Vaderstad Rapid Super XL Drill Brochure - LiveUpdater

Vaderstad Rapid Super XL Drill Brochure - LiveUpdater

Vaderstad Rapid Super XL Drill Brochure - LiveUpdater

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

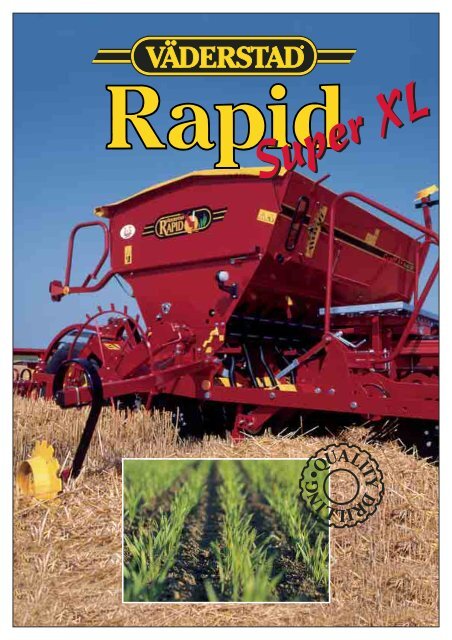

<strong>Super</strong> <strong>XL</strong>QUALITY DRILLING•

In partnership withEuropean agricultureVäderstad is a family owned Swedish manufacturing company started in1962 by Rune and Siw Stark to produce equipment for local farmers. Fromthese humble beginnings the company has grown to occupy a 26,000m 2state-of-the-art factory employing more than 370 dedicated and highlyskilled staff.Working in partnership with the farmer, our aim is to ensure that themachine performs in accordance with expectations, and as a company ourobjective is to strive for excellence, and to enhance the European farmingcommunity’s competitiveness globally.For example, our objective with the <strong>Rapid</strong> drills is to build versatile andprecise drilling tools that have an unsurpassed level of performance in allworking conditions, such as direct drilling, working in trash or on lightand heavy ploughed land.The <strong>Rapid</strong> drill has won several awards and the most important being thatthere are more than 10000 satisfied customers who underwrite the performanceand high engineering quality of the drill.Väderstad <strong>Rapid</strong> was in 2004 awarded by theRASE (Royal Agricultural Society of England)with a gold medal, motivated by the contributionthe machine has made to the agriculturein United Kingdom.

More than 10000Väderstad <strong>Rapid</strong> <strong>Drill</strong>sare working acrossEurope!

Large capacity and ability to workin virtually all types of conditionsare significant trademarks for the<strong>Rapid</strong> System. An extremely largehopper (up to 4250 litres) and thecapability of high working speedsprovide you with an superior output.This is due to the fact that theuniquely designed disc and coulterarrangement keeps an exact depthcontrol without affecting the performance.The front toolbars togetherwith the discs and coulterscreate an establishment second tonone. The penetration is secured inthe toughest conditions by usingthe sheer weight of the machinefor an exact seed placement, thusproviding you with great potentialfor direct drilling when the conditionsare right.The tractor and packer wheels infront of the <strong>Rapid</strong> achieve a considerableamount of tillage and consolidation.The front toolbars continuethe work and the discs millup a perfect seedbed in the actualrow which finally is firmed up bythe press wheels behind the <strong>Rapid</strong>.This ensures the all important soilseedcontact. All this done in onepass at great speed.Fertiliser placementWith the <strong>Rapid</strong>-<strong>Super</strong> <strong>XL</strong>, you havethe option to choose either a combinationfertiliser/seed drill C or aplain seed drill S. Regardless ofyour choice, you will have a drillwhich will provide you with countlesspossibilities in order to makeyour seed establishment substantiallymore efficient.A fertiliser placement drill optimisesthe nutrition in an environmentallyand economically soundapproach. This feature can also beutilised during autumn drillingwhen applying P and K.

