July 2012 - Foss

July 2012 - Foss

July 2012 - Foss

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

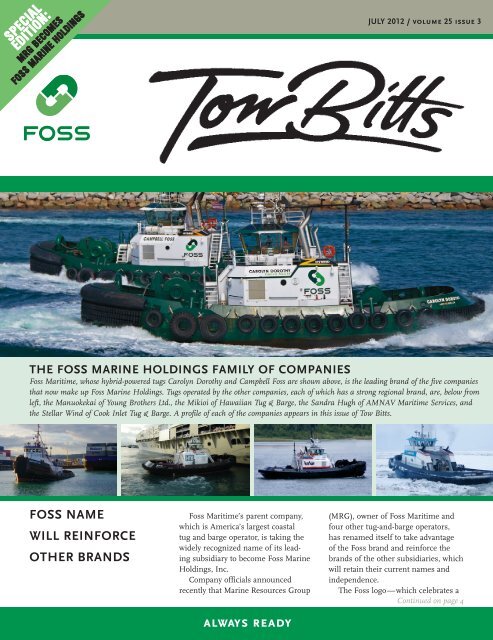

Vice President for Technical Services Mike Magill gives Connor Hansen, 8, a bit of coaching on how to christen his namesake vessel, the Connor <strong>Foss</strong> at <strong>Foss</strong> RainierShipyard. Connor is the great-great-great grandson of company founders Thea and Andrew <strong>Foss</strong>. In the background of the photo is Chaplain Kent Williams.<strong>Foss</strong> Offers Expert Vessel Maintenance, Repair Services,New Construction at Shipyards in Seattle and on ColumbiaJereme RuhlProviding a safe workingenvironment for employees andcustomers, and performing qualitywork for a fair price, are the keys tosuccess for <strong>Foss</strong> Shipyards, accordingto the company vice president incharge of the operations.“<strong>Foss</strong> has a proven track record,and that record provides the basis forour optimism that our business willcontinue to grow, said Mike Magill,vice president for technical services.<strong>Foss</strong> shipyards operates twofacilities, one on the Lake WashingtonShip Canal in Seattle, which focuseson vessel repairs and maintenance,and another on the Columbia River inRainier, Ore., which concentrates onnew construction.The Seattle yard includes three drydocks,the largest capable of handlingships up to 2,000 tons, plus cranes,lifts and other equipment requiredfor a full range of vessel services. Thesteam-powered <strong>Foss</strong> 300 floatingderrick, with a capacity of 75 tons, alsois available to shipyard customers, inaddition to performing work throughoutthe Puget Sound region.Experienced craftsmen in theSeattle yard have expertise in allrequired skills, including machining,engine mechanics, piping, carpentry,steel work, electrical work and rigging.Customers also have access to the<strong>Foss</strong> staff of marine engineers andnaval architects, who also oversee workon <strong>Foss</strong>’ own vessels both in Seattleand at the Rainier yard.Seattle Shipyard customers, inaddition to its internal customer(<strong>Foss</strong>), include owners of tugs, barges,large fishing vessels and yachts,research vessels, ferry operators andall manner of other floating craft.The <strong>Foss</strong> Rainier Shipyard,formerly a repair and maintenancefacility, turned out its first new tug in2004. That was the first of 10 Dolphin-Class tugs built for <strong>Foss</strong>, AMNAVand Hawaiian Tug & Barge. The newbuildsincluded the Carolyn Dorothy,the world’s first hybrid powered harbortug. Another Dolphin, the Campbell<strong>Foss</strong>, subsequently was retrofitted withhybrid power.Since the last Dolphin tug was6 • <strong>Foss</strong> Tow Bitts • ALWAYS READY • <strong>July</strong>, <strong>2012</strong>

