Hardwood Matters - National Hardwood Lumber Association

Hardwood Matters - National Hardwood Lumber Association

Hardwood Matters - National Hardwood Lumber Association

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

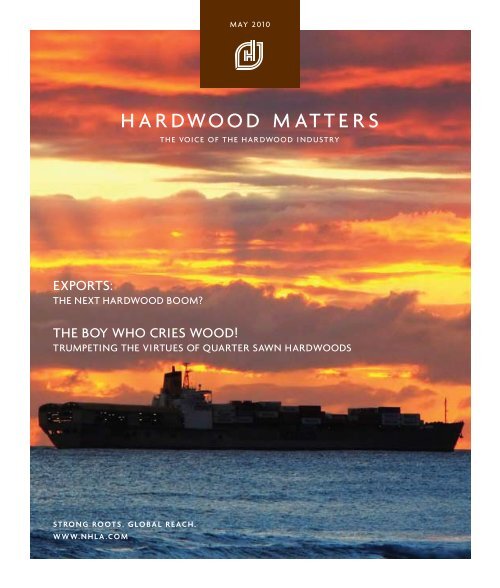

MAY 2010HARDWOOD MATTERSTHE VOICE OF THE HARDWOOD INDUSTRYEXPORTS:THE NEXT HARDWOOD BOOM?THE BOY WHO CRIES WOOD!TRUMPETING THE VIRTUES OF QUARTER SAWN HARDWOODSSTRONG ROOTS. GLOBAL REACH.WWW.NHLA.COM

WWW.NHLA.COM MAY 2010 HARDWOOD MATTERS 1

WWW.NHLA.COM MAY 2010 HARDWOOD MATTERS 3

1014DEPARTMENTS16 Making It Work17 Global Talk18 Green Wave20 Tally Sheet22 Education SpotlightREADER SERVICES6 Executive Director'sMessage8 Inside NHLA24 Calendar26 Job BoardIN THIS ISSUE...10 EXPORTS: The Next <strong>Hardwood</strong> Boom?By Tracy Powell14 THE BOY WHO CRIES WOOD!Trumpeting the Virtues of QuarterSawn <strong>Hardwood</strong>sBy Criswell DavisCONTENTS4 MAY 2010 HARDWOOD MATTERS WWW.NHLA.COM

CONTRIBUTORSTracy Powell is an award-winning writerand editor, contributing to several tradeand consumer magazines over the years. Agraduate of Indiana University’s school ofJournalism and a member of the Society ofProfessional Journalists, he has worked onstaff with two Indiana-based newspapersand two magazines. Based in Charlestown,Indiana, he currently serves as managingeditor for Automobile Quarterly and isan independent publishing consultantspecializing in book editing, design andliaison services. He can be reached attracewriter@sbcglobal.net.Russell Barratt is the Market Managerfor Simonds International in BigRapids, Michigan. He has been involvedwith the cutting tools manufacturingindustry since 1975 and employed bySimonds International since 1981. Heworks closely with Walter Oppliger ofSwitzerland on the development andintroduction of innovative filing roommachinery. Barratt is a frequent speakerand participant in trade associationmeetings and wood conferences.Criswell Davis, AIA/CES approvedArchitectural Marketing Manager, is agraduate of Colorado College where heearned a B.A. in Philosophy of Religion.He began his career in the lumber businesswith Frank Paxton <strong>Lumber</strong> in Cincinnatiin 1988 and started with Frank Miller<strong>Lumber</strong> in 1996. He has served on theBoard of Directors for the Wood ProductsManufacturers, <strong>Hardwood</strong> Federation PACand the Western <strong>Hardwood</strong> <strong>Association</strong>.He has been married for 35 years and hasone son, Cole, a recent graduate of MiamiUniversity (Ohio), and a daughter, Teagan,a senior at Columbia College in Chicago.WWW.NHLA.COM MAY 2010 HARDWOOD MATTERS 5

WWW.NHLA.COM MAY 2010 HARDWOOD MATTERS 7

INSIDE NHLANHLA CHIEF INSPECTOR JOB OPENINGThe <strong>National</strong> <strong>Hardwood</strong> <strong>Lumber</strong> <strong>Association</strong> (NHLA) headquartered in Memphis, Tennessee is currently seeking a Chief Inspector.The <strong>National</strong> <strong>Hardwood</strong> <strong>Lumber</strong> <strong>Association</strong> was originally founded in 1898 to establish a uniform system of grading rules for themeasurement and inspection of hardwood lumber. More than a century after origination, the NHLA standards and rules that were oncedeveloped to ease regional trade, are now employed worldwide for the same reason.NHLA employs a full-time staff of highly trained hardwood lumber inspectors in the U.S. and Canada who work to help evaluate, educateand train employees in inspection rules to improve their grading competency. NHLA Inspectors can also inspect lumber prior to shipmentto protect the shipper against complaints, inspect lumber at its destination to monitor incoming quality for a buyer and serve as impartialexperts to settle disputes between buyer and seller.The Chief Inspector is responsible for the day-to-day operations of the NHLA Inspection Services Department, Heat Treatment Programand Kiln-Drying Certification Program. The Chief Inspector has the final say in all grading rules interpretations, grade disputes, andadministration of the Sales Code Enforcement Guidelines and the <strong>Hardwood</strong> Claims Bureau.The ideal candidate will have the following qualifications:■ 10+ years of lumber grading experience in green, kiln-dried and surfaced lumber, including a wide variety of hardwood species■ Graduate of the NHLA Inspector Training School■ Proficient knowledge of the NHLA hardwood lumber grading rules and sales code■ Supervisor background including the development and maintenance of budgets■ Previous purchasing and sales experience is helpful■ Superior communications skills including writing and public speaking■ Ability to be a team player and work independently■ Proficiency in Microsoft programs such as Outlook, Word and Excel■ College degree or previous experience as a NHLA <strong>National</strong> Inspector is preferredThe Chief Inspector:■ Will supervise all national field inspectors and Heat Treatment Program staff■ Is required to develop all departmental budgets, monitor costs and expenses■ Will be required to travel throughout the country to provide in-house training or short courses for members and nonmembers, performre-inspections when necessary and assist national inspectors to ensure grade accuracy■ Will act as a substitute instructor, as needed, for the Inspector Training School in Memphis■ Acts as staff liaison to the Rules & Inspection Services Committee■ Will coordinate and conduct meetings, seminars and open forums regarding the Rules & Inspection Services during the NHLA AnnualConvention or wherever needed■ Will work with various industry organizations and government entities such as: ALSC and APHIS on projects as neededNHLA offers an excellent benefits package including medical, dental, life, disability, and 401(k).To apply, please send resume and salary requirements by mail, fax or email to the attention of Mark Barford, Executive Director.<strong>National</strong> <strong>Hardwood</strong> <strong>Lumber</strong> <strong>Association</strong>PO Box 34518 | Memphis, TN 38184-0518901-377-1082 | 901-382-6419 (fax) | m.barford@nhla.com8 MAY 2010 HARDWOOD MATTERS WWW.NHLA.COM