Step 1A <strong>Rapid</strong> with efficient toolbarswhich stretch the limitEfficient toolbars are one of thecornerstones of the <strong>Rapid</strong> concept.The <strong>Rapid</strong> can be optimised for anycondition. The seed placing unitswith the highly aggressive discs gothrough any hard surface and clodscutting down the seed to the correctdepth desired. The achievedeven emergence is the ultimatestart of a growing season. All of thisis attained at the same time, as considerablecost is cut and the performanceis outstanding. A substantialamount of time, wear and energyhave been saved in the process.Large contracting opportunities willnow be readily available.Three efficient steps to great establishment:Step 1 – soil tillage and levelling.The toolbars, which are hydraulicallyadjusted from the cab on thego, provides a good tilth and levelsthe surface. Here you have achoice of three different types: SystemCrossboard, System Agrillaand System Disc.Step 2 – tillage, seed drilling andfertilising. The discs and coulterscut through the soil and mill a perfectslot for both the fertiliser andseed at the pre-set depth. This providesan ultimate soil-seed contact.Step 3 – rolling and loosening.The rows are firmed up by the rearpress wheels, which bring up themoisture and restore the soil structure.The following harrow eradicatesthe wheel marks and providesa non-evaporative top layerwhile working in between the actualseed rows.

Step 2Step 3Large high quality discsThe seed discs and the System Disc toolbarhave large discs manufactured fromspecial hardened steel (V-55), which forcetheir way aggressively into the soil. The V-55 disc has been shown to have a lifetimeup to 50% longer than that of the formertype. Maintenance is thus minimised. The410 mm disc diameter provides the <strong>Rapid</strong>with its incredible versatility, whichincludes everything from direct drilling toconventional drilling. The seed coulterremains sharp and pointed, so therenowned drilling precision can beachieved even after long drilling sessions.∅ 410 mm

Most farms will have 15 to 30 daysavailable for drilling cereals in theautumn, the lower figure for heavysoils with more time for lighterland and/or farms starting to drillearly in September. While a higherfigure increases the area that canbe drilled, it reduces the time availablefor the primary cultivations.The seasonal capacity for differentdrill types and sizes depends onthe daily output and the number ofplanned drilling days available. Dailyoutput depends on a number offactors such as the working width,the forward speed, which can beinfluenced by the tractor power,and the number of hours workedeach day.If the secondary cultivations, drillingand ideally the rolling, can becompleted in one pass, there can beconsiderable labour and cost savingsand the technique is easier tomanage with fewer staff required.Using heavy duty <strong>Rapid</strong> drills, theaverage cost saving could be £20per hectare (a 25% savings and thetime saved about 80 minutes perhectare a 40% savings), comparedwith a conventional system. Furthersavings could be made if thediscing tractor also pulled thepress or the land was initiallydisced rather than ploughed.Where ploughing is chosen, onepass with a press or roll is oftenthe only mechanical cultivationrequired before drilling with the<strong>Rapid</strong>. The roll/press operationshould be close behind the ploughleaving a period of “weathering” tobreak down the seedbed predrilling.Comparing these final figures withthe initial system over 300 hectaresin the autumn there would be a significantfinancial annual savings ofabout £6,000, but also a savings ofapproximately 400 hours in theautumn equivalent to 6 weeks ofintense work for one person and atractor. In some cases this allows areduction of one regular employeeand one tractor.

15 cmEach individual disc is allowed to lift up 15 cm if it hits a stone, thanks to the patented rubber suspensionwhich is completely maintenance-free. The <strong>Rapid</strong> system is not affected by the presence of stones.

<strong>Rapid</strong> 300S <strong>Super</strong> <strong>XL</strong>A seed drill with smaller dimensionsbut very large capacity. Simplicity,flexibility and a work rate of 2 - 3ha/h in combination with narrowtransport width make this machinesuitable for contractors and the like.Draught requirement of around 110-130 hp. The 3 m <strong>Rapid</strong> is very quickand easy to transport on roads toand from the field. The large 2900litre seed hopper allows 10-11 ha tobe drilled on a single fill. (Wheat)<strong>Rapid</strong> 300C <strong>Super</strong> <strong>XL</strong>This combi drill has a total seedhopper volume of 3,100 litres with amoveable inner partition that permitsoptimum use of the space available.Narrow transport width and amoderate draught requirementmake the machine suitable for mediumsizedfarms and fast road transport.

