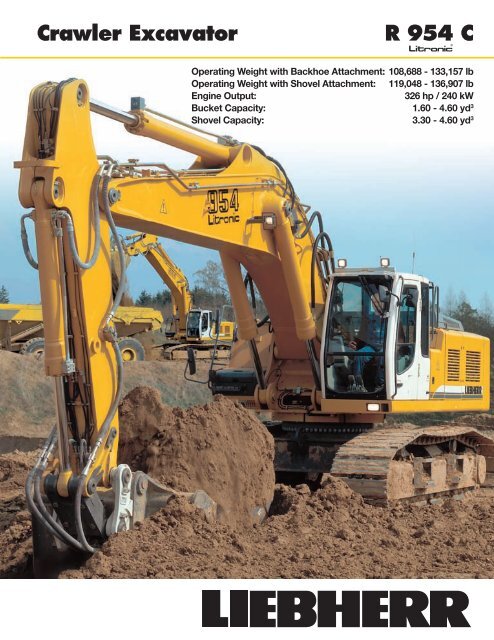

R 954 C Litronic Crawler Excavator - Lorusso Heavy Equipment

R 954 C Litronic Crawler Excavator - Lorusso Heavy Equipment

R 954 C Litronic Crawler Excavator - Lorusso Heavy Equipment

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Liebherr Diesel Engine• Specifically designed forconstruction equipment• Long life expectancy• Incline lubrication capabilityfor an up to 100% grade• LIDEC-Engine Control –Liebherr Diesel Engine Control• State-of-the-art technology withcommon rail injection system• Complies with emissionstandard IIIA / Tier 34 R <strong>954</strong> C <strong>Litronic</strong>

Dependable design• Designed with casted bell-housings• Features two separate pins• Maximum strength even at high forces• Long term advantages due to optimalstress-flow design6 R <strong>954</strong> C <strong>Litronic</strong>

ReliabilityThe high demand for performance and quality is converted into landmark solutions toachieve the highest level of dependability and availability. Liebherr has 50 years experiencein the production of hydraulic excavators and has an unparalleled competencein design and know-how.Technology with a visionOptimized hydraulicsPower packQuality to the last detail<strong>Heavy</strong>-duty attachmentswith long-term advantageRobust attachmentconceptOptimized stress flowExternal bypass lines at the control valve apply the oilflow to the appropriate attachment functions. The optimalhose routing from the control valve to the attachmentsubstantially increases the dependability of thehydraulic system.The individual components of the drive unit (i.e. constructionequipment engine, travel and swing gearboxes,main pumps and hydraulic cylinders), pro duced bysister companies of Liebherr are coordinated to fit eachother perfectly. They guarantee maximum dependabilityas an integral part of the total system which is designedfor long life expectancy.The clearly laid out routing of the hydraulic, lubricationand electrical lines assures the highest reliabilityand performance of the machine. Optimal corrosionprotection is achieved with pre-painted and surfacetreated parts.With the utilization of steel castings at every pivotpoint, the attachment is consistently able to withstandthe most server demands.The swing ring tower is made from one piece, whichtransfers the forces – following the principal of “stressflow design” - into the undercarriage. For lasting protectionagainst dirt and damage, Liebherr swing ringsare sealed and have internal teeth.Bucket linkage• Optional sealed linkage bearings• Optimal protection forunder-water work• Increased life expectancyof the attachmentKey components made by Liebherr• Decades of experience with the development,design and manufacturing of components• Engines, hydraulic pumps and motors, swingand travel gearboxes as well as electronicelements from in-house production• Manufacturing centers for components inGermany and Switzerland produce accordingto the latest production methodsR <strong>954</strong> C <strong>Litronic</strong>7

Hydraulic reservoir stop valve• Easy and quick interruption of the oilcircuit between hydraulic reservoir andhydraulic system• No drainage of fluid necessary forservice or repair work on the hydraulicsystem8 R <strong>954</strong> C <strong>Litronic</strong>

ComfortThe operator’s station is designed with comfort in mind. The standard automatic climatecontrol provides a pleasant working environment during any weather condition.Liebherr crawler excavators are service-friendly: maintenance work is easy andsimply accomplished due to well accessible service points.Standard maintenance advantageEasy accessibilityMaintenance friendlytrack componentsAll service points are easily accessible and the R <strong>954</strong> Cfeatures a central lubrication point as a standard feature.Daily preventive maintenance can be completedin a short period of time.Top rollers, track rollers and track link pins are lubricatedfor the life of the excavator. The grease cylinderof the idler tensioner is sealed against dirt.Work place with feel-well characterOptimal visibilityWell thought-outarrangementEasy operationThe operator station’s generously-sized windowsprovide outstanding visibility of the work and surroundingarea.Design and arrangement of the seat, controls anddisplays are perfectly tuned to each other in an ergonomically-integratedconcept. The operator’s seat hasshock-absorbing suspension and is adjustable to theindividual preference of each operator.The control consoles and information display are arrangedwithin clear view of the operator and are easyto reach. New joysticks, with reduced operating force,are ergonomically shaped and allow pleasant and fatigue-freework.Easy access• Comfortably positioned ascents on bothsides provide good accessibility to allservice points• Ergonomically positioned hand railsensure secure ascent and descent• Additional hand rails guaranteemaximum safetyLiebherr Operator’s station• Generously-sized windows allow for optimal visibility• Operator’s seat is individually adjustable and includesa shock-absorbing cushion• Standard automatic climate control• Right-side window without vertical center post• Lockable storage behind seatR <strong>954</strong> C <strong>Litronic</strong>9

Hydrostatic fan drive• The new cooling system consistsof two hydrostatically driven fans• The fan speed is thermostatically-controlledby the temperature of hydraulic fluid, chargingair and radiator fluid• Accelerated warm-up period• Fan uses only the needed power,reducing fuel consumption10 R <strong>954</strong> C <strong>Litronic</strong>

EconomyThe Liebherr crawler excavators maximize productivity. The sensitive excavatorcontrols assure optimal efficiency of excavator hydraulics and electronics. A wideselection of attachments, accessory tools and varied dimension undercarriagesprovide the correct choice for each application.Top technology for maximum profitabilityElectronic engine speedsensing controlLiebherr Tool ControlOutstanding parts availableQuick spareparts supplyProfessionalhelp on-callExtensive servicepackagesThis regulating system causes an efficient conversionof the engine output in hydraulic performance – whichresults in better utilization of the available engine power.The result: higher digging forces, shorter cycle timesand lower fuel consumption.Immediately after the exchange of a hydraulic tool,the required pressure and oil flow settings are availablewith the push of a button. Up to 10 combinationswith the designated names of the tools can be programmed.No tool changeover system is as simple ortime-saving.80,000 line items are always in stock for the globalpart requirements. Emergency part orders are shippedwithin 24 hours.Liebherr’s customer service is accessible on a 24/7basis. Qualified professionals are available around theclock to respond to all questions from part supplies torepair advise.Custom tailored service packages guarantee individuallyfocused technical and logistic attention. Liebherrprovides solutions with components from remanufacturedrepair or rebuild programs for every requirement– manufactured to maintain genuine quality.New bucket shape• The new L-shape features a longerbottom and a strong waved side cutters• Suitable for applications in rocky conditionsas well as for loading hard andcoarse material• Ideal for placing rip-rap onembankmentsTurbo charger with waste-gate• Optimized turbo charger technology• Full utilization of the performancepotential for power development inlower speed ranges• Less wear on the turbine componentsR <strong>954</strong> C <strong>Litronic</strong> 11

