Wire Rope Assembly and Fittings - Hanes Supply, Inc

Wire Rope Assembly and Fittings - Hanes Supply, Inc

Wire Rope Assembly and Fittings - Hanes Supply, Inc

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

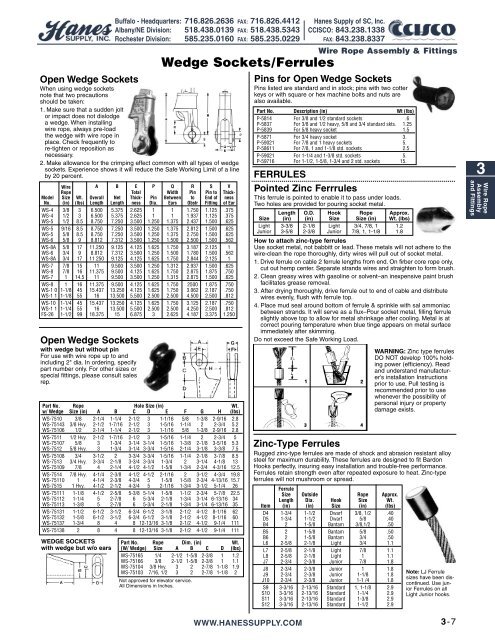

Buffalo - Headquarters: 716.826.2636 FAX: 716.826.4412Albany/NE Division: 518.438.0139 FAX: 518.438.5343Rochester Division: 585.235.0160 FAX: 585.235.0229Open Wedge SocketsWhen using wedge socketsnote that two precautionsshould be taken:1. Make sure that a sudden joltor impact does not dislodgea wedge. When installingwire rope, always pre-loadthe wedge with wire rope inplace. Check frequently tore-tighten or reposition asnecessary.2. Make allowance for the crimping effect common with all types of wedgesockets. Experience shows it will reduce the Safe Working Limit of a lineby 20 percent.<strong>Wire</strong> A B E P Q R S V<strong>Rope</strong> Total Width Pin Pin to Thick-Model Size Wt. Overall Net Thick- Pin Between to End of nessNo. (in) (lbs) Length Length ness Dia. Ears Obstr Fitting of EarWS-4 3/8 3 6.500 5.375 2.625 1 1 1.750 1.125 .375WS-4 1/2 3 6.500 5.375 2.625 1 1 1.937 1.125 .375WS-5 1/2 8.5 8.750 7.250 3.500 1.250 1.375 2.437 1.500 .625WS-5 9/16 8.5 8.750 7.250 3.500 1.250 1.375 2.812 1.500 .625WS-5 5/8 8.5 8.750 7.250 3.500 1.250 1.375 2.750 1.500 .625WS-6 5/8 9 8.812 7.312 3.500 1.250 1.500 2.500 1.500 .562WS-8A 5/8 17 11.250 9.125 4.125 1.625 1.750 3.187 2.125 1WS-6 3/4 9 8.812 7.312 3.500 1.250 1.500 1.780 1.500 .562WS-8A 3/4 17 11 250 9.125 4.125 1.625 1.750 2.844 2.125 1WS-7 7/8 15 11 9.500 3.500 1.250 1.312 2.937 1.500 .625WS-8 7/8 16 11.375 9.500 4.125 1.625 1.750 2.875 1.875 .750WS-7 1 14.5 11 9.500 3.500 1.250 1.315 2.875 1.500 .625WS-8 1 16 11.375 9.500 4.125 1.625 1.750 2500 1.875 .750WS-1 0 1-1/8 45 15.437 13.250 4.125 1.625 1.750 3.062 2.187 .750WS-1 1 1-1/8 55 16 13.500 5.500 2.500 2.500 4.500 2.500 .812WS-10 1-1/4 45 15.437 13.250 4.125 1.625 1.750 3.125 2.187 .750WS-1 1 1-1/4 55 16 13.500 5.500 2.500 2.500 4.250 2.500 .812FS-26 1-1/2 99 18.375 15 6.875 3 2.625 4.187 3.375 1.250Open Wedge Socketswith wedge but without pinFor use with wire rope up to <strong>and</strong>including 2" dia. In ordering, specifypart number only. For other sizes orspecial fittings, please consult salesrep.Part No. <strong>Rope</strong> Hole Size (in) Wt.w/ Wedge Size (in) A B C D E F G H (lbs)WS-7510 3/8 2-1/4 1-1/4 2-1/2 3 1-1/16 5/8 1-3/8 2-9/16 2.8WS-75143 3/8 Hvy. 2-1/2 1-7/16 2-1/2 3 1-5/16 1-1/4 2 2-3/4 5.2WS-75106 1/2 2-1/4 1-1/4 2-1/2 3 1-1/16 5/8 