Globalizing know how in multi-turn coils - Voith Hydro

Globalizing know how in multi-turn coils - Voith Hydro

Globalizing know how in multi-turn coils - Voith Hydro

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

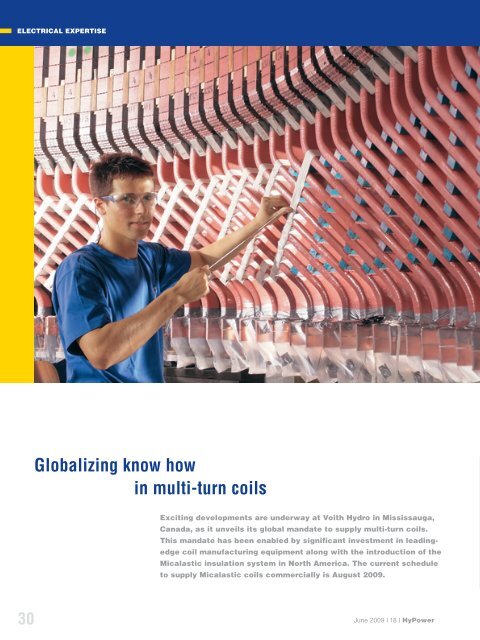

ELECTRICAL EXPERTISE<br />

30<br />

<strong>Globaliz<strong>in</strong>g</strong> <strong>know</strong> <strong>how</strong><br />

<strong>in</strong> <strong>multi</strong>-<strong>turn</strong> <strong>coils</strong><br />

Excit<strong>in</strong>g developments are underway at <strong>Voith</strong> <strong>Hydro</strong> <strong>in</strong> Mississauga,<br />

Canada, as it unveils its global mandate to supply <strong>multi</strong>-<strong>turn</strong> <strong>coils</strong>.<br />

This mandate has been enabled by significant <strong>in</strong>vestment <strong>in</strong> lead<strong>in</strong>gedge<br />

coil manufactur<strong>in</strong>g equipment along with the <strong>in</strong>troduction of the<br />

Micalastic <strong>in</strong>sulation system <strong>in</strong> North America. The current schedule<br />

to supply Micalastic <strong>coils</strong> commercially is August 2009.<br />

June 2009 I 18 I HyPower

The Micalastic <strong>in</strong>sulation technology<br />

has enjoyed a remarkable<br />

reputation for quality and reliability<br />

for many years already.<br />

The Mississauga location has been<br />

a market leader <strong>in</strong> provid<strong>in</strong>g generator<br />

modernization services with<strong>in</strong><br />

North America <strong>in</strong> addition to supply<strong>in</strong>g<br />

<strong>coils</strong>, hav<strong>in</strong>g supplied <strong>coils</strong> to<br />

over 300 generators across 230<br />

different generat<strong>in</strong>g stations over<br />

the past thirty-five years. This represents<br />

over one gigawatt of mach<strong>in</strong>es<br />

serviced with <strong>coils</strong> produced<br />

<strong>in</strong> Mississauga alone.<br />

Lead<strong>in</strong>g-edge <strong>in</strong> coil<br />

manufacture<br />

<strong>Voith</strong> <strong>Hydro</strong> has always demonstrated<br />

a technology leadership<br />

approach <strong>in</strong> the hydro <strong>in</strong>dustry <strong>in</strong><br />

both its design and manufactur<strong>in</strong>g<br />

approaches.<br />

New coil form<strong>in</strong>g mach<strong>in</strong>e.<br />

June 2009 I 18 I HyPower<br />

This is evidenced once more these<br />

days by the significant new <strong>in</strong>vestment<br />

<strong>in</strong> lead<strong>in</strong>g-edge coil manufactur<strong>in</strong>g<br />

equipment now <strong>in</strong>stalled <strong>in</strong><br />

Mississauga.<br />

This new equipment consists of:<br />

� Coil form<strong>in</strong>g mach<strong>in</strong>e<br />

� Electric press for <strong>coils</strong><br />

� Six-axis auto-tap<strong>in</strong>g mach<strong>in</strong>e<br />

� Micalastic Vacuum Pressure<br />

Impregnation (VPI) System.<br />

One of the key improvements of the<br />

w<strong>in</strong>d<strong>in</strong>g manufactur<strong>in</strong>g process is<br />

