VIESMANN - Viessmann

VIESMANN - Viessmann

VIESMANN - Viessmann

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

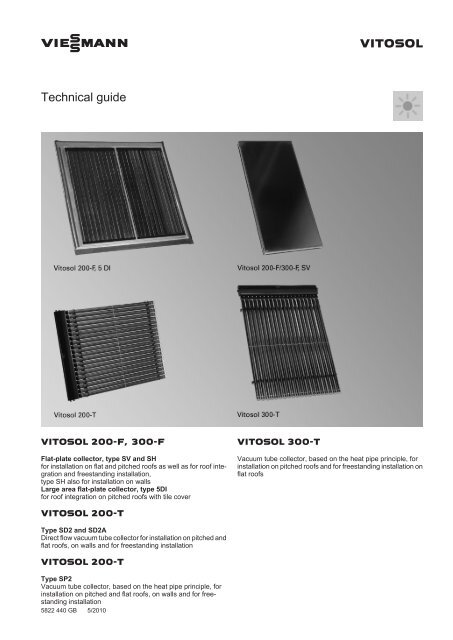

<strong>VIESMANN</strong> VITOSOL<br />

Technical guide<br />

VITOSOL 200-F, 300-F<br />

Flat-plate collector, type SV and SH<br />

for installation on flat and pitched roofs as well as for roof integration<br />

and freestanding installation,<br />

type SH also for installation on walls<br />

Large area flat-plate collector, type 5DI<br />

for roof integration on pitched roofs with tile cover<br />

VITOSOL 200-T<br />

Type SD2 and SD2A<br />

Direct flow vacuum tube collector for installation on pitched and<br />

flat roofs, on walls and for freestanding installation<br />

VITOSOL 200-T<br />

Type SP2<br />

Vacuum tube collector, based on the heat pipe principle, for<br />

installation on pitched and flat roofs, on walls and for freestanding<br />

installation<br />

5822 440 GB 5/2010<br />

VITOSOL 300-T<br />

Vacuum tube collector, based on the heat pipe principle, for<br />

installation on pitched roofs and for freestanding installation on<br />

flat roofs

Index<br />

Index<br />

1. Principles 1. 1 <strong>Viessmann</strong> collector range ....................................................................................... 5<br />

1. 2 Parameters for collectors .......................................................................................... 5<br />

■ Area designations ................................................................................................. 5<br />

■ Collector efficiency ................................................................................................ 6<br />

■ Thermal capacity ................................................................................................... 7<br />

■ Idle temperature .................................................................................................... 7<br />

■ Steam production capacity ................................................................................... 7<br />

■ Solar coverage ...................................................................................................... 8<br />

1. 3 Orientation, inclination and shading of the receiver surface ..................................... 8<br />

■ Inclination of the receiver surface ......................................................................... 8<br />

■ Orientation of the receiver surface ........................................................................ 8<br />

■ Avoiding shading of the receiver surface .............................................................. 8<br />

2. Vitosol 200-F 2. 1 Product description ................................................................................................... 10<br />

■ Benefits ................................................................................................................. 10<br />

■ Delivered condition ............................................................................................... 11<br />

2. 2 Specification ............................................................................................................. 12<br />

2. 3 Approved quality ....................................................................................................... 13<br />

3. Vitosol 200-F, type 5DI 3. 1 Product description ................................................................................................... 14<br />

■ Benefits ................................................................................................................. 14<br />

■ Delivered condition ............................................................................................... 14<br />

3. 2 Specification ............................................................................................................. 15<br />

3. 3 Approved quality ....................................................................................................... 15<br />

4. Vitosol 300-F 4. 1 Product description ................................................................................................... 16<br />

■ Benefits ................................................................................................................. 16<br />

■ Delivered condition ............................................................................................... 17<br />

4. 2 Specification ............................................................................................................. 18<br />

4. 3 Approved quality ....................................................................................................... 19<br />

5. Vitosol 200-T, type SD2 5. 1 Product description ................................................................................................... 20<br />

■ Benefits ................................................................................................................. 20<br />

■ Delivered condition ............................................................................................... 21<br />

5. 2 Specification ............................................................................................................. 22<br />

5. 3 Approved quality ....................................................................................................... 23<br />

6. Vitosol 200-T, type SD2A 6. 1 Product description ................................................................................................... 24<br />

■ Benefits ................................................................................................................. 24<br />

■ Delivered condition ............................................................................................... 25<br />

6. 2 Specification ............................................................................................................. 26<br />

6. 3 Approved quality ....................................................................................................... 27<br />

7. Vitosol 200-T, type SP2 7. 1 Product description ................................................................................................... 28<br />

■ Benefits ................................................................................................................. 28<br />

■ Delivered condition ............................................................................................... 28<br />

7. 2 Specification ............................................................................................................. 29<br />

7. 3 Approved quality ....................................................................................................... 30<br />

8. Vitosol 300-T 8. 1 Product description ................................................................................................... 31<br />

■ Benefits ................................................................................................................. 31<br />

■ Delivered condition ............................................................................................... 31<br />

8. 2 Specification ............................................................................................................. 32<br />

8. 3 Approved quality ....................................................................................................... 33<br />

9. Solar control units 9. 1 Solar control module, type SM1, part no. 7429 073 ................................................. 35<br />

■ Specification .......................................................................................................... 35<br />

■ Delivered condition ............................................................................................... 35<br />

■ Approved quality ................................................................................................... 35<br />

9. 2 Vitosolic 100, type SD1, part no. Z007 387 .............................................................. 36<br />

■ Specification .......................................................................................................... 36<br />

■ Delivered condition ............................................................................................... 36<br />

■ Approved quality ................................................................................................... 36<br />

9. 3 Vitosolic 200, type SD4, part no. Z007 388 .............................................................. 37<br />

■ Specification .......................................................................................................... 37<br />

■ Delivered condition ............................................................................................... 37<br />

■ Approved quality ................................................................................................... 38<br />

2 <strong>VIESMANN</strong> VITOSOL<br />

5822 440 GB

5822 440 GB<br />

Index (cont.)<br />

9. 4 Functions .................................................................................................................. 39<br />

■ Allocation to solar control units ............................................................................. 39<br />

■ Cylinder temperature limit ..................................................................................... 39<br />

■ Collector cooling function with Vitosolic 100 and 200 ........................................... 39<br />

■ Reverse cooling function with Vitosolic 100 and 200 ............................................ 39<br />

■ Collector emergency stop ..................................................................................... 39<br />

■ Minimum collector temperature limit ..................................................................... 39<br />

■ Reduction of stagnation time with solar control module ........................................ 40<br />

■ Interval function ..................................................................................................... 40<br />

■ Cooling function in Vitosolic 200 (only in systems with one consumer) ................ 40<br />

■ Frost protection ..................................................................................................... 40<br />

■ Thermostat function with solar control module and Vitosolic 100 ......................... 40<br />

■ Vitosolic 200 thermostat function, ΔT control and time switches .......................... 40<br />

■ Speed control with solar control module ............................................................... 40<br />

■ Vitosolic 100 speed control ................................................................................... 41<br />

■ Vitosolic 200 speed control ................................................................................... 41<br />

■ Heat statement with solar control module and Vitosolic 100 ................................ 41<br />

■ Vitosolic 200 heat statement ................................................................................. 41<br />

■ Suppression of DHW cylinder reheating by the boiler with solar control module .. 41<br />

■ Suppression of DHW cylinder reheating by boiler with the Vitosolic 100 .............. 41<br />

■ Suppression of DHW cylinder reheating by boiler with the Vitosolic 200 .............. 42<br />

■ Suppression of reheating by the boiler with central heating backup, with solar<br />

control module ...................................................................................................... 43<br />

■ Auxiliary function for DHW heating with solar control module .............................. 43<br />

