Download Brochure - Hilco Industrial

Download Brochure - Hilco Industrial

Download Brochure - Hilco Industrial

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

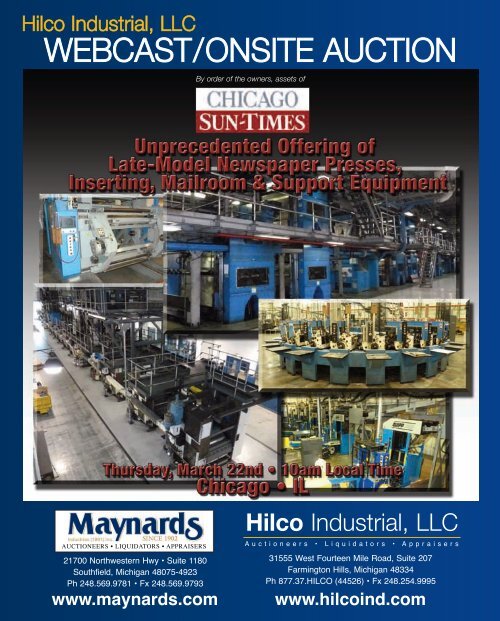

<strong>Hilco</strong> <strong>Industrial</strong>, LLCWebCast/OnsIte auCtIOnBy order of the owners, assets ofAuctioneers • LiquidAtors • ApprAisers21700 Northwestern Hwy • Suite 1180Southfield, Michigan 48075-4923Ph 248.569.9781 • Fx 248.569.9793www.maynards.com<strong>Hilco</strong> <strong>Industrial</strong>, LLCA u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r s31555 West Fourteen Mile Road, Suite 207Farmington Hills, Michigan 48334Ph 877.37.HILCO (44526) • Fx 248.254.9995www.hilcoind.com

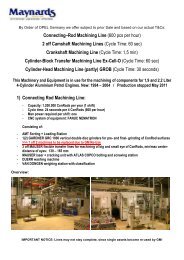

HILCO IndustrIaL, LLC &Maynards IndustrIesby order of the owners, assets ofauCtIOn datetHursday, MarCH 22 ndbegInnIng at 10aM LOCaL tIMePrevIeW dateWednesday, MarCH 21 st8aM tO 4PM LOCaL tIMe& by aPPOIntMentFor earlier inspection, please contactJohn Magnuson at 847.504.3204 oreMail JMagnuson@hilcoind.coMauCtIOn & PrevIeW LOCatIOn2800 sOutH asHLand avenueCHICagO, IL 60608WebCast / OnsIte auCtIOndIreCtIOnsFrOM CHICagO MIdWay InternatIOnaL aIrPOrt: exIt aIrPOrt andturn rIgHt OntO sOutH CICerO avenue. Merge OntO I-55 n /stevensOn exPy. take exIt 290 tOWard asHLand avenue, Merge OntOW 31st PL and turn LeFt OntO s asHLand avenue. destInatIOn WILL beOn tHe LeFt.FrOM CHICagO O’Hare InternatIOnaL aIrPOrt: exIt aIrPOrt tO I-90 e,Merge OntO I-94 e. take exIt 52a FOr tayLOr street, turn rIgHt. taketHe FIrst LeFt OntO s HaLsted street. turn rIgHt OntO s CanaLPOrtave, tHen a sLIgHt rIgHt OntO W CerMak rd. COntInue tO s asHLandave and turn LeFt. destInatIOn WILL be On tHe rIgHt.FurtHer InFOrMatIOn• an 18% buyer's PreMIuM WILL be CHarged On aLL assets. tHe buyer’sPreMIuM WILL be reduCed tO 15% FOr PayMents Made by CasH, COMPanyCHeCk Or WIre transFer. auCtIOn WILL be COnduCted In engLIsH, aCCePt-Ing u.s. CurrenCy OnLy.• REMOVAL DEADLINE ON ALL AssEts ExcEpt tHE pREssEs WILL BE ApRIL 20tH. tHEpREssEs MUst BE cOMpLEtELY REMOVED BY JUNE 30, 2012 - NO ExcEptIONs.• FOr FurtHer InFOrMatIOn On MaCHInery & equIPMent, PLease COntaCtJOHn MagnusOn at 847.504.3204 Or eMaIL JMagnusOn@HILCOInd.COM• FOr PayMents PLease COntaCt LesIa JOsePH at 616.732.1800 x19 OreMaIL LJOsePH@HILCOInd.COM Or HILCO aCCOunts reCeIvabLe atHIn_ar@HILCOInd.COM• FOr CustOMer servICe, PLease COntaCt sandI neeLy at 248.254.9999 x16Or eMaIL sneeLy@HILCOInd.COMFor complete press specs and diagramsplease visit www.hilcoind.com2to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1.877.37.HILCO (44526) or Maynards Industries 248.569.9781