INSIDE NHLANHLA WELCOMES NEW MEMBERSActive Member With Annual Sales Less than $1.5M■ J & T <strong>Lumber</strong> | Woodbine, KentuckyActive Member Branch■ Superior <strong>Hardwood</strong>s of Ohio, Inc. | Vincent, Ohio■ Main Street Forest Products | Maben, MississippiSustaining Member■ North Road Technologies/Nyle | Westport, Connecticut■ EnerNOC | Boston, Massachusetts■ SGS Systems & Services | Rutherford, New JerseyAssociate Member■ T R Miller Mill Company Inc. | Brewton, Alabama■ Marvin Windows & Doors | Ripley, TennesseeQuarter Ending March 2010NHLA ADDRESSES ATTENDEES OF THEKFIA ANNUAL MEETINGExecutive Director, Mark Barford presented a “State of the Industry”report to members of the Kentucky Forest Industries <strong>Association</strong>during the annual meeting in Bowling Green, Kentucky.Mark reported that the meeting had an air of cautious optimism."This meeting was held in Bowling Green for the first time in years,"he noted. "Although attendance was lower than in past years, likeall industry meetings, the crowd was energetic and hopeful for acontinued improvement this year."KFIA elected a new <strong>Association</strong> President, NHLA board member JohnSmith of Forest Products, Inc. "With John’s new position as KFIAPresident and the many mutual members from both <strong>Association</strong>s,NHLA will continue to work closely with KFIA to strengthen thehardwood industry throughout the region," stated Barford.WWW.NHLA.COM MAY 2010 HARDWOOD MATTERS 9

EXPORTS:THE NEXT HARDWOOD BOOM?EXPORTS:THE NEXT HARDWOOD BOOM?10 MAY 2010 HARDWOOD MATTERS WWW.NHLA.COM

Photo Courtesy of Kuehne + NagelBy Tracy PowellIn his State of the Union address in January, PresidentObama pledged his support of free-trade agreementsand to double American exports over the nextfive years, a new effort to boost employment. Theambitious plan is certainly needed: Exports fell from$1.8 trillion in 2008 to $1.5 trillion in 2009, due to theglobal recession. Doubling exports would constitute ajump that would push U.S. overseas sales to $3 trillionannually and, the White House says, create two millionjobs. Whether these numbers are realistic is currentlydebated, but exports do seem bound to grow – theworld is growing faster than America and the dollar isweak, although the currency is beginning to rebound.President Obama pledged hissupport of free-trade agreementsand to double American exportsover the next five years...Signing the “<strong>National</strong> Export Initiative” executive orderin March, the Obama Administration proposes spurringan overhaul of the Commerce Department's tradefunctions similar to the Department of Agriculture'sForeign Agricultural Service, which is superior in everyrespect when it comes to helping U.S. companiescompete abroad. Here at home, the administrationis trying to get more companies to export; less than1 percent currently do so, and of them 58 percentexport to just one country. One way the governmentplans to encourage increased export activity isby subsidizing exports by those companies thegovernment deems worthy of subsidies. The qualifierswere unknown at press time.The Commerce Department and the other federalagencies involved in the Export Promotion Cabinet, whichwas also announced in March, have until August 2010 tosubmit plans showing how they will double exports.How this new initiative will affect the hardwoodindustry is still to be seen. In response to PresidentObama's goal to open up foreign markets, theDepartment of the U.S. Trade Representativetasked the International Trade Commission to doan investigation on the challenges that small tomedium size exporters’ experience, and the <strong>Hardwood</strong>Federation was asked to testify.“Many in the industry are in export,” noted <strong>Hardwood</strong>Federation Chairman Jameson French. “In 2009,exports were 10 percent of total market share. [Yet,]every major product saw export drops. In firstquarter 2009, hardwood lumber exports were down35 percent from first quarter 2008 and 53 percentfrom the first quarter 2006 peak.”Stumbling blocks in export have included the fact thatmany competitor nations import raw materials dutyfree, while protecting domestic value-added industries.Red tape also adds delays and costs that are difficultfor small- and medium-sized businesses to cope with,noted French, one big headache being the requirementfor permits for some species but not all, involvingexpensive product tests that can only be performed incountry, resulting in high duties.“Some environmental procurement policies thatcould be required by other countries are not realisticfor the American hardwood industry and will beextremely difficult or impossible to meet,” Jamesonsaid of the ongoing challenges. “In addition, smallbusiness loans and credit lines have dried up becauseof the close association of the hardwood industryand the struggling housing market.”The hope is that such issues will be addressed as theinitiative matures. In the President’s proposed 2011budget, more money has been included to guaranteeexport-related small-business lending.Pessimists of Obama’s plan note that the world’sother major economic powers – Germany, Japan, andChina – are attempting to export themselves back toprosperity, too. What America has that many othercountries do not, however, is high-grade hardwoods.Thus the initiative bodes best for the hardwoodsindustry. The Middle East and North Africa remainsa key destination for American hardwoods amidstthe increasing demand within the region's furniture,interiors and flooring sectors, according to theAmerican <strong>Hardwood</strong> Export Council (AHEC),Hakan Ekstrom, president of Wood ResourcesInternational, recently noted in The Oregonian: "Somecountries in Asia are beginning to wake up a little. Youwill see them looking for more lumber."WWW.NHLA.COM MAY 2010 HARDWOOD MATTERS 11

