MX Technic Loader Brochure - LiveUpdater

MX Technic Loader Brochure - LiveUpdater

MX Technic Loader Brochure - LiveUpdater

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

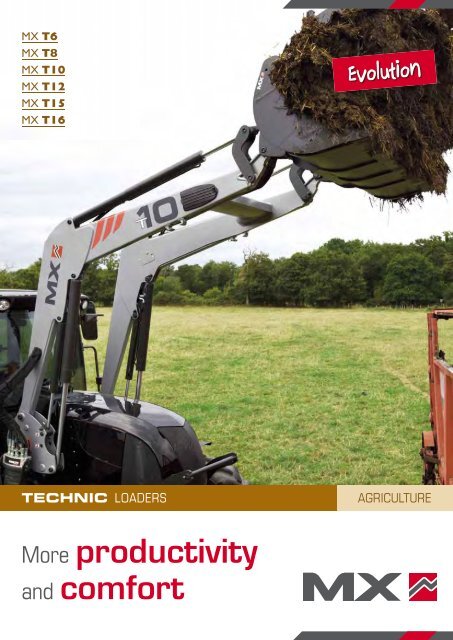

technicLOADERSFULLY inteGRAteDhYDRAULic ciRcUitModern design<strong>MX</strong> lines are clean and stylish; they perfectly complement new tractormodels.Protected circuitLocated internally all hydraulic andelectric circuits are protected fromoutside elements. Smoothed edges avoidany possible damage to the circuit.

technic LOADERSAgRicuLtuRESingle and double effectPatented by <strong>MX</strong> the concept of single and double acting lift action allowsoptimum use of the tractor hydraulics depending on the type of workbeing done.control becomes instinctive; the driver can feel a direct relationshipbetween the force exerted on the loader’s control lever in relation todesired ground pressure of the loader: the harder the lever is pushed, theharder the loader pushes down on the ground.(PAtenteD)• When lowering the loader in single acting, the tractor oil fl ow is thenfully available to crowd the implement back, no time is lost.• Whilst working in the single acting zone no ground pressure is exertedon the loader implements, resulting in reduced wear.Neutral PositionSingleActing lowerDoubleActing lower<strong>MX</strong> SYSteMhydraulicself levelling(PAtenteD)The bucket angle is automatically retained by two hydraulic compensating rams, perfectlyintegrated and permanently linked with the crowd rams.Adaptive levellingThe compensation rams have two positions so that the implement anglecan be adapted to the work being done.Lifting Pressure Weight+ 35 % of powerheight (mm)Bucket PositionPallet Position+ 35%+ 25%load (kg)■ Lift power without PCH■ Lift power with PCH- a pallet position to give a perfectparallelogram,- a bucket position to give a slightcrowd angle at maximum lift so notto loose any fl uid materials.Superior powerPCH System® increases actual liftcapacity by up to 35% without anyextra energy requirements from thetractor (i.e. oil pressure or flow).The pressure in the crowd rams,generated by the weight in theimplement, is transferred to thecompensating rams and boost liftingram power.OPtiOn

technic LOADERSagriculture Work stress freein total comfortWhilst working in total comfort tiredness is reduced, this allows complete attention to thetask at hand. <strong>MX</strong> TECHNIC loaders make your loading requirements easier, allowing you towork more efficiently, resulting in a complete “peace of mind” at the end of your working day.

technic LOADERSAgRicuLtuREImpeccable qualityfor intensive daily useDemands on modern farm machinery are ever increasing, and their reliability must be assuredday after day. With <strong>MX</strong>, build quality is of the highest priority, even down to the smallestcomponents. With a <strong>MX</strong> TECHNIC loader reliability is guaranteed.

