300, 400 & 500 - Rapid Granulator

300, 400 & 500 - Rapid Granulator

300, 400 & 500 - Rapid Granulator

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

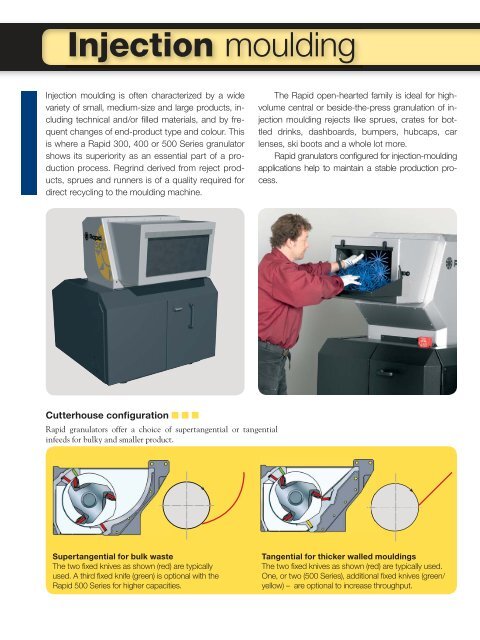

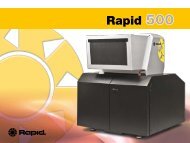

Injection mouldingInjection moulding is often characterized by a widevariety of small, medium-size and large products, includingtechnical and/or fi lled materials, and by frequentchanges of end-product type and colour. Thisis where a <strong>Rapid</strong> <strong>300</strong>, <strong>400</strong> or <strong>500</strong> Series granulatorshows its superiority as an essential part of a productionprocess. Regrind derived from reject products,sprues and runners is of a quality required fordirect recycling to the moulding machine.The <strong>Rapid</strong> open-hearted family is ideal for highvolumecentral or beside-the-press granulation of injectionmoulding rejects like sprues, crates for bottleddrinks, dashboards, bumpers, hubcaps, carlenses, ski boots and a whole lot more.<strong>Rapid</strong> granulators confi gured for injection-mouldingapplications help to maintain a stable production process.Cutterhouse configuration ■ ■ ■<strong>Rapid</strong> granulators offer a choice of supertangential or tangentialinfeeds for bulky and smaller product.Supertangential for bulk wasteThe two fi xed knives as shown (red) are typicallyused. A third fi xed knife (green) is optional with the<strong>Rapid</strong> <strong>500</strong> Series for higher capacities.Tangential for thicker walled mouldingsThe two fi xed knives as shown (red) are typically used.One, or two (<strong>500</strong> Series), additional fi xed knives (green/yellow) – are optional to increase throughput.