Web OFFset PrIntIng Presses(8) PRINTING PRESSES6 – Goss NewsliNer web offsetPriNtiNG Presses; S/Ns NL7031,NL7032, NL7033, NL7034, NL7035,NL7036 (1999); Cutoff: 22-3/4", Web Width:57-1/2" (Original), 54" & 50" Tabloid(Current), Max. Printing Length: 22.086",Max. Speed: 70,000-CPH, Each PressArranged with (1) 4/4 Tower (8-Couple), (1)4/1 Tower (5-Couple), (2) 2/2 Towers(4-Couples), (1) Sovereign 2:5:5 160-PageJaw Folder, Harland Simon Press Controls& Drives, WPC MicroTrak CLC+ ClosedLoop Color Plus Register System (New2003) with (2) Cameras, Touch ScreenOperator Control Panel, (2) Harland SimonOperator Control Consoles, PPSI Inker,Ryco SB Dampener, Angle Bars, WPCFor more information, please visit us on the web at www.hilcoind.com or www.maynards.com3

PrIntIng Presses, COnt. • COLOr regIstratIOn & LOadIng systeMs(8) PRINTING PRESSES, CONT.2 – Goss uNiversal 70 web offsetPriNtiNG Presses; (both 1999); Cutoff:22-3/4", Web Width: 40", Max. Speed:70,000-CPH, Max. Print Capability: 160-PageTabloid with 32-Pages Process Color, 32-Pages Spot Color, 96-Black Pages, EachPress Arranged with (1) 4/4 Tower (8-Couple),(5) Mono Units (2-Couple), (1) J 2:3:3 SingleFold Jaw Folder (Note: Press #9 AlsoEquipped with Ballon Folder), Harland SimonPress Controls & Drives, WPC MicroTrakCLC+ Closed Loop Color Plus RegisterSystem (New 2003) with (2) Cameras, TouchScreen Operator Control Panel, (2) HarlandSimon Operator Control Consoles, PPSIInker, Ryco SB Dampener, Angle Bars(8) COLOR REGISTRATION SYSTEMS8 – wPC MiCrotrak ClC+ Closed looP ColorPlus reGister systeM (New 2003), (6) Systemsup to 60” Wide, (2) Systems up to 40” Wide, with (2)Cameras, Touch Screen Operator Control Panel,Electrical ControlsCENTRAL INK DELIVERY SYSTEM1 –CeNtral iNk delivery systeM, (1999), with BEKSystems Model CST-41 Ink Delivery Controls, S/N CST-41-ISO499; (2) 5,863-Gallon Black Ink Tanks; (7) 1,241-Gallon Color Ink Tanks; Each Tank Mounted on LoadCells; All Associated Pump and Valve Assemblies,Piping, Etc.4 to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1.877.37.HILCO (44526) or Maynards Industries 248.569.9781

eeLstands • unWInders • PLateMakIng • Inserters(48) REELSTANDS11 – eNkel CtC-Hi-266050-33 2-arM reelstaNds; S/Ns 34-00026,34-00027, 34-00028, 34-00088, 34-00092, 34-00097, 34-00095,34-00104, 34-00100, 34-00109, 34-00107 (all 1998); Max. RollWeight: 3,300-Lbs., Roll Diameter: 24" – 50", Web Width: 14" – 60",Reel Core Inside Diameter: 3", Splicing Speed Range: Impresson-OnSpeed to Max. Press Speed, with DC Driven Web Tensioning,AutoSlack Mode, PLC, Hydraulic Power Unit19 – eNkel CtC-H-266050-33 2-arM reelstaNds; S/Ns 34-00029,34-00030, 34-00031, 34-00091, 34-00090, 34-00089, 34-00093,34-00094, 34-00098, 34-00099, 34-00096, 34-00103, 34-00101,34-00102, 34-00105, 34-00108, 34-00111, 34-00110, 34-00106 (all1998); Max. Roll Weight: 3,300-Lbs., Roll Diameter: 24" – 50", WebWidth: 14" – 60", Reel Core