Mechanisation-Alluvial-Artisanal-Diamond-Mining

Mechanisation-Alluvial-Artisanal-Diamond-Mining

Mechanisation-Alluvial-Artisanal-Diamond-Mining

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

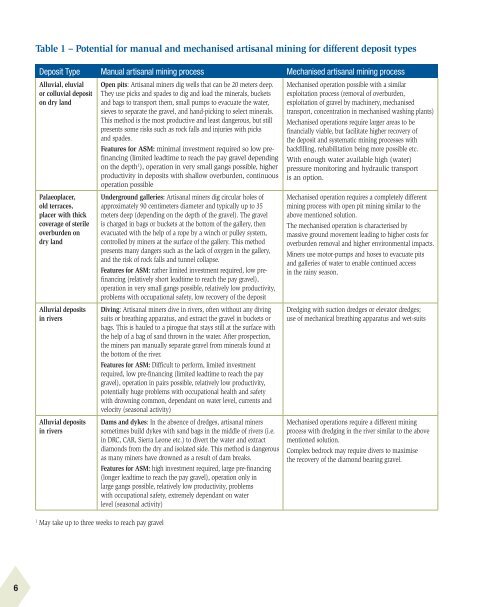

Table 1 – Potential for manual and mechanised artisanal mining for different deposit typesDeposit Type Manual artisanal mining process Mechanised artisanal mining process<strong>Alluvial</strong>, eluvialor colluvial depositon dry landPalaeoplacer,old terraces,placer with thickcoverage of sterileoverburden ondry land<strong>Alluvial</strong> depositsin rivers<strong>Alluvial</strong> depositsin riversOpen pits: <strong>Artisanal</strong> miners dig wells that can be 20 meters deep.They use picks and spades to dig and load the minerals, bucketsand bags to transport them, small pumps to evacuate the water,sieves to separate the gravel, and hand-picking to select minerals.This method is the most productive and least dangerous, but stillpresents some risks such as rock falls and injuries with picksand spades.Features for ASM: minimal investment required so low prefinancing(limited leadtime to reach the pay gravel dependingon the depth 1 ), operation in very small gangs possible, higherproductivity in deposits with shallow overburden, continuousoperation possibleUnderground galleries: <strong>Artisanal</strong> miners dig circular holes ofapproximately 90 centimeters diameter and typically up to 35meters deep (depending on the depth of the gravel). The gravelis charged in bags or buckets at the bottom of the gallery, thenevacuated with the help of a rope by a winch or pulley system,controlled by miners at the surface of the gallery. This methodpresents many dangers such as the lack of oxygen in the gallery,and the risk of rock falls and tunnel collapse.Features for ASM: rather limited investment required, low prefinancing(relatively short leadtime to reach the pay gravel),operation in very small gangs possible, relatively low productivity,problems with occupational safety, low recovery of the depositDiving: <strong>Artisanal</strong> miners dive in rivers, often without any divingsuits or breathing apparatus, and extract the gravel in buckets orbags. This is hauled to a pirogue that stays still at the surface withthe help of a bag of sand thrown in the water. After prospection,the miners pan manually separate gravel from minerals found atthe bottom of the river.Features for ASM: Difficult to perform, limited investmentrequired, low pre-financing (limited leadtime to reach the paygravel), operation in pairs possible, relatively low productivity,potentially huge problems with occupational health and safetywith drowning common, dependant on water level, currents andvelocity (seasonal activity)Dams and dykes: In the absence of dredges, artisanal minerssometimes build dykes with sand bags in the middle of rivers (i.e.in DRC, CAR, Sierra Leone etc.) to divert the water and extractdiamonds from the dry and isolated side. This method is dangerousas many miners have drowned as a result of dam breaks.Features for ASM: high investment required, large pre-financing(longer leadtime to reach the pay gravel), operation only inlarge gangs possible, relatively low productivity, problemswith occupational safety, extremely dependant on waterlevel (seasonal activity)1May take up to three weeks to reach pay gravelMechanised operation possible with a similarexploitation process (removal of overburden,exploitation of gravel by machinery, mechanisedtransport, concentration in mechanised washing plants)Mechanised operations require larger areas to befinancially viable, but facilitate higher recovery ofthe deposit and systematic mining processes withbackfilling, rehabilitation being more possible etc.With enough water available high (water)pressure monitoring and hydraulic transportis an option.Mechanised operation requires a completely differentmining process with open pit mining similar to theabove mentioned solution.The mechanised operation is characterised bymassive ground movement leading to higher costs foroverburden removal and higher environmental impacts.Miners use motor-pumps and hoses to evacuate pitsand galleries of water to enable continued accessin the rainy season.Dredging with suction dredges or elevator dredges;use of mechanical breathing apparatus and wet-suitsMechanised operations require a different miningprocess with dredging in the river similar to the abovementioned solution.Complex bedrock may require divers to maximisethe recovery of the diamond bearing gravel.6