Job Report R 974 - Liebherr

Job Report R 974 - Liebherr

Job Report R 974 - Liebherr

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

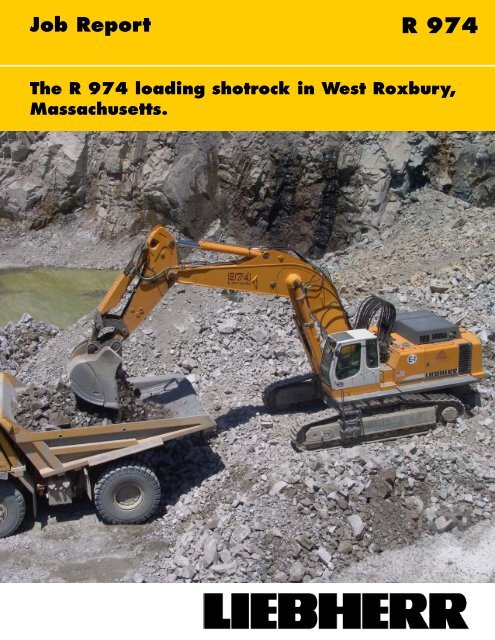

<strong>Job</strong> <strong>Report</strong>R <strong>974</strong>The R <strong>974</strong> loading shotrock in West Roxbury,Massachusetts.

SituationS.M. Lorusso & Sons, Inc is a family owned companyheadquartered in Walpole, Massachusetts producingcrushed stone, sand and gravel. Lorusso operates sixquarry locations throughout southeast Massachusettsand Cape Cod; one site has been in operation sincethe mid 1800s and still has great potential for futuredigging.S.M. Lorusso & Sons is currently in its fourthgeneration and run by Tony Lorusso and his son, A.J.Lorusso; the operations on Cape Cod are run byTony’s brother Sam Lorusso and his children, LauraPeterson, Sam Jr. and Paul Lorusso. S.M. Lorusso &Sons has maintained its success through seamlessoperations and maximizing resources. All aspects ofthe company are carefully monitored to ensureoptimum production levels are being achieved.? TaskReliable equipment and quick cycle times are majorfactors that must be considered when trying tooptimize production. Lorusso’s machines work 9hours a day, 5 days a week producing crushed stone,sand and gravel with a portable rock crushing plant aswell as stationary crushers.For years, Lorusso used wheel loaders to either loaddirectly into the rock crusher or load trucks which feedthe rock crusher. When Lorusso planned to switchloading with the wheel loaders to excavators, durable,reliable and efficient equipment was a necessity.! SolutionLorusso purchased two R <strong>974</strong>s, <strong>Liebherr</strong>’s largecrawler excavators, to take over loading the trucksand loading directly into the portable crusher. Lorussochose a machine sized slightly larger than needed soit would not be running at 100% capacity all the time,decreasing the amount of wear and increasinglongevity. Lorusso also chose the <strong>Liebherr</strong> because ithas a lower operating cost per hour than othermanufacturers. Switching to the crawler excavator asthe main loading tool also decreases Lorusso’sreliance upon rubber tires.<strong>Liebherr</strong>’s crawler excavators have excellent diggingforces, bucket fill factor and very fast cycle times.Lorusso said, “We’ve never had a backhoe that sizebefore and there were a lot of skeptical people thatdidn’t think it would work. Now they can’t believe howfast and how strong it digs.”<strong>Liebherr</strong> Construction Equipment Company4100 Chestnut Avenue, Newport News, Virginia 23607PH: 757-245-5251, Fax: 757-928-8701www.liebherr.com, E-Mail: info.lce@liebherr.com! PerformanceSince purchasing the R <strong>974</strong> in January, Lorusso hasexperienced an increase of 10-15% in production.Comparing a 6 yd bucket on the excavator to a 8 ydbucket on the loaders, Lorusso was surprised andvery pleased with the outstanding performance of theR <strong>974</strong>.Lorusso said, “The excavators give you the ability toplace the load. Placing the load makes a hugedifference, there is less spillage and less cleanup.You have a clear view of the size rocks that are beingplaced in the crusher, reducing the risk of oversizedrocks going into the crusher and slowing production.”The excavator is 20 –30 seconds faster than a wheelloader when loading 60 ton trucks. The operatorsprefer to use the excavator for loading and they havealso commented on the comfort of the cab and howsmoothly it drives; Lorusso is pleased because theoperators’ productivity levels remain high through theend of the day.Lorusso has been very pleased with the after salessupport he has received from his local dealer, Tools 4Hire. “So far it’s been excellent. I have not had anyissues, but they take care of everything. They arestocking a lot of parts and what they don’t stock theyreceive very quickly.”Technical DataR <strong>974</strong> B LitronicEngine ____________________ <strong>Liebherr</strong> D9408 TI-EEngine Output __________________ 395 kW/537 HPOperating Weight _____________179,680-194,440 lbGooseneck Boom ________________________ 23’8”Stick ___________________________________ 9’6”Bucket Capacity _________________________ 6 yd 3Printed in the USA by Letton Gooch #####-6-30-2006 Subject to change without notice.