Inside Diameter: 3", Splicing SpeedRange: Impresson-On Speed to Max. Press Speed, with DC DrivenWeb Tensioning, AutoSlack Mode, PLC, Hydraulic Power2 – eNkel CtC-Hi-264050-33 2-arM reelstaNds; S/Ns 34-00035,34-00033 (all 1998); Max. Roll Weight: 3,300-Lbs., Roll Diameter: 24"– 50", Web Width: 14" – 60", Reel Core Inside Diameter: 3", SplicingSpeed Range: Impresson-On Speed to Max. Press Speed, with DCDriven Web Tensioning, AutoSlack Mode, PLC, Hydraulic Power Unit4 – eNkel CtC-H-264050-33 2-arM reelstaNds; S/Ns 34-00032,34-00036, 34-00037, 34-00034 (all 1998); Max. Roll Weight: 3,300-Lbs.,Roll Diameter: 24" – 50", Web Width: 14" – 40", Reel Core InsideDiameter: 3", Splicing Speed Range: Impresson-On Speed to Max.Press Speed, with DC Driven Web Tensioning, AutoSlack Mode, PLC,Hydraulic Power Unit12 – eNkel aCtH-264050-33 2-arM reelstaNds; S/Ns 34-00007LH,34-00001RH, 34-00008LH, 34-00002RH, 34-00009LH, 34-00003RH,34-00010LH, 34-00004RH, 34-00011LH, 34-00012LH, 34-00006RH,N/A (all 1998); Max. Roll Weight: 3,300-Lbs., Roll Diameter: 24" –50", Web Width: 14" – 40", Reel Core Inside Diameter: 3", SplicingSpeed Range: Impresson-On Speed to Max. Press Speed, with DCDriven Web Tensioning, AutoSlack Mode, PLC, Hydraulic Power Unit(7) UNWINDERS7 – fiberCore equiPMeNt Model uN-40e 40" eleCtriCuNwiNders, S/Ns UN-40E-114, UN-40E-113, UN-40E-116,UN-40E-115, (3) N/A, (2008), 3/4-HP, Variable Speed, on Caster Base(2) ROLL LOADING SYSTEMS2 – MaCHiNe desiGN serviCe autoMatiC roll loadiNGsysteMs (1999), Each with Roll Staging Ramps with PneumaticBlocks, In-Ground Roll Transfer Tracks, In-Ground Press SpurTracks, Powered Transfer Tables, Low Profile Dollies, Controls,Operator Control ConsolesPLATEMAKING EQUIPMENT1 – aGfa advaNtaGe Cl 3850 Cls CtP Platesetter; S/N07/32225 (2007)2 – aGfa advaNtaGe dl 3850 CtP Platesetters; S/Ns08/30437, N/A (2008)3 – GluNz & JeNseN 85HdX iMaGe ProCessors; S/Ns94412-1028, 94412-1032, N/A (2008)4 – MetafiX uNiversal-rev 2 PH CoNtrol systeMs; S/Ns N/A(2008); PLC1 – Nela vCP-822 Plate beNder; S/N 01470-06, (2005)1 – Nela vCP-564 Plate beNder; S/N 58873, (2003)1 – aCuteCH 4-biN Plate sorter; S/N N/A (2008)1 – kf systeMs viPb-36 Gr001 Platesetter; S/N 9901 (1999);with K & F Model STMD 3-Way GR071, S/N 9907(8) INSERTERS1 – HeidelberG Harris NP-2299 iNserter; S/N NP22-137-D (1993; rebuilt 2006); 99-Pockets;22-Hoppers Including 13-MSLT, 6-MSH/MS, 2-MSL and 1-MS; Circular-Rotating; with Mueller MartiniWinLincs Packaging Line Control System (New 2008)1 – HeidelberG Harris NP-2299 iNserter; S/N NP22-120-D (1993; rebuilt 1999); 99-Pockets;22-Hoppers Including 4-MSLT, 15-MSH/MS, 1-MSL and 2-Unknown; Circular-Rotating; with MuellerMartini WinLincs Packaging Line Control System (New 2008)1 – HeidelberG NP-632-30 30-Head, dual-delivery, iNliNe