Technical DataEngineRating per ISO 9249 _____________ 326 hp (240 kW) at 1800 rpmModel _______________________________ Liebherr D 936 LType ________________________________ 6 cylinder in-lineBore/Stroke __________________ 4.80/5.90 inDisplacement ________________ 641 in 3Engine operation _________________ 4-stroke dieselunit pump systemturbo-charged and after-cooledreduced emissionsCooling _____________________________ water-cooled and integrated motor oil coolerAir cleaner _________________________ dry-type air cleaner with pre-cleaner, primary andsafety elements, automatic dust dischargeFuel tank ___________________________ 195 galStandard ___________________________ sensor controlled engine idlingElectrical systemVoltage _______________________ 24 VBatteries ______________________ 2 x 170 Ah/12 VStarter ________________________ 24 V/7.8 kWAlternator _____________________ three phase current 28 V/80 AHydraulic SystemHydraulic pumpfor attachment andtravel drive ___________________ two Liebherr variable flow, swash plate pumpsMax. flow _____________________ 2 x 92.5 gpmMax. pressure _______________ 5,075 psiPump regulation __________________ electro-hydraulic with electronic engine speedsensing regulation, pressure compensation, flowcompensation, automatic oil flow optimizerHydraulic pumpfor swing drive_______________ reversible, variable flow, swash plate pump,closed-loop circuitMax. flow _____________________ 56 gpmMax. pressure _______________ 5,569 psiHydraulic tank ____________________ 116 galHydraulic system _________________ 209 galHydraulic oil filter _________________ 2 full flow filters in return line with inte grated finefilter area (5 µm)Cooling system ___________________ cooler unit, consisting of radiator for enginecoolant with after-cooler core, sandwiched withcooler for hydraulic fluid and fuel with hydrostaticallycontrolled fan driveMODE selection __________________ adjustment of machine performance and thehydraulics via a mode selector to match applicationECO ___________________________ for economical and environmentally friendlyoperationPOWER _______________________ for maximum digging power and heavy duty jobsLIFT ___________________________ for liftingFINE __________________________ for precision work and lifting with sensitive movementsRPM adjustment _________________ step less adjustment of engine output via rpm ateach selected modeLiebherr Tool Control ____________ ten pre-adjustable pump flows and pressures foradd on toolsHydraulic ControlsPower distribution ________________ via monoblock control valve with integrated reliefand safety valvesFlow summation ____________ to boom and stickClosed-loop circuit _________ for uppercarriage swing driveServo circuitAttachment and swing _____ – proportional via joystick leversTravel _________________________ – proportional via foot pedals or removable handlevers– speed pre-selectionAdditional functions ______________ via joystick push buttons or foot pedalsSwing DriveDrive by ____________________________ Liebherr swash plate motor with integrated brakevalvesTransmission ______________________ Liebherr compact planetary reduction gearSwing ring _________________________ Liebherr, sealed single race ball bearing swingring, internal teethSwing speed ______________________ 0 – 5.6 rpm step lessSwing torque ______________________ 121,698 lbf ftHolding brake _____________________ wet multi-disc (spring applied, pressure released)Option ______________________________ pedal controlled positioning brakeOperator’s CabCab _________________________________ resiliently mounted, sound insulated, tintedwindows, front window stores overhead, doorwith sliding windowOperator’s seat ___________________ fully adjustable, shock absorbing suspension,adjustable to operator’s weight and size, 6-wayadjustable Liebherr seatJoysticks ___________________________ integrated into adjustable consolesMonitoring _________________________ LCD display with menu-driven current operatingdata display. Acoustical and optical warning signals.Automatic engine shut-off e.g. engine overheating, low engine oil pressure, low hydraulicfluid levelAir conditioning ___________________ standard air conditioning, combinedcooler/heater, additional dust filter in fresh air/recircu latedNoise emissionISO 6396 ___________________________ L pA (inside cab) = 77 dB(A)2000/14/EC _______________________ L WA (surround noise) = 105 dB(A)UndercarriageVersionHD _____________________________ heavy dutyS-HD __________________________ heavy-duty version for extreme and severe application,e.g. quarriesDrive ________________________________ Liebherr swash plate motors with integratedbrake valves on both sidesTransmission ______________________ Liebherr planetary reduction gearsTravel speed ______________________ HD: low range – 2.05 mphhigh range – 3.0 mphS-HD: low range – 1.6 mphhigh range – 2.3 mphDrawbar pull max. ________________ HD: 96,443 lbfS-HD: 124,319 lbfTrack components _______________ HD: D 7 G, maintenance-freeS-HD: D 8 K, maintenance-freeTrack rollers/Carrier rollers _____ HD: 10/2S-HD: 8/3Tracks ______________________________ sealed and greasedTrack pads_________________________ HD triple grouserS-HD double grouserDigging locks _____________________ wet multi-discs (spring applied, pressurereleased)AttachmentDesign ______________________________ high strength steel plates with steel castings inhigh-stress areasHydraulic cylinders _______________ Liebherr cylinders with special seal-system,shock absorbedPivots _______________________________ sealed, low maintenanceLubrication_________________________ semi-automatic central lubrication system (exceptlink and tilt geometry)Hydraulic connections ___________ pipes and hoses equipped with SAE split-flangeconnectionsBucket ______________________________ standard equipped with 59,525 lb lifting eye12 R <strong>954</strong> C <strong>Litronic</strong>

Backhoe Attachmentwith Gooseneck Boom 24’11”ft40m12Digging Envelope 1 2 3Stick lengths ft in 7’ 8” 9’6” 12’5”30108Max. digging depth ft in 24’11” 26’9” 29’8”Max. reach at ground level ft in 39’ 40’8” 43’7”Max. dump height ft in 26’ 9” 27’9” 29’4”Max. teeth height ft in 38’ 4” 39’4” 41’2”201064Digging force ISO lbf 55,753 48,784 40,690lb 56,879 48,722 41,006Breakout force ISO lbf 70,365 70,365 70,365lb 70,327 70,327 70,3272Breakout force max. ISO77,625 lbf/77,603 lb00-10-2Operating Weightand Ground Pressure-20-4-6Operating weight includes basic machine with gooseneck boom24’11”, stick 9’6” and bucket 2.60 yd 3 .UndercarriageHD-30-8-101412312 10 8 6 4 2 0 m40 30 20 10 0 ftPad width in 20” 24” 30”Weight lb 109,349 110,451 113,316Ground pressure psi 14.93 12.52 10.24Optional: heavy counterweight(<strong>Heavy</strong> counterweight increases the operating weight by 4,400 lb andground pressure by 0.57 psi)BucketsCutting width in 51” 1) 53” 2) 59” 1) 61” 2) 67” 1) 69” 2) 75” 1) 75” 1)Capacity ISO 7451 yd 3 2.15 2.15 2.60 2.60 3.10 3.10 3.50 3.90Weight lb 4,630 5,500 4,960 6,170 5,500 6,700 5,850 6,070Suitable for material up to a specific weight ofwith stick 7’8” lb/yd 3 – – 3,700 3,000 3,000 3,000 2,500 2,000with stick 9’6” lb/yd 3 3,700 3,700 3,000 3,000 2,500 2,500 2,000 –with stick 12’5” lb/yd 3 3,000 3,000 2,500 2,500 2,000 – – –1) Medium-duty bucket with Liebherr teeth size 25 (appropriate for materials up to classification 5, according to VOB, Section C, DIN 18300)2) <strong>Heavy</strong>-duty rock bucket with Esco teeth size 61 (appropriate for materials above classification 6, according to VOB, Section C, DIN 18300)16 R <strong>954</strong> C <strong>Litronic</strong>

Lift Capacitieswith Gooseneck Boom 24’11”Stick 7’8”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HD35 HDStick 9’6”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HD35 HD30 HD16,160x (16,160x)30 HD25 HD17,174x (17,174x) 11,199x (11,199x)25 HD14,793x (14,793x)20 HD18,651x (18,651x) 14,308 (16,777x)20 HD17,108x (17,108x) 14,462 (15,454x)15 HD38,779x (38,779x) 26,301x (26,301x) 18,850 (20,856x) 13,558 (17,857x)15 HD34,260x (34,260x) 24,207x (24,207x) 19,136 (19,423x) 13,669 (16,689x) 9,855 (13,580x)10 HD24,185 (30,622x) 17,306 (23,193x) 12,721 (19,136x)10 HD28,748x (28,748x) 24,912 (28,814x) 17,527 (21,958x) 12,743 (18,144x) 9,392 (15,829x)5 HD22,223 (33,488x) 16,050 (25,089x) 11,971 (20,260x)5 HD20,459x (20,459x) 22,619 (32,320x) 16,138 (24,141x) 11,927 (19,467x) 8,929 (15,807 )0 HD25,530x (25,530x) 21,319 (34,414x) 15,256 (26,125x) 11,464 (20,062 )0 HD27,315x (27,315x) 21,385 (33,995x) 15,190 (25,552x) 11,288 (19,908 ) 8,598 (15,432 )– 5 HD25,948x (25,948x) 34,392 (41,645x) 21,164 (33,731x) 14,947 (26,037x) 11,266 (19,842 )– 5 HD23,149x (23,149x) 33,863 (38,272x) 20,966 (33,951x) 14,727 (25,904x) 10,979 (19,555 )– 10 HD41,<strong>954</strong>x (41,<strong>954</strong>x) 35,164 (40,675x) 21,539 (31,526x) 15,124 (24,626x) 11,508 (19,114x)– 10 HD35,671x (35,671x) 34,480 (43,078x) 21,098 (32,386x) 14,727 (25,000x) 11,023 (19,599 )– 15 HD44,115x (44,115x) 34,899x (34,899x) 22,399 (27,381x) 15,829 (21,054x)– 15 HD49,494x (49,494x) 35,605 (37,920x) 21,738 (29,013x) 15,190 (22,355x)– 20 HD25,375x (25,375x) 19,423x (19,423x)– 20 HD38,735x (38,735x) 29,674x (29,674x) 22,730x (22,730x)– 25 HD– 25 HD– 30 HD– 30 HD– 35 HD– 35 HDStick 12’5”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HD35 HD30 HD25 HD20 HD15 HD10 HD5 HD0 HD– 5 HD– 10 HD– 15 HD– 20 HD– 25 HD10,670x (10,670x)12,500x (12,500x) 6,967x ( 6,967x)13,404x (13,404x) 10,494 (11,971x)16,998x (16,998x) 13,977 (14,815x) 10,031 (13,448x)37,897x (37,897x) 25,640x (25,640x) 18,100 (19,820x) 12,963 (16,491x) 9,436 (14,396x)30,821x (30,821x) 23,523 (29,983x) 16,513 (22,421x) 12,015 (18,100x) 8,863 (15,366x)11,045x (11,045x) 29,123x (29,123x) 21,760 (32,761x) 15,322 (24,383x) 11,222 (19,379x) 8,378 (15,234 )19,753x (19,753x) 33,510 (34,899x) 20,878 (33,797x) 14,573 (25,397x) 10,714 (19,290 ) 8,091 (14,925 )28,836x (28,836x) 33,687 (44,401x) 20,657 (33,246x) 14,308 (25,287x) 10,516 (19,092 ) 8,069 (14,903 )39,264x (39,264x) 34,436 (41,932x) 20,966 (31,019x) 14,462 (23,744x) 10,714 (18,342x)50,089x (50,089x) 35,472x (35,472x) 21,804 (26,610x) 15,146 (20,062x)24,824x (24,824x) 18,100x (18,100x)– 30 HD– 35 HDThe load values are quoted in lb on the backhoe bucket’s load hook, and may be swung 360° on firm and even ground. Values quoted in bracketsapply to the undercarriage when in longitudinal position. Capacities are valid for 24” wide, triple grouser pads. Indicated loads are based onISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via x). Maximum load for the backhoe bucket’slifting eye is 59,525 lb. Without bucket (2.60 yd 3 ), the lift capacities will increase by 4,960 lb, without bucket cylinder, link and lever they increaseby an additional 1,650 lb. Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of theload hook.R <strong>954</strong> C <strong>Litronic</strong> 17