Photo Courtesy of Criswell DavisTHE BOY WHO CRIES WOOD!TRUMPETING THE VIRTUES OF QUARTER SAWN HARDWOODSBy Criswell Davis“With his materials the architect can do whatever the masters have done with pigmentsor with sounds—in shadings as subtle, with combinations as expressive—perhapsoutlasting himself. Wood is universally beautiful to man. It is the most humanly intimateof all materials.” — Frank Lloyd WrightFrank Lloyd Wright was truly an architect inspired by nature and its influence is apparent in his collection of work. As early as 1908,Wright used the term “organic” to describe the marriage between site and structure, believing that every building should grownaturally from its environment. Post World War II optimism resulted in the consumerism of the 1950s, where organic architecturegave way to suburban boxes. When this shift in housing design and construction occurred, wood as a construction material began totake a backseat to other products such as carpeting and linoleum. A more modern, stark form of architecture emerged which drewconsumers away from the natural beauty of hardwoods.14 MAY 2010 HARDWOOD MATTERS WWW.NHLA.COM

In the new millennium, “Green” architecture has taken holdand threatens what had become a trend during the 90s andearly 2000s, of the return to hardwood for flooring, furniture,cabinetry and millwork. The “green” trend began in 1998, whenthe U.S. Green Building Council (USGBC) established the LEEDgreen building certification program, (Leadership in Energyand Environmental Design) with the objective to promotehealthy and sustainable building practices. LEED points areawarded on a 100-point scale, and credits are weighted toreflect their potential environmental impacts. For the last 12years, the LEED point system structure has promoted the useof steel, concrete and bamboo; while discouraging the use ofU.S. hardwoods, unless FSC certified. While the dissuasion ofhardwoods may have been unintentional, the rating systemdoes in fact award more points to bamboo flooring thancertified hardwood flooring because bamboo is classified as arapidly renewing material.If we wanted to encourage theuse of quartersawn hardwoodsand hardwoods in general, we weregoing to have to tell our story.In 2008, after 20 years in the hardwood industry (12 of thoseyears being with Frank Miller <strong>Lumber</strong> Company in Union City,Indiana), it was apparent that the time had come to have afresh discussion about the challenges and opportunities facingnot only Frank Miller <strong>Lumber</strong> but the hardwood industry as awhole. During a conversation with Tim Leyden, VP of Sales, thediscussion kept circling back to architects and designers. Thisgroup would be our target audience; these people would shapewhat our world looks like in the future, just as they always have.The question now, was how to reach this identified group.As a niche hardwood producer, Frank Miller <strong>Lumber</strong> hasseen quotes that reflect unrealistic expectations for theresource and has tried, often in vain, to push the realitiesof hardwoods back up the design pipeline to the architectsand designers without dissuading them from specifyinghardwoods. The answer to the question of how to reach thetarget audience was answered. If we wanted to encouragethe use of quartersawn hardwoods and hardwoods in generalfor residential and commercial design, we were going tohave to tell our story to architects. In order to tell our storyface-to-face, I would have to become approved by theAmerican Institute of Architects (AIA) to offer continuingeducation credit to architects for an hour-long presentationextolling the many virtues of quartersawn hardwoods andU.S. hardwoods generally; and Frank Miller <strong>Lumber</strong> wouldneed to become FSC Certified, since LEED certification isan increasingly important consideration for architects incontemporary design. By January 2009, Frank Miller <strong>Lumber</strong>was an FSC certified chain of custody supplier and I, asArchitectural Marketing Manager, was ready to set off acrossthe country to metaphorically plant the seeds of hardwoodutilization in contemporary designs for the future.While the focus of the AIA presentation is naturally onquartersawn hardwoods, the primary product line of FrankMiller <strong>Lumber</strong>, broad brush strokes are used to encouragethe use of all species of sustainable American hardwoods.For instance, in order to allay any fears that architects anddesigners may have about our hardwood resource dwindling,the presentation outlines the empirically verifiable sustainablenature of American hardwoods. As a large percentage of thisaudience believes that hardwood is clear-cut, time is devoted todiscussing selective harvesting and “Best Management Practices”.Explanation of forest ownership patterns are also outlined,as more than 73% of the hardwood resource in the U.S. iscontrolled by over 4 million private landowners, most of whomwill only harvest from their woods once or twice in theirlifetimes. Sharing the factual data that there is nearly twice asmuch hardwood in the U.S. now as compared to 50 years agoand that actual forestland has increased by more than 18%has proven to be one of the most compelling take-away factsfor the audience. For me, it is important that the audienceunderstand two major issues. First, the difficulties facing smalllot owners in becoming FSC certified, while mentioning thesuccessful program undertaken by Jack Seifert, State Foresterfor the Indiana Division of Forestry to bring 600,000 acres ofprivately held woods under the FSC Certification umbrella.Second, that the entire U.S. hardwood industry is sustainableand carefully managed, whether certified by FSC or not.It is likely that many in the audience have incorrectpreconceived notions of the nature of the hardwood industry.Dispelling these notions is a cornerstone of the presentation.Discussions on technological advances, the carbon negativenature of hardwoods and use of by-products for mulch, paperand fuel for kilns; leaves the audience with a much cleareridea of our industry’s responsible stewardship of this mostbeautiful of natural resources.Overall, the presentation is highly visual, with sample boards,a quarter White Oak log (which arouses the curiosity of TSAagents in many airports), an animation of the quartersawingprocess and many slides of quartersawn U.S. hardwoods in(Continued on page 28)WWW.NHLA.COM MAY 2010 HARDWOOD MATTERS 15