<strong>Rapid</strong> 400S <strong>Super</strong> <strong>XL</strong>A large dimensioned high capacitydrill. Capable of drilling in theexcess of 4 ha/hour and more than15 hectares of wheat in between fillingup, thus achieving at least 30 -40 hectares per day. Power requirementaround 150 hp. Fast, efficientand highly dependable.<strong>Rapid</strong> 400C <strong>Super</strong> <strong>XL</strong>Seed and fertiliser drill with an outstandingcapacity. The large hopperholds in excess of 4200 litres with anadjustable dividing wall which optimisesthe capacity whether you areworking with 500 kilo bags, big bagsor loading with an auger.

The <strong>Rapid</strong> is recognised worldwideas a machine which offers a veryprecise seeding depth.For users who wish to take the precisionlevel one step further there isnow the option of “Autocheck” and“Autopilot”.The system is particularly usefulwith <strong>Rapid</strong> 400C where there can bea large change in weight between afull and empty hopper.With Autocheck on the <strong>Rapid</strong> seeddrill, seed depth is measured continuously.The actual depth can beviewed on the Control-Station inthe tractor cab and adjusted manuallyusing the Control function.Autopilot is one step further along theroad to automatisation, since itenables not only measurement butalso adjustment to be controlled automatically.The system is ‘driven’ by acontinuous oil flow from the tractor.Everything is controlled from thetractor cab with the help of theControl-Station.

Consolidation across theentire widthIt is advisable to pack the entirewidth in front of your <strong>Rapid</strong> byusing wide tyres and our Pivotwheel packer. A considerableamount of tillage and consolidationwill be achieved together with anincreased output especially whenthe <strong>Rapid</strong> is used in a minimisedcultivation system, whether it isploughed or not.In line wheel pressThe Pivot wheel press is mountedin the three-point linkage behindthe tractor and therefore able toeven out the area pushed up bythe tractor wheels. This is particularlyessential when working onlighter soils but is generally recommendedall around. The pivot packerfollows the turning circle andcan therefore remain down whenturning on the headland.

SystemCrossboardTwo rows of Crossboard,second rowequipped with wearplate.• hydraulically operated fromthe cab• individually adjustablethrough a linkage• the Crossboard consists ofindividually flexible tinesSystemAgrillaTwo rows of Agrillatines in front of thesingle Crossboard.• hydraulically operated fromthe cab• individually adjustablethrough a linkageSystem DiscTwo rows ofcurved serratedrubber sprungdiscs in front ofthe single Crossboard• easily adjustable with a lever• individually adjustablethrough a linkage• disc diameter 410 mm

1Control-StationThe new Control-Station is veryeasily operated and providesthe driver with all of the necessaryinformation on drill activity.Any faults are shown on thedisplay screen, and the faultdiagnostics sub menu providesinformation on the status of thevarious sensors. A separate section(1) is fitted to the Control-Station when the variable seedrateoption is fitted.Grass seed boxThe grass seed box optiondesigned by Väderstad holds 250 lat 4 m width. The seed is fed outevenly across the whole drillingwidth and covered over by thewheel and following harrow. Thisallows for shallow placement of thegrass seed in one pass along withplacing the fertiliser and seed atdifferent depths.Phosphorus kitA ”phosphorus kit” enables theseed and phosphorus to go downin the same spout. With this attachmentthe main fertiliser rate isplaced between every other row atthe same time as the phophorus isplaced with the seed. The box isdriven by the fertiliser gear boxand comes with its own separatecalibration kit.

Simple adjustment, <strong>Rapid</strong> CThe cultivating depth of the discson System Disc can be easilyadjusted using clips that limit themovement of the hydraulic cylinders.The clips are easy to insertand remove without the use oftools. Spare clips are stored in acontainer beside the hydrauliccylinders.Hydraulic System Disc,<strong>Rapid</strong> CThe hydraulically controlled discson System Disc fold up when themachine is lifted to give sufficientroom for the soil during turning onheadlands. Folding of the discs iscontrolled by the same hydraulicfunction as lifting of the seed drill.Following harrowThe following harrow can beadjusted by altering workingangle and downward pressure.The tines work in between theseedrows. With the low-lift functionengaged, the harrow staysin work while turning on theheadlands. The following harrowhas a trip-function, whichprotects the harrow from beingdamaged when reversing.