Backhoe Attachmentwith Gooseneck Boom 26’3”ft5040302010m16141210864Digging Envelope 1 2 3Stick lengths ft in 7’8” 9’ 6” 12’5”Max. digging depth ft in 20’4” 22’ 2” 25’1”Max. reach at ground level ft in 40’8” 42’ 6” 45’3”Max. dump height ft in 33’2” 34’ 9” 37’3”Max. teeth height ft in 45’3” 46’11” 49’4”Digging force ISO lbf 55,753 48,784 40,690lb 56,879 48,722 41,006Breakout force ISO lbf 70,365 70,365 70,365lb 70,327 70,327 70,327Breakout force max. ISO77,625 lbf/77,603 lb020Operating Weightand Ground Pressure-10-2-4Operating weight includes basic machine with gooseneck boom 26’3”,stick 9’6” and bucket 2.60 yd 3 .UndercarriageHD-20-6-81412312 10 8 6 4 2 0 m40 30 20 10 0 ftPad width in 20” 24” 30”Weight lb 110,451 111,553 114,418Ground pressure psi 15.08 12.66 10.38Optional: heavy counterweight(<strong>Heavy</strong> counterweight increases the operating weight by 4,400 lb andground pressure by 0.57 psi)BucketsCutting width in 51” 1) 53” 2) 59” 1) 61” 2) 67” 1)Capacity ISO 7451 yd 3 2.15 2.15 2.60 2.60 3.10Weight lb 4,630 5,510 4,960 6,170 5,510Suitable for material up to a specific weight ofwith stick 7’8” lb/yd 3 3,700 3,000 3,000 3,000 2,500with stick 9’6” lb/yd 3 3,700 3,000 3,000 2,500 2,000with stick 12’5” lb/yd 3 3,000 2,500 2,500 2,000 –1) Medium-duty bucket with Liebherr teeth size 25 (appropriate for materials up to classification 5, according to VOB, Section C, DIN 18300)2) <strong>Heavy</strong>-duty rock bucket with Esco teeth size 61 (appropriate for materials above classification 6, according to VOB, Section C, DIN 18300)18 R <strong>954</strong> C <strong>Litronic</strong>

Lift Capacitieswith Gooseneck Boom 26’3”Stick 7’8”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HDStick 9’6”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HD35 HD22,201x (22,201x)35 HD14,793x (14,793x)30 HD25,948x (25,948x) 21,010 (22,090x)30 HD19,952x (19,952x) 13,338x (13,338x)25 HD27,249x (27,249x) 20,415 (22,553x) 14,043 (19,445x)25 HD23,523x (23,523x) 20,790 (21,319x) 14,286 (18,453x)20 HD40,609x (40,609x) 28,307 (29,630x) 19,158 (23,634x) 13,514 (19,798x)20 HD59,922x (59,922x) 37,743x (37,743x) 28,043x (28,043x) 19,511 (22,531x) 13,647 (18,960x) 9,634 (15,278x)15 HD25,022 (32,342x) 17,527 (24,912x) 12,655 (20,327x) 9,193 (16,138)15 HD40,234 (44,754x) 25,904 (31,019x) 17,857 (23,986x) 12,765 (19,643x) 9,215 (16,160 )10 HD22,046 (33,951x) 15,939 (25,794x) 11,773 (20,481 ) 8,774 (15,675)10 HD22,796 (33,290x) 16,182 (25,199x) 11,795 (20,194x) 8,686 (15,609 )5 HD20,349 (33,246x) 14,749 (25,772x) 11,023 (19,665 ) 8,378 (15,256)5 HD20,701 (33,598x) 14,837 (25,596x) 10,957 (19,621 ) 8,223 (15,102 )0 HD19,842 (30,600x) 14,088 (24,560x) 10,582 (19,158 ) 8,157 (15,036)0 HD15,631x (15,631x) 19,798 (31,835x) 13,999 (24,846x) 10,384 (18,982 ) 7,893 (14,749 )– 5 HD26,874x (26,874x) 19,974 (26,676x) 13,933 (22,046x) 10,450 (17,505x)– 5 HD27,646x (27,646x) 19,643 (28,506x) 13,691 (22,840x) 10,141 (18,056x) 7,826 (13,757x)– 10 HD21,627x (21,627x) 20,525 (21,451x) 14,242 (18,056x) 10,737 (13,845x)– 10 HD26,588x (26,588x) 20,018 (23,744x) 13,823 (19,401x) 10,252 (15,102x)– 15 HD14,352x (14,352x) 11,949x (11,949x)– 15 HD18,276x (18,276x) 17,262x (17,262x) 14,154x (14,154x) 9,855x ( 9,855x)– 20 HD– 20 HD– 25 HD– 25 HD– 30 HD– 30 HD– 35 HD– 35 HDStick 12’5”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HD8,708x ( 8,708x)35 HD30 HD25 HD20 HD15 HD10 HD5 HD0 HD– 5 HD– 10 HD– 15 HD– 20 HD14,176x (14,176x) 9,017x ( 9,017x)15,102x (15,102x) 13,691x (13,691x) 5,423x ( 5,423x)16,336x (16,336x) 14,771 (15,763x) 10,229 (12,059x)19,753x (19,753x) 19,687x (19,687x) 14,043 (17,549x) 9,877 (15,256x)40,014x (40,014x) 27,492 (28,594x) 18,563 (22,377x) 13,073 (18,453x) 9,348 (15,653x) 6,570 ( 9,502x)29,740x (29,740x) 24,185 (31,658x) 16,755 (24,008x) 12,015 (19,290x) 8,708 (15,653 ) 6,261 (11,993 )16,028x (16,028x) 21,561 (33,290x) 15,168 (25,022x) 11,045 (19,731 ) 8,113 (15,013 ) 5,952 (11,662 )18,409x (18,409x) 20,018 (32,915x) 14,066 (25,022x) 10,296 (18,916 ) 7,650 (14,528 ) 5,754 (11,442 )13,404x (13,404x) 25,243x (25,243x) 19,423 (30,710x) 13,470 (23,788x) 9,855 (18,431 ) 7,408 (14,242 )22,509x (22,509x) 32,188 (33,400x) 19,445 (26,896x) 13,338 (21,253x) 9,744 (16,623x) 7,408 (12,456x)25,552x (25,552x) 19,952 (21,451x) 13,625 (17,130x) 10,009 (12,963x) 7,871 ( 7,893x)13,867x (13,867x) 10,825x (10,825x) 6,438x (6,438x)– 25 HD– 30 HD– 35 HDThe load values are quoted in lb on the backhoe bucket’s load hook, and may be swung 360° on firm and even ground. Values quoted in bracketsapply to the undercarriage when in longitudinal position. Capacities are valid for 24” wide, triple grouser pads. Indicated loads are based onISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via x). Maximum load for the backhoe bucket’slifting eye is 59,525 lb. Without bucket (2.60 yd 3 ), the lift capacities will increase by 4,960 lb, without bucket cylinder, link and lever they increaseby an additional 1,650 lb. Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of theload hook.R <strong>954</strong> C <strong>Litronic</strong> 19