iNserter; S/N NP 632-123-D(1998) with Mueller Martini WinLincs Packaging Line Control System (New 2008)2 – HeidelberG NP-1372 iNserters; S/Ns NPS 1164-A-DR, NPS 1165-A-DR, (1999); 72-Pocket;13-Hopper; Circular-Rotating; Basic Capacity (Max.): 20,000-Cycles/Hour, Multi-Stuffer Capacity(Max.): 40,000-Cycles/Hour, CCW Rotation, Hopper Product Thickness Capacity: 96-pp (Broadsheet);0.005" (Card), Hopper Product Width Capacity: 6-1/4" to 17", Hopper Product Length: 11-1/2" (Max.),Max. Stuffed Pocket: 200-pp (Broadsheet), Pocket Jacket Width: 14" to 16", Pocket Jacket Height:10-1/2" to 12", Pocket Insert Width: 7" to 16", Pocket Insert Height: 4" to 12", with Mueller MartiniWinLincs Packaging Line Control System (New 2008), Fanned Fold-Edge First Belt Type Delivery1 – GMa sls-1000 22-Head, iNliNe iNserter; S/N 92-10241 (1992)1 – GMa sls-1000 16-Head, iNliNe iNserter; S/N 92-10240 (1992)1 – GMa sls-1000 14-Head, iNliNe iNserter; S/N 89-10120 (1989)DESERTER1 – Master flo Model d3H tHree out deserter, S/N 90201, 43" Stream Separation (Approx.);Max. Production: 225,000-IPHFor more information, please visit us on the web at www.hilcoind.com or www.maynards.com5

staCkers • straPPers • WraPPers • COnveyOrs • aIr HandLIng(22) STACKERS1 – quiPP PaCkMaN staCker; S/N 077X (2007); Wrapper/Inkjet1 – quiPP sJ500w staCker; S/N W105U (2004); Wrapper/Inkjet18 – quiPP sJ400w staCkers; S/Ns W403R, W104P, W091P, W079P,W065P, W085P, W072P, W084P, W063P, W012P, W090P, W062P, W073P,W093W, W105P, W092P, (2) N/A, (as New as 2001); Max. Batch Height:13.5"; Max. Bundle Height: 18"; Max. Batch Count: 9-Batches/Bundle; Max.Bundle Count: 999-Copies/Bundle; Nominal Product Size: 10.5" to 12" (L) by12" to 14" (W); Page Count: 6 to 400-Pg. Broadsheet; Orientation: Direct,Folded-Edge Leading; Alignment: Folded-Edge Perpendicular to StreamCenterline +/- 5 Degrees2 – HeidelberG (riMa) rs-3110sl staCkers; S/Ns 315609-10, 315608-10(1999); 17" Drop, with E300 PLC(27) STRAPPING MACHINES17 – dyNariC NP-1500 straPPiNG MaCHiNes; S/Ns N15.987, N15.1066,N15.817, N15.989, N15.971, N15.816, N15.935, N15.813, N15.812,N15.1067, N15.806, N15.937, N15.807, N15.970, N15.934, N15.818,N15.857 (1998-1999); Pack Width: 23.6" x 23.6" (Max.); 7.1" x 9.5" (Min.),Pack Height: 0.4" to 15.6", Output: 28-Packs/Minute (Single Strapping)9 – dyNariC NP-1500Hs straPPiNG MaCHiNes; S/Ns N15.930, 15.966,15.532, N15.931, 15.967, 15.968, 15.1028, 15.069, 15.065 (1998-1999);Pack Width: 23.6" x 23.6" (Max.); 7.1" x 9.5" (Min.), Pack Height: 0.4" to15.6", Output: 28-Packs/Minute (Single Strapping)1 – siGNode lbX PaCkMaN straPPiNG MaCHiNe, S/N LBXQ1005 (2007)(20) BOTTOM WRAPPERS20 – quiPP Model 5114 viPer bottoM wraPPers, S/N N/A, (1999)BUNDLE DISTRIBUTION SYSTEM1 – MaCHiNe desiGN serviCes fully-autoMated, siNGle-tiered zoNedbuNdle