1-3/8 2-9/16 2.8WS-7511 1/2 Hvy. 2-1/2 1-7/16 2-1/2 3 1-5/16 1-1/4 2 2-3/4 5WS-75107 5/8 3 1-3/4 3-1/4 3-1/4 1-5/16 1-3/8 2-1/8 3-5/16 5.3WS-7512 5/8 Hvy. 3 1-3/4 3-1/4 3-3/4 1-5/16 2-1/4 3-1/8 3-3/8 7.5WS-75108 3/4 3-1/2 2 3-3/4 3-3/4 1-5/16 1-1/4 2-1/8 3-7/8 8.5WS-7513 3/4 Hvy. 3-3/4 2-1/8 3-3/4 3-3/4 1-3/4 2 3-1/4 4-1/8 13WS-75109 7/8 4 2-1/4 4-1/2 4-1/2 1-5/8 1-3/4 2-3/4 4-3/16 12.5WS-7514 7/8 Hvy. 4-1/4 2-3/8 4-1/2 4-1/2 2-1/16 2 3-1/2 4-3/4 19.8WS-75110 1 4-1/4 2-3/8 4-3/4 5 1-5/8 1-5/8 2-3/4 4-13/16 15.7WS-7515 1 Hvy. 4-1/2 2-1/2 4-3/4 5 2-1/16 1-3/4 3-1/2 5-1/4 26WS-75111 1-1/8 4-1/2 2-5/8 5-3/8 5-1/4 1-5/8 1-1/2 2-3/4 5-7/8 22.5WS-75112 1-1/4 5 2-7/8 6 5-3/4 2-1/8 1-3/4 3-1/4 6-13/16 34WS-75113 1-3/8 5 2-7/8 6 5-3/4 2-1/8 1-3/4 3-1/4 6-13/16 35WS-75131 1-1/2 6-1/2 3-1/2 6-3/4 6-1/2 3-1/8 2-1/2 4-1/2 8-1/16 62WS-75132 1-5/8 6-1/2 3-1/2 6-3/4 6-1/2 3-1/8 2-1/2 4-1/2 8-1/16 60WS-75137 1-3/4 8 4 8 12-13/16 3-1/8 2-1/2 4-1/2 9-1/4 111WS-75138 2 8 4 8 12-13/16 3-1/8 2-1/2 4-1/2 9-1/4 111WEDGE SOCKETSwith wedge but w/o earsPart No. <strong>Rope</strong> Dim. (in) Wt.(W/ Wedge) Size A B C D (lbs)WS-75165 1/4 2-1/2 1-5/8 2-3/8 1 1.2WS-75166 3/8 2-1/2 1-5/8 2-3/8 1 1.1WS-75104 3/8 Hvy. 3 2 2-7/8 1-1/8 1.9WS-75103 7/16, 1/2 3 2 2-7/8 1-1/8 2Not approved for elevator service.All Dimensions in <strong>Inc</strong>hes.Wedge Sockets/Ferrules<strong>Hanes</strong> <strong>Supply</strong> of SC, <strong>Inc</strong>.CCISCO: 843.238.1338FAX: 843.238.8337<strong>Wire</strong> <strong>Rope</strong> <strong>Assembly</strong> & <strong>Fittings</strong>Pins for Open Wedge SocketsPins listed are st<strong>and</strong>ard <strong>and</strong> in stock; pins with two cotterkeys or with square or hex machine bolts <strong>and</strong> nuts arealso available.Part No. Description (in) Wt (lbs)P-5814 For 3/8 <strong>and</strong> 1/2 st<strong>and</strong>ard sockets .6P-5837 For 3/8 <strong>and</strong> 1/2 heavy, 5/8 <strong>and</strong> 3/4 st<strong>and</strong>ard skts. 1.25P-5839 For 5/8 heavy socket 1.5P-5871 For 3/4 heavy socket 3.P-59021 For 7/8 <strong>and</strong> 1 heavy sockets 5.P-58611 For 7/8, 1 <strong>and</strong> 1-1/8 std. sockets 2.5P-59021 For 1-1/4 <strong>and</strong> 1-3/8 std. sockets 5.P-59716 For 1-1/2, 1-5/8, 1-3/4 <strong>and</strong> 2 std. sockets 15.FERRULESPointed Zinc FerrrulesThis ferrule is pointed to enable it to pass under loads.Two holes are provided for pouring socket metal.Length O.D. Hook <strong>Rope</strong> Approx.Size (in) (in) Size Size (in) Wt. (lbs)Light 3-3/8 2-1/8 Light 3/4, 7/8, 1 