■ Auxiliary function for DHW heating with Vitosolic 100 .......................................... 43<br />

■ Auxiliary function for DHW heating with Vitosolic 200 .......................................... 43<br />

■ External heat exchanger with solar control module .............................................. 44<br />

■ External heat exchanger with Vitosolic 100 .......................................................... 45<br />

■ External heat exchanger with Vitosolic 200 .......................................................... 45<br />

■ Bypass circuits — optional extensions with Vitosolic 200 ..................................... 46<br />

■ Parallel relay with Vitosolic 200 ............................................................................ 47<br />

■ Cylinder 2 (to 4) on with Vitosolic 200 ................................................................... 47<br />

■ Cylinder heating with Vitosolic 200 ....................................................................... 47<br />

■ Cylinder priority control with Vitosolic 200 ............................................................ 47<br />

■ Utilisation of excess heat with Vitosolic 200 ......................................................... 47<br />

■ Cyclical heating ..................................................................................................... 47<br />

■ Relay kick with solar control module ..................................................................... 47<br />

■ Relay kick with Vitosolic 200 ................................................................................. 47<br />

■ SD module with Vitosolic 200 ............................................................................... 47<br />

9. 5 Accessories .............................................................................................................. 48<br />

■ Allocation to solar control units ............................................................................. 48<br />

■ Temperature sensor (DHW cylinder/heating water buffer cylinder/combi cylinder) 48<br />

■ Temperature sensor (DHW cylinder/heating water buffer cylinder/combi cylinder) 48<br />

■ Collector temperature sensor ................................................................................ 48<br />

■ Solar cell ............................................................................................................... 49<br />

■ Large display ......................................................................................................... 49<br />

■ Datalogger ............................................................................................................ 49<br />

■ High limit safety cut-out ......................................................................................... 50<br />

■ Control thermostat as temperature limiter (maximum limit) .................................. 50<br />

■ Temperature controller .......................................................................................... 51<br />

■ Temperature controller .......................................................................................... 51<br />

■ Stainless steel sensor well .................................................................................... 52<br />

■ Heat meter ............................................................................................................ 52<br />

■ Contactor relay ...................................................................................................... 53<br />

10. DHW cylinders 10. 1 Vitocell 100-U, type CVUA ........................................................................................ 54<br />

10. 2 Vitocell 100-B, type CVB .......................................................................................... 58<br />

10. 3 Vitocell 100-V, type CVW ......................................................................................... 64<br />

10. 4 Vitocell 300-B, type EVB ........................................................................................... 67<br />

10. 5 Vitocell 140-E, type SEI and Vitocell 160-E, type SES ............................................. 72<br />

10. 6 Vitocell 340-M, type SVK and Vitocell 360-M, type SVS .......................................... 75<br />

10. 7 Vitocell 100-V, type CVA .......................................................................................... 81<br />

10. 8 Vitocell 300-V, type EVI ............................................................................................ 87<br />

11. Installation accessories 11. 1 Solar-Divicon ............................................................................................................ 91<br />

11. 2 Connecting cable ...................................................................................................... 93<br />

11. 3 Installation kit for connection line .............................................................................. 93<br />

11. 4 Manual air vent valve ................................................................................................ 94<br />

11. 5 Air separator ............................................................................................................. 94<br />

11. 6 Quick-acting air vent valve (with tee) ........................................................................ 94<br />

11. 7 Connecting line ......................................................................................................... 94<br />

VITOSOL <strong>VIESMANN</strong> 3

Index (cont.)<br />

12. Information regarding design and<br />

operation<br />

11. 8 Solar flow and return line .......................................................................................... 95<br />

■ Connection set ...................................................................................................... 95<br />

■ Connection set ...................................................................................................... 95<br />

■ Connection set with locking ring fitting .................................................................. 95<br />

11. 9 Fill valve .................................................................................................................... 95<br />

11.10 Manual solar fill pump ............................................................................................... 96<br />

11.11 Solar expansion vessel ............................................................................................. 96<br />

11.12 Stagnation heat sink ................................................................................................. 97<br />

11.13 Freshwater module ................................................................................................... 97<br />

11.14 Automatic thermostatic mixing valve ........................................................................ 98<br />

11.15 Three-way diverter valve .......................................................................................... 98<br />

11.16 DHW circulation (threaded fitting) ............................................................................. 98<br />

12. 1 Snow load and wind load zones ............................................................................... 98<br />

12. 2 Installation information .............................................................................................. 99<br />

■ Distance from the edge of the roof ........................................................................ 99<br />

■ Routing pipework .................................................................................................. 99<br />

■ Equipotential bonding/lightning protection of the solar thermal system ................ 99<br />

12. 3 Collector fixing .......................................................................................................... 99<br />

■ Pitched roof installation — above roof installation ................................................ 100<br />

■ Above roof installation with rafter anchors ............................................................ 100<br />

■ Above roof installation with roof hooks ................................................................. 103<br />

■ Pitched roof installation – roof integration ............................................................. 105<br />

■ Flat roof installation ............................................................................................... 106<br />

■ Installation on walls ............................................................................................... 112<br />

■ Installation information for solar lines .................................................................... 114<br />

■ Installation information for thermal insulation ........................................................ 115<br />

12. 4 Sizing the solar thermal system ................................................................................ 115<br />

■ System for heating DHW ...................................................................................... 116<br />

■ System for DHW heating and central heating backup .......................................... 117<br />

■ Swimming pool water heating system – heat exchanger and collector ................ 118<br />

12. 5 Sizing the pipework ................................................................................................... 120<br />

■ Solar thermal system operating modes ................................................................ 120<br />

■ Installation examples (hydraulic connection) Vitosol-F, types SV and SH ............ 120<br />

■ Installation examples (hydraulic connection) Vitosol 200-T, type SD ................... 121<br />

■ Installation examples (hydraulic connection) Vitosol 200-T, type SP2 ................. 122<br />

■ Installation examples (hydraulic connection) Vitosol 300-T .................................. 124<br />

■ Pressure drop of the solar thermal system ........................................................... 124<br />

■ Flow velocity and pressure drop ........................................................................... 126<br />

■ Sizing the circulation pump ................................................................................... 128<br />

■ Ventilation ............................................................................................................. 128<br />

12. 6 Safety equipment ...................................................................................................... 129<br />

■ Stagnation in solar thermal systems ..................................................................... 129<br />

■ Expansion vessel .................................................................................................. 131<br />

■ Safety valve .......................................................................................................... 134<br />

■ High limit safety cut-out ......................................................................................... 134<br />

12. 7 Additional function for DHW heating ......................................................................... 134<br />

12. 8 Connecting the DHW circulation and thermostatic mixing valve .............................. 135<br />

13. Appendix 13. 1 Subsidy programs, permits and insurance ............................................................... 135<br />

13. 2 Glossary .................................................................................................................... 136<br />

■ Absorber ............................................................................................................... 136<br />

■ Absorption ............................................................................................................. 136<br />

■ Irradiance (insolation) ........................................................................................... 136<br />

■ Emission ............................................................................................................... 136<br />

■ Evacuation ............................................................................................................ 136<br />

■ Steam production capacity ................................................................................... 136<br />

■ Steam range ......................................................................................................... 136<br />

■ Heat pipe ............................................................................................................... 136<br />

■ Condenser ............................................................................................................ 136<br />

■ Convection ............................................................................................................ 136<br />

■ Standard roof pitch ................................................................................................ 136<br />

■ Selectively coated surface .................................................................................... 136<br />

■ Radiation energy ................................................................................................... 136<br />

■ Dispersion ............................................................................................................. 137<br />

■ Vacuum ................................................................................................................. 137<br />

■ Heat transfer medium ........................................................................................... 137<br />

■ Efficiency ............................................................................................................... 137<br />

14. Keyword index .............................................................................................................................................. 138<br />

