STARRETT-WEBBER GAGE BLOCKS - JW Donchin CO.

STARRETT-WEBBER GAGE BLOCKS - JW Donchin CO.

STARRETT-WEBBER GAGE BLOCKS - JW Donchin CO.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

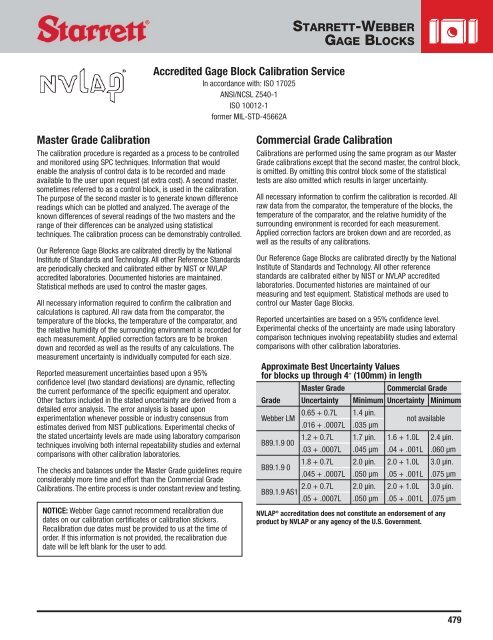

<strong>STARRETT</strong>-<strong>WEBBER</strong><strong>GAGE</strong> <strong>BLOCKS</strong>Accredited Gage Block Calibration ServiceIn accordance with: ISO 17025ANSI/NCSL Z540-1ISO 10012-1former MIL-STD-45662AMaster Grade CalibrationThe calibration procedure is regarded as a process to be controlledand monitored using SPC techniques. Information that wouldenable the analysis of control data is to be recorded and madeavailable to the user upon request (at extra cost). A second master,sometimes referred to as a control block, is used in the calibration.The purpose of the second master is to generate known differencereadings which can be plotted and analyzed. The average of theknown differences of several readings of the two masters and therange of their differences can be analyzed using statisticaltechniques. The calibration process can be demonstrably controlled.Our Reference Gage Blocks are calibrated directly by the NationalInstitute of Standards and Technology. All other Reference Standardsare periodically checked and calibrated either by NIST or NVLAPaccredited laboratories. Documented histories are maintained.Statistical methods are used to control the master gages.All necessary information required to confirm the calibration andcalculations is captured. All raw data from the comparator, thetemperature of the blocks, the temperature of the comparator, andthe relative humidity of the surrounding environment is recorded foreach measurement. Applied correction factors are to be brokendown and recorded as well as the results of any calculations. Themeasurement uncertainty is individually computed for each size.Reported measurement uncertainties based upon a 95%confidence level (two standard deviations) are dynamic, reflectingthe current performance of the specific equipment and operator.Other factors included in the stated uncertainty are derived from adetailed error analysis. The error analysis is based uponexperimentation whenever possible or industry consensus fromestimates derived from NIST publications. Experimental checks ofthe stated uncertainty levels are made using laboratory comparisontechniques involving both internal repeatability studies and externalcomparisons with other calibration laboratories.The checks and balances under the Master Grade guidelines requireconsiderably more time and effort than the Commercial GradeCalibrations.The entire process is under constant review and testing.NOTICE: Webber Gage cannot recommend recalibration duedates on our calibration certificates or calibration stickers.Recalibration due dates must be provided to us at the time oforder. If this information is not provided, the recalibration duedate will be left blank for the user to add.Commercial Grade CalibrationCalibrations are performed using the same program as our MasterGrade calibrations except that the second master, the control block,is omitted. By omitting this control block some of the statisticaltests are also omitted which results in larger uncertainty.All necessary information to confirm the calibration is recorded. Allraw data from the comparator, the temperature of the blocks, thetemperature of the comparator, and the relative humidity of thesurrounding environment is recorded for each measurement.Applied correction factors are broken down and are recorded, aswell as the results of any calibrations.Our Reference Gage Blocks are calibrated directly by the NationalInstitute of Standards and Technology. All other referencestandards are calibrated either by NIST or NVLAP accreditedlaboratories. Documented histories are maintained of ourmeasuring and test equipment. Statistical methods are used tocontrol our Master Gage Blocks.Reported uncertainties are based on a 95% confidence level.Experimental checks of the uncertainty are made using laboratorycomparison techniques involving repeatability studies and externalcomparisons with other calibration laboratories.Approximate Best Uncertainty Valuesfor blocks up through 4 (100mm) in lengthMaster GradeCommercial GradeGrade Uncertainty Minimum Uncertainty MinimumWebber LM 0.65 + 0.7L 1.4 µin. not available.016 + .0007L .035 µmB89.1.9 00B89.1.9 01.2 + 0.7L 1.7 µin. 1.6 + 1.0L 2.4 µin..03 + .0007L .045 µm .04 + .001L .060 µm1.8 + 0.7L 2.0 µin. 2.0 + 1.0L 3.0 µin..045 + .0007L .050 µm .05 + .001L .075 µm2.0 + 0.7L 2.0 µin. 2.0 + 1.0L 3.0 µin.B89.1.9 AS1.05 + .0007L .050 µm .05 + .001L .075 µmNVLAP ® accreditation does not constitute an endorsement of anyproduct by NVLAP or any agency of the U.S. Government.479