Backhoe Attachmentwith Gooseneck Boom 30’2” and <strong>Heavy</strong> Counterweightft4030m1412108Digging Envelope 1 2 3*Stick lengths ft in 9’6” 12’5” 16’5”Max. digging depth ft in 31’8” 34’7” 38’1”Max. reach at ground level ft in 46’3” 49’1” 52’2”Max. dump height ft in 31’6” 33’2” 35’1”Max. teeth height ft in 43’2” 44’9” 46’ ”2010642Digging force ISO lbf 48,784 40,690 33,721lb 48,722 41,006 33,731Breakout force ISO lbf 70,365 70,365 53,055lb 70,327 70,327 53,131* with bucket R 944 C00-10-20-30-40-2-4-6-8-10-12123Operating Weightand Ground PressureOperating weight includes basic machine with gooseneck boom 30’2”,stick 12’5” and bucket 2.15 yd 3 .UndercarriagePad width in 20” 24” 30”Weight lb 115,301 116,403 119,268Ground pressure psi 15.65 13.23 10.8HD16141210864 2 0 m50 40 30 20 100 ftBucketsCutting width in 51” 1) 59” 1) 67” 1) 47” 2) 53” 2) 69” 2) 65” 2)Capacity ISO 7451 yd 3 2.15 2.60 3.00 1.60 1.95 2.30 2.60Weight lb 4,630 4,960 5,500 2,980 3,200 3,420 3,700Suitable for material up to a specific weight ofwith stick 9’6” lb/yd 3 3,000 2,500 2,000 – – – –with stick 12’5” lb/yd 3 3,000 2,000 – – – – –with stick 16’5” lb/yd 3 – – – 3,700 3,000 3,000 2,5001) Medium-duty bucket with Liebherr teeth size 25 (appropriate for materials up to classification 5, according to VOB, Section C, DIN 18300)2) Medium-duty bucket from R 944 C litronic` with teeth size 2020 R <strong>954</strong> C <strong>Litronic</strong>

Lift Capacitieswith Gooseneck Boom 30’2” and <strong>Heavy</strong> CounterweightStick 9’6”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HDStick 12’5”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HD35 HD35 HD7,297x ( 7,297x)30 HD10,494x (10,494x)30 HD8,929x ( 8,929x)25 HD11,707x (11,707x) 10,825x (10,825x)25 HD9,304x ( 9,304x) 8,818 ( 8,973x)20 HD29,476x (29,476x) 19,511x (19,511x) 15,256x (15,256x) 12,875x (12,875x) 11,420 (11,442x) 8,333 (10,053x)20 HD11,244x (11,244x) 10,031x (10,031x) 8,510 ( 9,304x)15 HD24,361x (24,361x) 17,725x (17,725x) 14,264 (14,308x) 10,692 (12,280x) 7,981 (11,067x)15 HD20,966x (20,966x) 15,697x (15,697x) 12,787x (12,787x) 10,869 (11,001x) 8,047 ( 9,855x)10 HD20,988x (20,988x) 17,240 (20,128x) 13,051 (15,807x) 9,943 (13,228x) 7,562 (11,596x)10 HD24,758 (25,552x) 17,990 (18,320x) 13,360 (14,418x) 10,031 (12,037x) 7,540 (10,516x) 5,556 (6,680x)5 HD17,130x (17,130x) 15,807 (21,958x) 12,059 (17,086x) 9,304 (14,066x) 7,187 (12,103x)5 HD22,289 (27,029x) 16,270 (20,525x) 12,236 (15,917x) 9,281 (13,051x) 7,055 (11,155x) 5,291 (7,275x)0 HD21,076 (23,589x) 15,036 (22,972x) 11,398 (17,968x) 8,818 (14,705x) 6,900 (12,434x)0 HD21,164 (26,786x) 15,168 (22,024x) 11,376 (17,064x) 8,686 (13,867x) 6,680 (11,685x)– 5 HD14,308x (14,308x) 21,186 (30,093x) 14,749 (23,193x) 11,067 (18,342x) 8,576 (14,969x) 6,812 (12,434x)– 5 HD15,785x (15,785x) 20,834 (30,424x) 14,595 (22,774x) 10,869 (17,769x) 8,311 (14,396x) 6,438 (11,993x)– 10 HD21,517x (21,517x) 28,484x (28,484x) 21,539 (28,881x) 14,837 (22,708x) 11,023 (18,144x) 8,576 (14,727x)– 10 HD17,439x (17,439x) 24,295x (24,295x) 20,944 (29,762x) 14,440 (22,752x) 10,648 (17,924x) 8,135 (14,,506x) 6,393 (11,861x)– 15 HD32,871x (32,871x) 33,753x (33,753x) 22,179 (26,874x) 15,234 (21,407x) 11,332 (17,152x) 8,929 (13,603x)– 15 HD25,772x (25,772x) 33,819x (33,819x) 21,363 (28,307x) 14,617 (21,980x) 10,737 (17,417x) 8,245 (13,977x)– 20 HD37,346x (37,346x) 29,630x (29,630x) 23,193 (23,766x) 16,006 (19,004x) 12,037 (14,903x)– 20 HD35,009x (35,009x) 33,687x (33,687x) 22,134 (25,838x) 15,146 (20,260x) 11,155 (16,006x) 8,752 (12,346x)– 25 HD23,171x (23,171x) 18,695x (18,695x) 14,418x (14,418x)– 25 HD38,096x (38,096x) 28,197x (28,197x) 21,914x (21,914x) 16,094 (17,108x) 12,103 (12,875x)– 30 HD– 30 HD19,709x (19,709x) 15,234x (15,234x)– 35 HD– 35 HDStick 16’5”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HD35 HD30 HD25 HD20 HD15 HD10 HD5 HD0 HD– 5 HD– 10 HD– 15 HD– 20 HD– 25 HD– 30 HD8,863x ( 8,863x)9,061x ( 9,061x) 4,740x ( 4,740x)10,163x (10,163x) 9,546x ( 9,546x) 7,694 ( 8,333x)12,765x (12,765x) 11,244x (11,244x) 9,722 (10,252x) 7,408 ( 9,634x)17,857x (17,857x) 24,074x (24,074x) 17,990x (17,990x) 14,595x (14,595x) 11,839 (12,478x) 9,149 (11,067x) 7,077 (10,119x)10,714x (10,714x) 25,684 (28,263x) 18,783 (20,657x) 14,242 (16,358x) 11,023 (13,669x) 8,598 (11,883x) 6,724 (10,648x)12,677x (12,677x) 23,810 (30,909x) 17,372 (22,708x) 13,228 (17,835x) 10,318 (14,727x) 8,135 (12,610x) 6,415 (11,089x)10,009x (10,009x) 17,130x (17,130x) 22,884 (32,165x) 16,469 (24,008x) 12,522 (18,894x) 9,789 (15,521x) 7,760 (13,140x) 6,217 (11,310 )15,984x (15,984x) 22,840x (22,840x) 22,575 (32,320x) 16,028 (24,560x) 12,125 (19,467x) 9,480 (15,939x) 7,562 (13,382x) 6,173 ( 8,025x)22,179x (22,179x) 29,696x (29,696x) 22,686 (31,548x) 15,961 (24,339x) 12,015 (19,423x) 9,392 (15,873x) 7,562 (13,118x)29,145x (29,145x) 37,611 (38,140x) 23,171 (29,829x) 16,204 (23,281x) 12,170 (18,651x) 9,568 (15,102x)37,457x (37,457x) 35,362x (35,362x) 23,986 (26,874x) 16,799 (21,142x) 12,677 (16,799x) 10,141 (12,985x)39,838x (39,838x) 28,704x (28,704x) 22,090x (22,090x) 17,174x (17,174x) 12,677x (12,677x)– 35 HDThe load values are quoted in lb on the backhoe bucket’s load hook, and may be swung 360° on firm and even ground. Values quoted in bracketsapply to the undercarriage when in longitudinal position. Capacities are valid for 24” wide, triple grouser pads. Indicated loads are based onISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via x). Maximum load for the backhoe bucket’slifting eye is 59,525 lb/46,297 lb*. Without bucket (2.15 yd 3 /2.00 yd 3 *), the lift capacities will increase by 4,630 lb/3,200 lb*, without bucket cylinder,link and lever they increase by an additional 1,650 lb/1,320 lb*. Lifting capacity of the excavator is limited by machine stability, hydraulic capacityand maximum permissible load of the load hook.* only for stick 16’5”R <strong>954</strong> C <strong>Litronic</strong> 21

Backhoe Attachmentwith Gooseneck Boom HD 22’ftm12Digging Envelope 1 2353025108Stick lengths ft in 7’8” 9’6”Max. digging depth ft in 22’9” 24’7”Max. reach at ground level ft in 35’9” 37’5”Max. dump height ft in 23’7” 24’5”Max. teeth height ft in 34’9” 35’9”2015105642Digging force ISO lbf 55,753 48,784lb 56,879 48,722Breakout force ISO lbf 70,365 70,365lb 70,327 70,327Breakout force max. ISO77,625 lbf/77,603 lb0-5-10-15-20-250-2-4-6-81210840 35 30 25 20 15 106124 2 0 m5 0 ftOperating Weightand Ground PressureOperating weight includes basic machine with gooseneck boom HD22’, stick HD 7’8” and bucket 3.10 yd 3 .UndercarriageS-HDPad width in 20” 24” 30”Weight lb 121,693 123,238 125,220Ground pressure psi 16.9 14.2 11.5Optional: heavy counterweight(<strong>Heavy</strong> counterweight increases the operating weight by 4,400 lb andground pressure by 0.57 psi)BucketsCutting width in 53” 1) 61” 1) 69” 1) 77” 1)Capacity ISO 7451 yd 3 2.15 2.60 3.10 3.50Weight lb 5,500 6,170 6,720 7,280Suitable for material up to a specific weight ofwith stick 7’8” lb/yd 3 3,700 3,700 3,700 3,000with stick 9’6” lb/yd 3 3,700 3,700 3,000 2,5001) <strong>Heavy</strong>-duty rock bucket with Esco teeth size 61 (appropriate for materials above classification 6, according to VOB, Section C, DIN 18300)22 R <strong>954</strong> C <strong>Litronic</strong>

