The Ama-Drainer Family. - Saga

The Ama-Drainer Family. - Saga

The Ama-Drainer Family. - Saga

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

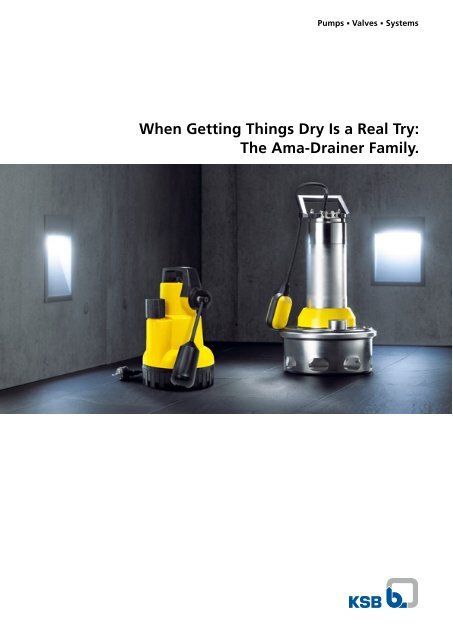

Pumps n Valves n SystemsWhen Getting Things Dry Is a Real Try:<strong>The</strong> <strong>Ama</strong>-<strong>Drainer</strong> <strong>Family</strong>.

2<strong>The</strong> <strong>Ama</strong>-<strong>Drainer</strong> product family.Strong family traits for efficient sewage removal.With the <strong>Ama</strong>-<strong>Drainer</strong>®pump series, you can be sure to keepdry. <strong>The</strong>re is an optimum pump for every application, matchedto the properties and solids content of the fluid to be pumped.Three different sizes of the free passage and three variants makesure of this: “A” is used for standard fluids, “C” for aggressivefluids and “R” for oily liquids. “N” describes the new model.Series 300 – ApplicationsN and N C modelsnAutomatic drainage of pits, shafts, yards and cellarssubject to a flooding risknLowering the surface water levelnDrainage of underground passagesnExtraction of water from rivers and reservoirsnDrainage<strong>Ama</strong>-<strong>Drainer</strong> ® N 301<strong>Ama</strong>-<strong>Drainer</strong> ® N 358Also available with LevelControl Basic 2Series 400 and 500 – ApplicationsVariants A, C and RnAutomatic drainage of pits, shafts, yards and cellarssubject to a flooding risknLowering the surface water levelnDrainage of underground passagesnExtraction of water from rivers and reservoirsnDrainagen<strong>Ama</strong>-<strong>Drainer</strong> 35 mm - Disposal of highlycontaminated, fibre-containing water, e.g. fromlaundries, common washing facilities, washingmachines and dishwashers (also hot water cycle),industrial plants<strong>Ama</strong>-<strong>Drainer</strong> ® A 4.../10<strong>Ama</strong>-<strong>Drainer</strong> ® A 522/11<strong>Ama</strong>-<strong>Drainer</strong> ® A, C, R 5.../10K<strong>Ama</strong>-<strong>Drainer</strong> ® A 4.../35Also available with LevelControl Basic 2

LevelControl Basic 2 3LevelControl Basic 2. Fast, easy, efficient.Multitude of accessoriesand options available<strong>The</strong> level-dependent control unit for tank filling and emptyingprocesses is easy to understand, install and operate. Thanksto its factory-set parameters and generously dimensioned con-nection space, the unit is ready for swift commissioning.LevelControl Basic 2 comes into its own in the widest rangeof applications involving waste water and sewage.Reliable operation based oncomprehensive informationnBacklit display indicates major parametersnDisplay of a wide variety of measured valuesnOperation and fault indication per pumpComprehensive functionality makesfor high system availabilitynOvercurrent and short-circuit protection by motorprotection switches (400 V model)nHigh water alertnMonitoring of the pumping stationnSystem redundancy by control of stand-by pumpnOptional activation of functional check run after idle periodnRechargeable battery retrofit kit for powering electronics,sensors and alarm equipment, e.g. hornTechnical DataNumber of pumps 1 or 2Direct startingUp to 4 kWStar/deltaUp to 22 kW, higher ratings on requestAmbient temperature -10°C to 50°C, extended temperaturerange down to -30°C on requestMains voltage230 V / 400 VMains frequency 50 Hz / 60 HzControlled variable LevelEnclosure IP 54SensorsFloat switches, digital level switches,pneumatic system, bubbler system,4...20 mA sensor inputExplosion protection ATEX model/non-ATEX model

