VisionXP Vision - Rehm Group

VisionXP Vision - Rehm Group

VisionXP Vision - Rehm Group

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

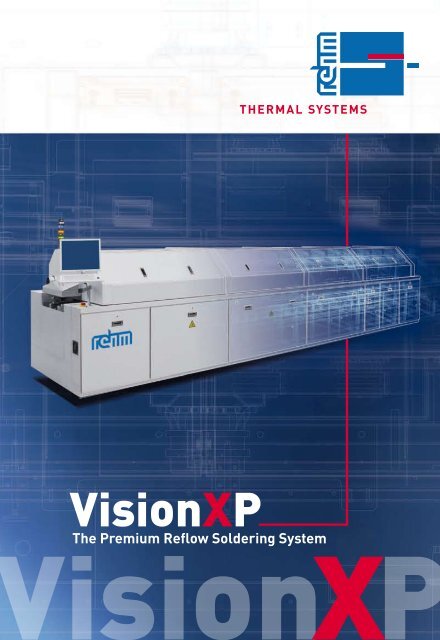

THERMAL SYSTEMS<strong><strong>Vision</strong>XP</strong>The Premium Reflow Soldering Systemision XP

Pyrolysis and condensation trap(for crystalline and liquid residues)optimal heat transferreduced maintenance expensesand reduced downtime<strong><strong>Vision</strong>XP</strong>The Premium Reflow Soldering SystemAs a co-founder of modern Reflow-Convection-Soldering Systems thecompany <strong>Rehm</strong> has been establishedsuccessfully since 1990 in the nationalmarket as well as worldwide. Theknow-how and experience in reflowtechnology of many years is now integratedin the <strong><strong>Vision</strong>XP</strong>-series. Optimizedfor customer requirements the<strong><strong>Vision</strong>XP</strong> stands for productivity andflexibility.

THERMAL SYSTEMSlowest cost of ownershipprocess reliability meetinglead free requirementsvarious software tools forprocess documentation1.Optimized Residue Managementby combining pyrolysis and coldcondensation.Main featuresof the <strong><strong>Vision</strong>XP</strong>:3.Reduced operating costs and thusreduced „costs of ownership“Easy accessibility for mainenancework as well as longermainenance intervals.2.

Stable, clean, flexible.The Transport SystemOur flexible system saves you money.Maintenance and downtime are reducedby means of a continuous processbased on an absolutely reliable conveyor,as well as an ingenious mechanicalsystem.The conveyor system has been laid outin accordance with requirements specifiedfor future placement machines,and optional for a maximum width of508 mm.The optionally available center supportmakes it possible to process largepanel formats – an additional advantagefor flexible manufacturing!The following variants are available: Single-lane conveyor Dual-lane conveyor(synchronous/asynchronous) Multi-Track conveyorDual-lane conveyor

Be convincedof the qualityand productivity of the <strong><strong>Vision</strong>XP</strong>!<strong>Vision</strong>The Premium Reflow Soldering SystemXInnovation for success!Clean process chamber!PyrolysisThe <strong><strong>Vision</strong>XP</strong>‘s residue managementsystem combines the pyrolysis actionmechanisms in the preheating andpeak range with cold condensationin the cooling zone. This way boththe amount of liquid residues (dripformation in particular) and that ofthe crystalline residues can be drasticallyreduced. The <strong><strong>Vision</strong>XP</strong> therebyachieves a considerably higher level ofefficiency than all other commerciallyavailable systems, which work withdifferent operating principles. highly efficient clean process chamber reduced maintenance expenses minimized down-timepyrolysispreheatingzone

THERMAL SYSTEMSIt’s your choice – air doping or nitrogenPAirdopingIn the case of air doping, the processchamber is contaminated with atmosphericoxygen. A defined leak is createdin the process chamber by meansof a servo-valve to this end, which isopened just far enough to generatethe desired residual oxygen value. Thereflow system’s nitrogen consumptionis not influenced by this procedure, andalways remains constant. Air doping isadvisable for SMD production lines forwhich loading circumstances and conveyorwidths vary only minimally in thereflow oven.StickstoffregelungWith the nitrogen control the desiredppm level is held constant by continuouslymeasuring the residual oxygenvalue. This is accomplished by injectingnitrogen into the process chamberin a variable fashion dependingupon the measured residual oxygenvalue. This results in varying nitrogenconsumption levels depending uponthe extent to which the reflow systemis loaded with PCBs and the selectedconveyor width, allowing for reducednitrogen consumption.peakzone coolingzoneEasy maintenanceThe great advantage of the pyrolysisis the maintenance free technology.The high granulate life time makes aperiod of a year for the change of thegranulate possible.With the new condensate trap <strong>Rehm</strong>breaks new ground. The filters wherethe liquid residues condensate can beexchanged and cleaned easily. condensate trapWith the <strong><strong>Vision</strong>XP</strong> you can reduce thedown time and thus increase the productivityof your SMD production line.fabric filter

THERMAL SYSTEMSModular design.The system types<strong><strong>Vision</strong>XP</strong> nitro 4550 (Type 944)System length: 7,45mThroughput: 200/h*<strong><strong>Vision</strong>XP</strong> nitro 4200 (Type 934)System length: 7,10mThroughput: 180/h*<strong><strong>Vision</strong>XP</strong> nitro 3850 (Type 834)System length: 6,75mThroughput: 160/h*Innovation for success!<strong>Rehm</strong> Thermal Systems is an internationalsupplier of soldering systems and thermalsystem solutions for the electronics industry.We supply custom tailored solutions fora great variety of applications in modernelectronics manu-facturing with highprecision, innovative, reliable systems andintelligent software.<strong><strong>Vision</strong>XP</strong> nitro 2450 (Typ 523)System length: 5,00mThroughput: 100/h*<strong><strong>Vision</strong>XP</strong> nitro 2100 (Typ 422)System length: 4,30mThroughput: 75/h*<strong><strong>Vision</strong>XP</strong> nitro 3500 (Type 734)System length: 6,40mThroughput: 145/h*<strong><strong>Vision</strong>XP</strong> nitro 3150 (Type 634)System length: 6,05mThroughput: 130/h**Approximate values at a PCB-length of300mm and a distance of 100 mm.www.rehm-group.com<strong>Rehm</strong> Thermal Systems GmbHLeinenstrasse 7D-89143 Blaubeuren-SeissenTelefon: +49 7344-9606-0Fax: +49 7344-9606-25E-Mail: info@rehm-group.comInternet: www.rehm-group.comOctober 2008. Technical changes without prior notice.