the <strong>in</strong>troduction of six-axis controlled<br />

tap<strong>in</strong>g for <strong>coils</strong>. The tap<strong>in</strong>g<br />

mach<strong>in</strong>e wraps the f<strong>in</strong>e mica tape<br />

with an adjustable and consistent<br />

overlap and tension around the slot<br />

and end-w<strong>in</strong>d<strong>in</strong>g portions of the<br />

<strong>coils</strong>, thus ensur<strong>in</strong>g uniform thickness<br />

over the full length of the coil,<br />

<strong>in</strong>clud<strong>in</strong>g the knuckle of the coil.<br />

In comb<strong>in</strong>ation with a modern and<br />

sophisticated VPI technology,<br />

this also ensures a void free, high<br />

dielectric <strong>in</strong>sulation system.<br />

Advanced computerized design tools.<br />

ELECTRICAL EXPERTISE<br />

Benefits of this new coil manufactur<strong>in</strong>g<br />

equipment to our customers<br />

are<br />

� Best-<strong>in</strong>-class delivery cycle times<br />

with shorter manufactur<strong>in</strong>g cycles<br />

� 50% less handl<strong>in</strong>g of <strong>coils</strong> <strong>in</strong><br />

production<br />

� Highest quality product properties<br />

� Unprecedented repeatability and<br />

reproducibility of coil dimensions.<br />

Another key advantage of the new<br />

equipment is <strong>in</strong> the design phase<br />

for new generators and for generators<br />

be<strong>in</strong>g modernized. The high<br />

precision of the new coil equipment<br />

will allow design eng<strong>in</strong>eers <strong>in</strong> <strong>Voith</strong><br />

<strong>Hydro</strong> to further maximize the<br />

amount of copper <strong>in</strong> generators<br />

which <strong>in</strong> <strong>turn</strong> will benefit customers<br />

with mach<strong>in</strong>es that have higher<br />

efficiencies and lower losses. With<br />

regard to modernization solutions<br />

efforts of <strong>Voith</strong> <strong>Hydro</strong> dur<strong>in</strong>g the<br />