4 <strong>VIESMANN</strong> VITOSOL<br />

5822 440 GB

5822 440 GB<br />

Principles<br />

Together with advanced <strong>Viessmann</strong> heating systems, solar thermal<br />

systems create an optimum system solution for DHW and swimming<br />

pool water heating, central heating backup and other low temperature<br />

applications.<br />

1.1 <strong>Viessmann</strong> collector range<br />

Flat-plate and vacuum tube collectors from <strong>Viessmann</strong> are suitable for<br />

DHW and swimming pool water heating, for central heating backup,<br />

as well as for the generation of process heat. The conversion of light<br />

into heat at the absorber is identical for both types of collector.<br />

Flat-plate collectors are easily and safely installed above and integrated<br />

into domestic roofs. Increasingly, collectors are also mounted on<br />

walls or as floorstanding units. Flat-plate collectors are more affordable<br />

than vacuum tube collectors. They are used for DHW heating systems,<br />

swimming pool water heating and for central heating backup.<br />

In vacuum tube collectors, the absorber is similar to a Thermos flask<br />

in that it is set into an evacuated glass tube. A vacuum has good thermal<br />

insulation properties. Heat losses are therefore lower than with<br />

flat-plate collectors, especially with high inside or low outside temperatures,<br />

i.e. under the particular operating conditions that are to be<br />

expected when heating or air conditioning a building.<br />

In <strong>Viessmann</strong> vacuum tube collectors, every vacuum tube can be rotated.<br />

This means the absorber can be optimally aligned to the sun even<br />

in unfavourable installation situations. Vacuum tube collectors with<br />

direct flow can also be installed horizontally on flat roofs. The yield per<br />

m 2 collector area is a little reduced in this case, but this is offset by a<br />

correspondingly larger collector area. <strong>Viessmann</strong>'s "ESOP" calculation<br />

program produces a yield comparison.<br />

1.2 Parameters for collectors<br />

Area designations<br />

B<br />

Flat-plate collector<br />

A<br />

C<br />

This technical guide includes a summary of all technical documents<br />

for the required components, as well as design and sizing information<br />

especially for systems for detached houses. This technical guide is a<br />

product-related addition to <strong>Viessmann</strong>'s "Solar thermal systems" technical<br />

guide. You can obtain a printed version from your <strong>Viessmann</strong><br />

sales consultant or download it from the <strong>Viessmann</strong> website<br />

(www.viessmann.de), where you will also find electronic aids regarding<br />

collector fixing and maintaining the correct pressure in solar thermal<br />

systems.<br />

Flat-plate collectors cannot be mounted horizontally, as the glass<br />

cover cannot be kept clean simply through rain, and the venting of the<br />

collector would be more difficult. Generally speaking, all collector types<br />

can be mounted on walls. When installed parallel to a wall (facing<br />

south), on an annual average, approximately 30 % less radiation hits<br />

the collector than in installations on 45° supports. If the main period of<br />

use falls into spring and autumn or winter (central heating backup),<br />

higher yields may still be achieved from the collectors, subject to the<br />

prevailing conditions. It should be noted that installation on walls is<br />

subject to certain legal requirements. For the rules regarding the<br />

implementation of collector systems, see the "technical rules for the<br />

use of linear supported glazing" (TRLV) issued by the Deutsches Institut<br />

für Bautechnik (DIBT) (see chapter "Technical Building Regulations").<br />

■ Gross area A<br />

Describes the external dimensions (length x width) of a collector. It<br />

is decisive when planning the installation and when calculating the<br />

roof area required, as well as for most subsidy programs when<br />

applying for subsidies.<br />

■ Absorber area B<br />

Selectively coated metal area, which is set into the collector.<br />

■ Aperture area C<br />

The aperture area is the technically relevant specification for designing<br />

a solar thermal system and for the use of sizing programs.<br />

Flat-plate collector:<br />

Area of collector cover through which solar rays can enter.<br />

Vacuum tube collector:<br />

Sum of longitudinal sections of the single tubes. Since the tubes are<br />

smaller at the top and bottom with no absorber area, the aperture<br />

area of these devices is slightly larger than the absorber area.<br />

VITOSOL <strong>VIESMANN</strong> 5<br />

1

1<br />

Principles (cont.)<br />

C<br />

Vacuum tube collector<br />

B<br />

Collector efficiency<br />

A<br />

The efficiency of a collector (see chapter "Specification" for the relevant<br />

collector) specifies the proportion of insolation hitting the aperture<br />

area that can be converted into useable heat. The efficiency depends,<br />

among other things, on the operating conditions of the collector. The<br />

calculation method is the same for all collector types.<br />

Some of the insolation striking the collectors is "lost" through reflection<br />

and absorption at the glass pane and through absorber reflection. The<br />

ratio between the insolation striking the collector and the radiation that<br />

is converted into heat on the absorber is used to calculate the optical<br />

efficiency η 0.<br />

When the collector heats up, it transfers some of that heat to the ambience<br />

through thermal conduction of the collector material, thermal<br />

radiation and convection. These losses are calculated by means of the<br />

heat loss factors k 1 and k 2 and the temperature differential ΔT (given<br />

in K) between the absorber and the ambience:<br />

ŋ = ŋ<br />

0<br />

- k 1 - ΔT - k 2<br />

- ΔT²<br />

Eg Eg<br />

Efficiency curves<br />

The optical efficiency η 0 and the heat loss factors k 1 and k 2 together<br />

with temperature differential ΔT and the irradiance E g are sufficient to<br />

determine the efficiency curve. Maximum efficiency is achieved when<br />

the differential between the absorber and ambience temperature ΔT<br />

and the thermal losses is zero. The higher the collector temperature,<br />

the higher the heat losses and the lower the efficiency.<br />

The typical operating ranges of the collectors can be read off the efficiency<br />

curves. This gives the adjustment options of the collectors.<br />

Typical operating ranges (see following diagram):<br />

1 Solar thermal system for DHW at low coverage<br />

2 Solar thermal system for DHW at higher coverage<br />

3 Solar thermal systems for DHW and solar central heating backup<br />

4 Solar thermal systems for process heat/solar-powered air conditioning<br />

6 <strong>VIESMANN</strong> VITOSOL<br />

5822 440 GB

5822 440 GB<br />

Principles (cont.)<br />

Efficiency<br />

0.85<br />

0.80<br />

0.70<br />

0.60<br />

0.50<br />

0.40<br />

0.30<br />

0.20<br />

0 20 40 60 80 100<br />

Temperature differential in K<br />

A Vitosol 200-F<br />

B Vitosol 200-F, type 5DI<br />

C Vitosol 300-F<br />

Thermal capacity<br />

The thermal capacity in kJ/(m 2 · K) indicates the amount of heat absorbed<br />

by the collector per m 2 and K. This heat is only available to the<br />

system to a limited extent.<br />

Idle temperature<br />

The idle temperature is the maximum temperature that the collector<br />

can reach during insolation of 1000 W/m 2 .<br />

Steam production capacity<br />

The steam production capacity in W/m 2 indicates the maximum output<br />

at which a collector produces steam during stagnation and transfers it<br />

to the system, when evaporation occurs.<br />

D Vitosol 200-T, type SD<br />

E Vitosol 200-T, type SP2<br />

F Vitosol 300-T<br />

If no heat is drawn from the collector, it will heat up until it reaches the<br />

