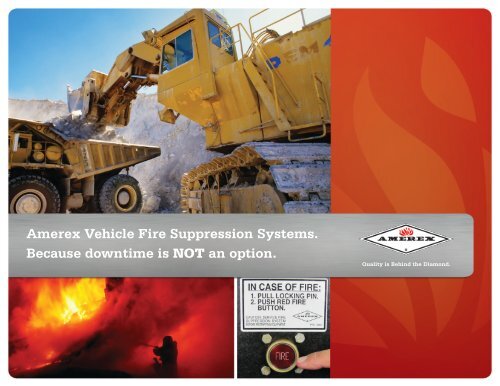

Amerex Vehicle Fire Suppression Systems. Because downtime is ...

Amerex Vehicle Fire Suppression Systems. Because downtime is ...

Amerex Vehicle Fire Suppression Systems. Because downtime is ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Quality <strong>is</strong> Behind the Diamond.Diamonds have long been a symbol forquality. At <strong>Amerex</strong> we pride ourselves onthe quality of the products we bring to themarketplace. We have to. We make productsthat are the keystone in the protection of lifeand property. Through the years <strong>Amerex</strong> hasearned its reputation for quality. It’s part ofthe reason we chose the diamond for a logo.

Single Release System ApplicationsHaul TrucksWheel LoadersDrillsDozersGradersTrack LoadersSingle Release Sequence of Operation• <strong>Fire</strong> starts in the machine producing heat and toxic gases.• The detectors sense the heat and send a signal to the control panel.• The control panel interprets the signal and begins the d<strong>is</strong>chargesequence activating the alarm relay for shutdowns.• The operator may choose to activate the manual release locatedin the cab or at ground level at any time to begin the d<strong>is</strong>chargesequence.• The linear actuator receives the signal from the control panel andopens the cylinder valve. The fire suppression agent travels throughthe d<strong>is</strong>tribution network to the nozzles and d<strong>is</strong>perses the agent.• The fire <strong>is</strong> suppressed allowing for personnel to evacuate the machineand utilize hand held fire extingu<strong>is</strong>hers or other methods if necessary.Note: The drawing shown <strong>is</strong> a conceptual and not intended to be a design drawing. A complete hazard analys<strong>is</strong>and r<strong>is</strong>k assessment will have to be performed on the vehicle to determine the most probable ignition sourcesalong with the fire character<strong>is</strong>tics and quantity of the various fuels exposed to those ignition sources. Finalplacement of the fire suppression components should be based on the hazard analys<strong>is</strong> and in coordination withthe end user.

<strong>Amerex</strong> <strong>Vehicle</strong> <strong>Fire</strong> System FeaturesSystem Control PanelThe Control Panel (CP) <strong>is</strong> the “brains” of the system. The CPinterprets the signal from the detection circuit and initiates the cylinderd<strong>is</strong>charge, simultaneously operating the relays which can be used tostop the flow of flammable fuels.Automatic Detection24-hour automatic heat sensors rapidly detect fire and signals the CPto start the d<strong>is</strong>charge sequence suppressing the fire and mitigating thedamage.Agent CylindersStored pressure cylinders hold the fire suppression agent in a statethat prevents contamination thus reducing maintenance costs.D<strong>is</strong>tribution NetworkHydraulic hose or stainless steel tubing carries the fire suppressionagent to the d<strong>is</strong>charge nozzles and d<strong>is</strong>perses the chemical throughoutthe harzard area.System ActuationAll systems have the capability to be actuated electrically,pneumatically or as a redundant system featuring both electric andpneumatic actuation.

Dual Release System ApplicationsHydraulic ShovelsHydraulic ExcavatorsLarge Haul TrucksDraglinesDual Release Sequence of Operation• <strong>Fire</strong> starts in the machine producing heat and toxic gases• The detectors sense the heat and send a signal the control panel• The operator may choose to operate the manual release located inthe cab or at ground level at any time to signal the control paneland begin the d<strong>is</strong>charge sequence• The control panel interprets the signal and begins the d<strong>is</strong>chargesequence activating the alarm relay for shutdowns• Stage One release begins when the linear actuator receives thesignal from the control panel and opens the dry chemical cylindervalves allowing the fire suppression agent to travel throughthe d<strong>is</strong>tribution network to the nozzles which d<strong>is</strong>perse agentthroughout the hazard area providing rapid fire knockdown.• Stage Two release begins after the preset time delay countdownhas ended. The linear actuator receives a signal from the controlpanel and opens the Integrated Cooling (ICE) wet chemical cylindervalves. The fire suppression agent to travel through the d<strong>is</strong>tributionnetwork to the nozzles and d<strong>is</strong>perses liquid agent throughout thehazard area onto the heated surfaces cooling these surfaces andreducing the possibility of the fire reflashing.• The fire <strong>is</strong> suppressed allowing for personnel to evacuate themachine and utilize hand held fire extingu<strong>is</strong>hers or other methods ifnecessary.Note: The drawing shown <strong>is</strong> a conceptual and not intended to be a design drawing. A complete hazard analys<strong>is</strong>and r<strong>is</strong>k assessment will have to be performed on the vehicle to determine the most probable ignition sourcesalong with the fire character<strong>is</strong>tics and quantity of the various fuels exposed to those ignition sources. Finalplacement of the fire suppression components should be based on the hazard analys<strong>is</strong> and in coordination withthe end user.