design phase, this new equipment<br />

will allow to further <strong>in</strong>crease generator<br />

up-rate potential to customers.<br />

31

ELECTRICAL EXPERTISE<br />

32<br />

Six-axis auto-tap<strong>in</strong>g mach<strong>in</strong>e.<br />

One global standard<br />

<strong>in</strong> <strong>in</strong>sulation<br />

The current <strong>in</strong>sulation system be<strong>in</strong>g<br />

used <strong>in</strong> Mississauga is Thermalastic.<br />

As such, <strong>coils</strong> currently produced<br />

for North America from this<br />

location were based on the Thermalastic<br />

<strong>in</strong>sulation system. Both Micalastic<br />

and Thermalastic systems<br />

are epoxy res<strong>in</strong> based and both<br />

have a long tradition <strong>in</strong> the <strong>in</strong>dustry<br />

recognized worldwide for its technical<br />

features and reliability.<br />

<strong>Voith</strong> <strong>Hydro</strong>’s approach has always<br />

been to provide customers with the<br />

best eng<strong>in</strong>eered solution for their<br />

unique applications. Mov<strong>in</strong>g to one<br />

global standard <strong>in</strong> <strong>in</strong>sulation systems,<br />

Micalastic will offer technological<br />

advantages that will benefit<br />

customers <strong>in</strong> many ways:<br />

� Lead<strong>in</strong>g-edge technology <strong>in</strong><br />

<strong>in</strong>su lation will ensure cont<strong>in</strong>uation<br />

of the best eng<strong>in</strong>eered <strong>in</strong>sulation<br />

systems for customer applications.<br />

� Insurance of un<strong>in</strong>terrupted and<br />

stable supply of product to customers.<br />

ECP<br />

OCP<br />

Corona-control f<strong>in</strong>ishes.<br />

� Technology offer to the marketplace<br />

that is technology specific<br />

as opposed to site specific.<br />

No matter where your <strong>Voith</strong><br />

<strong>Hydro</strong> product comes from, the<br />

uniqueness of technology and<br />

eng<strong>in</strong>eer<strong>in</strong>g approach around<br />

the globe will be based on one<br />

global standard and the philosophy<br />

of eng<strong>in</strong>eered reliability.<br />

Micalastic <strong>in</strong> high-voltage<br />

hydro generators<br />

The common characteristics shared<br />

by all types of Micalastic <strong>in</strong>sulation<br />

are the use of <strong>in</strong>organic f<strong>in</strong>e mica<br />

tape as a base material, and heatcur<strong>in</strong>g<br />

synthetic res<strong>in</strong>s as a bond<strong>in</strong>g<br />

material. This, coupled with stateof-the-art<br />

manufactur<strong>in</strong>g techniques<br />

geared to the various types and<br />

size of mach<strong>in</strong>es, makes for its<br />

most outstand<strong>in</strong>g features which<br />

are high breakdown strength, longterm<br />

resistance to electrical stress,<br />

and a low power factor (tan �) as<br />

well as excellent resistance to<br />

mechanical and thermal stress.<br />

The Micalastic <strong>in</strong>sulation system<br />

is based on Vacuum Pressure<br />

Impregnation technology and meets<br />

Thermal Class 155 (IEC)/Class F<br />

(IEEE) standards.<br />

Process Control<br />

Six Sigma tools are currently be<strong>in</strong>g<br />

used to monitor the coil manufactur<strong>in</strong>g<br />

process and collect data on<br />

an ongo<strong>in</strong>g basis. This will eventually<br />

lead to process harmonization<br />

across the locations of <strong>Voith</strong> <strong>Hydro</strong><br />

that manufacture this product:<br />

Shanghai, Ch<strong>in</strong>a, São Paulo, Brazil,<br />

and Mississauga, Canada. So, <strong>in</strong><br />

addition to the global standard <strong>in</strong><br />

<strong>in</strong>sulation technology as such, the<br />

global process and its control will be<br />

consistent. Global process control<br />

ensures early warn<strong>in</strong>g and a failsafe<br />

system with<strong>in</strong> production for<br />

the highest quality and eng<strong>in</strong>eered<br />

reliability to customers.<br />

Go<strong>in</strong>g global<br />

Micalastic <strong>coils</strong> have been the<br />

standard outside North America for<br />

quite some time. Supply of Micalastic<br />

<strong>coils</strong> outside North America will<br />

be seamless. With<strong>in</strong> North America,<br />

the supply of Micalastic <strong>coils</strong> for<br />

the majority of customers will be a<br />

non-event s<strong>in</strong>ce both Micalastic and<br />

Thermalastic systems fundamentally<br />

share many of the same characteristics.<br />

June 2009 I 18 I HyPower

In fact, there are several customers<br />

and mach<strong>in</strong>es <strong>in</strong> Canada and <strong>in</strong> the<br />

U.S. that already have Micalastic<br />

<strong>coils</strong> <strong>in</strong>stalled and supplied by the<br />

Brazilian location of <strong>Voith</strong> <strong>Hydro</strong> <strong>in</strong><br />

the past. These Micalastic <strong>coils</strong><br />

have performed absolutely flawlessly<br />

s<strong>in</strong>ce that time.<br />

Design<br />

Computerized design tools allow<br />

model<strong>in</strong>g of the performance of the<br />

entire generator. Optimization of the<br />

coil design with respect to losses,<br />

heat<strong>in</strong>g and overall rat<strong>in</strong>g is performed.<br />

Based on extensive test<br />

results on completed projects, the<br />

calibrated calculation allows the<br />

w<strong>in</strong>d<strong>in</strong>g performance to be guaranteed.<br />

June 2009 I 18 I HyPower<br />

The range of applicability for <strong>multi</strong><strong>turn</strong><br />

coil w<strong>in</strong>d<strong>in</strong>gs is up to 150 MVA<br />

and voltages up to 15.75 kV. Higher<br />

voltages are possible by request.<br />

The new coil manufactur<strong>in</strong>g equipment<br />

<strong>in</strong> Mississauga was commissioned<br />

<strong>in</strong> January 2009 and the<br />

impregnation system follow<strong>in</strong>g <strong>in</strong><br />

April. Micalastic coil qualification<br />

trials started <strong>in</strong> May and <strong>coils</strong><br />

will be commercially available by<br />

August 2009.<br />

This <strong>in</strong>deed is an excit<strong>in</strong>g chapter<br />

for <strong>Voith</strong> <strong>Hydro</strong>, as it aga<strong>in</strong> demonstrates<br />