MAKING IT WORKCHIPPER KNIFE MAINTENANCEBy Russell BarrattA quick refresher on chipper knife maintenance is not veryglamorous, but it’s precisely because of that reason that it’s worth areview. The chipper is often taken for granted; tucked away in thebowels of the mill and thought of as “waste disposal” equipment –fair enough. But it’s still important to make sure that the knife isproducing acceptable chip and doing so cost effectively. We’ll leaveit to a psychiatric journal to review the disturbing question of howone can come to think of chipper knives as “not glamorous” butbandsaws as “glamorous”.Grinding chipper knives properly revolves around managing heatbuild-up; specifically at the cutting edge. Excess heat will draw downthe hardness of the steel in the knives. If that steel is heated andthen quenched, surface hardening will occur along with microscopicfracturing caused by the quick shrinkage in the surface steel. Chipperknives are typically hardened into the middle 50’s Rockwell C. If theknives get a couple points too high they become very brittle and ifthey get down a couple points too low the knives dull very quickly.New knives are quite uniform in hardness, but careless grindingprocedures can change that very quickly. We rely on the mass ofsteel in the knife to absorb and carry away the heat generated inthe grinding process. By its nature, there is not much mass at thecutting edge of the knife; only the slim roughly 30º included anglewedge of steel at the cutting edge, not a significant heat absorbingmass. It’s slightly diabolical that the most easily burned part of theknife is the critical cutting edge."Rule of Thumb"To avoid damaging the heattreatment of the cutting edgeyou have to avoid getting it toohot. The basic “rule of thumb” isquite literally a Rule of Thumb.If you cannot comfortably layyour thumb on the bevel of theknife after the grinding wheelhas passed over it, it’s too hot!This is a good first check but it may not be enough to protect thecutting edge. In manufacturing knives, my company grinds a lot ofknives; very aggressively on heavy grinders but without damagingthe heat treat in the cutting edges. One of the keys to this successis that the grinding wheel is always traveling across the bevel of theknife in the same direction – from the cutting edge to the heel of thebevel. The heat generated will “push” in front of the grind, allowingthe heat to be pushed away from the cutting edge and down intothe heavy part of the knife where it can be safely absorbed. All ofthese knife grinders are designed with the grinding wheel (actually asegmental chuck, not a solid wheel) tipped just a bit so that it onlymakes contact on one edge. If you have a grinder that makes contacton both edges of the wheel it will be necessary to grind very timidlywith a soft wheel to avoid damage.Another important key to effective grinding is properly using thecoolant system on the grinder. The real purpose of coolant is to flushthe grinding wheel, keeping it clean and cutting sharp. The flow ofcoolant needs to be on the wheel, not on the knife.When the grinding cycle iscomplete, the knives willhave a burr hanging on thecutting edge. By runningyour finger up the backof the knife, across thecutting edge (not along theedge!), it’s quite easy to feelthe burr. A few momentsDe-burring a Chipper Knifewith a honing stone willremove the burr and refine the cutting edge. This process needs to beroutine, on every knife, with every sharpening. Use a circular honingstone, in a circular motion, tipped slightly so that it’s making solidcontact on the cutting edge. Work the wide side of the knife first,then the narrow side and then the wide side again. When finished,wipe the residual burr off with the end of a hardwood dowel. It onlytakes 30 seconds per knife.It’s also important to check Babbitt. Babbitt should never be thickerthan the knife or the knife clamp will grasp the babbitt instead of theknife – a very unsafe condition. If you find chipper knives “workingloose” in the chipper, first check the babbit. To check, lay the knifeflat on a workbench and draw a straightedge down the flat of the knifeon both sides. If it catches on the babbitt then it’s a clear indicationthat the babbitt is “proud” – no good, quite dangerous in fact.(Continued on page 28)16 MAY 2010 HARDWOOD MATTERS WWW.NHLA.COM

GLOBAL TALKMTC GLOBAL WOOD MARKET ANNOUNCEDThe Malaysian Timber Council (MTC) is organizing the inaugural‘MTC Global WoodMart 2010’ to provide a premier one-stop selling,buying and networking platform for suppliers and buyers of timberproducts from Malaysia and around the world. Tropical hardwoods, aswell as temperate softwoods and hardwoods, will be showcased at theMTC Global WoodMart 2010 – to be held October 19 and 20 at theKuala Lumpur Convention Centre in the heart of the city.International suppliers from around the world, and notably the USA,have already begun to book space which is limited and will be allocatedin June. MTC is offering an early bird package to exhibitors who signup before May 30.Malaysia is a significant manufacturer of furniture and wood productsfor which material supplies are imported as well as sourced locally. TheMTC Global WoodMart 2010 opens up a fresh vista of opportunitiesfor timber businesses to meet suppliers and buyers of timber productsfrom all over the world in the fast growing Southeast Asian region.For more see www.globalwoodmart.myFOREIGN COMPETITION REPORT ON THE U.S. BUILDING PRODUCTS INDUSTRY IS NOW AVAILABLEJordan, Knauff & Company, a middle-market investment bank with a specialized practice in the building products industry, has announced thepublication of the second annual issue of the Foreign Competition Report for the U.S. Building Products Industry. The report summarizes importstatistics and growth rates of the top importing countries in eleven different building products categories. The report includes information on thefollowing industry segments: windows and doors, vinyl profiles, glass, flooring, fencing, siding, roofing, decking, columns, cabinets and engineeredwood products. This report will be published annually in order to inform building products manufacturers of the level of risk of foreign competitionfaced by the various building products segments.Complimentary copies of the Foreign Competition Report have been posted to Jordan, Knauff & Company’s Research Portal, which is located atwww.jordanknauff.com/windoor.WWW.NHLA.COM MAY 2010 HARDWOOD MATTERS 17