Lift Capacitieswith Gooseneck Boom HD 22’Stick 7’8”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 S-HD35 S-HD30 S-HDStick 9’6”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 S-HD35 S-HD30 S-HD25 S-HD16,623x (16,623x)25 S-HD20 S-HD17,571x (17,571x)20 S-HD15,763x (15,763x) 13,162x (13,162x)15 S-HD30,203x (30,203x) 31,813x (31,813x) 23,545x (23,545x) 19,555x (19,555x) 14,749 (17,417x)15 S-HD21,231x (21,231x) 17,880x (17,880x) 14,881 (16,006x)10 S-HD41,447x (41,447x) 28,021 (28,043x) 19,467 (21,936x) 13,999 (18,607x)10 S-HD37,765x (37,765x) 26,015x (26,015x) 19,709 (20,481x) 14,043 (17,394x)5 S-HD39,419 (46,429x) 25,662 (31,725x) 18,122 (24,097x) 13,272 (19,753x)5 S-HD40,653 (45,085x) 26,125 (30,225x) 18,232 (22,928x) 13,206 (18,805x)0 S-HD21,451x (21,451x) 38,228 (48,237x) 24,317 (33,665x) 17,218 (25,463x) 12,787 (20,415x)0 S-HD21,385x (21,385x) 38,537 (47,951x) 24,449 (32,871x) 17,152 (24,714x) 12,588 (19,798x)– 5 S-HD38,074x (38,074x) 38,272 (46,716x) 23,876 (33,731x) 16,843 (25,618x)– 5 S-HD33,400x (33,400x) 38,052 (47,620x) 23,722 (33,665x) 16,601 (25,375x) 12,280 (19,930x)– 10 S-HD54,498x (54,498x) 39,088 (42,880x) 24,185 (31,658x) 17,086 (23,876x)– 10 S-HD46,782x (46,782x) 38,515 (44,798x) 23,744 (32,430x) 16,579 (24,449x)– 15 S-HD49,339x (49,339x) 35,737x (35,737x) 25,353 (26,367x)– 15 S-HD56,218x (56,218x) 38,956x (38,956x) 24,515 (28,506x)– 20 S-HD– 20 S-HD39,132x (39,132x) 27,866x (27,866x)– 25 S-HD– 25 S-HD– 30 S-HD– 30 S-HD– 35 S-HD– 35 S-HDThe load values are quoted in lb on the backhoe bucket’s load hook, and may be swung 360° on firm and even ground. Values quoted in bracketsapply to the undercarriage when in longitudinal position. Capacities are valid for 24” wide, double grouser pads. Indicated loads are based onISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via x). Maximum load for the backhoe bucket’slifting eye is 59,525 lb. Without bucket (3.10 yd 3 ), the lift capacities will increase by 6,170 lb without bucket cylinder, link and lever they increase byan additional 1,650 lb. Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of theload hook.R <strong>954</strong> C <strong>Litronic</strong> 23

Backhoe Attachmentwith Gooseneck Boom HD 24’11”ft40m12Digging Envelope 1 2Stick lengths ft in 7’ 8” 9’6”30108Max. digging depth ft in 24’ 7” 26’5”Max. reach at ground level ft in 38’10” 40’8”Max. dump height ft in 27’ 1” 28’Max. teeth height ft in 38’ 8” 39’8”201064Digging force ISO lbf 55,753 48,784lb 56,879 48,722Breakout force ISO lbf 70,365 70,365lb 70,327 70,3272Breakout force max. ISO77,625 lbf/77,603 lb00-10-2Operating Weightand Ground Pressure-20-4-6Operating weight includes basic machine with gooseneck boom HD24’11”, stick HD 7’8” and bucket 2.60 yd 3 .UndercarriageS-HD-814121081264 2 0 mPad width in 20” 24” 30”Weight lb 122,795 124,340 126,323Ground pressure psi 17.1 14.4 11.740 30 20 100 ftOptional: heavy counterweight(<strong>Heavy</strong> counterweight increases the operating weight by 4,400 lb andground pressure by 0.57 psi)BucketsCutting width in 53” 1) 61” 1) 69” 1)Capacity ISO 7451 yd 3 2.15 2.60 3.10Weight lb 5,500 6,170 6,720Suitable for material up to a specific weight ofwith stick 7’8” lb/yd 3 3,700 3,000 3,000with stick 9’6” lb/yd 3 3,700 3,000 2,5001) <strong>Heavy</strong>-duty rock bucket with Esco teeth size 61 (appropriate for materials above classification 6, according to VOB, Section C, DIN 18300)24 R <strong>954</strong> C <strong>Litronic</strong>

Lift Capacitieswith Gooseneck Boom HD 24’11”Stick 7’8”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 S-HD35 S-HD30 S-HDStick 9’6”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 S-HD35 S-HD30 S-HD25 S-HD15,521x (15,521x) 13,272x (13,272x)25 S-HD13,051x (13,051x)20 S-HD16,932x (16,932x) 14,727 (14,991x)20 S-HD15,454x (15,454x) 13,735x (13,735x) 7,716x ( 7,716x)15 S-HD36,046x (36,046x) 24,251x (24,251x) 18,960x (18,960x) 13,845 (16,028x)15 S-HD32,011x (32,011x) 22,289x (22,289x) 17,593x (17,593x) 13,977 (14,903x) 9,899 (13,294x)10 S-HD24,934 (28,153x) 17,703 (21,120x) 12,853 (17,218x) 9,370 (13,735x)10 S-HD28,947x (28,947x) 25,794 (26,500x) 17,990 (19,930x) 12,919 (16,248x) 9,348 (13,977x)5 S-HD22,686 (30,755x) 16,248 (22,840x) 11,993 (18,254x) 8,951 (15,102x)5 S-HD20,900x (20,900x) 23,215 (29,696x) 16,402 (21,958x) 11,971 (17,483x) 8,796 (14,617x)0 S-HD26,235x (26,235x) 21,671 (31,570x) 15,366 (23,766x) 11,420 (18,827x)0 S-HD27,161x (27,161x) 21,804 (31,195x) 15,344 (23,215x) 11,266 (18,298x) 8,422 (14,947x)– 5 S-HD25,728x (25,728x) 35,318 (41,028x) 21,495 (30,887x) 15,036 (23,634x) 11,199 (18,607x)– 5 S-HD22,597x (22,597x) 34,833 (37,655x) 21,319 (31,129x) 14,815 (23,501x) 10,891 (18,431x)– 10 S-HD40,852x (40,852x) 36,266 (37,457x) 21,936 (28,748x) 15,234 (22,245x) 11,486 (17,064x)– 10 S-HD34,679x (34,679x) 35,561 (39,771x) 21,495 (29,586x) 14,815 (22,619x) 10,957 (17,505x)– 15 S-HD40,477x (40,477x) 31,769x (31,769x) 22,950 (24,736x) 16,072 (18,783x)– 15 S-HD47,245x (47,245x) 34,723x (34,723x) 22,267 (26,301x) 15,366 (20,040x)– 20 S-HD22,443x (22,443x) 16,976x (16,976x)– 20 S-HD34,987x (34,987x) 26,654x (26,654x) 20,194x (20,194x)– 25 S-HD– 25 S-HD– 30 S-HD– 30 S-HD– 35 S-HD– 35 S-HDThe load values are quoted in lb on the backhoe bucket’s load hook, and may be swung 360° on firm and even ground. Values quoted in bracketsapply to the undercarriage when in longitudinal position. Capacities are valid for 24” wide, double grouser pads. Indicated loads are based onISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via x). Maximum load for the backhoe bucket’slifting eye is 59,525 lb. Without bucket (2.60 yd 3 ), the lift capacities will increase by 6,170 lb without bucket cylinder, link and lever they increase byan additional 1,650 lb. Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of theload hook.R <strong>954</strong> C <strong>Litronic</strong> 25