P.16-17impeccablebuild quality<strong>MX</strong> use the very latestmanufacturing techniquesfrom the initial profi lingof the steel up to the fi nalassembly of the loader.High qualitysurface fi nish<strong>MX</strong> loaders initially gothrough an intensive shotblasting process whichallows perfect adherenceof the primer paint. Nexta polyurethane top coatis applied and oven bakedto give a highly resistantsurface fi nish.Reinforcedpivot pointsPivot points arereinforced by a supportring.Thus, these new pivotpins with a fl at faceincrease product life. Awell-known and well-triedtechnic.Protectivegrease pointsAll grease points arerecessed into the end ofthe pivot pins, pointingoutwards, thus areperfectly protected andeasily accessible.neW PiVOt BUSh100%pivot bushesNew bi-metalic bushesare added to all pivotpoints. Made of two alloys(steel and bronze), withsome bushes having awider surface area, theservice intervals andproduct life of a loaderhas been considerablyincreased.Strengthand fatigue testingThroughout theirdevelopment <strong>MX</strong>TECHNIC loadershave been subjected tointensive deformation andfatigue tests on a purposebuilt rig, which simulatesextreme user conditions.With <strong>MX</strong> strength anddurability are guaranteed.Systematic testingof all loadersAll functions on <strong>MX</strong>TECHNIC loadersare fully tested beforedespatch. Productreliability as guaranteedfrom day one.

technic LOADERSAgRicuLtuREFull compatibilitywith <strong>MX</strong> front linkage<strong>MX</strong> loaders and <strong>MX</strong> front linkages are fully compatible, they offer easy interchange-ability withminimum downtime, without the requirement of special tools. Using a front linkage and loadercombination offers a real day-to-day advantage and ensures the tractors full potential is utilised.cost effective with modular designBy integrating common chassis parts and sharinghydraulic components the unit cost can besignifi cantly reduced. I.e. the same hydraulic valvecan be used to operate both the loader and frontlinkage; also the SHOCK Eliminator® can beshared.Maximum versatilityfor your tractorUnrestricted use of theloader is possible whenthe front linkagearms are intheir foldedposition, thenwith the aidof its Fitlock IIhitching system theloader can be removed in seconds, henceallowing unrestricted use of the front linkage.

P.18-19tractor hydraulics freefor other equipmentThe <strong>MX</strong> control valve can be used to operate allfunctions of the front linkage, thus leaving the reartractor hydraulic couplings completely free forany rear mounted equipment.Common controlCommon Shock Eliminator®

technic LOADERSAgRicuLtuREHitching systemstailored to your exact needsThere is an ever increasing need for frequent implement changes, which themselves arebecoming more and more sophisticated. <strong>MX</strong> offers a choice of hitching methods thatexactly meet your requirements.<strong>MX</strong> SYSteMHITCHING1Automatic hitchingof work implementsWith MASTER-ATTACH System® the implement is automatically locked by crowding to the maximum.To unlock simply operate the lever conveniently situated on the tractors near side.Automaticlocking leverLocking pins«CLIC»Selfcentering“V”Simple hitching without comprising performanceDue to the sophisticated design and cinematics of the <strong>MX</strong> implementcarrier there is minimum implement overhang with maximum crowdand dump angles. A robust and automatic implement carrier (30mmdia. locking pins) that can support high capacity implements.Easy connectionImplements are equipped with guides to allow easy hitching with selfcentring V on implement carriage.Automatic hitching«CLAC»Strong, reliableand easy to use,it enables allcouplings of onehydraulic line tobe connected simultaneously in onesimple action, even under pressure.

HITCHING2HITCHING3Automatic hitchingand removal of non hydraulic/electricimplementsAllows hitching and removal of implements without leaving the tractor seat. A comfort offeredby the FAST-LOCK System®, particularly when frequent implement changes are required.OPtiOnLockedSafeA safety system requiring a double action on the control leverensures correct positioning of the loader before the implementcan be removed, the additional security offered by the FAST-LOCK.Fully automatic hitching/unhitchingof implements with hydraulic andelectric functions (PAtenteD)SPEED-LINK System® allows inter-changeability of all implements, including those with hydraulicand electric connections without leaving the tractor seat.Connection componentsfully protectedP.20-21<strong>MX</strong> SYSteMUnlocked<strong>MX</strong> SYSteMcomfort• change implements in amatter of seconds• no mistakes whenconnecting hydraulics andelectrics• no risk of untimely anddangerous unlockingconnectioncomponentsfully protectedThe hydraulic couplingsand electric connectorsare perfectly protectedby weather proofcovers that open andclose automaticallywhen connecting anddisconnecting.4OPtiOnhitching/unhitching tailored toyour implements in serviceIt is also possible to choose a specifi c hitching system : Euro hitching, combined <strong>MX</strong>/Euro, Euro/SMS/ALO3 or <strong>MX</strong>/Faucheux blanc hitching. They allow a limitless versatility and a perfect compatibility.<strong>MX</strong> SYSteM<strong>MX</strong> positionOPtiOnEuro position