GREEN WAVEFURNITURE, MUSICAL INSTRUMENTS MUST NOW DECLAREBASIC INFORMATION UNDER U.S. LACEY ACTApril 1, 2010 marks the beginning of enforcement for basic information transparencyrequirements under the Lacey Act for guitars, revolvers, hand tools, pool cues and certain types offurniture. The U.S. Lacey Act, amended in May 2008, makes it a federal crime to trade in illegalwood products. Under a phased-in process, many sectors also have to declare the scientific nameand the country of harvest for any plant constituents of their imported products.Other wood product sectors, including those importing sawn timber, flooring, and joinery havebeen declaring this information to the U.S. government for nearly a year. Now, an importer ofchairs manufactured in Vietnam will declare, for example, that the wooden frame is made ofteak (Tectona grandis) from Thailand. Importers of billiards equipment might declare that thecocobolo in pool cues (Dalbergia retusa) is from Nicaragua.This information – collected by USDA’s APHIS – will allow the implementing agencies to targetenforcement actions and better understand how the U.S. market demand for wood products isaffecting forests worldwide.The declaration form can be found on the APHIS website. Importers must print and mail it toAPHIS or submit the information electronically via an automated broker interface. It is expectedthat an electronic interface will become publicly available in the future as the U.S. governmentcontinues to refine its implementation of the Lacey Act.For a full list of sectors included in the April 1 phase-in, visit the APHIS website(www.aphis.usda.gov/plant_health/lacey_act/index.shtml).DOVETAIL PARTNERS INC. UPDATES 2004 STUDY –FOREST CERTIFICATION: A STATUS REPORTIn September 2004, Dovetail Partners, Inc. released the report “A Land Manager’s Guide to FSC & SFI: To Certifyor Not To Certify, Is That a Question?” Over the past six years, this report has been directly downloaded thousandsof times from the Dovetail website as well as being uploaded and made available through other organizations.Six years later, the original study has been updated and is now available for review. The 2010 report reviews thecurrent status of forest certification programs, summarizes changes that have occurred over the past six years andspeculates on what the future may bring in terms of opportunities and challenges. This report examines the NorthAmerican context with some limited global references and with particular attention paid to programs of the ForestStewardship Council (FSC) and Sustainable Forestry Initiative (SFI). Information is also provided regardingthe American Tree Farm System (ATFS) of the American Forest Foundation (AFF), the Canadian Standards<strong>Association</strong> (CSA) and the Programme for the Endorsement of Forest Certification schemes (PEFC).To view or download the complete report visit www.dovetailinc.org.18 MAY 2010 HARDWOOD MATTERS WWW.NHLA.COM

GREEN WAVEBANANA LEAVES, THE NEXT WOOD REPLACEMENT PRODUCT?According to the Australian Securities Exchange (ASX), Papyrus Australia (PPY) is the developerof a world-first technology that converts the waste trunk of the banana palm into alternatives toforest wood products to be used in the paper, packaging, furniture, building, construction andother industries. It was founded by Ramy Azer in 1995 in response to an increasingly stringentenvironmental and regulatory situation facing the paper industry.According to a company issued press release, it is estimated that the banana fibre segment of theveneer and board industry will be worth over US$20 billion annually by 2020.“There are about 10 million hectares of banana plantations with over 1,500 plants per hectare inover 160 countries, which create 2.5 billion tons of decomposing raw material every year,” saidPapyrus Australia managing director Ramy Azer. “The Papyrus technology has the capacity toutilize this renewable and abundant source of fibre to provide both the timber and paper industrieswith a new, innovative, low cost and environmentally-sustainable solution,” Azer added.The company’s achievements were recently recognized with the Investor Ready Award by SouthAustralia’s Top 20 Innovation Awards and the KPMG Excellence in Cleantech Award by theCleverGreen Innovators to Watch Awards.WWW.NHLA.COM MAY 2010 HARDWOOD MATTERS 19

TALLY SHEETWOOD-MIZER UNVEILS THE NEW WM3500The new WM3500 thin kerf headrig by Wood-Mizer Products, Inc.is now available for purchase globally. The company has alsorebranded the LT300 model, renaming it the WM3000 to align itwith the company’s industrial class headrigs.The new WM3500 is an industrial-grade horizontal headrig thatincludes all the energy, labor and yield benefits of the WM3000.The features that set it apart are a wider throat capacity toaccommodate larger logs, faster hydraulic log handling and threeside supports.WOOD-MIZER OPENS NEW TEXASSALES CENTERWood-Mizer Products, Inc. has a new Authorized Sales Centerlocated in Kirbyville, Texas. The authorized division willoffer Wood-Mizer portable mill products, Wood-Mizer bladeproducts, AWMV Industrial equipment and provide serviceand support for existing customers.“We’re proud to offer more options for our industrial customersand think the new WM3500 is perfect for companies that handlebig, heavy hardwoods with a focus on productivity,” explains DarrylFloyd, Sales Director. For more information call 1-800-553-0182or visit www.awmv.com.The Texas branch opened in later January and is managed byJay and Belinda Durham. The Texas branch can be reached at409-382-2714 or by visiting www.woodmizer.com.Photo © AWMVALAN LECHEM PROMOTED TO PRESIDENTOF WESTON WOOD SOLUTIONS INC.Alan Lechmen, Vice President of Weston Wood Solutions has been promoted toPresident of Weston Wood Solutions, effective April 2, 2010. Alan started his careerat Weston more than 20 years ago and has served as Vice President since 2005.“Alan is an excellent lumberman,” said Rick Ekstein, President of Weston ForestGroup. “He truly understands the global nature of our industry and we are veryconfident that Alan can guide Weston Wood Solutions into the future, bringingvalue to our customers, suppliers, staff and shareholders.”20 MAY 2010 HARDWOOD MATTERS WWW.NHLA.COM

WWW.NHLA.COM MAY 2010 HARDWOOD MATTERS 21

EDUCATIONSPOTLIGHTNHLA GRADUATES THE 161 ST CLASSCommencement exercises for the 161st Class of the NHLA Inspector Training School were held on April 9, 2010.Graduates were:■ Wesley Boles of Cookeville, Tennessee | Hermitage <strong>Hardwood</strong> <strong>Lumber</strong> Sales, Inc.Recipient of the Westside <strong>Hardwood</strong> Club Award for Highest Board Run Average■ Gregory Carroll of Vicksburg, Mississippi■ Caleb Hanna of Sparta, Tennessee | White County <strong>Lumber</strong> Co., Inc.Recipient of the <strong>Lumber</strong>men’s Club of Memphis Leadership Award■ Jim Hunt of Tupelo, Mississippi | Main Street Forest Products■ Jed McManis of Hamden, Ohio | Industrial Timber & <strong>Lumber</strong> Co.Recipient of the Howard Hanlon Award for Second Highest Overall Average■ Timothy Meunier of Whitesville, New York | Whitesville Wood ProductsRecipient of the J.P. Hamer Award for Most Improved Student■ Troy Niblock of White Pigeon, Michigan | Banks <strong>Hardwood</strong>s, Inc.■ Andrew Orosco of Oswego, Illinois | Frank Paxton <strong>Lumber</strong> CompanyRecipient of the South Central <strong>Lumber</strong>men’s Award for Best Attitude/Citizenship■ Zach Vinzant of Carbon, Indiana | Pike <strong>Lumber</strong> Co., Inc.Recipient of the John Thomson Award for Highest Overall AverageThe 2010 Inspector Training School summer program begins June 14 at Montcalm Community College M-TEC in Greenville, Michigan.Students of the summer program can benefit from a condensed curriculum (10 weeks instead of 14 weeks) and more convenient andaffordable location. School Instructor, Rich Hascher will travel to Michigan and preside over the class, giving the students the same traditionof excellence they would receive in Memphis.For more information about the summer school program or to register online, visit www.nhla.com. Questions can be directed to ChrisChurchill, Education Program Manager at 901-399-7555 or c.churchill@nhla.com.Dates for the 163rd Class of the Inspector Training School have been set. The fall program runs September 8 – December 10, 2010.Enrollment is now open and can be accessed at www.nhla.com.22 MAY 2010 HARDWOOD MATTERS WWW.NHLA.COM