distributioN systeM, (1999), Equipped with (8) PSC/Flo-TurnModel FT3622-90, 90° Rubber Belt Conveyors; (3) PSC/Flo-Turn Model FTSP3622 x 90, 90° Inclined Rubber Belt Conveyors; (9) MDI 25'L x 20"W PlasticCleated Belt Conveyors; (3) MDI 10'L x 20"W Plastic Cleated Belt Conveyors; (9)MDI 12'L x 20"W Plastic Cleated Belt Conveyors; (2) MDI 15'L x 20"W PlasticCleated Belt Conveyors; (4) MDI 18'L x 20"W Plastic Cleated Belt Conveyors; (1)MDI 11'6"L x 20"W Plastic Cleated Belt Conveyor; (3) MDI 4'L x 20"W PlasticCleated Belt Conveyors; (2) MDI 8'L x 17"W Rubber Belt Conveyors; (2) MDI 12'Lx 17"W Rubber Belt Conveyors; (40) Inline Stack Jogging Units; All Related DriveMotors, Controls, Etc. (Note: All Counts and Measurements Are Approximate. FullDrawings and Details Available.)CONVEYORS2 – HeidelberG Model NP556 iNliNe droP CoNveyors, S/Ns N/A12 – HeidelberG Model NP200 iNliNe droP CoNveyors, S/Ns NDC-631-D,NDC-632-D, NDC-630-D, NDC-614-D, NDC-616-D, NDC-613-D, NDC-615-D, (5)N/A, (all 1999), Product Width: 7" to 17"; Product Length: 5" to 13", ProductThickness: 160-Pages Broadsheet, 256-Pages Tabloid; Fold Edge Loading;80,000-Cycles per Hour (Max), with Controls3 – HeidelberG Model NP125 iNliNe droP CoNveyors, S/Ns NDC-620-D,NDC-597-D, N/A (all 1999)2 – k &M droP CoNveyor systeMs7 – GraPHiC MaNaGeMeNt Model af100 12"w HoP load CoNveyors,S/Ns 92-1351, 92-1355, 92-1350, 92-1356, 92-1364, 92-1341, 92-1360, (all1992), Variable Incline and Infeed Speed Controls, On Casters2 – Harris Model NP2120-NP1301 12"w HoP load CoNveyors, S/NsNPL-604-G, NPL-532-G, Variable Incline and Infeed Speed Controls, On Castersover 10,000' of HeidelberG GriPPer CoNveyorquaNtity of busCHMaN Model 788146 30" wide sCraP CoNveyor, (1998),Approximately 450' Long, Flat and Incline Sections, Bolted Construction, Rubber Belt,Drive MotorsAIR HANDLING EQUIPMENT2 – iNGersoll-raNd Model ssr-eP125 125-HP rotary sCrew tyPe airCoMPressors, S/Ns F36058U98119, F36057U98118 (1998), 571-CFM, 125-PSIG, with Intellisys PLC2 – iNGersoll-raNd Model ssr-eP100 100-HP rotary sCrew tyPe airCoMPressors, S/Ns F17910U97113, N/A (1997), 446-CFM, 125-PSIG, withIntellisys PLC1 – kaeser Model sfC 75s, 100-HP rotary sCrew tyPe airCoMPressor, S/N 1015 (2005), 125-PSIG, with Kaeser Sigma PLC1 – kaeser Model bsd 50t 50-HP rotary sCrew tyPe airCoMPressor, S/N 1032 (2005), 125-PSIG, with Kaeser Sigma PLC2 – iNGersoll-raNd dXr 600 refriGerated air dryer, S/Ns98ADXR0121, N/A (1998), with System Operation Monitor2 – iNGersoll-raNd Model ts 800 refriGerated air dryers, S/Ns2075770004, DR10011088-032301 (2001), 175-PSI, with Electronic Control1 – iNGersoll-raNd Model ts 5a refriGerated air dryer, S/NDN00001980-010809 (2009), with Intellisys PLC4 – quiNCy Model qsvi-40 40-HP vaCuuM PuMPs, S/Ns 35154, N/A, AirCooled, Filter, Skid Mounted Design1 – sCales Model svsd-40 40-HP vaCuuM PuMP, S/N 92 389, Air Cooled,Filter, Skid Mounted Design1 – busCH 20-HP vaCuuM PuMP, S/N N/A6 to schedule an auction, please call <strong>Hilco</strong> <strong>Industrial</strong>, LLC at 1.877.37.HILCO (44526) or Maynards Industries 248.569.9781

