Aftout Essahli - Sade

Aftout Essahli - Sade

Aftout Essahli - Sade

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

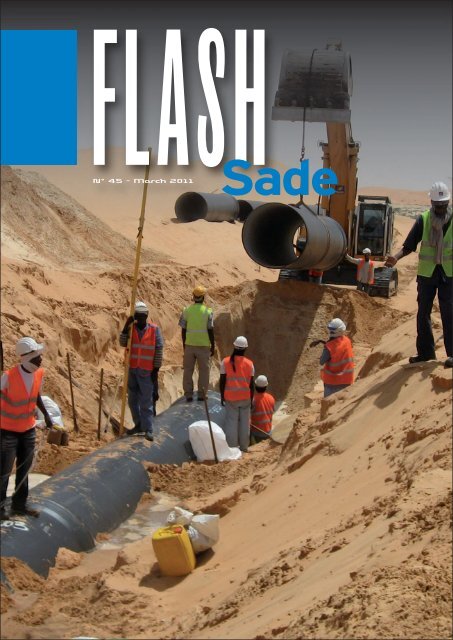

Interview with Denis LOPEZSADE Civil Engineer on the<strong>Aftout</strong> <strong>Essahli</strong> project■ What experience did you have of this type of project?I have been working on SADE’s overseas projects since I joined thecompany in 1991. In 19 years, I must have worked for two periods ofsix months in France. This project was carried out on familiarground for me because I had previously taken part in the laying of120 km of pipes in Senegal, in two sections, together with projectsin southern Morocco and in many other countries in Africa.• ensure that all thesupplies were easilytraceable;• deal with theclimatic andgeotechnicalconditions;■ What was your methodology?The success of this project essentially depended on theorganisation, skills and motivation of our teams and our partnersover the whole period of the operations. For the pipe laying,we created four teams which operated withtheir own resources from our Tiguent base.They consisted of Mauritanians supervised bypersonnel already trained in our methods fromSenegal, Burkina-Faso, Ghana and France. Theywere the central elements of the system and wewere careful to provide them with the bestsupply and living logistics, improve their skills and keep theirmotivation levels high to meet deadlines and laying qualitystandards compatible with our own requirements and thecontractual data.■ Four teams who were actually four Work Centres?Yes, and competing in a healthy way. On average, each team laid 15pipes per day with a record of 33 pipes in one day. We thus laid justover twenty thousand Ø 1400 mm pipes (weighing 5.6 tonneseach) and nearly thirteen hundred Ø 1100 mm pipes betweenNovember 2007 and August 2009.■ What was your organisation upstream and downstream fromthe laying teams?We had to:• ensure that the pipes and connection parts manufactured byPont-à-Mousson, which arrived in Nouakchott by ship fromAntwerp (42 dedicated shipments in all), were correctly supplied,unloaded, stored in the port, transported and then sided;“All of this constituteda real daily challengefor three years.”• supervise theconstruction of the civil engineering works all along the pipe(more than 400 structures);• follow terrain features precisely;• carry out tests while advancing at the sametime;• make sure that we always had the rightequipment, the right local partners and theright people available and coordinate themoptimally while providing them with good livingconditions. In the peak period, this concernednearly 650 people working on a construction site open 6 days aweek.All of this constituted a real daily challenge for three years.■ What were the key features of this project?There were many key features, and they were all positive! Theyranged from the laying of the first pipe in 2007 to the laying of thelast pipe in 2009, and included the initial tests of the installation,which were all successful. They also included the organisation setup, the way in which it was maintained for the whole period of theproject, the quality of our partners and subcontractors, the way inwhich the contractual requirements were met, and the results interms of training and safety.Our greatest reward is the fact that this high-quality functionalutility is now one of Mauritania’s national assets. The satisfactionand confidence expressed by our customer, together with asplendid opening ceremony, completed the feeling of a job welldone. I am ready for more...M a r c h 2 0 1 1 • F l a s h S a d e 4 55

Head Office28, rue de La Baume - 75379 Paris Cedex 08Tel.: +33 (0)1 53 75 99 11 - Fax: +33 (0)1 53 75 99 02www.sade-cgth.fr