technic LOADERSagriculture An implementfor every task<strong>MX</strong> implements are perfectly suited to their working environment and have been developedfollowing extensive analysis of farmers needs. All implements are manufactured with a continuouswelding technique which considerably increases durability. A paint dipping process followed bya baking process produces a very hard wearing surface coating, hence extending the life of theimplement.Earth BucketUnequalled strengthDigging bucket with teeth welded to a heavy duty wear blade. Its cylindricalback and tubular upper edge give excellent rigidity. Additionally its cylindricalback enables the bucket to be fully loaded by rolling the material, and offersgood material discharge without sticking to bucked edges.Nb ofteethWeight(kg)Width(mm)Nb ofint. rein.Capacity (liter)Height(mm)BT 130 5 165 1300 - 350 460 640BT 150 6 180 1500 - 400 530 640BT 180 7 210 1800 1 480 620 640BT 200 7 230 2000 1 540 700 640BT 220 8 255 2200 1 590 770 640Loose Material BucketOptimized fillingThis bucket is suitable for a wide range of tasks when loading loose material.(E.g; gravel, cereals, fertiliser,etc.). Its design incorporates a heavy-duty wearplate, tubular upper edge and cylindrical back, all of which enhance itsperformance and strength.Weight(kg)Width(mm)Nb ofint. rein.Capacity (liter)Height(mm)BR 130 154 1300 - 350 460 640BR 150 167 1500 - 400 530 640BR 180 195 1800 1 480 650 640BR 200 210 2000 1 540 700 640BR 220 225 2200 1 590 770 640

P.22-23SlurryBucketIdeal for semi-fl uid materialThis bucket is particularly useful for loading semi-liquid material. It retainsthe characteristics of the Loose Material bucket however it has an increasedvolume.Weight(kg)Width(mm)Nb ofint. rein.Capacity (liter)Height(mm)BL 200 255 2000 2 730 1000 700BL 220 275 2200 2 800 1100 700BL 250 305 2500 2 910 1210 700* BBL 220 has rounded edges suitable for handling roots.cerealBucketincreased productivityThis is a high volume bucket designed to load cereals and other low densitymaterials.Weight(kg)Width(mm)Nb ofint. rein.Capacity (liter)Height(mm)BC 180 315 1800 2 990 1300 815BC 200 335 2000 2 1100 1450 815BC 220 355 2200 2 1200 1600 815BC 250 390 2500 2 1370 1825 8151030 mmRequires a3rd function4 in 1 BucketHighly versatileA real universal implement, this bucket can be usedfor all types of applications: digging, loading, grading,snow clearing… With its strong jaw and highly resistantwear blades, it can be used as a bucket or dozer bladewithout changing implements.Nb ofteethWeight(kg)Width(mm)Capacity (liter)Height(mm)BQU 150 6 370 1530 320 420 860BQU 180 7 415 1830 385 500 860BQU 210 8 470 2130 450 585 860high-tip BucketSpecifi cally developedto load high trailersThis bucket allows loading of high-sided grain lorrieswith a tractor/front end loader combination (I.e. 80hptractor with <strong>MX</strong> T10 or equivalent). With its frontpivoting bucket it is safe and easy to load into thecentre of a trailer. The buckets tipping mechanismis fitted on the outside of the bucket for maximumprotection, whilst maintaining maximum bucket volume.Requires a 3rd functionHigh-Tip Bucket gives an additional 1-10 m liftheight to maximum loader lift heightWeight(kg)Capacity (liter)Height(mm)BRDS 180 lame d’attaque 2,00 m 470 1000 1300 835BRDS 210 lame d’attaque 2,30 m 510 1200 1550 835BRDS 250 lame d’attaque 2,70 m 570 1370 1800 835