FOrkLIFts • rOLLIng stOCk • Parts InventOry • suPPOrt equIPMentOVER $4.7 MILLION IN SPARE PARTS INVENTORYover $4.7 MillioN iN sPare Parts iNCludiNG More tHaN 7,000assorted liNe iteMs froM 100’s of suPPliers: Goss, Heidelberg,Dynaric, Quipp, AGFA, RIMA, Accurate Web Parts, Allen-Bradley, BEK, CASystems, Conveyor Craft, Cooper Bussman, FMC, Gammerler, HarlandSimon, K & M, McMaster-Carr, MegTec, MIR, Motion Industries, Nela, Newark,Omron, PPSI, Pressline Services, Reliance, Revere, Seelos, Seimens,Signode, Skarlupka, Steiner, Technotrans, Telemecanique, Timken, and manymore. Visit www.hilcoind.com for complete list.(22) FORKLIFTS1 – MitsubisHi Model 2fbC30 6,0000-lb. forklift, S/N A2BC320225,Electric, Side Shift, 3-Stage Mast, Cushion Tires, with Bolzoni RA-150-N RotatingPaper Roll Clamp (New 2006)1 – koMatsu Model fb30sHs-4 5,600-lb. forklift, S/N 030834A, Electric,183" Lift, 3-Stage Mast, Side Shift, Cushion Tires1 – CrowN 4000 series 5,000-lb. forklift, S/N 9A128921, Electric1 – MitsubisHi Model fbC25 4,800-lb. forklift, S/N AFB200669, Electric,179" Lift, Side Shift, 3-Stage Mast, Cushion Tires, with Bolzoni Rotating ForkAttachment (New 2006)1 – koMatsu Model fb25sH-4 4,700-lb. forklift, S/N 32463A, Electric, SideShift, 3-Stage Mast, Cushion Tires1 – koMatsu Model fG2510a 4,500-lb. forklift, S/N N/A, Electric, Side Shift,3-Stage Mast, Cushion Tires1 – koMatsu Model fb25sH-4 4,480-lb. forklift, S/N 030169A, Electric,Side Shift, 3-Stage Mast, Cushion Tires1 – toyota Model fbCu25 3,550-lb. forklift, S/N 65448, Electric, 107.5" Lift,with 36" Forks, Arranged for Paper Roll Clamp Attachment (Not Included)1 – CrowN 3,450-lb. forklift, S/N 7A45768, Electric, 3-Wheel Design1 – CrowN Model 4500 series 3,300-lb. forklift, S/N 9A156115, Electric, 276"Lift, 4-Stage Mast, with Bolzoni RA-150-N Rotating Paper Roll Clamp (New 2006)7 – fMC Model Nar-32 (tyPe 3100z002) 3,200-lb. eleCtriC forklifts,S/Ns 769, 768, 771, 871, 873, 874, 872, (all 1999), with Winker Mast, RotatingFork Attachment, Sick Proximity Sensors, Amerden PLC Control, FMC AGVManual Control Pendant (Note: Previously Used as Automated Guided Vehiclesfor Paper Roll Handling and Insert Pallet Handling)2 – CrowN Model 55f-sss-a172 (4500 series) 2,750-lb. forklifts, S/Ns9A156165, 9A156164, Electric, 3-Wheel Design, Side Shift, Cushion Tires3 – CrowN Model ltef-16 (4500 series) 2,250-lb. forklifts, S/Ns9A156162, 9A156161, N/A, Electric, 3-Wheel Design, 172" Lift, 2-Stage Mast, withLTS DR2100A Scale