Pre-emergence markerAutomatically controlled by thetramlining system. Making iteasier to keep track of the tramlinesand also facilitates preemergenceapplication.Individually depth controls,disc/coulter pairsThe <strong>Rapid</strong>-principle means thatone press wheel controls the depthof one pair of discs through a parallellinkage. This is how themachine drills to a very precisedepth.Each disc is sprung individually ona rubber suspension. The suspensionis a soft, practically everlasting,device that protects the disc,bearing, coulter and machine fromtoo much strain. The rubber suspensionsare also a key feature inthe depth control system.Tungsten carbide reinforced coultersminimizes wear and tear.Standard featuresAll Väderstad drills are suppliedwith a precision drilling kit as standard.The kit consists of weighingscales and a rate test bag whichallow fast and accurate tests out inthe field, and an ingenious depthmeter with which sowing depthcan be measured accurately.

Uniform distributionSimple calibrationCalibration is quick and simple on the <strong>Rapid</strong> <strong>Super</strong><strong>XL</strong>. Position the calibration trays under the seedhousings and run the calibration test directly onthe gearbox by turning the required number of revolutions.Calibration is done by adjustment on thegearbox. The scale is clear and easy to set. The outputrate can be adjusted linearly in relation to thescale. Calibration is done in the same way for bothseed and fertiliser.Uniform distributionThe seed distribution system, designed byVäderstad, ensures accurate distribution of seeddown to rate of 2 kg/ha. When drilling small seedssuch as oilseed the wide feed wheel can be disengaged.An even distribution of low seed rates isensured using the micro feed wheel. The studdeddrive wheel gives a uniform feed rate even undervariable conditions. Variable seedrate option.

Case studyFarm Summary<strong>Rapid</strong> allows all possibilities!280 hectare Suffolk cereal heavy land farm. 1/3rd of thearea is particularly heavy boulder clay and 2/3rds is moreof a clay loam. The farm is owned and run by three people.A casual is employed for a short period at harvest.The orginal cultivation system comprised 4 furrowplough, power harrow (slow pass), power harrow (quickpass), roll, spring tine, old IH cultivator and drill with atotal cost £ 97 - £ 109/ha and time of 275 - 312 min/haThe farm needed to think how it could manage withoutone person. A 5 furrow plough replaced the old 4 furrow.The power harrow is now used occasionally to level andinitially work the ploughed land. The new <strong>Rapid</strong> systemcomprised of 5 furrow plough + furrow splitter powerharrow (quick pass), new heavy rill, <strong>Rapid</strong> drill 300 (3m)and roll with a total cost of £ 91/ha and time of203 min/ha.Overall the changes have worked well giving a cost savingof about £ 12 per hectare and a considerable timesaving of approximately 25%.

<strong>Rapid</strong> 300-400S/C <strong>Super</strong> <strong>XL</strong> and 12,5 cm row spaceModel Weight with Hopper Weight approx. incl. Wheel Spool RemarksWorking width System Disc/ capacity System Disc dim valvescm Coulter (kg)* litresRD 300S <strong>Super</strong> <strong>XL</strong> 166 2900 3400 740×170-15” °° _______________RD 300C <strong>Super</strong> <strong>XL</strong> 179 3100 4300 740×170-15” °° _______________RD 400S <strong>Super</strong> <strong>XL</strong> 150 4000 4500 740×170-15” °° _______________RD 400C <strong>Super</strong> <strong>XL</strong> 159 4200 5200 740×170-15” °° _______________* Fertiliser coulter lifted upS = Seed only C = CombiRear lights are standard.Tramlining: (175 cc tramlining with 2 row shut off are standard)1 - 20 multiple widths, centre pair tramlining1 row shut offCentre line 138, 163, 188 and 213 cm2 row shut offCentre line 150, 175* and 200 cm. The seed pipes are crossed over when tramlining at 150 and 200 cm.Main officeSubsidiariesImporterVÄDERSTAD LTDVÄDERSTAD OÜVÄDERSTADVÄDERSTAD SIAVÄDERSTAD UABVÄDERSTAD SARLVÄDERSTAD GmbHVÄDERSTAD Sp.z o.oVÄDERSTAD KftVÄDERSTAD Ltd.Unit One, Ellesmere Business ParkGrantham, Lincolnshire NG31 7XTTel. 01476 581 900 • Fax 01476 581 901www.vaderstad.comDistributor:The company retains the right to make changes to specifications and design. Patents awarded and pending990100-ENGB Mjölby Tryckeri AB/Desktopteknik AB 2004.09