Wire Rope Assembly and Fittings - Hanes Supply, Inc

Wire Rope Assembly and Fittings - Hanes Supply, Inc

Wire Rope Assembly and Fittings - Hanes Supply, Inc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

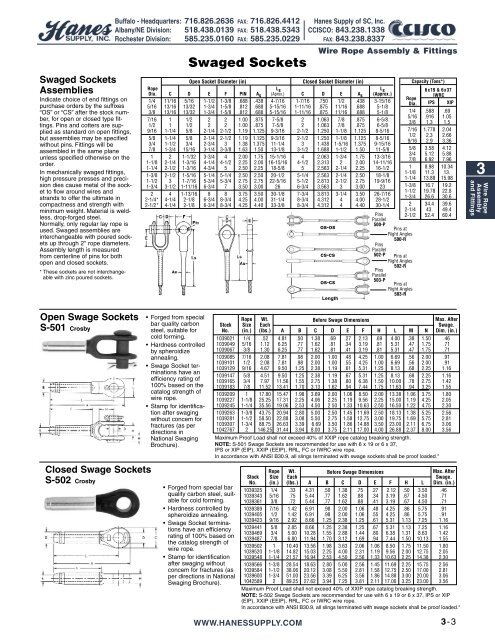

Swaged SocketsAssembliesIndicate choice of end fittings onpurchase orders by the suffixes“OS” or “CS” after the stock number,for open or closed type fittings.Pins <strong>and</strong> cotters are suppliedas st<strong>and</strong>ard on open fittings,but assemblies may be specifiedwithout pins. <strong>Fittings</strong> will beassembled in the same planeunless specified otherwise on theorder.In mechanically swaged fittings,high pressure presses <strong>and</strong> precisiondies cause metal of the socketto flow around wires <strong>and</strong>str<strong>and</strong>s to offer the ultimate incompactness <strong>and</strong> strength withminimum weight. Material is weldless,drop-forged steel.Normally, only regular lay rope isused. Swaged assemblies areinterchangeable with poured socketsup through 2" rope diameters.<strong>Assembly</strong> length is measuredfrom centerline of pins for bothopen <strong>and</strong> closed sockets.* These sockets are not interchangeablewith zinc poured sockets.Buffalo - Headquarters: 716.826.2636 FAX: 716.826.4412Albany/NE Division: 518.438.0139 FAX: 518.438.5343Rochester Division: 585.235.0160 FAX: 585.235.0229Swaged Sockets<strong>Hanes</strong> <strong>Supply</strong> of SC, <strong>Inc</strong>.CCISCO: 843.238.1338FAX: 843.238.8337<strong>Wire</strong> <strong>Rope</strong> <strong>Assembly</strong> & <strong>Fittings</strong>Open Socket Diameter (in)Closed Socket Diameter (in)<strong>Rope</strong> L s L sDia. C D E F PIN A s (Aprox.) C D E A s (Approx.)1/4 11/16 5/16 1-1/2 1-3/8 .688 .438 4-7/16 1-7/16 .750 1/2 .438 3-15/165/16 13/16 13/32 1-3/4 1-5/8 .812 .688 5-15/16 1-11/16 .875 11/16 .688 5-1/83/8 13/16 13/32 1-3/4 1-5/8 .812 .688 5-15/16 1-11/16 .875 11/16 .688 5-1/87/16 1 1/2 2 2 1.00 .875 7-5/8 2 1.063 7/8 .875 6-5/81/2 1 1/2 2 2 1.00 .875 7-5/8 2 1.063 7/8 .875 6-5/89/16 1-1/4 5/8 2-1/4 2-1/2 1.19 1.125 9-3/16 2-1/2 1.250 1-1/8 1.125 8-5/165/8 1-1/4 5/8 2-1/4 2-1/2 1.19 1.125 9-3/16 2-1/2 1.250 1-1/8 1.125 8-5/163/4 1-1/2 3/4 2-3/4 3 1.38 1.375 11-1/4 3 1.438 1-5/16 1.375 9-15/167/8 1-3/4 15/16 3-1/4 3-3/8 1.63 1.50 13-1/8 3-1/2 1.688 1-1/2 1.50 11-5/81 2 1-1/32 3-3/4 4 2.00 1.75 15-1/16 4 2.063 1-3/4 