Attachment with Digital ReadoutROLLING STOCK9 – CrowN Model wP2335-45 4,500-lb. eleCtriC walkie tyPe Pallet truCks,S/Ns 5A362138, 5A362033, 5A362293, 5A343266, 5A313308, 5A362032, 5A362137,5A313309, N/A (as New as 2008)1 – kalMar Model wf45 4,500-lb. eleCtriC walkie tyPe Pallet truCk, S/NWF45342360021 – koMatsu- Model Mwl22 4,500-lb. eleCtriC walkie tyPe Pallet truCk,S/N MWL34236450011 – yale Model MPb040-eN24t2748 4,000-lb. eleCtriC walkie tyPe PallettruCk, S/N B827N09120A3 – bt PriMe Mover Model wsX30 3,000-lb. eleCtriC walk beHiNd forklifts,S/Ns WSX3029138002, N/A, 104" Lift1 – koMatsu 3,000-lb. eleCtriC walk beHiNd Pallet truCk, S/N N/A, ,45 – tHorX eleCtriC Pallet truCks1 – GeNie Model z-34/22N 500-lb. booM lift, S/N N/A, Electric, 40'6" Lift1 – skyJaCk Model sJiii 3220 800-lb. sCissor lift, S/N N/A, Electric, 20' Lift1 – eCoNoMy Model Cub Cs-2033Xt 500-lb. sCissor lift, S/N G469864, Electric,20' Lift1 – skyJaCk Model sJPX40 350-lb. booM lift, S/N N/A, Electric, 40' Lift1 – teNNaNt Model atlv 4300 rider-tyPe floor CleaNer, S/N 4300-1599PAPER ROLL CLAMPS1 – CasCade 4,500-lb. PaPer roll ClaMP, N/A, with Power Rotation3 – bolzoNi Model ra-150-N 3,300-lb. PaPer roll ClaMPs, S/Ns N/A, (2006), withPower RotationDUST COLLECTORS3 – seNeCa eNviroNMeNtal ProduCts Model 45 fMri 4 dust ColleCtors,S/Ns 982692, 982693, 982695 (1998), BlowerMISCELLANEOUS WAREHOUSE & SUPPORT EQUIPMENT4 – wulfteC Model wsMl-150-b sMart series stretCH wraPPers, S/Ns57948-20-0209, 57948-4-0209, 57948-1-0209, N/A, (2009), Semi-Automatic, 58" Dia.Table, Adjustable Speed Controls1 – laNteCH Model q300 stretCH wraPPer, S/N QM013855, Semi-Automatic,65" Dia. Table, Adjustable Speed Controls1 – MareN Model 2060 20" X 60" baler, S/N 985262, (1998), 10-HP1 – MtC 2-toN X 18' sPaN traveliNG GaNtry CraNe, with Coffing 2-Ton ElectricChain Hoist, Pendant Control1 – videoJet CHesHire series 7000 (987000-82) base, S/N 992240004RL, with Model568 Conveyor2 – forklift battery CHaNGiNG statioNs with Large Quantity of Assorted Chargersand BatteriesOVer 180 SectiOnS Of Pallet rack, 110"W x 48"D x 19’-22'H (Approx.), Wire ShelvingOVer 50 SectiOnS Of 108"W x 48"D x 60"H Pallet rack, Each Section with (2) FloorMounted Paper Roll ChocksQuantity Of SHOP eQuiPment: Parts Washer, Shop Press, Horizontal Band Saw,Engine Lathe, Welder, Jogging TablesQuantity Of General Plant maintenance & PrODuctiOn SuPPOrt eQuiPmentFor more information, please visit us on the web at www.hilcoind.com or www.maynards.com7