A welder is at work at <strong>Foss</strong> Shipyard in Seattle. Experienced craftsmen at the yard have expertise in all required skills in vessel maintenance and repair.finished in 2009, the Rainier yardcompleted a line handling boat, theLucy <strong>Foss</strong>, to work with Chevrontankers in Southern California, anda crew boat, the Ava <strong>Foss</strong>, for theChevron operation. A station boat forthe San Francisco Bar Pilots, the yard’sfirst commercial project, was finishedin 2009.In June 2011 <strong>Foss</strong> Rainier delivereda shallow draft, triple-screw tug, theCapt. Frank Moody, to Delta Western,Inc. The vessel was designed for thedual mission of pushing barges upshallow Alaska river systems, and forconventional ocean towing.The yard recently finishedconstruction of the Connor <strong>Foss</strong>, whichwill transport ship pilots to and from astation in Astoria, Ore., and iscurrently working on an all-aluminum20-car ferry for the Washington StateDepartment of Transportation.Magill said the yards have not beenimmune to the negative economicclimate that has plagued the country,but they plan to grow by capturingmarket share.“We have reorganized to positionourselves to take advantage of themarket by focusing our sales staff solelyon customer service,” he said.“We believe this will provide greatervisibility of our services and facilitiesTHREE NEW OCEAN TUGS TO BE BUILTAT FOSS RAINIER SHIPYARD IN OREGONand will bring us additionalopportunities.”The yards, he said, are exploring“all opportunities,” not just projectswell suited for current facilities.“We wouldn’t pass up an opportunitywithout evaluating partnerships,facility expansion and all availableresources, human and otherwise.”An example of that approach, hesaid, includes construction of the ferry,which is starting at Rainier but willconclude in Eastern Washington withassistance of Colville tribal memberswhose reservation it will serve.<strong>Foss</strong> also is adding 10,000 squarefeet to its existing footprint at theRainier yard.<strong>Foss</strong> Maritime recentlyannounced plans to build three newocean-going tugs, with constructioncommencing in the first quarter of2013 at <strong>Foss</strong> Rainier Shipyard on theColumbia River in Oregon.Vice President for TechnicalServices Mike Magill, who oversees<strong>Foss</strong> Shipyards and the company’sengineering department, said theboats would be 130 feet in lengthand would be designed to reach100 metric tons of bollard pull.“It’s time to start replacing ourocean fleet for age reasons, andthere also are some businessopportunities that these boats will putus in the running for,” Magill said.The Glosten Associates will be<strong>Foss</strong>’ naval architecture partner on theproject. Design work is expected to becompleted by the end of this year.Machinery will include CaterpillarC280-8 main engines, compliantwith Tier II environmental standardsand equipped with Reintjes reductiongears. Markey Machinery willsupply the direct diesel drive towwinch, which will feature a side-by-sidedrum design.In addition to the low-emissionsengines, the tugs will have a numberof “green” features including: Noballast tanks, so no transportation ofinvasive species; holding tanks forblack and gray water to permitoperations in no-discharge zones;biodegradable oil in all hydraulic oilsystems; and LED lighting.<strong>July</strong>, <strong>2012</strong> • ALWAYS SAFE • <strong>Foss</strong> Tow Bitts • 7

The Tug Manuokekai and two of Young Brothers’ four new barges, berthed at the Port of Honolulu.Young Brothers Barge Service is a Hawaiian Lifeline;Company Carries all Manner of Freight through IslandsIn an island state where communitiesare separated by water, not roads,Young Brothers, Ltd., provides theintrastate highway. The company is alicensed common carrier, regulatedby the State of Hawaii, and carries allmanner of cargo between Honoluluand the neighbor islands.Its scheduled service, operated withsix tugs and seven barges (four builtsince 2007), makes Young Brothersunique among <strong>Foss</strong> Marine Holdingscompanies. It also operates in aunique, isolated and small market inthe middle of the Pacific Ocean.“That distance from the mainlandis an issue, and the economy hereis relatively small, so we don’t haveeasy access to parts or even backupequipment,” said Glenn Hong, whois president of both Young Brothersand Hawaiian Tug & Barge, also a <strong>Foss</strong>Marine Holdings company. “But thebiggest difference is that we are acommon carrier.”Young Brothers has been operatingsince 1900, when Herbert, Williamand Jack Young arrived in Honoluluand started a “bumboat” business,delivering supplies to ships in theharbor. Thirteen years later, thecompany expanded to provide oceantowing, rescue service and bargetransportation between the islands.Hawaiian Tug & Barge was formedin 1959 to separate harbor operationsand charter activities from theinterisland freight business.Saltchuk Resources, the parentcompany of <strong>Foss</strong> Marine Holdings,bought both Young Brothers andselected assets of Hawaiian Tugand Barge from Hawaiian ElectricIndustries in 1999.Hong explained that as a commoncarrier, Young Brothers mustmaintain a schedule and charge itscustomers according to its approvedtariffs. Seeking changes in those tariffscan be a challenging and time-consuming process. The company’smost recent rate adjustments,approved in December 2011, were firstsought in September 2010.“We devote lots of resources tothe regulatory process,” Hong said.“And there’s a huge industry built uparound the regulatory process—lawyers,economists and others.“In the meantime, we have abusiness to run.”The efficiency of that businesshas been greatly improved by YoungBrothers’ acquisition of the four newbarges from U.S. Barge in Portland.Almost twice as big as the ones theyreplaced, the barges have enabledYoung Brothers to significantlyincrease per-sailing capacities, nearlyeliminate tandem tows, and slightlyreduce the number of sailings.The capacity of the new barges is abit over 600 TEUs, and new top-pickmachines used to load them enablefive-high stacking, compared to8 • <strong>Foss</strong> Tow Bitts • ALWAYS READY • <strong>July</strong>, <strong>2012</strong>

