Common Industrial Protocol (CIP) - ODVA

Common Industrial Protocol (CIP) - ODVA

Common Industrial Protocol (CIP) - ODVA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

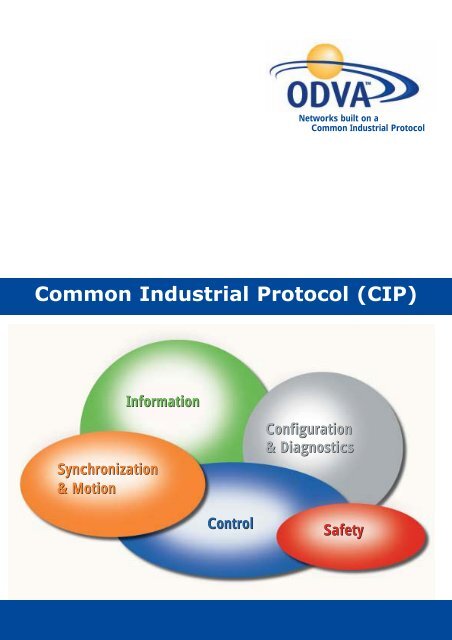

Networks built on a<strong>Common</strong> <strong>Industrial</strong> <strong>Protocol</strong><strong>Common</strong> <strong>Industrial</strong> <strong>Protocol</strong> (<strong>CIP</strong>)Synchronization& MotionInformationConfiguration& DiagnosticsControlSafety

The <strong>CIP</strong> Technology<strong>CIP</strong> Object Model <strong>CIP</strong> is a strictly objectorientedprotocol, at the upper layers. Each<strong>CIP</strong> object has attributes (data), services(commands), connections, and behaviors(relationship between attribute values andservices). <strong>CIP</strong> includes an extensive objectlibrary to support general purpose networkcommunications, network services such as filetransfer, and typical automation functions suchas analog and digital input/output devices, HMI,motion control, and position feedback.ApplicationobjectsAssemblyobjectsI/OParameterobjectExplicitmessageConnection manager orconnection objectMessagerouterIdentityobjectOptionalRequiredNetworkspecific linkobject(s)To provide interoperability, the same object, orgroups of objects, implemented in two or moredevices behaves identically from device todevice. A grouping of objects used in a device isreferred to as that device's "Object Model." TheObject Model in <strong>CIP</strong> is based on the producerconsumercommunication model which canprovide more efficient use of network resourcesthan a source-destination model by allowing theexchange of application information between asending device (e.g., the producer) and manyreceiving devices (e.g., the consumers) withoutrequiring data to be transmitted multiple timesby a single source to multiple destinations.<strong>CIP</strong> networkDevice Profiles In order to provide furtherinteroperability in <strong>CIP</strong> Networks comprised ofdevices from multiple vendors, <strong>CIP</strong> definesstandard grouping of objects as "Device Profiles."In addition to the set of objects implemented inthe device, Device Profiles specify configurationoptions and I/O data formats. Devices thatimplement one of the standard Device Profileswill respond to all the same commands and willhave the same network behavior as otherdevices that follow that same profile.The <strong>CIP</strong> Application Coverage forSafety, Synchronization and Motion<strong>CIP</strong> Sync (Synchronization) <strong>CIP</strong> Sync is a timesynchronization extension to <strong>CIP</strong>, based on therecent IEEE-1588 standard – Precision ClockSynchronization <strong>Protocol</strong> for NetworkedMeasurement and Control Systems – providingthe increased control coordination needed forsequencing demanding events recording,distributed motion control and other highlydistributed applications where absolute timesynchronizationof devices is vital.<strong>CIP</strong> Motion (Real-time, Deterministic MultiaxisMotion Control) <strong>CIP</strong> Motion is an extension toEtherNet/IP that allows integration of fielddevices and motion drives on the same network,eliminating the need for a separate motionoptimized network. This provides lower systemcost, improved system performance, and greatlyreduced system complexity.<strong>CIP</strong> Safety (Functional Safety) <strong>CIP</strong> Safetyprovides the ability to mix safety devices andstandard devices on the same network or wirefor seamless integration and increased flexibility.The safety protocol provides fail-safecommunication between nodes such as safetyI/O blocks, safety interlock switches, safety lightcurtains and safety PLCs in safety applications upto Safety Integrity Level (SIL) 3 according to IEC61508 standards.

The <strong>CIP</strong> Advantage<strong>Common</strong> network application layers are the key to advanced communication and truenetwork integration. The <strong>Common</strong> <strong>Industrial</strong> <strong>Protocol</strong> (<strong>CIP</strong>), which is managed jointly by<strong>ODVA</strong> and ControlNet International, allows complete integration of control with information,multiple <strong>CIP</strong> Networks and Internet technologies. Built on a single, media-independentplatform that provides seamless communication from the plant floor through the enterprisewith a scalable and coherent architecture, <strong>CIP</strong> allows companies to integrate I/O control,device configuration and data collection across multiple networks. This ultimately helpsminimize engineering and installation time and costs while maximizing ROI.• Comprehensive suite of messages andservices for manufacturing automationprovides functionality needed forcontrol, configuration, information,safety, synchronization and motion.• Producer-consumer architecture allowsefficient use of network bandwidth.• Seamless bridging and routing allowstopology options for networkarchitectures without having to programor configure intermediate devices.• Device profiles provide commonapplication interface.• Conformance practice helps to ensureinteroperable, multi-vendor systems.• Specification management andenhancement process promotes stable,open, and expanding networktechnologiesDeviceNet, DeviceNet Safety, <strong>CIP</strong>, <strong>CIP</strong> Motion,CompoNet, <strong>CIP</strong> Safety and <strong>CIP</strong> Sync are trademarks of<strong>ODVA</strong>. EtherNet/IP is a trademark of ControlNetInternational under license by <strong>ODVA</strong>. Other trademarksare property of their respective owners.©2006 <strong>ODVA</strong>, Inc.Ann Arbor, Michigan USATel +1 734-975-8840Fax +1 734-922-0027Email odva@odva.orgWeb www.odva.orgPUB00122R0–ENGLISHNetworks built on a<strong>Common</strong> <strong>Industrial</strong> <strong>Protocol</strong>