technic LOADERSAgRicuLtuREManure ForkEffective handling of manureIts cylindrical back reduces adherence of manure and increases the volumeof the implement. Its implement tines (860 mm long) are secured with acontinuous tie bar, rather than nuts that come loose. Wear pads on each endgive the implement a long working life.Nb ofint. rein.Weight(kg)Width(mm)Nb oftinesHeight(mm)Depth(mm)BF 118 - 128 1180 6 510 990BF 140 - 143 1400 7 510 990BF 160 - 158 1620 8 510 990BF 180 2 171 1840 9 510 990BF 200 2 185 2060 10 510 990BF 225 2 200 2280 11 510 990j1235 mmGrab forManure Forkto increase your outputA top grab specifically designed for the Manure Fork, itis available as factory fitted or retrofit. Its large crosssection tines offer excellent durability, even for the mostdifficult works. A 90° opening allows optimum use of the grab.Requires a3rd functionCapacity (liter)Weight(kg)Width(mm)Nb oftinesGF 125 for BF 118 580 110 1240 11GF 150 for BF 140 700 120 1480 12GF 170 for BF 160 800 128 1680 13GF 190 for BF 180 900 133 1880 13GF 205 for BF 200 1000 140 2045 14GF 225 for BF 225 1230 147 2265 15Multi-purpose bucketthe multi-purpose implement!Manure - Silage - Bulk feedA multi-purpose implement combining a bucket andgrab. Its cylindrical back allows easy and clean loading.The wide opening grab allows optimum use of theimplement.1250 mmNb ofint. rein. Capacity(liter)Requires a3rd functionWeight(kg)Width(mm)Depth(mm)Nb oftinesHeight(mm)BMS 125 - 610 270 1260 690 11 640BMS 150 - 730 295 1500 690 12 640BMS 170 - 830 320 1700 690 13 640BMS 200 1 980 360 2040 690 14 640BMS 225 1 1100 385 2260 690 15 640BMS 250 1 1220 420 2510 690 17 640Pallet fork and carrierAdaptable to all pallet sizesAll models are supplied with approved pallet tines. Side stops prevent thepallet tines from accidentally sliding off.Weight(kg)Width(mm)FeeDinG BUcKetSDimensionsof tines(mm)Height(mm)TR 1 500 kg 170 1320 1050 x 100 x 32 780TR 2 500 kg 195 1320 1200 x 100 x 40 780The <strong>MX</strong> feeding bucket canbe filled directly from theclamp, and then feed can bedistributed to the livestock(see specific Feeding Bucketsleaflet).

P.24-25Special grab for small logsideal for handling branches, seaweed and sugar caneSpecialised grab for handling sugar cane, small logs, brushwood, seaweed, etc. Thetines are bolt-on allowing them to be adjusted.Requires a3rd functionWeight(kg)Width(mm)Height(mm)Depth(mm)Opening(mm)GV 350 1 300 830 775 1 380Silage bladeBetter output for maize silageFor use with <strong>MX</strong> T10 loaders or above. Also available with 3 point linkage mounting bracket for use witha front linkage.Weight(kg)Width(mm)Depth(mm)Height(mm)LE 250 - 3pt linkage inclusive 360 2 500 170 1 060hoisting hookAnti-drop system mandatoryWeight(kg)Lift capacity(kg)CL 2500 130 2 500Option : two additionaltines.neWneWManubal L40Simple bale spikeSimple spike for easy handling of round or square bales.Specification2 fixed tines of ø 35x1050 mm working length820 mm between centresManubal V40the most compact and versatileManubal c40Adapts to all wrapped bale sizesThe Manubal C40 is the optimal solution for stacking round wrapped silagebales whatever the weight and diameter.Specification2 mobile clamping arms with synchronized openingFor bales from ø 1.00 m to 1.75 mBale weight up to 1200 kgEasily handling 1 or 2 round or square bales, it guarantees a maximalproductivity. With the wrapped bale kit, it becomes extremely versatile.SpecificationCompact (overall height 1.05m)Grip with 6 tines, height 800 mmPick up 1 or 2 bales (round or square)Find all the MANUBAL ® range products in thespecifi c leafl et.