idle temperature. In this state, the thermal losses are of the same<br />

magnitude as the radiation absorbed.<br />

VITOSOL <strong>VIESMANN</strong> 7<br />

1

1<br />

Principles (cont.)<br />

Solar coverage<br />

Solar coverage<br />

in %<br />

100<br />

90<br />

80<br />

70<br />

60 A<br />

50<br />

40<br />

30<br />

20<br />

10<br />

B<br />

300 350 400 450 500 550<br />

Energy (yield) in kWh/(m²/p.a.)<br />

A Conventional sizing for DHW systems in detached houses<br />

B Conventional sizing for large solar thermal systems<br />

1.3 Orientation, inclination and shading of the receiver surface<br />

Inclination of the receiver surface<br />

600<br />

The yield of a solar thermal system varies depending on the inclination<br />

and orientation of the collector area. If the receiver surface is angled,<br />

the angle of incidence changes, as does the irradiance, and consequently<br />

the amount of energy. This is greatest when the radiation hits<br />

the receiver surface at right angles. In our latitudes, this case never<br />

arises relative to the horizontal. Consequently, the inclination of the<br />

receiver surface can optimise the yield. In Germany, a receiver surface<br />

angled 35° receives approx. 12 % more energy when oriented towards<br />

the south (compared with a horizontal position).<br />

Orientation of the receiver surface<br />

An additional factor for calculating the amount of energy that can be<br />

expected is the orientation of the receiver surface. In the northern<br />

hemisphere, an orientation towards south is ideal. The following figure<br />

shows the interaction of orientation and inclination. Relative to the<br />

horizontal, greater or lesser yields result. A range for optimum yield of<br />

a solar thermal system can be defined between south-east and southwest<br />

and at angles of inclination between 25 and 70°. Greater deviations,<br />

for example, for installation on walls, can be compensated for by<br />

a correspondingly larger collector area.<br />

±0%<br />

-15% +10%<br />

+5%<br />

-40% -20%<br />

-25%<br />

West South<br />

South-west<br />

Avoiding shading of the receiver surface<br />

±0%<br />

+10% -15%<br />

+5%<br />

-20% -40%<br />

Looking at the installation of a collector facing south, we recommend<br />

that the area between south-east and south-west is kept free of shading<br />

(at an angle towards the horizon of up to 20°). It should be remembered<br />

that the system is to operate for longer than 20 years, and that<br />

during this time, for example, trees would grow substantially.<br />

-25%<br />

South East<br />

South-east<br />

The solar coverage rate indicates what percentage of the energy<br />

required annually for DHW applications can be covered by the solar<br />

thermal system.<br />

Designing a solar thermal system always entails finding a good compromise<br />

between yield and solar coverage. The higher the selected<br />

solar coverage, the more conventional energy is saved.<br />

However, this is linked to an excess of heat in summer. This means a<br />

lower average collector efficiency and consequently lower yields<br />

(energy in kWh) per m 2 absorber area.<br />

8 <strong>VIESMANN</strong> VITOSOL<br />

5822 440 GB

5822 440 GB<br />

Principles (cont.)<br />

20°<br />

VITOSOL <strong>VIESMANN</strong> 9<br />

1

2<br />

Vitosol 200-F<br />

2.1 Product description<br />

The main component of the Vitosol 200-F, type SV2A/SH2A is the<br />

highly selectively coated absorber. It ensures a high absorption of<br />

insolation and low emission of thermal radiation. A meander-shaped<br />

copper pipe through which the heat transfer medium flows is part of<br />

the absorber.<br />

The heat transfer medium absorbs the absorber heat through the copper<br />

pipe. The absorber is encased in a highly insulated collector housing<br />

that minimises the thermal losses of the collector.<br />

The high-grade thermal insulation provides temperature stability and<br />

is free from gas emissions. The cover comprises a solar glass panel.<br />

The glass has a very low iron content, thereby reducing reflection losses.<br />

A Solar glass cover, 3.2 mm<br />

B Aluminium cover strip<br />

C Pane gasket<br />

D Absorber<br />

E Meander-shaped copper pipe<br />

Benefits<br />

■ Powerful flat-plate collector with a highly selectively coated<br />

absorber.<br />

■ Absorber designed as meander layout with integral headers. Up to<br />

12 collectors can be linked in parallel.<br />

■ Universal application for above roof, roof integration and freestanding<br />

installation – with vertical or horizontal orientation. Type SH is<br />

suitable for installation on walls.<br />

■ Attractive collector design; frame in RAL 8019 (brown). Upon<br />

request, the frame is also available in all other RAL colours.<br />

■ The selectively coated absorber, the cover made from low ferrous<br />

solar glass and the highly effective thermal insulation ensure high<br />

solar yields.<br />

Up to 12 collectors can be combined together to create a single collector<br />

array. For this purpose, the standard delivery includes flexible<br />

connecting pipes with O-rings.<br />

A connection set with locking ring fittings enables the collector array<br />

to be readily connected to the pipes of the solar circuit. The collector<br />

temperature sensor is mounted in a sensor well set in the solar circuit<br />

flow.<br />

The Vitosol 200-F, type SV2B/SH2B with a special absorber coating<br />

is designed for coastal regions (see chapter "Specification").<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

H<br />

K<br />

F Melamine epoxy foam insulation<br />

G Melamine epoxy foam insulation<br />

H Aluminium frame in RAL 8019<br />

K Steel bottom plate with an aluminium-zinc coating<br />

■ Permanently sealed and high stability through all-round folded aluminium<br />

frame and seamless pane gasket.<br />

■ Puncture-proof and corrosion-resistant back panel.<br />

■ Easy to assemble <strong>Viessmann</strong> fixing system with statically-tested and<br />

corrosion-resistant components made from stainless steel and aluminium<br />

– standard for all <strong>Viessmann</strong> collectors.<br />

■ Quick and reliable collector connection through a flexible corrugated<br />

stainless steel pipe plug-in connector.<br />

10 <strong>VIESMANN</strong> VITOSOL<br />

5822 440 GB

5822 440 GB<br />

Vitosol 200-F (cont.)<br />

Delivered condition<br />

The Vitosol 200-F is delivered fully assembled ready to connect. <strong>Viessmann</strong> offers complete solar heating systems with Vitosol 200-F<br />

(packs) for DHW heating and/or central heating backup (see pack<br />

pricelist).<br />

VITOSOL <strong>VIESMANN</strong> 11<br />

2

2<br />

Vitosol 200-F (cont.)<br />

2.2 Specification<br />

Vitosol 200-F is available with 2 different absorber coatings. Type<br />

SV2B/SH2B has a special absorber coating that allows these collectors<br />

to be used in coastal regions.<br />

Distance to the coast:<br />

■ up to 100 m:<br />

only use type SV2B/SH2B<br />

■ between 100 and 1000 m:<br />

type SV2B/SH2B is recommended<br />

Note<br />

<strong>Viessmann</strong> does not accept liability when type SV2A/SH2A is used in<br />

such regions.<br />

Type SV2A SH2A SV2B SH2B<br />

Gross area<br />

(required when applying for subsidies)<br />

m2 2.51<br />

Absorber area m2 2.32<br />

Aperture area m2 2.33<br />

Installation position (see figure below) A (above roof/ B (above roof/ A (above roof/ B (above roof/<br />

roof integration), roof integration), roof integration), roof integration),<br />