Lift Capacitieswith Gooseneck Boom 22’ and <strong>Heavy</strong> CounterweightStick 7’8”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HD35 HD30 HDStick 9’6”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HD35 HD30 HD25 HD15,587x (15,587x)25 HD20 HD18,783x (18,783x)20 HD16,887x (16,887x) 12,214x (12,214x)15 HD25,926x (25,926x) 33,224x (33,224x) 24,824x (24,824x) 20,812x (20,812x) 16,028 (16,292x)15 HD22,421x (22,421x) 19,092x (19,092x) 16,138 (17,262x)10 HD43,563x (43,563x) 29,586x (29,586x) 21,032 (23,303x) 15,388 (19,930x)10 HD39,573x (39,573x) 27,448x (27,448x) 21,231 (21,804x) 15,410 (18,695x)5 HD42,571 (45,900x) 27,844 (33,510x) 19,864 (25,596x) 14,771 (21,120x)5 HD43,630 (47,444x) 28,219 (31,923x) 19,930 (24,405x) 14,683 (20,150x)0 HD41,535 (50,772x) 26,632 (35,605x) 19,048 (27,073x) 14,330 (21,804x)0 HD21,120x (21,120x) 41,756 (50,464x) 26,720 (34,767x) 18,982 (26,279x) 14,132 (21,186x)– 5 HD38,471x (38,471x) 41,579 (49,185x) 26,235 (35,693x) 18,717 (27,249x)– 5 HD33,753x (33,753x) 41,337 (50,111x) 26,059 (35,605x) 18,453 (27,007x) 13,867 (21,341x)– 10 HD55,292x (55,292x) 42,307 (45,283x) 26,500 (33,621x) 18,938 (25,485x)– 10 HD47,444x (47,444x) 41,734 (47,223x) 26,081 (34,392x) 18,453 (26,081x)– 15 HD52,161x (52,161x) 38,030x (38,030x) 27,514 (28,219x)– 15 HD59,194x (59,194x) 41,293x (41,293x) 26,742 (30,402x)– 20 HD– 20 HD41,910x (41,910x) 30,027x (30,027x)– 25 HD– 25 HD– 30 HD– 30 HD– 35 HD– 35 HDStick 12’5”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HD35 HD30 HD25 HD20 HD15 HD10 HD5 HD0 HD– 5 HD– 10 HD– 15 HD– 20 HD9,348x ( 9,348x)13,470x (13,470x)16,204x (16,204x) 14,925x (14,925x) 7,584x ( 7,584x)47,840x (47,840x) 32,761x (32,761x) 23,678x (23,678x) 19,224x (19,224x) 15,609 (16,667x) 10,670x (10,670x)17,505x (17,505x) 42,659x (42,659x) 28,947x (28,947x) 20,260 (22,267x) 14,749 (18,475x) 10,957 (12,192x)21,120x (21,120x) 42,637 (48,458x) 27,139 (32,871x) 19,070 (24,758x) 14,021 (19,996x) 10,582 (11,067x)28,947x (28,947x) 41,337 (50,354x) 26,037 (34,921x) 18,298 (26,257x) 13,558 (20,856x)38,845x (38,845x) 41,138 (49,295x) 25,640 (35,009x) 17,968 (26,411x) 13,404 (20,569x)51,235x (51,235x) 41,756 (45,371x) 25,882 (32,783x) 18,166 (24,560x)55,204x (55,204x) 37,567x (37,567x) 26,852 (27,051x)– 25 HD– 30 HD– 35 HDThe load values are quoted in lb on the backhoe bucket’s load hook, and may be swung 360° on firm and even ground. Values quoted in bracketsapply to the undercarriage when in longitudinal position. Capacities are valid for 24” wide, triple grouser pads. Indicated loads are based onISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via x). Maximum load for the backhoe bucket’slifting eye is 59,525 lb. Without bucket (3.10 yd 3 ), the lift capacities will increase by 5,510 lb, without bucket cylinder, link and lever they increaseby an additional 1,650 lb. Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of theload hook.26 R <strong>954</strong> C <strong>Litronic</strong>

Lift Capacitieswith Gooseneck Boom 24’11” and <strong>Heavy</strong> CounterweightStick 7’8”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HD35 HDStick 9’6”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HD35 HD30 HD16,160x (16,160x)30 HD25 HD17,174x (17,174x) 11,199x (11,199x)25 HD14,793x (14,793x)20 HD18,651x (18,651x) 16,402 (16,777x)20 HD17,108x (17,108x) 15,454x (15,454x)15 HD38,779x (38,779x) 26,301x (26,301x) 20,856x (20,856x) 15,675 (17,857x)15 HD34,260x (34,260x) 24,207x (24,207x) 19,423x (19,423x) 15,763 (16,689x) 11,596 (13,580x)10 HD27,690 (30,622x) 19,930 (23,193x) 14,815 (19,136x)10 HD28,748x (28,748x) 28,418 (28,814x) 20,150 (21,958x) 14,859 (18,144x) 11,133 (15,829x)5 HD25,728 (33,488x) 18,673 (25,089x) 14,066 (20,260x)5 HD20,459x (20,459x) 26,125 (32,320x) 18,761 (24,141x) 14,021 (19,467x) 10,670 (16,513x)0 HD25,530x (25,530x) 24,824 (34,414x) 17,880 (26,125x) 13,558 (20,900x)0 HD27,315x (27,315x) 24,890 (33,995x) 17,813 (25,552x) 13,404 (20,371x) 10,340 (16,865x)– 5 HD25,948x (25,948x) 39,683 (41,645x) 24,670 (33,731x) 17,571 (26,037x) 13,360 (20,723x)– 5 HD23,149x (23,149x) 38,272x (38,272x) 24,471 (33,951x) 17,350 (25,904x) 13,073 (20,547x)– 10 HD41,<strong>954</strong>x (41,<strong>954</strong>x) 40,455 (40,675x) 25,022 (31,526x) 17,747 (24,626x) 13,603 (19,114x)– 10 HD35,671x (35,671x) 39,749 (43,078x) 24,604 (32,386x) 17,350 (25,000x) 13,118 (19,621x)– 15 HD44,115x (44,115x) 34,899x (34,899x) 25,904 (27,381x) 18,453 (21,054x)– 15 HD49,494x (49,494x) 37,920x (37,920x) 25,243 (29,013x) 17,813 (22,355x)– 20 HD25,375x (25,375x) 19,423x (19,423x)– 20 HD38,735x (38,735x) 29,674x (29,674x) 22,730x (22,730x)– 25 HD– 25 HD– 30 HD– 30 HD– 35 HD– 35 HDStick 12’5”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HD35 HD30 HD25 HD20 HD15 HD10 HD5 HD0 HD– 5 HD– 10 HD– 15 HD– 20 HD– 25 HD10,670x (10,670x)12,500x (12,500x) 6,967x ( 6,967x)13,404x (13,404x) 11,971x (11,971x)16,998x (16,998x) 14,815x (14,815x) 11,773 (13,448x)37,897x (37,897x) 25,640x (25,640x) 19,820x (19,820x) 15,080 (16,491x) 11,177 (14,396x)30,821x (30,821x) 27,029 (29,983x) 19,136 (22,421x) 14,110 (18,100x) 10,604 (15,366x)11,045x (11,045x) 29,123x (29,123x) 25,265 (32,761x) 17,946 (24,383x) 13,316 (19,379x) 10,119 (16,094x)19,753x (19,753x) 34,899x (34,899x) 24,383 (33,797x) 17,196 (25,397x) 12,809 (20,062x) 9,833 (16,358x)28,836x (28,836x) 38,956 (44,401x) 24,163 (33,246x) 16,932 (25,287x) 12,610 (19,886x) 9,811 (15,146x)39,264x (39,264x) 39,705 (41,932x) 24,471 (31,019x) 17,086 (23,744x) 12,809 (18,342x)50,089x (50,089x) 35,472x (35,472x) 25,309 (26,610x) 17,769 (20,062x)24,824x (24,824x) 18,100x (18,100x)– 30 HD– 35 HDThe load values are quoted in lb on the backhoe bucket’s load hook, and may be swung 360° on firm and even ground. Values quoted in bracketsapply to the undercarriage when in longitudinal position. Capacities are valid for 24” wide, triple grouser pads. Indicated loads are based onISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via x). Maximum load for the backhoe bucket’slifting eye is 59,525 lb. Without bucket (2.60 yd 3 ), the lift capacities will increase by 4,960 lb, without bucket cylinder, link and lever they increaseby an additional 1,650 lb. Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of theload hook.R <strong>954</strong> C <strong>Litronic</strong> 27