its technological leadership<br />

<strong>in</strong> the supply of <strong>multi</strong>-<strong>turn</strong> <strong>coils</strong><br />

through its significant <strong>in</strong>vestment<br />

<strong>in</strong> equipment and Micalastic technology<br />

<strong>in</strong> Mississauga, Canada.<br />

Micalastic Insulation System, the <strong>Voith</strong> <strong>Hydro</strong> VPI Technology<br />

Relative dielectric constant, �r , 20 °C, 50 Hz / 60 Hz<br />

Tang � at 0.2 UN , 20 °C, 50 Hz / 60 Hz<br />

1<br />

/2 (Tang � / 0.6 UN – Tang � / 0.2 UN ), 20 °C, 50 Hz / 60 Hz<br />

Max. � Tang � / step 0.2 UN (from 0.2 UN to 1.0 UN )<br />

Breakdown strength, 50 Hz / 60 Hz, slot side<br />

S<strong>in</strong>gle stator bars (half coil)<br />

Surge voltage endurance along slot<br />

Test voltage, 50 Hz / 60 Hz, UPRMS , 1 m<strong>in</strong><br />

S<strong>in</strong>gle stator bars (half coil)<br />

F<strong>in</strong>ish w<strong>in</strong>d<strong>in</strong>g assembly<br />

Ratio between test DC and AC voltage UpDC / UpAC Test voltage, conductor strands, 50 Hz / 60 Hz<br />

Permissible surge voltage on w<strong>in</strong>d<strong>in</strong>gs <strong>in</strong> operation<br />

Maximum permissible temperature IEC 62114 / IEC 60034-18<br />

Flammability: as per model test<br />

Test voltage, 50 Hz / 60 Hz, UPRMS , 1 m<strong>in</strong> – Leads<br />

kV/mm<br />

kV<br />

kV<br />

kV/mm<br />

kV<br />

kV<br />

kV<br />

V<br />

kV<br />

kV<br />

°C<br />

kV<br />

Micalastic records <strong>in</strong> hydro<br />

Author<br />

William.Malus@voith.com<br />

≈ 4<br />

� 1.5% / � 1.0% – w/o resp. w. ICP<br />

� 0.15% / � 0.10% – w/o resp. w. ICP<br />

� 0.25% / � 0.10% – w/o resp. w. ICP<br />

� 25<br />

Up � 6.0 UN at slot side<br />

Up � 3.0 UN at front side<br />

� 50 (1.2 / 50 �s wave)<br />

Us � (4 UN + 5 kV) at slot side<br />

ELECTRICAL EXPERTISE<br />

We look forward to pass<strong>in</strong>g on the<br />

great benefits of this highly eng<strong>in</strong>eered<br />

product to our customers<br />

all over the world.<br />

� Insulation system started and<br />

cont<strong>in</strong>uously developed s<strong>in</strong>ce 1957<br />

� More than 55 million accumulated<br />

service hours<br />

� More than 300,000 bars and <strong>coils</strong><br />

supplied<br />

� More than 6,300 accumulated service<br />

years<br />

� Applied to approximately 500 hydro units<br />

worldwide over 5 MVA<br />

William Malus<br />

Chief Operat<strong>in</strong>g Officer,<br />

Mississauga, Canada<br />

Standard: Up = (2 UN + 6 kV)<br />

(higher values can be applied after request)<br />

Up = (2 UN + 1 kV)<br />

1.7<br />

220<br />

� 3.5 UN at Uphase-core<br />

� 5 UN at Uphase-phase<br />

155, Class F<br />

Self-ext<strong>in</strong>guish<strong>in</strong>g<br />

1.5 x Up<br />

UN = rated (l<strong>in</strong>e-to-l<strong>in</strong>e) voltage<br />

33