Nuclear Plant Journal Nuclear Plant Journal - Digital Versions

Nuclear Plant Journal Nuclear Plant Journal - Digital Versions

Nuclear Plant Journal Nuclear Plant Journal - Digital Versions

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

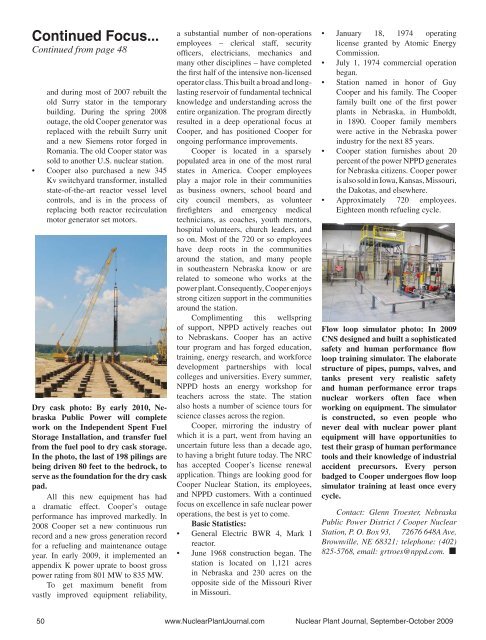

Continued Focus...Continued from page 48and during most of 2007 rebuilt theold Surry stator in the temporarybuilding. During the spring 2008outage, the old Cooper generator wasreplaced with the rebuilt Surry unitand a new Siemens rotor forged inRomania. The old Cooper stator wassold to another U.S. nuclear station.• Cooper also purchased a new 345Kv switchyard transformer, installedstate-of-the-art reactor vessel levelcontrols, and is in the process ofreplacing both reactor recirculationmotor generator set motors.Dry cask photo: By early 2010, NebraskaPublic Power will completework on the Independent Spent FuelStorage Installation, and transfer fuelfrom the fuel pool to dry cask storage.In the photo, the last of 198 pilings arebeing driven 80 feet to the bedrock, toserve as the foundation for the dry caskpad.All this new equipment has hada dramatic effect. Cooper’s outageperformance has improved markedly. In2008 Cooper set a new continuous runrecord and a new gross generation recordfor a refueling and maintenance outageyear. In early 2009, it implemented anappendix K power uprate to boost grosspower rating from 801 MW to 835 MW.To get maximum benefit fromvastly improved equipment reliability,a substantial number of non-operationsemployees – clerical staff, securityofficers, electricians, mechanics andmany other disciplines – have completedthe first half of the intensive non-licensedoperator class. This built a broad and longlastingreservoir of fundamental technicalknowledge and understanding across theentire organization. The program directlyresulted in a deep operational focus atCooper, and has positioned Cooper forongoing performance improvements.Cooper is located in a sparselypopulated area in one of the most ruralstates in America. Cooper employeesplay a major role in their communitiesas business owners, school board andcity council members, as volunteerfirefighters and emergency medicaltechnicians, as coaches, youth mentors,hospital volunteers, church leaders, andso on. Most of the 720 or so employeeshave deep roots in the communitiesaround the station, and many peoplein southeastern Nebraska know or arerelated to someone who works at thepower plant. Consequently, Cooper enjoysstrong citizen support in the communitiesaround the station.Complimenting this wellspringof support, NPPD actively reaches outto Nebraskans. Cooper has an activetour program and has forged education,training, energy research, and workforcedevelopment partnerships with localcolleges and universities. Every summer,NPPD hosts an energy workshop forteachers across the state. The stationalso hosts a number of science tours forscience classes across the region.Cooper, mirroring the industry ofwhich it is a part, went from having anuncertain future less than a decade ago,to having a bright future today. The NRChas accepted Cooper’s license renewalapplication. Things are looking good forCooper <strong>Nuclear</strong> Station, its employees,and NPPD customers. With a continuedfocus on excellence in safe nuclear poweroperations, the best is yet to come.Basic Statistics:• General Electric BWR 4, Mark Ireactor.• June 1968 construction began. Thestation is located on 1,121 acresin Nebraska and 230 acres on theopposite side of the Missouri Riverin Missouri.• January 18, 1974 operatinglicense granted by Atomic EnergyCommission.• July 1, 1974 commercial operationbegan.• Station named in honor of GuyCooper and his family. The Cooperfamily built one of the first powerplants in Nebraska, in Humboldt,in 1890. Cooper family memberswere active in the Nebraska powerindustry for the next 85 years.• Cooper station furnishes about 20percent of the power NPPD generatesfor Nebraska citizens. Cooper poweris also sold in Iowa, Kansas, Missouri,the Dakotas, and elsewhere.• Approximately 720 employees.Eighteen month refueling cycle.Flow loop simulator photo: In 2009CNS designed and built a sophisticatedsafety and human performance flowloop training simulator. The elaboratestructure of pipes, pumps, valves, andtanks present very realistic safetyand human performance error trapsnuclear workers often face whenworking on equipment. The simulatoris constructed, so even people whonever deal with nuclear power plantequipment will have opportunities totest their grasp of human performancetools and their knowledge of industrialaccident precursors. Every personbadged to Cooper undergoes flow loopsimulator training at least once everycycle.Contact: Glenn Troester, NebraskaPublic Power District / Cooper <strong>Nuclear</strong>Station, P. O. Box 93, 72676 648A Ave,Brownville, NE 68321; telephone: (402)825-5768, email: grtroes@nppd.com. 50 www.<strong>Nuclear</strong><strong>Plant</strong><strong>Journal</strong>.com <strong>Nuclear</strong> <strong>Plant</strong> <strong>Journal</strong>, September-October 2009