<strong>Amerex</strong> <strong>Vehicle</strong> <strong>Fire</strong> System FeaturesSystem Control PanelThe Control Panel (CP) <strong>is</strong> the “brains” of the system. The CPinterprets the signal from the detection circuit and initiates twoseparate d<strong>is</strong>charges of the dual agent cylinders in the programmedsequences. The CP controls relays which can be used to stop the flowof flammable fuels.Automatic Detection24-hour automatic heat sensors rapidly detect fire and signals the CPto start the d<strong>is</strong>charge sequence suppressing the fire and mitigating thedamage.Agent CylindersStored pressure cylinders hold the fire suppression agent in a statethat prevents contamination thus reducing maintenance costs.The initial d<strong>is</strong>charge of dry chemical agent provides for rapid fireknockdown. The second d<strong>is</strong>charge of wet agent provides cooling of theheated surfaces to reduce the possibility of reignition.D<strong>is</strong>tribution NetworkHydraulic hose or stainless steel tubing carries the fire suppressionagent to the d<strong>is</strong>charge nozzles and d<strong>is</strong>perses the chemical throughoutthe harzard area.System ActuationAll systems have the capability to be actuated electrically,pneumatically or as a redundant system featuring both electric andpneumatic actuation.

<strong>Fire</strong> Protection <strong>is</strong> not a commodity itemTo maximize your production you need a partner who will work with you to develop and integrate a customizedsolution to meet your needs. We have an engineering team dedicated to vehicle fire protection. They understand ther<strong>is</strong>ks and work closely with your maintenance teams to develop new products and processes to reduce <strong>downtime</strong>.The safest dec<strong>is</strong>ion you will ever makeWe know that you have a lot of choices. We also know the importance of fire protection to your business. We arecommitted to providing the best possible fire solution and it shows in our innovation, quality and commitment toservice. <strong>Amerex</strong> has been providing fire fighting products since 1971. We are the worldwide leader in hand portableand wheeled fire extingu<strong>is</strong>hers. Our product line also includes Gas Detection, Industrial, Kitchen, and Clean Agentsystems. <strong>Amerex</strong> products are proudly made in the USA.

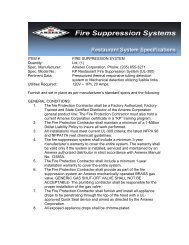

Specifications:Agent CylindersDry Chemical available in ABC and PK agents• Models available (numbers represent pounds offirefighting agent) V13, V25, VH25 (horizontalmount),V50, VS50 (short cylinder) and V75• Stored pressure• Agent cylinder pressure monitoring switchavailable• Operating temperature range -40º F to +150º FLiquid Cooling Agent (ICE)• Models available (numbers represent gallons ofagent) ICE 14 and ICE 28• Foaming agent• Stored pressure• Operating temperature range -40º F to +120º FControl PanelsSingle Zone protection• Single zone detection and release• Superv<strong>is</strong>ed circuits• Diagnostic LED’s• Audible and v<strong>is</strong>ual alarms• Relay available for shutdown and auxiliarydevice activation• Test circuit• Operating temperature range -40º F to +150º F• Operating voltage range 10-30 VDC• Operating current 47 mA• Self charging back up battery provides 24 hourbackup in case of main power failureDual zone protection• Same as above except the following• Dual zones of detection and release• Operating voltage range 10-42 VDC• Operating current 50 mA• Integrated manual release• Data logging and event recordingDetectorsFixed temp/Rate of R<strong>is</strong>e compensated heatdetector• Factory sealed in mounting bracket withpluggable wire connectors• Temperatures available +325º F, +450º FLinear Heat sensing wire• Fixed temperature activation +356º F• Available in factory terminated lengths or bulkfor cut to fit applications• Factory terminated lengths available withstainless steel wire protective coveringProgrammable Heat Detector (PhD)• Adjustable temperature set point for rapid headdetection• Fixed temperature, rate of r<strong>is</strong>e orcombination fixed temp/rate of r<strong>is</strong>e options• Data logging records temperatures and heatevents• Single part number for the heat detector – youprogram the desired temperature• Programming <strong>is</strong> completed/data logging <strong>is</strong>viewed via interface with a laptop computer orhandheld service tool• Can be used as a diagnostic tool for evaluatingambient temperature rangesOther• Nitrogen cylinder equipped with pressure gaugefor v<strong>is</strong>ual determination of charge status• Manual system activation can be performed viaelectronic and/or pneumatic methods• Fully Factory Mutual approved system

Quality <strong>is</strong> Behind the Diamond.<strong>Amerex</strong> CorporationPost Office Box 817595 Gadsden HighwayTrussville, AL 35173-0081 U.S.A.Internationally recognized ISO 9001 and ISO 14001 reg<strong>is</strong>tered firmPhone 205.655.3271Fax 800.654.5980 (USA)205.655.0854 (Int’l)sales@amerex-fire.comwww.amerex-fire.com© 2012 <strong>Amerex</strong> Corporation Part No.: SL-1800 09/2012