EDUCATIONSPOTLIGHTNHLA ASKED AND YOU DELIVEREDIn January of this year, the NHLA InspectorTraining School requested replacement lumber ina variety of thickness, length and species.As usual, the NHLA membership respondedgenerously and quickly with a truck full of lumberarriving at the School in April!NHLA would like to give special thanks to alldonor companies for their generosity and supportof the Inspector Training School.■ Fitzpatrick & Weller, Inc.■ Wagner <strong>Hardwood</strong>s LLC■ Emporium <strong>Hardwood</strong>s■ Hickman <strong>Lumber</strong> Company■ Industrial Timber & <strong>Lumber</strong> Co.Transportation was provided byIndustrial Timber & <strong>Lumber</strong> Co.WWW.NHLA.COM MAY 2010 HARDWOOD MATTERS 23

CALENDARWHERE IN THE WORLD IS NHLA?Expo Richmond 2010 – East CoastSawmill & Logging Equipment ExpoRichmond, VA | May 21–22Attending: Tom Walthousen,Director of Industry RelationsMissouri Forest Products <strong>Association</strong>(MFPA) Summer MeetingLake Ozark, MO | July 23–24Participating: Mark Barford, Executive DirectorInternational Woodworking Fair(IWF) 2010Atlanta, GA | August 25 –28Participating: Tom Walthousen,Director of Industry Relations2010 NHLA Annual Convention& Exhibit ShowcaseVancouver, BC, Canada | October 13–16INDUSTRY EVENTSNortheastern ForestProducts EquipmentExpositionEssex Junction, VT | May 7–8Interzum MoscowMoscow, Russia | May 11–15<strong>Hardwood</strong> Plywood &Veneer <strong>Association</strong> SpringConventionScottsdale, AZ | May 23–25GreenbuildAbu Dhabi, UAE | May 24–26AIA <strong>National</strong> ConventionMiami, FL | June 10–12China Furniture andWoodworks 2010Dalian, China | June 10–13Saw Tech Log ExpoFort Frances, Ontario, CanadaJune 12–13Forest Products Society64th InternationalConventionMadison, WI | June 20–22Appalachian <strong>Hardwood</strong>Manufacturers SummerConferenceWhite Sulphur Springs, WVJuly 25–27Furniture ChinaShanghai, China | September 7–10Kentucky Wood ExpoMadisonville, KYSeptember 17–18London Design FestivalLondon, UK | September 18–26IntermobIstanbul, Turkey | October 16–20Fall High Point MarketHigh Point, NC | October 16–212010 SAF <strong>National</strong>ConventionAlbuquerque, NM | October 27–31NAWLA Traders MarketChicago, IL | November 4–624 MAY 2010 HARDWOOD MATTERS WWW.NHLA.COM

CALENDAREDUCATION & TRAINING3-Day <strong>Lumber</strong> GradingShort CourseWarren, PA | May 3–5Warren Forest Higher Ed. CouncilInstructor: Barry Kibbey, <strong>National</strong> InspectorContact: Donna Smith814-723-3222 | 814-723-3340 (fax)dsmith@hi-ed.orgLeadership, Management andDevelopmentWashington, D.C. | Session 2: May 10–13Contact: Chris Churchill901-399-7555 | c.churchill@nhla.com3-Day <strong>Lumber</strong> GradingShort CourseShanghai, China | May 27–29Shanghai Furen Timber Wholesale MarketInstructor: Bob Sabistina,International ConsultantContact: Chris Churchill901-399-7555 | c.churchill@nhla.com<strong>Hardwood</strong>s 101Memphis and Pickwick Lake, TN | June 7–10Contact: Chris Churchill901-399-7555 | c.churchill@nhla.com4-Day <strong>Lumber</strong> GradingShort CourseMillersburg, OH | June 7–10Yoder <strong>Lumber</strong> Company andOhio Forestry <strong>Association</strong>Instructor: Barry Kibbey, <strong>National</strong> InspectorContact: John Dorka614-497-9580 | 614-497-9581 (fax)john@ohioforest.org3-Day <strong>Lumber</strong> GradingShort CourseMcConnellsville, NY | June 14–16Harden FurnitureContact: Dave McGowan315-335-8105 | dmcgowan@harden.comInspector Training SchoolSummer ProgramGreenville, MI | June 14–August 27Montcalm Community College M-TECContact: Chris Churchill901-399-7555 | c.churchill@nhla.com4-Day <strong>Lumber</strong> GradingShort CourseSandy Lake, PA | July 19–22McKeever Environmental Learning CenterInstructor: Barry Kibbey, <strong>National</strong> Inspector724-376-1000 | 724-376-8235 (Fax)info@mckeever.orgInspector Training SchoolMemphis, TN | September 8–December 10NHLA HeadquartersInstructor: Rich HascherContact: Chris Churchill901-399-7555 | c.churchill@nhla.com3-Day <strong>Lumber</strong> GradingShort CourseBeijing, China | September 16–18Beijing Dongba Timber Wholesale MarketInstructor: Bob Sabistina,International ConsultantContact: Chris Churchill901-399-7555 | c.churchill@nhla.com3-Day <strong>Lumber</strong> GradingShort CourseGuangzhou, China | December 9–11Guangzhou Yuzhu TimberWholesale MarketInstructor: Bob Sabistina,International ConsultantContact: Chris Churchill901-399-7555 | c.churchill@nhla.comWWW.NHLA.COM MAY 2010 HARDWOOD MATTERS 25