1.2Junior 3-5/8 2-3/8 Junior 7/8, 1, 1-1/8 1.8How to attach zinc-type ferrulesUse socket metal, not babbitt or lead. These metals will not adhere to thewire-clean the rope thoroughly, dirty wires will pull out of socket metal.1. Drive ferrule on cable 2 ferrule lengths from end. On firber core rope only,cut out hemp center. Separate str<strong>and</strong>s wires <strong>and</strong> straighten to form brush.2. Clean greasy wires with gasoline or solvent–an inexpensive paint brushfacilitates grease removal.3. After drying thoroughly, drive ferrule out to end of cable <strong>and</strong> distributewires evenly, flush with ferrule top.4. Place mud seal around bottom of ferrule & sprinkle with sal ammoniacbetween str<strong>and</strong>s. It will serve as a flux–Pour socket metal, filling ferruleslightly above top to allow for metal shrinkage after cooling. Metal is atcorrect pouring temperature when blue tinge appears on metal surfaceimmediately after skimming.Do not exceed the Safe Working Load.WARNING: Zinc type ferrulesDO NOT develop 100% holdingpower (efficiency). Read<strong>and</strong> underst<strong>and</strong> manufacturer'sinstallation Instructionsprior to use. Pull testing isrecommended prior to usewhenever the possibility ofpersonal injury or propertydamage exists.Zinc-Type FerrulesRugged zinc-type ferrules are made of shock <strong>and</strong> abrasion resistant alloysteel for maximum durability. These ferrules are designed to fit BardonHooks perfectly, insuring easy installation <strong>and</strong> trouble-free performance.Ferrules retain strength even after repeated exposure to heat. Zinc-typeferrules will not mushroom or spread.FerruleSize Outside <strong>Rope</strong> Approx.Length Dia. Hook Size Wt.Item (in) (in) Size (in) (lbs)D4 1-3/4 1-1/2 Dwarf 3/8, 1/2 .40D5 1-3/4 1-1/2 Dwarf 5/8 .40B4 2 1-5/8 Bantam 3/8,1/2 .50B5 2 1-5/8 Bantam 5/8 .50B6 2 1-5/8 Bantam 3/4 .50L6 2-5/8 2-1/8 Light 3/4 1.1L7 2-5/8 2-1/8 Light 7/8 1.1L8 2-5/8 2-1/8 Light 1 1.1J7 2-3/4 2-3/8 Junior 7/8 1.8J8 2-3/4 2-3/8 Junior 1 1.8J9 2-3/4 2-3/8 Junior 1-1/8 1.8J10 2-3/4 2-3/8 Junior 1-1 /4 1.8S9 3-3/16 2-13/16 St<strong>and</strong>ard 1, 1-1/8 2.9S10 3-3/16 2-13/16 St<strong>and</strong>ard 1-1/4 2.9S11 3-3/16 2-13/16 St<strong>and</strong>ard 1-3/8 2.9S12 3-3/16 2-13/16 St<strong>and</strong>ard 1-1/2 2.9Note: LJ Ferrulesizes have been discontinued.Use juniorFerrules on allLight Junior hooks.3<strong>Wire</strong> <strong>Rope</strong><strong>Assembly</strong><strong>and</strong> <strong>Fittings</strong>WWW.HANESSUPPLY.COM3-7