C, D<br />

C, D, E C, D<br />

C, D, E<br />

Spacing between collectors<br />

Dimensions<br />

mm 21<br />

Width mm 1056 2380 1056 2380<br />

Height mm 2380 1056 2380 1056<br />

Depth mm 90 90 90 90<br />

The following values apply to the absorber area:<br />

– Optical efficiency % 79.3 78.3<br />

– Thermal loss correction value k1 W/(m2 · K) 4.04 4.07<br />

– Thermal loss correction value k2 W/(m2 · K2 ) 0,0182 0,016<br />

Thermal capacity kJ/(m2 · K) 5.0 4.6<br />

Weight kg 40.9 42.6<br />

Liquid content<br />

(heat transfer medium)<br />

litres 1.83 2.48 1.83 2.48<br />

Permiss. operating pressure<br />

(see chapter "Solar expansion vessel")<br />

bar 6<br />

Max. idle temperature<br />

Steam output<br />

°C 186 185<br />

– Favourable installation position W/m2 60<br />

– Unfavourable installation position W/m2 100<br />

Connection Ø mm 22<br />

B<br />

C<br />

A<br />

E<br />

D<br />

12 <strong>VIESMANN</strong> VITOSOL<br />

5822 440 GB

5822 440 GB<br />

Vitosol 200-F (cont.)<br />

2380<br />

2200<br />

90<br />

Type SV2A/SV2B<br />

1056<br />

KR Collector return (inlet)<br />

KV Collector flow (outlet)<br />

876<br />

1056<br />

90<br />

Type SH2A/SH2B<br />

KR Collector return (inlet)<br />

KV Collector flow (outlet)<br />

2.3 Approved quality<br />

2380<br />

90<br />

51<br />

KV<br />

KR<br />

The collectors meet the requirements of the "Blue Angel" certificate of<br />

environmental excellence to RAL UZ 73.<br />

Tested in accordance with Solar KEYMARK and EN 12975.<br />

90<br />

51<br />

KV<br />

KR<br />

CE designation according to current EC Directives.<br />

VITOSOL <strong>VIESMANN</strong> 13<br />

2

3<br />

Vitosol 200-F, type 5DI<br />

3.1 Product description<br />

The main component of the Vitosol 200-F, type 5DI, is the highly<br />

selectively coated copper absorber. It ensures a high absorption of<br />

insolation and low emission of thermal radiation. Copper pipes are fitted<br />

to the absorber through which the heat transfer medium flows.<br />

The heat transfer medium absorbs the absorber heat through the copper<br />

pipe. The absorber is encased in a highly insulated collector housing<br />

that minimises the thermal losses of the collector.<br />

The high-grade thermal insulation provides temperature stability and<br />

is free from gas emissions. The cover comprises a solar glass panel.<br />

The glass has a very low iron content, thereby reducing reflection losses.<br />

A Solar glass cover, 4 mm<br />

B Aluminium cover frame<br />

C Harp-shaped absorber made from copper<br />

D Aluminium housing, natural finish<br />

E Mineral fibre insulating strips<br />

Benefits<br />

■ Large flat-plate collector with a highly selectively coated absorber.<br />

■ High efficiency through highly selectively coated absorber, integral<br />

piping and highly effective insulation.<br />

Delivered condition<br />

The collector is delivered complete with roofing frame, connecting<br />

pipes and lifting eyes.<br />

At the back of the collector are flexible, thermally insulated flow and<br />

return pipes as well as the sensor well for the collector temperature<br />

sensor.<br />

Vitosol 200-F, type 5DI, are designed exclusively for roof integration.<br />

F Thermal insulation made from mineral fibre<br />

G Reinforcing frame<br />

H Flexible connecting pipe with thermal insulation<br />

K Mounting hooks<br />

■ Absorber area: 4.76 m 2<br />

■ Quick installation due to the roofing frame fitted onto the collector,<br />

flexible connections and lifting eyes.<br />

14 <strong>VIESMANN</strong> VITOSOL<br />

5822 440 GB

5822 440 GB<br />

Vitosol 200-F, type 5DI (cont.)<br />

3.2 Specification<br />

Gross area<br />

(required when applying for subsidies)<br />

m2 5.25<br />

Absorber area m2 4.65<br />

Aperture area m2 Dimensions<br />

4.85<br />

Width mm 2570<br />

Height mm 2040<br />

Depth<br />

The following values apply to the absorber area:<br />

mm 116<br />

– Optical efficiency % 81.9<br />

– Thermal loss correction value k1 W/(m2 · K) 3.92<br />

– Thermal loss correction value k2 W/(m2 · K2 ) 0.0234<br />

Thermal capacity kJ/(m2 · K) 6.4<br />

Weight kg 105<br />

Liquid content<br />

(heat transfer medium)<br />

litres 4.2<br />

Permiss. operating pressure bar 6<br />

Max. idle temperature °C 198<br />

Steam output W/m2 100<br />

Connection Ø mm 22<br />

Idle temperature<br />

Temperature at the hottest part of the collector when no heat is drawn<br />

off, at 1000 W global radiation.<br />

KR Collector return (inlet)<br />

KV Collector flow (outlet)<br />

3.3 Approved quality<br />

2870<br />

2570<br />

The collectors meet the requirements of the "Blue Angel" certificate of<br />

environmental excellence to RAL UZ 73.<br />

Tested in accordance with Solar KEYMARK and EN 12975.<br />

2445<br />

KR,<br />

KV<br />

116<br />

35 2040<br />

CE designation according to current EC Directives.<br />

VITOSOL <strong>VIESMANN</strong> 15<br />

3

4<br />

Vitosol 300-F<br />

4.1 Product description<br />

The main component of the Vitosol 300-F, type SV3A/SH3A, is the<br />

highly selectively coated absorber and the cover with an anti-reflex<br />

glass pane. This cover significantly improves the optical efficiency of<br />

the collector. The absorber ensures high absorption of insolation and<br />

low emissions of thermal radiation. A meander-shaped copper pipe<br />

through which the heat transfer medium flows is part of the absorber.<br />

The heat transfer medium absorbs the absorber heat through the copper<br />

pipe. The absorber is encased in a highly insulated collector housing<br />

that minimises the thermal losses of the collector.<br />

The high-grade thermal insulation is resistant to temperature, releases<br />

no gas and is optimised for the demands made of a high performance<br />

collector.<br />

A Cover made from solar glass with an anti-reflex coating, 3.2 mm<br />

B Aluminium cover strip<br />

C Pane gasket<br />

D Absorber<br />

E Meander-shaped copper pipe<br />

Benefits<br />

■ High performance flat-plate collector with anti-reflex glass.<br />

■ Attractive collector design; frame in RAL 8019 (brown). Upon<br />

request, the frame is also available in any other RAL colour.<br />

■ Absorber designed as meander layout with integral headers. Up to<br />

12 collectors can be linked in parallel.<br />

■ Universal application for above roof, roof integration and freestanding<br />

installation – with vertical or horizontal orientation. Type SH is<br />

suitable for installation on walls.<br />

■ High efficiency through highly selectively coated absorber and cover<br />

made from translucent anti-reflex glass.<br />

Up to 12 collectors can be combined together to create a single collector<br />

array. For this purpose, the standard delivery includes flexible<br />

connecting pipes with O-rings.<br />

A connection set with locking ring fittings enables the collector array<br />

to be readily connected to the pipes of the solar circuit. The collector<br />

temperature sensor is mounted in a sensor well set in the solar circuit<br />

flow.<br />

The Vitosol 300-F, type SV3B/SH3B with a special absorber coating<br />

is designed for coastal regions (see chapter "Specification").<br />

A<br />

B<br />

C<br />

D<br />

E<br />

F<br />

G<br />

H<br />

K<br />

F Melamine epoxy foam insulation<br />

G Melamine epoxy foam insulation<br />

H Aluminium frame in RAL 8019<br />

K Steel bottom plate with an aluminium-zinc coating<br />

■ Permanently sealed and high stability through all-round folded aluminium<br />

frame and seamless pane gasket.<br />

■ Puncture-proof and corrosion-resistant back panel made from zinc<br />

plated sheet steel.<br />

■ Easy to assemble <strong>Viessmann</strong> fixing system with statically-tested and<br />

corrosion-resistant components made from stainless steel and aluminium<br />

– standard for all <strong>Viessmann</strong> collectors.<br />

■ Quick and reliable collector connection through a flexible corrugated<br />

stainless steel pipe plug-in connector.<br />

16 <strong>VIESMANN</strong> VITOSOL<br />

5822 440 GB

5822 440 GB<br />

Vitosol 300-F (cont.)<br />

Delivered condition<br />

The Vitosol 300-F is delivered fully assembled ready to connect. <strong>Viessmann</strong> offers complete solar heating systems with Vitosol 300-F<br />