Lift Capacitieswith Gooseneck Boom 26’3” and <strong>Heavy</strong> CounterweightStick 7’8”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HDStick 9’6”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HD35 HD22,201x (22,201x)35 HD14,793x (14,793x)30 HD25,948x (25,948x) 22,090x (22,090x)30 HD19,952x (19,952x) 13,338x (13,338x)25 HD27,249x (27,249x) 22,553x (22,553x) 16,160 (19,445x)25 HD23,523x (23,523x) 21,,319x (21,319x) 16,402 (18,453x)20 HD40,609x (40,609x) 29,630x (29,630x) 21,782 (23,634x) 15,609 (19,798x)20 HD59,922x (59,922x) 37,743x (37,743x) 28,043x (28,043x) 22,134 (22,531x) 15,763 (18,960x) 11,376 (15,278x)15 HD28,528 (32,342x) 20,150 (24,912x) 14,771 (20,327x) 10,935 (17,064x)15 HD44,754x (44,754x) 29,410 (31,019x) 20,481 (23,986x) 14,859 (19,643x) 10,957 (16,557x)10 HD25,552 (33,951x) 18,563 (25,794x) 13,867 (20,679x) 10,516 (16,998x)10 HD26,301 (33,290x) 18,805 (25,199x) 13,889 (20,194x) 10,428 (16,667x)5 HD23,854 (33,246x) 17,372 (25,772x) 13,140 (20,525x) 10,119 (16,513x)5 HD24,207 (33,598x) 17,461 (25,596x) 13,051 (20,305x) 9,965 (16,424x)0 HD23,347 (30,600x) 16,711 (24,560x) 12,677 (19,555x) 9,921 (15,278x)0 HD15,631x (15,631x) 23,303 (31,835x) 16,623 (24,846x) 12,478 (19,665x) 9,634 (15,587x)– 5 HD26,874x (26,874x) 23,479 (26,676x) 16,557 (22,046x) 12,544 (17,505x)– 5 HD27,646x (27,646x) 23,149 (28,506x) 16,314 (22,840x) 12,236 (18,056x) 9,568 (13,757x)– 10 HD21,627x (21,627x) 21,451x (21,451x) 16,865 (18,056x) 12,831 (13,845x)– 10 HD26,588x (26,588x) 23,523 (23,744x) 16,446 (19,401x) 12,346 (15,102x)– 15 HD14,352x (14,352x) 11,949x (11,949x)– 15 HD18,276x (18,276x) 17,262x (17,262x) 14,154x (14,154x) 9,855x ( 9,855x)– 20 HD– 20 HD– 25 HD– 25 HD– 30 HD– 30 HD– 35 HD– 35 HDStick 12’5”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 HD8,708x ( 8,708x)35 HD30 HD25 HD20 HD15 HD10 HD5 HD0 HD– 5 HD– 10 HD– 15 HD– 20 HD14,176x (14,176x) 9,017x ( 9,017x)15,102x (15,102x) 13,691x (13,691x) 5,423x ( 5,423x)16,336x (16,336x) 15,763x (15,763x) 11,971 (12,059x)19,753x (19,753x) 19,687x (19,687x) 16,138 (17,549x) 11,640 (15,256x)40,014x (40,014x) 28,594x (28,594x) 21,186 (22,377x) 15,168 (18,453x) 11,089 (15,653x) 8,069 ( 9,502x)29,740x (29,740x) 27,690 (31,658x) 19,379 (24,008x) 14,110 (19,290x) 10,450 (16,006x) 7,760 (12,170x)16,028x (16,028x) 25,067 (33,290x) 17,791 (25,022x) 13,140 (19,798x) 9,877 (16,116x) 7,452 (13,095x)18,409x (18,409x) 23,523 (32,915x) 16,689 (25,022x) 12,390 (19,687x) 9,414 (15,763x) 7,253 (12,302x)13,404x (13,404x) 25,243x (25,243x) 22,928 (30,710x) 16,094 (23,788x) 11,949 (18,717x) 9,149 (14,683x)22,509x (22,509x) 33,400x (33,400x) 22,950 (26,896x) 15,961 (21,253x) 11,839 (16,623x) 9,149 (12,456x)25,552x (25,552x) 21,451x (21,451x) 16,248 (17,130x) 12,103 (12,963x) 7,893x ( 7,893x)13,867x (13,867x) 10,825x (10,825x) 6,438x ( 6,438x)– 25 HD– 30 HD– 35 HDThe load values are quoted in lb on the backhoe bucket’s load hook, and may be swung 360° on firm and even ground. Values quoted in bracketsapply to the undercarriage when in longitudinal position. Capacities are valid for 24” wide, triple grouser pads. Indicated loads are based onISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via x). Maximum load for the backhoe bucket’slifting eye is 59,525 lb. Without bucket (2.60 yd 3 ), the lift capacities will increase by 4,960 lb, without bucket cylinder, link and lever they increaseby an additional 1,650 lb. Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of theload hook.28 R <strong>954</strong> C <strong>Litronic</strong>

Lift Capacitieswith Gooseneck Boom HD 22’ and <strong>Heavy</strong> CounterweightStick 7’8”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 S-HD35 S-HD30 S-HDStick 9’6”Height Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 S-HD35 S-HD30 S-HD25 S-HD16,623x (16,623x)25 S-HD20 S-HD17,571x (17,571x)20 S-HD15,763x (15,763x) 13,162x (13,162x)15 S-HD30,203x (30,203x) 31,813x (31,813x) 23,545x (23,545x) 19,555x (19,555x) 16,843 (17,417x)15 S-HD21,231x (21,231x) 17,880x (17,880x) 16,006x (16,006x)10 S-HD41,447x (41,447x) 28,043x (28,043x) 21,936x (21,936x) 16,094 (18,607x)10 S-HD37,765x (37,765x) 26,015x (26,015x) 20,481x (20,481x) 16,138 (17,394x)5 S-HD44,732 (46,429x) 29,189 (31,725x) 20,768 (24,097x) 15,388 (19,753x)5 S-HD45,085x (45,085x) 29,652 (30,225x) 20,878 (22,928x) 15,322 (18,805x)0 S-HD21,451x (21,451x) 43,541 (48,237x) 27,844 (33,665x) 19,842 (25,463x) 14,881 (20,415x)0 S-HD21,385x (21,385x) 43,850 (47,951x) 27,977 (32,871x) 19,798 (24,714x) 14,705 (19,798x)– 5 S-HD38,074x (38,074x) 43,585 (46,716x) 27,403 (33,731x) 19,489 (25,618x)– 5 S-HD33,400x (33,400x) 43,365 (47,620x) 27,249 (33,665x) 19,224 (25,375x) 14,396 (19,930x)– 10 S-HD54,498x (54,498x) 42,880x (42,880x) 27,712 (31,658x) 19,731 (23,876x)– 10 S-HD46,782x (46,782x) 43,828 (44,798x) 27,271 (32,430x) 19,224 (24,449x)– 15 S-HD49,339x (49,339x) 35,737x (35,737x) 26,367x (26,367x)– 15 S-HD56,218x (56,218x) 38,956x (38,956x) 28,043 (28,506x)– 20 S-HD– 20 S-HD39,132x (39,132x) 27,866x (27,866x)– 25 S-HD– 25 S-HD– 30 S-HD– 30 S-HD– 35 S-HD– 35 S-HDThe load values are quoted in lb on the backhoe bucket’s load hook, and may be swung 360° on firm and even ground. Values quoted in bracketsapply to the undercarriage when in longitudinal position. Capacities are valid for 24” wide, double grouser pads. Indicated loads are based onISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via x). Maximum load for the backhoe bucket’slifting eye is 59,525 lb. Without bucket (3.10 yd 3 ), the lift capacities will increase by 6,170 lb without bucket cylinder, link and lever they increaseby an additional 1,650 lb. Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissible load of theload hook.R <strong>954</strong> C <strong>Litronic</strong> 29

Shovel Attachmentft3025m108Digging EnvelopeMax. reach at ground level 27’11”Max. dump height 20’ 8”Max. crowd length 11’ 1”Bucket opening width T 5’ 5”201564TMax. crowd forceMax. crowd force at ground levelMax. breakout force97,792 lbf/97,665 lb61,822 lbf/61,730 lb79,807 lbf/79,807 lb1052Operating Weightand Ground Pressure0-50-2Operating weight includes basic machine with cab elevation, shovelattachment and bottom dump bucket 4.10 yd 3 , level II.UndercarriageHD-10-410864 2 0 mPad width in 20” 24”Weight lb 119,048 120,150Ground pressure psi 16.2 13.730 25 2015105 0ftBottom Dump BucketCutting width SAE in 73” 73” 85” 85” 85”Capacity SAE yd 3 3.30 3.30 4.10 4.10 4.10Weight lb 10,582 11,354 11,023 12,346 13,007Suitable for material up to a specific weight of lb/yd 3 3,700 3,700 3,000 3,000 3,00Wear kit level II III I II ILevel I: For non-abrasive materials, such as limestone without flint inclusion, shot material or easily breakable rock, i.e., deteriorated rock, softlimestone, shale, etc.Level II: For pre-blasted heavy rock, or deteriorated, cracked material (classification 3 to 4, accord. to DIN 18300).Level III: For highly-abrasive materials such as rock with a high silica content, sandstone etc. R <strong>954</strong> C <strong>Litronic</strong> 31

