Lubrication Manual for THK LM Guides - Hennlich

Lubrication Manual for THK LM Guides - Hennlich

Lubrication Manual for THK LM Guides - Hennlich

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

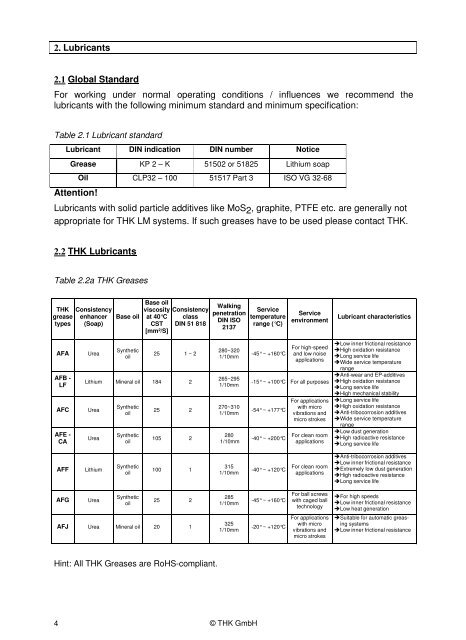

2. Lubricants2.1 Global StandardFor working under normal operating conditions / influences we recommend thelubricants with the following minimum standard and minimum specification:Table 2.1 Lubricant standardLubricant DIN indication DIN number NoticeGrease KP 2 – K 51502 or 51825 Lithium soapAttention!Oil CLP32 – 100 51517 Part 3 ISO VG 32-68Lubricants with solid particle additives like MoS 2 , graphite, PTFE etc. are generally notappropriate <strong>for</strong> <strong>THK</strong> <strong>LM</strong> systems. If such greases have to be used please contact <strong>THK</strong>.2.2 <strong>THK</strong> LubricantsTable 2.2a <strong>THK</strong> Greases<strong>THK</strong>greasetypesConsistencyenhancer(Soap)Base oilBase oilviscosityat 40°CCST[mm²/S]ConsistencyclassDIN 51 818WalkingpenetrationDIN ISO2137Servicetemperaturerange (°C)ServiceenvironmentLubricant characteristicsAFAAFB -LFAFCAFE -CAUreaSyntheticoil25 1 ~ 2Lithium Mineral oil 184 2UreaUreaSyntheticoilSyntheticoil25 2105 2280~3201/10mm265~2951/10mm270~3101/10mm2801/10mm-45° ~ +160°CFor high-speedand low noiseapplications-15° ~ +100°C For all purposes-54° ~ +177°C-40° ~ +200°CFor applicationswith microvibrations andmicro strokesFor clean roomapplicationsLow inner frictional resistanceHigh oxidation resistanceLong service lifeWide service temperaturerangeAnti-wear and EP-additivesHigh oxidation resistanceLong service lifeHigh mechanical stabilityLong service lifeHigh oxidation resistanceAnti-tribocorrosion additivesWide service temperaturerangeLow dust generationHigh radioactive resistanceLong service lifeAFFLithiumSyntheticoil100 13151/10mm-40° ~ +120°CFor clean roomapplicationsAnti-tribocorrosion additivesLow inner frictional resistanceExtremely low dust generationHigh radioactive resistanceLong service lifeAFGUreaSyntheticoil25 2AFJ Urea Mineral oil 20 12851/10mm3251/10mm-45° ~ +160°C-20° ~ +120°CFor ball screwswith caged balltechnologyFor applicationswith microvibrations andmicro strokesFor high speedsLow inner frictional resistanceLow heat generationSuitable <strong>for</strong> automatic greasingsystemsLow inner frictional resistanceHint: All <strong>THK</strong> Greases are RoHS-compliant.4© <strong>THK</strong> GmbH