(packs) for DHW heating and/or central heating backup (see pack<br />

pricelist).<br />

VITOSOL <strong>VIESMANN</strong> 17<br />

4

4<br />

Vitosol 300-F (cont.)<br />

4.2 Specification<br />

Vitosol 300-F is available with 2 different absorber coatings. Type<br />

SV3B/SH3B has a special absorber coating that allows these collectors<br />

to be used in coastal regions.<br />

Distance to the coast:<br />

■ up to 100 m:<br />

only use type SV3B/SH3B<br />

■ between 100 and 1000 m:<br />

type SV3B/SH3B is recommended<br />

Note<br />

<strong>Viessmann</strong> does not accept liability when type SV3A/SH3A is used in<br />

such regions.<br />

Type SV3A SH3A SV3B SH3B<br />

Gross area<br />

(required when applying for subsidies)<br />

m2 2.51<br />

Absorber area m2 2.32<br />

Aperture area m2 2.33<br />

Installation position (see figure below) A (above roof/ B (above roof/ A (above roof/ B (above roof/<br />

roof integration), roof integration), roof integration), roof integration),<br />

C, D<br />

C, D, E C, D<br />

C, D, E<br />

Spacing between collectors<br />

Dimensions<br />

mm 21<br />

Width mm 1056 2380 1056 2380<br />

Height mm 2380 1056 2380 1056<br />

Depth mm 90 90 90 90<br />

The following values apply to the absorber area:<br />

– Optical efficiency % 83.4 80.3<br />

– Thermal loss correction value k1 W/(m2 · K) 3.66 3.77<br />

– Thermal loss correction value k2 W/(m2 · K2 ) 0,0169 0,0156<br />

Thermal capacity kJ/(m2 · K) 5.0 4.6 4.6 4.6<br />

Weight kg 41.3 43.1<br />

Liquid content<br />

(heat transfer medium)<br />

litres 1.83 2.48 1.83 2.48<br />

Permiss. operating pressure<br />

(see chapter "Solar expansion vessel")<br />

bar 6<br />

Max. idle temperature<br />

Steam output<br />

°C 206 205<br />

– Favourable installation position W/m2 60<br />

– Unfavourable installation position W/m2 100<br />

Connection Ø mm 22<br />

B<br />

C<br />

A<br />

E<br />

D<br />

18 <strong>VIESMANN</strong> VITOSOL<br />

5822 440 GB

5822 440 GB<br />

Vitosol 300-F (cont.)<br />

2380<br />

2200<br />

90<br />

Type SV3A/SV3B<br />

1056<br />

KR Collector return (inlet)<br />

KV Collector flow (outlet)<br />

876<br />

1056<br />

90<br />

Type SH3A/SH3B<br />

KR Collector return (inlet)<br />

KV Collector flow (outlet)<br />

4.3 Approved quality<br />

2380<br />

90<br />

51<br />

KV<br />

KR<br />

The collectors meet the requirements of the "Blue Angel" certificate of<br />

environmental excellence to RAL UZ 73.<br />

Tested in accordance with Solar KEYMARK and EN 12975.<br />

90<br />

51<br />

KV<br />

KR<br />

CE designation according to current EC Directives.<br />

VITOSOL <strong>VIESMANN</strong> 19<br />

4

5<br />

Vitosol 200-T, type SD2<br />

5.1 Product description<br />

A Header casing<br />

B Melamine epoxy foam insulation<br />

C Return pipe<br />

D Coaxial manifold and distributor pipe<br />

E Coaxial heat exchanger pipe<br />

F Absorber<br />

G Evacuated glass tube<br />

The Vitosol 200-T vacuum tube collector is available in the following<br />

versions:<br />

■ 1 m 2 with 10 tubes<br />

■ 2 m 2 with 20 tubes<br />

■ 3 m 2 with 30 tubes.<br />

Benefits<br />

■ Highly efficient, direct flow vacuum tube collector for high solar<br />

energy utilisation.<br />

■ Universal application through vertical or horizontal installation in any<br />

location, either on rooftops or on walls.<br />

■ Easy and safe connection of the individual tubes through an innovative<br />

plug-in system.<br />

■ The absorber areas integrated into the vacuum tubes are not susceptible<br />

to contamination.<br />

■ Tubes can be rotated for optimum orientation towards the sun,<br />

thereby maximising the energy yield.<br />

The Vitosol 200-T can be installed on pitched roofs, flat roofs, on walls<br />

and as a freestanding collector.<br />

On pitched roofs the collectors may be positioned in line (tubes at right<br />

angles to the roof ridge) or across (tubes parallel to the roof ridge).<br />

■ DHW heating systems:<br />

The collectors may be positioned vertically (tubes at right angles to<br />

the ridge of the roof) or horizontally (tubes parallel to the ridge of the<br />

roof).<br />

■ Systems to back up central heating:<br />

The collectors should be installed horizontally (tubes parallel to the<br />

ridge of the roof) with connection from below. This will positively<br />

influence the stagnation characteristics.<br />

The vacuum in the glass tubes ensures optimum thermal insulation.<br />

Convection losses between the glass tube and the absorber are almost<br />

completely eliminated. This enables the utilisation of even low radiation<br />

levels (diffused radiation).<br />

A highly selectively coated copper absorber is integrated into each<br />

vacuum tube. It ensures high absorption of insolation and low emissions<br />

of thermal radiation.<br />

A coaxial heat exchanger pipe, through which the heat transfer<br />

medium flows, is arranged on the absorber. The heat transfer medium<br />

absorbs heat from the absorber via the heat exchanger pipe.<br />

The heat exchanger pipe feeds into a distributor pipe.<br />

To fully utilise the available solar energy, every vacuum tube is able to<br />

pivot so that the absorber can be turned towards the sun.<br />

Up to 5 collectors can be joined in series to create a single collector<br />

array (collector arrays arranged in series should be of the same<br />

size).<br />

For this purpose, the standard delivery includes flexible connecting<br />

pipes with O-rings.<br />

The flow and return pipes integrated into the connecting casing enable<br />

the connection of the solar flow and solar return pipes of several collectors<br />

on one side.<br />

A connection set with locking ring fittings enables the collector array<br />

to be readily connected to the pipes of the solar circuit. Install the collector<br />

temperature sensor in a sensor well in the flow pipe of the solar<br />

heating circuit.<br />

■ Highly effective thermal insulation of the header casing for minimum<br />

thermal losses.<br />

■ Easy assembly through the <strong>Viessmann</strong> fixing system and corrugated<br />

stainless steel plug-in connectors.<br />

■ The flow and return connection on one side through the integral<br />

header inside the header casing minimises the effort required in<br />

connection with pipework.<br />

■ Attractive collector design, header casing in RAL 8019 (brown).<br />

20 <strong>VIESMANN</strong> VITOSOL<br />

5822 440 GB

5822 440 GB<br />

Vitosol 200-T, type SD2 (cont.)<br />

Delivered condition<br />

Packed in separate cartons:<br />

■ Vacuum tubes, 10 pce. per packing unit<br />

■ Header casing with mounting rails<br />

<strong>Viessmann</strong> offers complete solar thermal systems with Vitosol 200-T<br />