JOB BOARDChief InspectorThe <strong>National</strong> <strong>Hardwood</strong> <strong>Lumber</strong> <strong>Association</strong> (NHLA) headquartered inMemphis, Tennessee is currently seeking a Chief Inspector.The Chief Inspector is responsible for the day-to-day operations of theNHLA Inspection Services Department, Heat Treatment Program andKiln-Drying Certification Program. The Chief Inspector has the final say inall grading rules interpretations, grade disputes, and administration of theSales Code Enforcement Guidelines and the <strong>Hardwood</strong> Claims Bureau.To read full job description, see page 8.<strong>Lumber</strong> InspectorITL Corporation is seeking a full time <strong>Lumber</strong> Inspector. Responsibilitiesinclude accurate inspection of both green and kiln dried and leadershipof crew. This position is located in Marion, North Carolina.Qualified candidates will have basic computer skills and must be agraduate of the NHLA Inspector Training School. Experience is preferredbut not required. Please send resumes via mail, fax or email to:ITL Corporation | Attn: Kenny WarnerP.O. Box 150 | Marlinton, WV 24954304-799-4745 | 304-799-4117 (fax) | kenny@itlcorp.comExperienced Yard SupervisorGraham <strong>Lumber</strong> has a position available for an experienced YardSupervisor. Duties of the position include: Supervision of the stacker,two inspection lines, AD yard, and Kilns. The Yard Supervisor will beresponsible for 36 employees and their safety and all quality andproduction targets. The person in this position will work with the salesdepartment and General Manager to set inspection schedules and Kilnschedules. The Yard Supervisor reports directly to the General Manager.Qualified candidates will have a minimum of 5 years inspection and kilndry experience as well as 5 years of supervisory experience. Salary isnegotiable. Submit resumes to Keith Snider at ksnider@ahiwood.com.Graham <strong>Lumber</strong> CompanyPO Box 679 Hwy 412 W | Linden, TN 37096931-589-2143 | 931-589-5914 (fax)<strong>Lumber</strong> GraderSavage <strong>Lumber</strong> Company located in Doyle, Tennessee has a positionavailable for an experienced <strong>Lumber</strong> Grader. Candidates with lumber gradingexperience should contact Alex Savage at savagelumber@blomand.net.Savage <strong>Lumber</strong> CompanyPO Box 39 | Doyle, TN 38559931-657-2211 | 931-657-2214 (fax)Bandmill SawyerAmerican Walnut Company has a position available for an experiencedBandmill Sawyer in St. Joseph Missouri. Please send resume to thefollowing address:American Walnut Company | Attn: Alan Eckley2801 South 2nd Street | St. Joseph, Missouri 64501913-371-1820 | 913-371-1823 (fax)americanwalnut@americanwalnut.com | www.americanwalnut.comSawyer – Circular SawSavage <strong>Lumber</strong> Company is seeking an experienced Sawyer forCircular Saw. Qualified candidates should contact Alex Savage atsavagelumber@blomand.net.Savage <strong>Lumber</strong> CompanyPO Box 39 | Doyle, TN 38559931-657-2211 | 931-657-2214 (fax)<strong>Lumber</strong> GraderSavage <strong>Lumber</strong> Company has a position available for an entry level<strong>Lumber</strong> Grader in Doyle, Tennessee. Interested candidates shouldcontact Alex Savage at savagelumber@blomand.net.Savage <strong>Lumber</strong> CompanyPO Box 39 | Doyle, TN 38559931-657-2211 | 931-657-2214 (fax)<strong>Lumber</strong> InspectorAugusta <strong>Lumber</strong> located in Waynesboro, Virginia is seeking an Inspectorfor grade green and kiln dried lumber. Candidatesshould be a graduate of the NHLA Inspector Training School.Salary range is $12 to $14 per hour. Please contact Jeff Byrd atjeffbyrd@augustalumber.com or call 540-649-5927.Augusta <strong>Lumber</strong>567 N. Charlotte Ave. | Waynesboro, VA 22980540-946-9153 (fax)<strong>Lumber</strong> InspectorTioga <strong>Hardwood</strong>s is seeking a <strong>Lumber</strong> Inspector for green and kiln driedhardwoods in central/northern New York. Candidates must be competentin the application of the NHLA grading rules and able to perform at linespeed. Salary is negotiable.Tioga <strong>Hardwood</strong>s12685 State Route 38 | Berkshire, NY 13736607-657-8686 | 607-657-2532 (fax) | keving@tiogahardwoods.com26 MAY 2010 HARDWOOD MATTERS WWW.NHLA.COM

