Bearings for hydro power machines - Voith Hydro

Bearings for hydro power machines - Voith Hydro

Bearings for hydro power machines - Voith Hydro

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

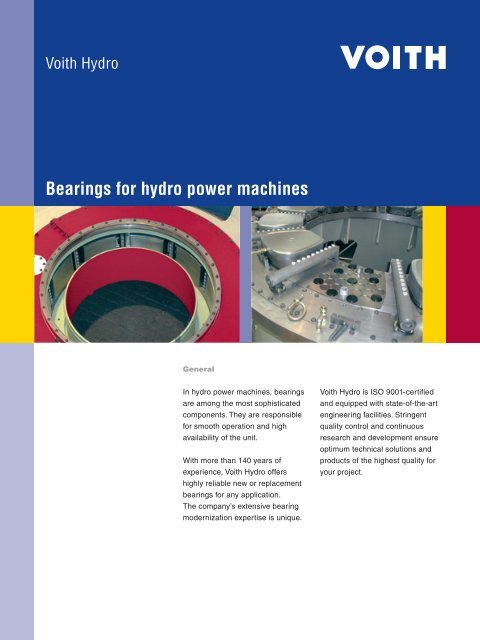

<strong>Bearings</strong> <strong>for</strong> <strong>hydro</strong> <strong>power</strong> <strong>machines</strong><br />

General<br />

In <strong>hydro</strong> <strong>power</strong> <strong>machines</strong>, bearings<br />

are among the most sophisticated<br />

components. They are responsible<br />

<strong>for</strong> smooth operation and high<br />

availability of the unit.<br />

With more than 140 years of<br />

experience, <strong>Voith</strong> <strong>Hydro</strong> offers<br />

highly reliable new or replacement<br />

bearings <strong>for</strong> any application.<br />

The compa ny’s extensive bearing<br />

modernization expertise is unique.<br />

<strong>Voith</strong> <strong>Hydro</strong> is ISO 9001-certified<br />

and equipped with state-of-the-art<br />

engineering facilities. Stringent<br />

quality control and continuous<br />

research and development ensure<br />

optimum technical solutions and<br />

products of the highest quality <strong>for</strong><br />

your project.

Products and expertise<br />

<strong>Hydro</strong>dynamic bearings ensure<br />

wear-free operation.<br />

Pump-turbine workshop assembly<br />

of segmented guide bearing<br />

Bearing applications<br />

<strong>Hydro</strong>dynamic bearings are installed<br />

in generators and turbines<br />

with vertical and horizontal shafts.<br />

<strong>Voith</strong> <strong>Hydro</strong>’s bearings are designed<br />

<strong>for</strong> very high reliability and availability.<br />

Individual needs of each application<br />

are considered to ensure<br />

wear-free operation over decades<br />

with only minimum service requirements.<br />

Bearing types<br />

Thrust bearing during assembly<br />

Our services and supplies include<br />

bearings <strong>for</strong> any type or size of<br />

<strong>hydro</strong> <strong>power</strong> <strong>machines</strong>:<br />

� Tilting segment thrust and guide<br />

bearings; oil lubricated<br />

� Journal guide bearings; either oil<br />

or water lubricated<br />

� Magnetic thrust bearings; special<br />

applications<br />

Cooling system<br />

Oil circulation is achieved either by<br />

centrifugal <strong>for</strong>ces of the rotating<br />

shaft or by external pumps. Heat<br />

exchangers are normally placed<br />

outside the bearing housing. Internal<br />

coolers as an option are also available.<br />

Effective instrumentation<br />

rounds out the cooling system to<br />

guarantee the bearing’s function.

Bearing segments and support components<br />

Bearing housing seals<br />

<strong>Voith</strong> <strong>Hydro</strong> also specializes in<br />

seals. Depending on the application,<br />

individually designed splash<br />

protection or pressurized air seals<br />

are available, complete with oil<br />

dust extraction systems.<br />

Rehabilitation and service<br />

As a worldwide supplier of complete<br />

<strong>hydro</strong> <strong>power</strong> <strong>machines</strong>,<br />

<strong>Voith</strong> <strong>Hydro</strong> is the ideal choice<br />

when it comes to replacing or<br />

servicing your equipment. Special<br />

boundary conditions and applications,<br />

<strong>for</strong> example bi-directional<br />

units, are considered at an early<br />

stage. <strong>Voith</strong> <strong>Hydro</strong> can optimize<br />

your new or replacement bearing<br />

<strong>for</strong> maximum efficiency.<br />

Temperature distribution analysis by FEA<br />

Bearing per<strong>for</strong>mance<br />

<strong>Voith</strong> <strong>Hydro</strong> uses numerical tools<br />

such as CFD (Computational Fluid<br />

Dynamics) and FEA (Finite Element<br />

Analysis) to predict the bearing’s<br />

behavior during operation. Proper<br />

monitoring assures that the condition<br />

of the bearing is always known.<br />

2<br />

3

<strong>Voith</strong> <strong>Hydro</strong> Holding GmbH & Co. KG<br />

Alexanderstrasse 11<br />

89522 Heidenheim/Germany<br />

Tel. +49 7321 37 0<br />

Fax +49 7321 37 7828<br />

info.voith<strong>hydro</strong>@voith.com<br />

www.voith<strong>hydro</strong>.com<br />

A <strong>Voith</strong> and Siemens Company<br />

References <strong>Voith</strong> <strong>Hydro</strong> guide bearings References <strong>Voith</strong> <strong>Hydro</strong> thrust bearings<br />

Range of experience<br />

Journal guide bearings<br />

Bearing diameter ≤ 1 000 mm<br />

Oil film thickness > 50 μm<br />

Guide bearings with tilting segments<br />

Bearing diameter ≤ 4 300 mm<br />

Segment size ≤ 500 mm<br />

Oil film thickness ≥ 50 μm<br />

Thrust bearings with tilting segments<br />

Outer bearing diameter ≤ 4 600 mm<br />

Segment size ≤ 900 mm<br />

Bearing loads ≤ 31 000 kN<br />

Oil film thickness ≥ 25 μm<br />

t3345 e 05.2009 1000 MSW Technical data and illustrations subject to change.