Young Brothers new top-lift machines can stack five-containers-high on the new barges, effectively increasing their capacity by 25 percent.four-high with Young Brothers’ formerequipment.“It was a nice matching of theinvestment in the bigger platformsand higher-capacity lifts,” Hong said.Experienced and capable crews alsoare an important part of the success ofYoung Brothers, according to Hong.Because the islands are close together,the crews make much more frequentport stops than a long-haul tug would,usually 12 in-and-outs a week.In addition to carrying freight fromHonolulu to the neighbor islands ofHawaii, Maui, Molokai, Lanai andKauai, Young Brothers also does asubstantial back-haul business, whichHong describes as an important partof its service. Customers includeagricultural interests, rental caroperators and smaller businesses onthe neighbor islands.Hong says Young Brothers offers “auniversal and comprehensive service.”“This market requires frequent andregular service,” he said. “And youhave to be able to carry freight of allkinds—palletized, dry and reefer, aswell as autos and other deck cargo.We do it all.”The Manuokekai departs the Port of Honolulu with a bargeload of cargo bound for the neighbor islands.<strong>July</strong>, <strong>2012</strong> • ALWAYS SAFE • <strong>Foss</strong> Tow Bitts • 9

NORTH KOREAN ADVENTUREFour Tractor Tugs, Skilled Operators Make HTBHawaii’s Leading Harbor Services ProviderHawaiian Tug & Barge (HTB) isthe state’s leading harbor servicesprovider, performing ship assists andother work at the Port of Honoluluand the ports of the neighbor islands.The company operates five Z-drivetractor tugs, including two state-ofthe art Dolphin-class tugs built at<strong>Foss</strong> Rainier Shipyard on theColumbia River.“The Dolphins are recognized asthe cream of the ship assist markethere in Hawaii,” said HTB PresidentGlenn Hong, who is also presidentof sister company Young BrothersLimited.HTB has two competitors forharbor work, but Hong said hiscompany has “by far the majority ofthe market.” He attributes that edge toHTB’s 24-7 dispatch service, the highquality of its vessels and equipmentand its “highly capable crews.”“All together, that means we providequick, responsive and highly capableservice,” Hong said. “As a result, theindustry knows that HTB is the bestoption, and that is reflected in the factThe Pi’Ilani is one of two dolphin-class tugs operated by Hawaiian Tug and Bargethat we have a majority of themarket.”In addition to ship assists, HTBoffers contract towing, constructionsupport and other harbor services.Young Brothers performed harborservices until 1959, when HTB wasformed to handle that part of thebusiness, leaving Young Brothers as acommon carrier. Saltchuk Resources,parent company of <strong>Foss</strong> MarineHoldings, bought HTB and YoungBrothers in 1999. Since then, the twocompanies have been operated as one,with two distinct lines of business.MUSICAL CHAIRS UNDERWAY FOR HTB/YB EXECUTIVE TEAMThe executive team at HawaiianTug and Barge/Young Brothers willbe engaged in a sort of “managementmusical chairs,” from <strong>July</strong> throughNovember of this year.Glenn Hong, president of bothcompanies, said the three vicepresidents will trade jobs, returningto their regular positions after thefive-month exercise.“We’re doing it to broaden theexposure and experience of keyexecutives in the company, so at theend of this assignment, they will havea greater depth of understanding ofthe company,” Hong said.Under the temporary assignments:Young Brothers Vice President andGeneral Manager Matt Humphrey willmove to human resources; HumanResources Vice President Dean Kapoiwill move to government affairs; andVice President for Strategic Planningand Government Affairs Roy Catalaniwill manage Young Brothers.FMH SELLING SOUTHAMERICAN HOLDINGS<strong>Foss</strong> Marine Holdings recently soldthe Paraguay and Uruguay operationsof Mercusor Shuttle Group (MSG) toParaguay’s main port operator Puertosy Estibajes S.A., “Puerto Fenix.”MSG will continue to operate in theHidrovia Parana Paraguay under itsnew ownership. <strong>Foss</strong> Marine Holdingsalso is in the process of selling itsother South American operations.10 • <strong>Foss</strong> Tow Bitts • ALWAYS READY • <strong>July</strong>, <strong>2012</strong>

