415 /16 12 10 76 1 1 /4 3-F 3-F 34 3 /4 24 36 69 1 /2 74 7 /8(114.1) (30.5) (25.4) (193.0) (3.2) (7.6) (7.6) (88.3) (60.9) (91.4) (176.5) (190.2)<strong>AB</strong>120-W 543 /16 12 10 85 3 /8 1 1 /4 3-F 3-F 34 3 /4 24 36 69 1 /2 74 7 /8(137.6) (30.5) (25.4) (216.8) (3.2) (7.6) (7.6) (88.3) (60.9) (91.4) (176.5) (190.2)<strong>AB</strong>150-W 631 /2 12 10 94 3 /4 1 1 /2 3-F 3-F 34 3 /4 24 36 69 1 /2 74 7 /8(161.3) (30.5) (25.4) (260.7) (3.8) (7.6) (7.6) (88.3) (60.9) (91.4) (176.5) (190.2)<strong>AB</strong>200-W 7815 /16 16 1 /2 10 110 2 3-F 3-F 34 3 /4 24 36 69 1 /2 74 7 /8(200.5) (41.9) (25.4) (279.4) (5.1) (7.6) (7.6) (88.3) (60.9) (91.4) (176.5) (190.2)<strong>AB</strong>250-W 947 /16 15 12 125 1 /2 2 3-F 3-F 34 3 /4 24 36 69 1 /2 74 7 /8(239.9) (38.1) (30.5) (318.8) (5.1) (7.6) (7.6) (88.3) (60.9) (91.4) (176.5) (190.2)Specifications subject to change without notice. Consult factory to consult on other boiler options.Since 1916 • Subsidiary of Bryan Steam CorporationP.O.Box 27, Peru, Indiana 46970-0027 U.S.A.Phone: 765-473-6651 • Internet: www.bryanboilers.comFax: 765-473-3074 • E-mail: bryanboilers@iquest.netForm No. 7600-3 ©1995 Bryan <strong>Boilers</strong> Printed in USA97-4485