4Product BenefitsPuts an end to everyday spills and puddles:Series 30012Perfectly tightMagnetic switch with adjustable, variablelevel control and maximum travel stop.Straightforward adaptation to external control withlocking deviceEasy to replaceCable with plug-type connector67High operating reliabilityMotor with triple shaft seal and barrier liquid lubrication.Additional lubrication of sealing surfaces in the event ofdry-runningDurableHigh-quality plastic casing for light weight and corrosionresistance. Low-noise operation, abrasion and shock resistant345No backflow in discharge pipeIntegrated swing check valveLow space requirementE.g. in narrow tanks due to vertical discharge nozzleProtected against overloadIntegrated motor protection89Economic operationHigh pump output at high efficiency, thanks to optimisedhydraulic systems and drivesProtection against overheatingJacket cooling enables operation with the motor outsidethe fluid.213456978

5Characteristic Curves <strong>Ama</strong>-<strong>Drainer</strong> N 301/302/303/35814H(m)12108®<strong>Ama</strong>-<strong>Drainer</strong> N 303Technical DataMax. capacity:16.5 m 3 /h (4.6 l/s)Max. head:12 mMax. temperature: +50 °C642®<strong>Ama</strong>-<strong>Drainer</strong> N 358®<strong>Ama</strong>-<strong>Drainer</strong> N 301®<strong>Ama</strong>-<strong>Drainer</strong> N 30200 2 4 6 8 10 12 14 16 18 Q(m 3 /h)0 1 2 3 4 5 Q(l/s)<strong>Ama</strong>-<strong>Drainer</strong> N 301 SE<strong>Ama</strong>-<strong>Drainer</strong> N 302 SE / 303 SEmin 400x400min 400x400Rp 1”1/4min 400Rp 1”1/4min 500mim 1)mim 1)autom.manuell7015238325autom.manuell11015278363214.5214.5335335Particle 50 Hz Cable Weightsize P 2 1-230V length Stand. vers. C<strong>Ama</strong>-<strong>Drainer</strong> N DN max.mm kW A m kg301 SE 1 1/4 10 0.18 1.9 3.0 4.76302 SE 1 1/4 10 0.356 4.0 3.0 6.29303 SE 1 1/4 10 0.50 4.9 3.0 6.52301 SE/NE 1 1/4 10 0.18 1.9 10.0 5.64302 SE/NE 1 1/4 10 0.356 4.0 10.0 7.17303 SE/NE 1 1/4 10 0.50 4.9 10.0 7.40358 SE/NE 1 1/2 35 0.43 4.0 10.0 7.50

6For drainage on a large scale:Series 400/5001234Fast installationPumps with AC motor supplied ready to be plugged in.No external electrical installationProtected against overloadDry-running protection and integrated motoroverload protectionReliable operationSiC/SiC mechanical seal with oil reservoir for reliableshaft seal and good dry-running propertiesLow space requirementE.g. in narrow tanks due to vertical discharge nozzle(versions 10, 35)5678Safe operationFloat switch can be locked at specific switching pointMaintenance-freeGrease-lubricated bearings sealed for lifeVariableSimple retrofitting to cooled variant (version 10)Easy to serviceSturdy, detachable bearing bracket – fast replacementin case of repair15623748

Your local KSB representative:KSB AktiengesellschaftJohann-Klein-Straße 967227 Frankenthal (Germany)www.ksb.com2331.02/4-10 / 05.12 / DAMM&BIERBAUM / © KSB Aktiengesellschaft 2012 Subject to technical modification without prior noticeMore space for solutions.