JOB BOARDOperations ManagerThe Frank Paxton <strong>Lumber</strong> Company has been a leader in thehardwood distribution market for almost 100 years. The Kansas City,Missouri division is recruiting an Operations Manager. The position’sresponsibilities include: supervising shipping, receiving, daily orderprocessing, warehouse inventory and the physical plant. In addition,the operations manager will manage all warehouse, mill and driverpersonnel. We are a safety oriented company, dedicated to providingquality products in a competitive market. The ideal candidate will possessa bachelor’s degree, have prior managerial experience, have the abilityto multi-task, and preferably have prior hardwood lumber experience.The company offers a competitive salary with strong benefits, salary isnegotiable. Please send resumes to kcmillwork@paxtonwood.comFrank Paxton <strong>Lumber</strong> | Kansas City, MO800-333-7298 | 816-241-5110 (fax)<strong>Lumber</strong> InspectorParton <strong>Lumber</strong> Company is seeking a <strong>Lumber</strong> Inspector of red and whiteoak, poplar and eastern white pine. On the job training on pine shopgrades is available. Parton <strong>Lumber</strong> saws approximately 56 million boardfeet annually.Interested candidates should contact Alfred Mayo atamayo@partonlumber.com or by phone at 828-287-9669.Parton <strong>Lumber</strong> Company251 Parton Road | Rutherfordton, NC828-287-9423 (fax) | www.partonlumber.com<strong>Lumber</strong> InspectorDevereaux Sawmill is one of Michigan's largest hardwood manufacturers.We care about our people, our customers and our natural resource; andwe are seeking candidates who feel the same. Devereaux is currentlyseeking an Inspector to grade and tally both green and kiln driedlumber. Candidates must be able to upgrade and demonstrate goodcommunication skills, work ethic and leadership potential. Experience ispreferred but not required and salary is based on qualifications.Devereaux Sawmill, Inc.2872 North Hubbardston Road | Pewamo, MI 48873989-593-2552 | 989-593-2329 (fax)todd@devereauxsawmill.com | www.devereauxsawmill.com<strong>Lumber</strong> InspectorGraham <strong>Lumber</strong> Company in Selmer, Tennessee is seeking a <strong>Lumber</strong>Inspector to inspect, evaluate, and grade green lumber off of the chain toits highest value according to NHLA grading rules and to ensure a qualityproduct in a safe and productive manner. Interested candidates shouldcontact Keith Snider, General Manager at ksnider@ahwood.com.Graham <strong>Lumber</strong> Company860 Hwy 142 | Selmer TN, 38375731-645-9169 | 731-645-9924 (fax)SawyerGraham <strong>Lumber</strong> Company is seeking a Sawyer. The position requires oneto efficiently derive the highest value from the raw material and producethe most, good lumber possible without wasting fiber by properlypositioning and feeding logs through the headrig in a safe and productivemanner. Interested candidates should contact Keith Snider, GeneralManager at ksnider@ahwood.com.Graham <strong>Lumber</strong> Company860 Hwy 142 | Selmer TN, 38375731-645-9169 | 731-645-9924 (fax)Sawmill ManagerPike <strong>Lumber</strong> Company is seeking a Sawmill Manager for a new state-of-theartsawmill in Milan, Indiana. Candidates should be experienced in hardwoodband sawmilling, scanning technologies and supervision. The position isavailable immediately, as the sawmill manager needs to be on-site duringthe spring 2010 construction process. Pike <strong>Lumber</strong> Company is a 105 yearoldcompany. Interested persons should contact Samantha Howard atshoward@pikelumber.com or 574-893-4511.Pike <strong>Lumber</strong> CompanyPO Box 247 | Akron, Indiana 46910www.pikelumber.com.<strong>Lumber</strong> InspectorBauman Sawmill located in Ontario, Canada is seeking a <strong>Lumber</strong>Inspector that is a graduate of the NHLA Inspector Training School. Twoyears of experience is preferred but all applicants will be considered.Salary is negotiable. Contact Bruce Steinacker, Manager at bruce@baumansawmill.com or 519-698-2741Bauman Sawmill4201 Powell Road | Wallenstein, Ontario, Canada N0B 2S0Current job openings are posted by members at www.nhla.com.For more information, visit www.nhla.com or contact Chris Churchillat 901-399-7555 or email at c.churchill@nhla.com.WWW.NHLA.COM MAY 2010 HARDWOOD MATTERS 27

MAKING IT WORK (Continued from page 16)You should also pay attention to your counter knife maintenance. The term counter knife is actually a misnomer, as it’s not intended to cut anything.A counter knife is really a wear plate designed to deflect chips coming off the cutting edge of the knife. As a counter knife wears, its point will get wornaway from the abrasive action of the chip. When this happens, wood starts to pack between the counter knife and the chipper knife. This can easilybreak knives and if it’s allowed to continue will start tweaking the pockets in the chipper itself. At that point you’ll routinely get broken knives, again avery dangerous situation, and the fix becomes a large expense.Not very sexy stuff these chippers, hiding down in the basement, working behind closed doors, but hey – we can’t all be born bandsaws. I hope that theimproving conditions are reaching you, here’s to 2010!THE BOY WHO CRIESWOOD! (Continued from page 15)stairs, floors, millwork, furniture and cabinetryworldwide. With a historical perspective keptfirmly in mind, through the use of visual aids,attendees are able to relate U.S. hardwoodsto the most contemporary of design projects.The NHLA grading rules are also part of thepresentation as architects and designers needto be aware of the realities of the resourcein order to help them avoid the pitfalls ofunrealistic specifications and expectations interms of perfectly clear widths and lengths.To date, the AIA presentation has reachedmore than 600 architects and designers, insome of the most prestigious firms in theUnited States. And I am currently workingon an ongoing basis with several high-endfirms, writing realistic lumber specificationsand offering advice on species of hardwoodsappropriate to the project being designed.The undertaking of this educationalinitiative, a Frank Miller <strong>Lumber</strong> marketingeffort, is seen as benefiting the entirehardwood industry. As an employee ofFrank Miller <strong>Lumber</strong>, I am solely dedicatedto this task and credit the forward-thinkingorientation of the owners of the company,who want to see a healthy future for theentire industry. That future depends ondesigners and architects specifying U.S.hardwoods for their projects. When theyfeel comfortable in their newly acquiredknowledge of beautiful, sustainable U.S.hardwoods, they will, I believe, incorporatehardwoods into more projects.28 MAY 2010 HARDWOOD MATTERS WWW.NHLA.COM

HOW DOE S THISGUITARRELATE TO YOU?Memphis, Tennessee is famous for Elvis Presley, Rock–n-Roll and the MemphisBlues; a guitar based style of blues music created in the 1920s and 1930s. The guitarpictured here has a Walnut top and an ash body, providing for an exceptionallycomfortable weight and balance. The combination produces clear bell-like highs,pronounced mids and strong lows. The neck of the guitar is a “C” shape single piececonstructed of hard rock maple.FYI: This unique guitar, aptly named the “Bluesmaster II”, stands up to any classicdesign and has been found in the hands of many musical giants such as Eric Clapton,Bono, Albert King, Elliot Easton, Marshall Crenshaw, Glen Frey, Billy Gibbons… TheBluesmaster design is made by Saint Blues Guitar Workshop in Memphis, Tennessee.Photo Courtesy of Saint Blues Guitar Workshop