Atlanta • Birmingham • Birmingham (UK) • Boston • Charlotte • Chicago • Connecticut • Dallas • Detroit • Grand Rapids • Guadalajara (MX) • Hong Kong (Greater China) •Irapuato (MX) • Leeds (UK) • London (UK) • Los Angeles • Mexico City (MX) • Monterrey (MX) • New York • San Francisco • Singapore • Thailand • Toronto • Villahermosa (MX)<strong>Hilco</strong> <strong>Industrial</strong>, LLCA u c t i o n e e r s • L i q u i d a t o r s • A p p r a i s e r sHeadquarters31555 W. Fourteen Mile Road, Suite 207Farmington Hills, MI 48334Ph: 877-37-HILCO (44526)Fx: 248.254.9995www.hilcoind.comPresortedFirst Class MailU.S. PostagePaidDetroit, Mich.Permit No. 2655Forwarding Service RequestedHILCO IndustrIaL, LLC& Maynards IndustrIesWebCast/OnsIte auCtIOnBy order of the owners, assets ofTerms of SaleAn 18% buyer's premium will be charged on all assets. thebuyer’s premium will be reduced to 15% for paymentsmade by cash, company check or wire transfer. Everythingwill be sold to the highest bidder for cash, in accordancewith the Auctioneer’s customary “terms of sale”, copies ofwhich will be posted on the premises of the sale and subjectto additional terms announced the day of sale. All itemswill be sold “as is, where-is” without any warranties,expressed or implied. Although obtained from sourcesdeemed reliable, the Auctioneer makes no warranty orguarantee to the accuracy of the information herein contained.Bidders are encouraged to thoroughly inspect theitems on which they intend to bid prior to sale. Absolutelyno items will be removed until the day after the conclusionof the sale and payment is made in full. subject to additions,deletions and prior sale.Payment: ALL pURcHAsEs MUst BE pAID IN FULL ONtHE DAY OF tHE AUctION. If you intend to pay by wiretransfer, we will accept payment the day after the saleONLY IF a deposit of 25% of total purchases is made onthe day of the sale. contact our office for wire transferinstructions. Only cash, wire transfer or certified check,payable to <strong>Hilco</strong> <strong>Industrial</strong>, LLc will be accepted. companychecks payable to <strong>Hilco</strong> <strong>Industrial</strong>, LLc will be acceptedonly if accompanied by a bank letter of guarantee, (seesample letter below). All sales are subject to sales tax.purchasers claiming exemptions from taxes must provideproof satisfactory to the Auctioneer of their entitlement toclaim such exemptions.Sample Bank Letter(Bank Name) unconditionally guarantees payment to<strong>Hilco</strong> <strong>Industrial</strong>, LLc from (company Name). thisguarantee will be valid for purchases made at theAuction of chicago sun times on March 22, 2012.FollowUs on:HILCO <strong>Industrial</strong>, LLC is a division of <strong>Hilco</strong> trading, LLC • Headquarters 5 revere drive, ste. 206 • northbrook, IL 60062 • all rights reservedCity of Chicago auctioneer & License: robert Levy: #2078724, • IL auctioneer & License: tim Pfister #441001667 • IL License #444.000215Printed in usa • sun0058 • Please visit our website at www.hilcoind.com to review our complete terms and conditions.