(packs) for DHW heating (see pack pricelist).<br />

VITOSOL <strong>VIESMANN</strong> 21<br />

5

5<br />

Vitosol 200-T, type SD2 (cont.)<br />

5.2 Specification<br />

Type, SD2 1 m2 2 m2 3 m2 Number of tubes 10 20 30<br />

Gross area<br />

(required when applying for subsidies)<br />

m2 1.44 2.88 4.32<br />

Absorber area m2 1.03 2.05 3.07<br />

Aperture area m2 1.06 2.11 3.17<br />

Installation position (see figure below) A, B, C, D, E, F<br />

Spacing between collectors<br />

Dimensions<br />

mm 47 47 47<br />

Width a mm 709 1418 2127<br />

Height b mm 2031 2031 2031<br />

Depth c<br />

The following values apply to the absorber area:<br />

mm 143 143 143<br />

– Optical efficiency % 82.0 82.0 83.2<br />

– Thermal loss correction value k1 W/(m2 · K) 1.62 1.62 1.87<br />

– Thermal loss correction value k2 W/(m2 · K2 ) 0.0068 0.0068 0.0041<br />

Thermal capacity kJ/(m2 · K) 9.8 9.8 9.8<br />

Weight kg 26 51 76<br />

Liquid content<br />

(heat transfer medium)<br />

litres 2.2 4.2 6.2<br />

Permiss. operating pressure<br />

(see chapter "Solar expansion vessel")<br />

bar 6 6 6<br />

Max. idle temperature<br />

Steam output<br />

°C 295 282 282<br />

– Favourable installation position W/m2 100 100 100<br />

– Unfavourable installation position W/m2 200 200 200<br />

Connection Ø mm 22 22 22<br />

B<br />

C<br />

D<br />

A<br />

F<br />

E<br />

22 <strong>VIESMANN</strong> VITOSOL<br />

5822 440 GB

5822 440 GB<br />

Vitosol 200-T, type SD2 (cont.)<br />

KR Collector return<br />

KV Collector flow<br />

5.3 Approved quality<br />

a<br />

b<br />

Ø 65<br />

The collectors meet the requirements of the "Blue Angel" certificate of<br />

environmental excellence to RAL UZ 73.<br />

Tested in accordance with Solar KEYMARK and EN 12975.<br />

c<br />

KR<br />

KV<br />

CE designation according to current EC Directives.<br />

VITOSOL <strong>VIESMANN</strong> 23<br />

5

6<br />

Vitosol 200-T, type SD2A<br />

6.1 Product description<br />

A Header casing<br />

B Melamine epoxy foam insulation<br />

C Return pipe<br />

D Coaxial manifold and distributor pipe<br />

E Coaxial heat exchanger pipe<br />

F Absorber<br />

G Evacuated glass tube<br />

The Vitosol 200-T vacuum tube collector is available in the following<br />

versions:<br />

Benefits<br />

■ Highly efficient, direct flow vacuum tube collector for high solar<br />

energy utilisation.<br />

■ Universal application through vertical or horizontal installation in any<br />

location, either on rooftops or on walls.<br />

■ Easy and safe connection of the individual tubes through an innovative<br />

plug-in system.<br />

■ The absorber areas integrated into the vacuum tubes are not susceptible<br />

to contamination.<br />

■ Tubes can be rotated for optimum orientation towards the sun,<br />

thereby maximising the energy yield.<br />

■ 2 m 2 with 20 tubes<br />

■ 3 m 2 with 30 tubes.<br />

The Vitosol 200-T can be installed on pitched roofs, flat roofs, on walls<br />

and as a freestanding collector.<br />

On pitched roofs the collectors may be positioned in line (tubes at right<br />

angles to the roof ridge) or across (tubes parallel to the roof ridge).<br />

■ DHW heating systems:<br />

The collectors may be positioned vertically (tubes vertical, relative<br />

to the roof ridge) or horizontally (tubes parallel to the roof ridge).<br />

■ Systems to back up central heating:<br />

The collectors should be installed horizontally (tubes parallel to the<br />

roof ridge). This will positively influence the stagnation characteristics.<br />

The vacuum in the glass tubes ensures optimum thermal insulation.<br />

Convection losses between the glass tube and the absorber are almost<br />

completely eliminated. This enables even low radiation levels to be<br />

utilised.<br />

Each vacuum tube contains a highly selectively coated copper<br />

absorber. It ensures high absorption of insolation and low emissions<br />

of thermal radiation.<br />

A coaxial heat exchanger pipe, through which the heat transfer<br />

medium flows, is arranged on the absorber. The heat transfer medium<br />

absorbs heat from the absorber via the heat exchanger pipe.<br />

The heat exchanger pipe feeds into a distributor pipe.<br />

To fully utilise the available solar energy, every vacuum tube is able to<br />

pivot so that the absorber can be turned towards the sun.<br />

Up to 15 m 2 collector surface can be joined in series to create a single<br />

collector array (collectors arranged in series should be of the same<br />

size).<br />

For this purpose, the standard delivery includes flexible connecting<br />

pipes with O-rings.<br />

The flow and return pipes integrated into the connecting casing enable<br />

the connection of the solar flow and solar return pipes of several collectors<br />

on one side.<br />

A connection set with locking ring fittings enables the collector array<br />

to be readily connected to the pipes of the solar circuit. Install the collector<br />

temperature sensor in a sensor well in the flow pipe of the solar<br />

heating circuit.<br />

■ Highly effective thermal insulation of the header casing for minimum<br />

thermal losses.<br />

■ Easy assembly through the <strong>Viessmann</strong> fixing system and corrugated<br />

stainless steel plug-in connectors.<br />

■ The flow and return connection on one side through the integral<br />

header inside the header casing minimises the effort required in<br />

connection with pipework.<br />

■ Attractive collector design, header casing in RAL 8019 (brown).<br />

24 <strong>VIESMANN</strong> VITOSOL<br />

5822 440 GB

5822 440 GB<br />

Vitosol 200-T, type SD2A (cont.)<br />

Delivered condition<br />

Packed in separate cartons:<br />

■ Vacuum tubes, 10 pce. per packing unit<br />

■ Header casing with mounting rails<br />

<strong>Viessmann</strong> offers complete solar thermal systems with Vitosol 200-T<br />