‘Complete Customer Satisfaction’ is AMNAV’s GoalAMNAV Maritime Services startedout as a small ship-assist company inthe San Francisco Bay Area in 1976and has grown and diversified into oneof the leading providers of maritimeservices on the West Coast.With current operations in boththe Bay Area and in the ports ofLos Angeles and Long Beach, AMNAVoperates seven tugs. Its Bay Areavessels include four state-of-the-art5,080 horsepower Dolphin Classtugs built at <strong>Foss</strong> Rainier Shipyard inOregon, making the fleet the mostmodern in the region.“For 35 years, AMNAV has hadone overriding goal,” said AMNAVPresident Milt Merritt, “completecustomer satisfaction by doing thesafest and best job possible with themost capable, crew, equipment andsupport available. Day-in and day-out,we dock more ships than any companyon the Bay.”The founder of the companywas high school shop teacherBob Whipple, who started out bybuying a 65-foot, 450-horsepower U.S.Navy harbor tug at an auction andupgrading it to 1,250 horsepower. Hissecond vessel was an 85-foot formerNavy tug, which he boosted fromAMNAV recently assisted and escorted the historic battleship USS Iowa from Richmond to sea. The shipwill be a floating museum in Los Angeles.850-horsepower to 4,000 horsepower.In 1984 Whipple purchased thetugs of a Port Arthur, Texas, shipdockingoperation owned by Merritt,who moved to San Francisco tomanage the company. Today AMNAVreports to the <strong>Foss</strong> Marine Holdings.Merritt said the company considersits employees to be its strongestasset, noting that half have been withthe company an average of 20 years.The company, he added, is entering itsfourth consecutive year without alost-time injury.As evidence of his employees’skills, Merritt pointed to an incident inJune when an ammo ship his tugs wereassisting first lost steering and then lostpower at 8.5 knots. The pilot wrote inhis report, “I ordered (the tug) poweredindirect, full to port. Giving an order likethis is one thing...Capt. Will Benedict’sresponse was immediate and perfectlyexecuted.”In addition to ship docking, AMNAVhas coastal offshore towing capability.“Our tugs are maintained by our ownin-house welders, fitters and paintingcrew,” Merritt said. “We can tow or fixalmost anything that floats.”FOSS MARITIME VICE PRESIDENT MOVES TO HOLDING COMPANYSusan Hayman,formerly vice presidentfor environmental andgovernmental affairs at<strong>Foss</strong> Maritime, is thenew vice president forenvironmental andregulatory affairs at <strong>Foss</strong>Marine Holdings (FMH).Paul Stevens, chiefexecutive officer at theholding company, said Hayman hashad an impressive track record sincejoining <strong>Foss</strong> Maritime in 2006 andher experience and skills will now be aresource for all FMH companies.Hayman joined <strong>Foss</strong> Maritime asvice president for HSQE and initiateda safety program that has resulted insteep drops in injuries in marineoperations and in the company’s twoshipyards. She also led development ofthe hybrid tug.A 1980 graduate of the U.S.Merchant Marine Academy, Haymanholds an MBA from Harvard BusinessSchool. Her career includes seagoingpositions for Exxon Shipping as wellas railroad experience for CSX.She also worked at APL where shebecame operations vice president forEurope, area manager for CentralEurope and global vice president forPort and Container Security. Afterbeing called to active duty in theUnited States Navy in 2002, Haymanreturned to APL as global vicepresident for Environmental Affairs.In her most recent position at <strong>Foss</strong>Maritime, Hayman was responsiblefor environmental strategies andengagement with lawmakers andregulators on issues impacting <strong>Foss</strong>.In her new role, Hayman will havethe same responsibilities for all FMHcompanies and will report to ChiefOperating Officer Steve Scalzo.<strong>July</strong>, <strong>2012</strong> • ALWAYS SAFE • <strong>Foss</strong> Tow Bitts • 11

660 W. Ewing St.Seattle, WA 98119PRESORTEDSTANDARDU.S. POSTAGE PAIDSEATTLE, WAPERMIT NO. 15551UNITED UNDER THE FOSS BRAND<strong>Foss</strong> Marine Holdings, formerly Marine Resources Group (MRG) is the holding company for five tug/barge operators, including,from top, <strong>Foss</strong> Maritime, AMNAV Maritime Services, Cook Inlet Tug & Barge, Hawaiian Tug & Barge and Young Brothers, Ltd..