Shovel AttachmentSuper Mass Excavationft3025m108Digging EnvelopeMax. reach at ground level 27’11”Max. dump height 20’ 8”Max. crowd length 11’ 1”Bucket opening width T 5’ 5”201564TMax. crowd forceMax. crowd force at ground levelMax. breakout force97,792 lbf/97,665 lb61,822 lbf/61,730 lb79,807 lbf/79,807 lb1052Operating Weightand Ground Pressure0-5-100-2-410864 2 0 mOperating weight includes basic machine with heavy counterweight,cab elevation, shovel attachment and bottom dump bucket 4.10 yd 3 ,level II.UndercarriageS-HDPad width in 20” 24”Weight lb 135,362 136,907Ground pressure psi 18.8 15.830 25 2015105 0ftBottom Dump BucketCutting width SAE in 85” 85”Capacity SAE yd 3 4.60 4.60Weight lb 13,889 14,660Suitable for material up to a specific weight of lb/yd 3 3,000 3,000Wear kit level II IIILevel I: For non-abrasive materials, such as limestone without flint inclusion, shot material or easily breakable rock, i.e., deteriorated rock, softlimestone, shale, etc.Level II: For pre-blasted heavy rock, or deteriorated, cracked material (classification 3 to 4, accord. to DIN 18300).Level III: For highly-abrasive materials such as rock with a high silica content, sandstone etc.32 R <strong>954</strong> C <strong>Litronic</strong>

Abmessungen SMEFEDA1AW1HC C1KQPV1LUZNSBGX1HD ft in S-HD ft inA 10’11” 10’11”A1 11’ 4” 11’ 4”C 13’ 5” 13’ 9”C1 14’ 14’ 4”D 12’ 8” 12’ 8”E 12’ 8” 12’ 8”F 7’ 3” 7’ 3”H 9’ 6” 9’11”K 4’ 5” 4’ 9”L 14’ 5” 14’ 1”P 3’10” 4’ 3”HD ft in S-HD ft inQ 21” 24”S 9’ 6” 9’ 6”U 17’ 8” 17’ 6”Z 21’ 8” 21’ 4”N 20” 24” 30” 20” 24” 30”B 11’ 7” 11’ 7” 12’ 11’11” 11’11” 12’G 12’ 2” 12’ 2” 12’ 2” 12’ 6” 12’ 6” 12’ 6”V1 33’ 8” 33’ 6”W1 12’ 12’ 2”X1 40’ 6” 40’ 6” R <strong>954</strong> C <strong>Litronic</strong> 33

Backhoe AttachmentSuper Mass Excavation with Gooseneck Boom 22’ SMEand <strong>Heavy</strong> Counterweightftm12Digging Envelope353025108Stick lengths ft in 9’ 2”SMEMax. digging depth ft in 24’ 7”Max. reach at ground level ft in 36’11”Max. dump height ft in 23’11”Max. teeth height ft in 33’ 4”20151064Digging force ISO lbf 64,520lb 64,595Breakout force ISO lbf 77,784lb 77,823520-5-10-150-2-4Operating Weightand Ground PressureOperating weight includes basic machine with heavy counterweight,gooseneck boom SME 22’, stick SME 9’2” and bucket HD 4.30 yd 3 .UndercarriageS-HD-20-25-6-81210864 2 0 mPad width in 20” 24” 30”Weight lb 129,630 131,174 133,157Ground pressure psi 17.9 15.2 12.440 35 30 25 20 15 105 0 ftBuckets HD HD-VCutting width SAE in 83” 1) 89” 1) 77” 2)Capacity ISO 7451 yd 3 4.30 4.60 3.90Weight lb 7,826 8,377 9,039Suitable for material up to a specific weight of lb/yd 3 3,000 2,700 3,0001) <strong>Heavy</strong> duty rock bucket with teeth size V 61 SD (appropriate for material above classification 6, according to VOB, section C DIN 18300)2) HD-V rock bucket with teeth size V 61 SD (appropriate for material above classification 6, according to VOB, section C DIN 18300)34 R <strong>954</strong> C <strong>Litronic</strong>

Lift CapacitiesSuper Mass Excavation with Gooseneck Boom 22’ SMEand <strong>Heavy</strong> CounterweightStick 9’2” SMEHeight Under- Radius of load from centerline of machine (ft)(ft) carriage 10 15 20 25 30 35 40 4540 S-HD35 S-HD30 S-HD25 S-HD20 S-HD15 S-HD10 S-HD5 S-HD0 S-HD– 5 S-HD– 10 S-HD– 15 S-HD– 20 S-HD14,440x (14,440x) 11,861x (11,861x)19,753x (19,753x) 16,292x (16,292x) 14,418x (14,418x)35,847x (35,847x) 24,030x (24,030x) 18,563x (18,563x) 14,595 (15,587x)42,174x (42,174x) 27,381 (27,756x) 19,026 (20,723x) 13,691 (16,755x)30,887x (30,887x) 40,940 (44,225x) 25,684 (29,983x) 17,880 (22,223x) 13,051 (17,549x)48,325x (48,325x) 40,675 (43,387x) 25,022 (30,424x) 17,350 (22,641x) 12,809 (17,461x)59,282x (59,282x) 40,190x (40,190x) 25,199 (28,903x) 17,483 (21,451x)48,678x (48,678x) 33,973x (33,973x) 24,582x (24,582x)22,024x (22,024x)– 25 S-HD– 30 S-HD– 35 S-HDThe load values are quoted in lb on the backhoe bucket’s load hook, and may be swung 360° on firm and even ground. Values quoted in bracketsapply to the undercarriage when in longitudinal position. Capacities are valid for 24” wide, double-grouser pads. Indicated loads are based onISO 10567 standard and do not exceed 75 % of tipping or 87 % of hydraulic capacity (indicated via x). Maximum load for the backhoe bucket’slifting eye is 59,525 lb. Without bucket HD (4.30 yd 3 ), the lift capacities will increase by 7,826 lb, without bucket cylinder, link and lever theyin crease by an additional 2,050 lb. Lifting capacity of the excavator is limited by machine stability, hydraulic capacity and maximum permissibleload of the load hook.R <strong>954</strong> C <strong>Litronic</strong> 35

<strong>Equipment</strong>UndercarriageTwo-stage travel motorsThree track guides per track frameLifetime lubricated track rollersTracks sealed and greasedIdler protectionPads 24”Pads 20”Pads 30”Different undercarriage versionsFour track guideStrong bottom sheet center partRenforced coverUppercarriageLockable tool boxHandrails, non slip surfacesTool kitMaintenance-free swing brake lockMaintenance-free HD-batteriesMain switch for electric circuitSound insulationElectric re-fueling pumpFoot pedal swing positioning brakeCustomized colors<strong>Heavy</strong> CounterweightHydraulicsElectronic pump regulationStep less work mode selectorAccumulator for controlled attachment lowering with engine turned-offFilter with integrated fine filter area (5 µm)Pressure test portsLeakage filterLiebherr Tool ControlHydraulic tank shut-off valvePressure compensationFlow compensationAdditional hydraulic circuitsBio-degradable hydr. oilFilter for secondary circuitEngineAfter-cooledUnit pump systemTurbo chargerDry-type air cleaner w/pre-cleaner, main and safety elementAir filter with automatic dust ejectorTwo hydrostatic fansSensor controlled engine idlingFuel water separatorConform with standard level IIIA / Tier 3Engine cold starting aidS = Standard, O = OptionS O••••••••••••S O•••••••••••S O•••••••••••••S O••••••••••Operator’s CabLoad bearing sectional profile structureRoof right window and windshield armoredTinted windowsRight window made of one piece (without post)Door with sliding windowRain hood over front window openingWiper bladesEmergecy exit rear windowSun blindsSeat and consoles independently adjustable (6-way adjustable seat)Storage trayClosed storage spaceCoat hookRemovable foot matDome lightCigarette lighter and ashtraySeat beltMechanical hour meters, readable from outside the cabDisplays for engine operating conditionAutomatic air conditioning with defrosterRadio installationRadio stereoCoolerSun shadeHeatAdditional flood lights (front/back)Wiper for lower windowRoof window wiperBullet proof window (fixed installation – can not be opened)Upper protection guard (FOPS)Air power seat adjustment with heated cushionElectronic theft protectionBeaconExtinguisherAttachmentOptions and/or special attachments, supplied by vendors other than Liebherr, are only to be installed with theknowledge and approval of Liebherr to retain warranty.S O••••••••••••••••••••••••••••••••••S OSemi-automatic central lubrication system (except link and tilt geometry) •Cylinders with shock absorbers•ReGeneration plus•SAE split flanges on all high pressure lines•Two flood lights on boom•Sealed pivots/O-ring sealant between bucket and stick•59,525 lb lift eye on bucket or on quick change coupler •Automatic central lubrication system (except link and tilt geometry)•Central lubrication for lever with protection cover•Bucket kinematics sealed up completely•Overload warning device•Hydr. or mechanical quick change coupler•Likufix•Piston rod protection•Hydraulic lines for additional tools•Quick disconnect hose couplers for additional tools•Liebherr line of buckets•Special application buckets•Customized colors•Printed in Germany by Höhn RG-BK-RP LFR/SP 10450936-1-04.09 All illustrations and data may differ from standard equipment. Subject to change without notice. All indicated loads are based in accordance with ISO 9248.Liebherr Construction <strong>Equipment</strong> Co.4100 Chestnut Avenue, Newport News, VA 23607, USA (757) 245 5251, Fax (757) 928 8701www.liebherr.us, E-Mail: info.lce@liebherr.com