(packs) for DHW heating (see pack pricelist).<br />

VITOSOL <strong>VIESMANN</strong> 25<br />

6

6<br />

Vitosol 200-T, type SD2A (cont.)<br />

6.2 Specification<br />

Type SD2A 2 m2 3 m2 Number of tubes 20 30<br />

Gross area<br />

(required when applying for subsidies)<br />

m2 2.88 4.32<br />

Absorber area m2 2.01 3.02<br />

Aperture area m2 2.14 3.23<br />

Installation position (see figure below) A, B, C, D, E, F<br />

Spacing between collectors<br />

Dimensions<br />

mm 47 47<br />

Width a mm 1418 2127<br />

Height b mm 2043 2043<br />

Depth c<br />

The following values apply to the absorber area:<br />

mm 143 143<br />

– Optical efficiency % 78.9 79.1<br />

– Thermal loss correction value k1 W/(m2 · K) 1.36 1.10<br />

– Thermal loss correction value k2 W/(m2 · K2 ) 0.0075 0.0076<br />

Thermal capacity kJ/(m2 · K) 10.0 10.1<br />

Weight kg 61 95<br />

Liquid content<br />

(heat transfer medium)<br />

litres 4.2 6.2<br />

Permiss. operating pressure<br />

(see chapter "Solar expansion vessel")<br />

bar 6 6<br />

Max. idle temperature<br />

Steam output<br />

°C 295 295<br />

– Favourable installation position W/m2 100 100<br />

– Unfavourable installation position W/m2 200 200<br />

Connection Ø mm 22 22<br />

B<br />

C<br />

D<br />

A<br />

F<br />

E<br />

26 <strong>VIESMANN</strong> VITOSOL<br />

5822 440 GB

5822 440 GB<br />

Vitosol 200-T, type SD2A (cont.)<br />

KR Collector return<br />

KV Collector flow<br />

6.3 Approved quality<br />

a<br />

b<br />

Ø 65<br />

The collectors meet the requirements of the "Blue Angel" certificate of<br />

environmental excellence to RAL UZ 73.<br />

Tested in accordance with Solar KEYMARK and EN 12975.<br />

c<br />

KR<br />

KV<br />

CE designation according to current EC Directives.<br />

VITOSOL <strong>VIESMANN</strong> 27<br />

6

7<br />

Vitosol 200-T, type SP2<br />

7.1 Product description<br />

A<br />

B<br />

C<br />

D<br />

E<br />

E<br />

C<br />

D<br />

A Twin pipe heat exchanger<br />

B Adaptor<br />

C Absorber<br />

Benefits<br />

■ Highly efficient vacuum tube collector based on the heat pipe principle<br />

for high operational reliability.<br />

■ Universal application through vertical or horizontal installation in any<br />

location, either on rooftops, walls or for freestanding installation.<br />

■ The absorber areas with Sol-titanium coating that are integrated into<br />

the vacuum tubes, are not susceptible to contamination.<br />

■ Efficient heat transfer through fully encapsulated condensers and<br />

twin-pipe Duotec heat exchanger.<br />

Delivered condition<br />

Packed in separate cartons:<br />

■ Vacuum tubes, 10 pce per packing unit<br />

■ Header casing with mounting rails<br />

D Heat pipe<br />

E Evacuated glass tube<br />

The Vitosol 200-T vacuum tube collector is available in the following<br />

versions:<br />

■ 2 m 2 with 20 tubes<br />

■ 3 m 2 with 30 tubes.<br />

Vitosol 200-T can be installed on pitched roofs, flat roofs, on walls and<br />

as freestanding collectors.<br />

On pitched roofs the collectors may be positioned in line (tubes at right<br />

angles to the roof ridge) or across (tubes parallel to the roof ridge).<br />

A highly selectively coated copper absorber is integrated into each<br />

vacuum tube. It ensures high absorption of insolation and low emissions<br />

of thermal radiation.<br />

A heat pipe filled with an evaporation liquid is arranged on the<br />

absorber. The heat pipe is connected to the condenser. The condenser<br />

is fitted inside a "Duotec" twin-pipe heat exchanger.<br />

This involves a so-called "dry connection", i. e. the tubes can be rotated<br />

or replaced even when the installation is filled and under pressure.<br />

The heat is transferred from the absorber to the heat pipe. This causes<br />

the liquid to evaporate. The steam rises into the condenser. The heat<br />

is transferred to the passing heat transfer medium by the twin-pipe heat<br />

exchanger containing the condenser which causes the steam to condense.<br />

The condensate flows back into the heat pipe and the process<br />

is repeated.<br />

The angle of inclination must be greater than zero to guarantee circulation<br />

of the evaporator liquid in the heat exchanger.<br />

Deviations from the south can be partially compensated by turning the<br />

vacuum tubes.<br />

Collector areas of up to 15 m 2 can be joined to form a single collector<br />

array. For this purpose, the standard delivery includes flexible connecting<br />

pipes with O-rings.<br />

A connection set with locking ring fittings enables the collector array<br />

to be readily connected to the pipes of the solar circuit. The collector<br />

temperature sensor is installed in a sensor mount on the flow pipe in<br />

the header casing of the collector.<br />

■ Tubes can be rotated for optimum alignment to the sun, thereby<br />

maximising the energy yield.<br />

■ Dry connection, meaning pipes can be fitted or replaced when the<br />

system is full.<br />

■ Highly effective thermal insulation of the header casing for minimum<br />

thermal losses.<br />

■ Easy installation through the <strong>Viessmann</strong> assembly and connection<br />

systems.<br />

<strong>Viessmann</strong> offers complete solar thermal systems with Vitosol 200-T<br />

(packs) for DHW heating and/or central heating backup (see pack<br />

pricelist).<br />

28 <strong>VIESMANN</strong> VITOSOL<br />

5822 440 GB

5822 440 GB<br />

Vitosol 200-T, type SP2 (cont.)<br />

7.2 Specification<br />

Type SP2 2 m2 3 m2 Number of tubes 20 30<br />

Gross area<br />

(required when applying for subsidies)<br />

m2 2.88 4.32<br />

Absorber area m2 2.00 3.02<br />

Aperture area m2 2.15 3.23<br />

Installation position (see figure below) A, B, C, D, E, F, G<br />

Spacing between collectors<br />

Dimensions<br />

mm 102 102<br />

Width a mm 1420 2129<br />

Height b mm 2040 2040<br />

Depth c<br />

The following values apply to the absorber area:<br />

mm 143 143<br />

– Optical efficiency % 76.6 76.6<br />

– Thermal loss correction value k1 W/(m2 · K) 1.42 1.42<br />

– Thermal loss correction value k2 W/(m2 · K2 ) 0,005 0,005<br />

Thermal capacity kJ/(m2 · K) 8.4 8.4<br />

Weight kg 58 87<br />

Liquid content<br />

(heat transfer medium)<br />

litres 1.13 1.65<br />

Permiss. operating pressure bar 6 6<br />

Max. idle temperature °C 270 270<br />

Steam output W/m2 100 100<br />

Connection Ø mm 22 22<br />

B<br />

C<br />

D<br />

A<br />

F<br />

E<br />

VITOSOL <strong>VIESMANN</strong> 29<br />

7

7<br />

Vitosol 200-T, type SP2 (cont.)<br />

KR Collector return<br />

KV Collector flow<br />

7.3 Approved quality<br />

a<br />

b<br />

Ø 65<br />

The collectors meet the requirements of the "Blue Angel" certificate of<br />

environmental excellence to RAL UZ 73.<br />

Tested in accordance with Solar KEYMARK and EN 12975.<br />

c<br />

KR<br />

KV KV<br />

CE designation according to current EC Directives.<br />

30 <strong>VIESMANN</strong> VITOSOL<br />

5822 440 GB

5822 440 GB<br />

Vitosol 300-T<br />

8.1 Product description<br />

A<br />

B<br />

C<br />

D<br />

E<br />

E<br />

C<br />

D<br />

A Twin-pipe heat exchanger<br />

B Condenser<br />

Benefits<br />

■ Highly efficient vacuum tube collector based on the heat pipe principle<br />

for high operational reliability.<br />

■ The absorber areas with a highly selective coating that are integrated<br />

into the vacuum tubes are not susceptible to contamination.<br />

■ Efficient heat transfer through fully encapsulated condensers and<br />

twin-pipe Duotec heat exchanger.<br />

■ Tubes can be rotated for optimum alignment with the sun, thereby<br />

maximising the energy yield.<br />

Delivered condition<br />

C Absorber<br />

D Heat pipe<br />

E Evacuated glass tube<br />

The Vitosol 300-T vacuum tube collector is available in the following<br />

versions:<br />

■ 2 m 2 with 20 tubes<br />

■ 3 m 2 with 30 tubes.<br />

The Vitosol 300-T can be installed on pitched roofs or freestanding on<br />

flat roofs.<br />

A highly selectively coated copper absorber is integrated into each<br />

vacuum tube. It ensures high absorption of insolation and low emissions<br />

of thermal radiation.<br />

A heat pipe filled with an evaporation liquid is arranged on the<br />

absorber. The heat pipe is connected to the condenser. The condenser<br />

is fitted inside a "Duotec" twin-pipe heat exchanger.<br />

This involves a so-called "dry connection", i. e. the tubes can be rotated<br />

or replaced even when the installation is filled and under pressure.<br />

The heat is transferred from the absorber to the heat pipe. This causes<br />

the liquid to evaporate. The steam rises into the condenser. The heat<br />

is transferred to the passing heat transfer medium by the twin-pipe heat<br />

exchanger containing the condenser which causes the steam to condense.<br />

The condensate flows back into the heat pipe and the process<br />

is repeated.<br />

The angle of inclination must be at least 25 ° to guarantee circulation<br />

of the evaporator liquid in the heat exchanger.<br />