VisionXP Vision - Rehm Group

VisionXP Vision - Rehm Group

VisionXP Vision - Rehm Group

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

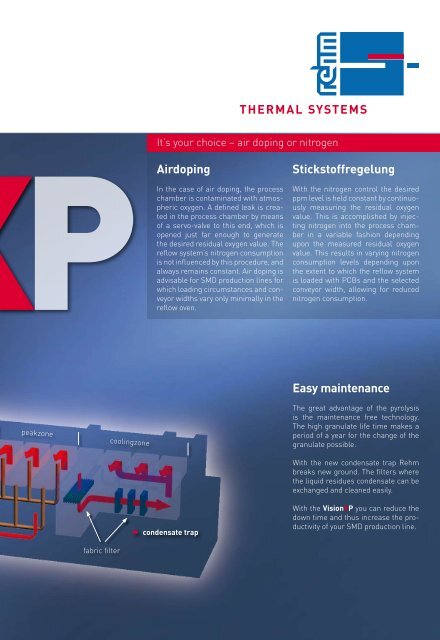

THERMAL SYSTEMSIt’s your choice – air doping or nitrogenPAirdopingIn the case of air doping, the processchamber is contaminated with atmosphericoxygen. A defined leak is createdin the process chamber by meansof a servo-valve to this end, which isopened just far enough to generatethe desired residual oxygen value. Thereflow system’s nitrogen consumptionis not influenced by this procedure, andalways remains constant. Air doping isadvisable for SMD production lines forwhich loading circumstances and conveyorwidths vary only minimally in thereflow oven.StickstoffregelungWith the nitrogen control the desiredppm level is held constant by continuouslymeasuring the residual oxygenvalue. This is accomplished by injectingnitrogen into the process chamberin a variable fashion dependingupon the measured residual oxygenvalue. This results in varying nitrogenconsumption levels depending uponthe extent to which the reflow systemis loaded with PCBs and the selectedconveyor width, allowing for reducednitrogen consumption.peakzone coolingzoneEasy maintenanceThe great advantage of the pyrolysisis the maintenance free technology.The high granulate life time makes aperiod of a year for the change of thegranulate possible.With the new condensate trap <strong>Rehm</strong>breaks new ground. The filters wherethe liquid residues condensate can beexchanged and cleaned easily. condensate trapWith the <strong><strong>Vision</strong>XP</strong> you can reduce thedown time and thus increase the productivityof your SMD production line.fabric filter