1.75 13-3/161-1/8 2-1/4 1-3/16 4-1/4 4-1/2 2.25 2.00 16-15/16 4-1/2 2.313 2 2.00 14-11/161-1/4 2-1/2 1-3/16 4-3/4 5 2.50 2.25 18-5/8 5 2.563 2-1/4 2.25 16-1/21-3/8 2-1/2 1-5/16 5-1/4 5-1/4 2.50 2.50 20-1/2 5-1/4 2.563 2-1/4 2.50 18-1/81-1/2 3 1-7/16 5-3/4 5-3/4 2.75 2.75 22-5/16 5-1/2 2.813 2-1/2 2.75 19-9/161-3/4 3-1/2 1-11/16 6-3/4 7 3.50 3.00 26 6-3/4 3.563 3 3.00 232 4 1-13/16 8 8 3.75 3.50 30-1/8 7-3/4 3.813 3-1/4 3.50 26-7/162-1/4* 4-1/4 2-1/8 6-3/4 8-3/4 4.25 4.00 31-1/4 8-3/4 4.312 4 4.00 28-1/22-1/2* 4-1/4 2-1/8 6-3/4 8-3/4 4.25 4.40 33-3/8 8-3/4 4.312 4 4.40 30-1/4os-oscs-csos-csLengthPinsParallel500-PPinsParallel502-PPinsParallel503-PPins atRight Angles500-RPins atRight Angles502-RPins atRight Angles503-RCapacity (Tons*)6x19 & 6x37IWRC<strong>Rope</strong>Dia. lPS XIP1/4 .588 .695/16 .916 1.053/8 1.3 1.57/16 1.778 2.041/2 2.3 2.669/16 2.9 3.365/8 3.58 4.123/4 5.12 5.887/8 6.92 7.961 8.98 10.341-1/8 11.3 13.1-1/4 13.88 15.981-3/8 16.7 19.21-1/2 19.78 22.81-3/4 26.6 30.62 34.4 39.62-1/4 43. 49.42-1/2 52.4 60.43<strong>Wire</strong> <strong>Rope</strong><strong>Assembly</strong><strong>and</strong> <strong>Fittings</strong>Open Swage SocketsS-501 CrosbyClosed Swage SocketsS-502 Crosby• Forged from specialbar quality carbonsteel, suitable forcold forming.• Hardness controlledby spheroidizeannealing.• Swage Socket terminationshave anefficiency rating of100% based on thecatalog strength ofwire rope.• Stamp for identificationafter swagingwithout concem forfractures (as perdirections inNational SwagingBrochure).• Forged frorn special barquality carbon steel, suitablefor cold forming.• Hardness controlled byspheroidize annealing.• Swage Socket terminationshave an efficiencyrating of 100% based onthe catalog strength ofwire rope.• Stamp for identificationafter swaging withoutconcem for fractures (asper directions in NationalSwaging Brochure).<strong>Rope</strong> Wt. Before Swage DimensionsMax. AfterStock Size EachSwage.No. (in.) (lbs.) A B C D E F H L M N Dim. (in.)1039021 1/4 .52 4.81 .50 1.38 .69 .27 2.13 .69 4.00 .38 1.50 .461039049 5/16 1.12 6.25 .77 1.62 .81 .34 3.19 .81 5.31 .47 1.75 .711039067 3/8 1.30 6.25 .77 1.62 .81 .41 3.19 .81 5.31 .47 1.75 .711039085 7/16 2.08 7.81 .98 2.00 1.00 .48 4.25 1.00 6.69 .56 2.00 .911039101 1/2 2.08 7.81 .98 2.00 1.00 .55 4.25 1.00 6.69 .56 2.00 .911039129 9/16 4.67 9.50 1.25 2.38 1.19 .61 5.31 1.25 8.13 .68 2.25 1.161039147 5/8 4.51 9.50 1.25 2.38 1.19 .67 5.31 1.25 8.13 .68 2.25 1.161039165 3/4 7.97 11.56 1.55 2.75 1.38 .80 6.38 1.50 10.00 .78 2.75 1.421039183 7/8 11.52 13.41 1.70 3.13 1.62 .94 7.44 1.75 11.63 .94 3.25 1.551039209 1 17.80 15.47 1.98 3.69 2.00 1.06 8.50 2.00 13.38 1.06 3.75 1.801039227 1-1/8 25.25 17.31 2.25 4.06 2.25 1.19 9.56 2.25 15.00 1.19 4.25 2.051039245 1-1/4 35.56 19.06 2.53 4.50 2 50 1.33 10.63 2.50 16.50 1.22 4.75 2.301039263 1-3/8 43.75 20.94 2.80 5.00 2.50 1.45 11.69 2.50 18.13 1.38 5.25 2.561039281 1-1/2 58.50 22.88 3.08 5.50 2.75 1.58 12.75 3.00 19.75 1.69 5.75 2.811039307 1-3/4 88.75 26.63 3.39 6.69 3.50 1.86 14.88 3.50 23.00 2.11 6.75 3.061042767 2 146.25 31.44 3.94 8.00 3.75 2.11 17.00 4.00 26.88 2.37 8.00 3.56Maximum Proof Load shall not exceed 40% of XXIP rope catalog breaking strength.NOTE: S-501 Swage Sockets are recommended for use with 6 x 19 or 6 x 37,IPS or XIP (EIP), XXIP (EEIP), RRL, FC or IWRC wire rope.In accordance with ANSI B30.9, all slings terminated with swage sockets shall be proof loaded.*<strong>Rope</strong> Wt. Before Swage DimensionsMax. AfterStock Size EachSwage.No. (in.) (lbs.) A B C D E F H L Dim. (in.)1039325 1/4 .33 4.31 .50 1.38 .75 .27 2.12 .50 3.50 .461039343 5/16 .75 5.44 .77 1.62 .88 .34 3.19 .67 4.50 .711039361 3/8 .72 5.44 .77 1.62 .88 .41 3.19 .67 4.50 .711039389 7/16 1.42 6.91 .98 2.00 1.06 .48 4.25 .86 5.75 .911039405 1/2 1.42 6.91 .98 2.00 1.06 .55 4.25 .86 5.75 .911039423 9/16 2.92 8.66 1.25 2.38 1.25 .61 5.31 1.13 7.25 1.161039441 5/8 2.85 8.66 1.25 2.38 1.25 .67 5.31 1.13 7.25 1.161039469 3/4 5.00 10.28 1.55 2.88 1.44 .80 6.38 1.31 8.63 1.421039487 7/8 6.80 11.94 1.70 3.12 1.69 .94 7.44 1.50 10.13 1.551039502 1 10.40 13.56 1.98 3.63 2.06 1.06 8.50 1.75 11.50 1.801039520 1-1/8 14.82 15.03 2.25 4.00 2.31 1.19 9.56 2.00 12.75 2.051039548 1-1/4 21.57 16.94 2.53 4.50 2.56 1.33 10.63 2.25 14.38 2.301039566 1-3/8 28.54 18.63 2.80 5.00 2.56 1.45 11.69 2.25 15.75 2.561039584 1-1/2 38.06 20.12 3.08 5.50 2.81 1.58 12.75 2.50 17.00 2.811039600 1-3/4 51.00 23.56 3.39 6.25 3.56 1.86 14.88 3.00 20.00 3.061042589 2 89.25 27.62 3.94 7.25 3.81 2.11 17.00 3.25 23.00 3.56Maximum Proof Load shall not exceed 40% of XXIP rope catalog breaking strength.NOTE: S-502 Swage Sockets are recommended for use with 6 x 19 or 6 x 37, IPS or XIP(EIP), XXIP (EEIP), RRL, FC or IWRC wire rope.In accordance with ANSI B30.9, all slings terminated with swage sockets shall be proof loaded.*WWW.HANESSUPPLY.COM3-3