technic LOADERSAgRicuLtuRE<strong>MX</strong> SYSteMPackDistri OriginePackPROPILOTPackFLEXPILOTPackTECHPILOTInstanthitchingand removalInstant connectionof loader hydraulicsand electricsHydraulicself levelling■ ■ ■ ■■ ■ ■ ■■ ■ ■ ■Automaticreturn to pre-setpositionSynchronisation of graband bucket movementsneWElectrical original valves- ■Shock Absorber ■ ■ ■ ■Automatic hitchingof work implements■ ■ ■ ■Automatic hitching andremoval of non hydraulic/electric implementsFully automatic hitching/unhitching of implementswith hydraulicand electric functions.Instant hydraulicconnectionloader/implementCable control - ■ - -PACK EQUIPEMENTLow pressurehydraulic control- - ■ -Electronic control - - - ■Weighing System3 rd hydraulic funtion ■ ■ ■ ■OPtiON■ StANDARDin order to be adaptable to all work applications, we proposedifferent equipment levels for <strong>MX</strong> tEcHNic loaders.Adaptable, optional equipment can be retro-fi tted throughoutthe life cycle of the loader.create a loader tailored to your needs !

P.26-27<strong>MX</strong> T6 <strong>MX</strong> T8 <strong>MX</strong> T10 <strong>MX</strong> T12 <strong>MX</strong> T15 <strong>MX</strong> T16Maximum height at implement pivot* 3,75 m 3,85 m 4,00 m 4,15 m 4,60 m 4,60 mMaximum height under horizontal bucket ● 1 3,50 m 3,60 m 3,75 m 3,90 m 4,35 m 4,35 mMaximum height under dumped bucket ● 2 # 2,95 m 3,05 m 3,20 m 3,35 m 3,80 m 3,80 mDigging depth ● 5 0,20 m 0,20 m 0,20 m 0,20 m 0,20 m 0,20 mDumping angle at full height ● 3 # 52° 55° 55° 55° 50° 50°Crowd angle at ground level ● 4 # 47° 52° 52° 52° 51° 51°Lift force at implement pivot, ground level* 1600 kg 2100 kg 2400 kg 2720 kg 3000 kg 3000 kgLift capacity at implement pivot overthe entire lifting range*Lift capacity on pallet 0.60 m out on forks:- at ground level*1 250 kg 1 890 kg 2 190 kg 2 490 kg 2 670 kg 2 670 kgWithout PCH 1 150 kg 1 350 kg 1 580 kg 1 770 kg 1 930 kg 1 930 kgWith PCH 1 450 kg 1 800 kg 2 080 kg 2 360 kg 2 660 kg 2 660 kgTECHNICAL SPECIFICATIONWithout PCH 1000 kg 1300 kg 1540 kg 1750 kg 1890 kg 1890 kg- at 2m from ground levelWith PCH 1380 kg 1720 kg 2000 kg 2250 kg 2560 kg 2560 kgWithout PCH 900 kg 1200 kg 1470 kg 1690 kg 1850 kg 1850 kg- at 3m from ground levelWith PCH 1350 kg 1630 kg 1980 kg 2230 kg 2460 kg 2460 kgWithout PCH 860 kg 1120 kg 1450 kg 1570 kg 1750 kg 1750 kg- at maximum height levelWith PCH 1350 kg 1610 kg 1960 kg 2200 kg 2350 kg 2350 kgLifting time 3,9 sec 4,6 sec 5,4 sec 6,2 sec 8,2 sec 8,2 secDumping time 1,0 sec 1,0 sec 1,0 sec 1,4 sec 1,4 sec 1,4 secCharacteristics measured at 190 bars at a fl ow rate of 60 litres/min - Values may vary according to type of tractor used.*Value at implement pivot are not to be considered as working data.# Values given with <strong>MX</strong> BR loose material bucket.321Only criteria of benefi t to the operator have beenconsidered when developing <strong>MX</strong> loaders> Implement lifting and dumping speed> Payload lift capacity on pallet at a maximum of 2 m from the ground> Forward reach of dumped bucket at full lift height> Ground clearance under dumped bucket54

01/11 EN - <strong>MX</strong> reserves the right to modify the specifi cation, fi ttings and prices of the models shown, without notice.this brochure is not a contractual document. Reproduction of this document is prohibited.www.m-x.eu19, rue de RennesBP 83221FR-35690 AcigNEtél :+33 (0)2 99 62 52 60Fax :+33 (0)2 99 62 50 22email : contact@m-x.eu©Mailleux company copyright