+ SPECIALIST COMPLETIONS - Zenith Oilfield Technology Ltd

+ SPECIALIST COMPLETIONS - Zenith Oilfield Technology Ltd

+ SPECIALIST COMPLETIONS - Zenith Oilfield Technology Ltd

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

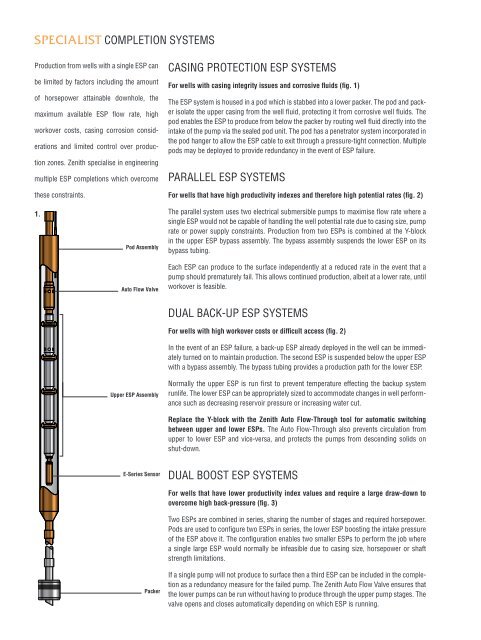

<strong>SPECIALIST</strong> COMPLETION SYSTEMSProduction from wells with a single ESP canbe limited by factors including the amountof horsepower attainable downhole, themaximum available ESP flow rate, highworkover costs, casing corrosion considerationsand limited control over productionzones. <strong>Zenith</strong> specialise in engineeringmultiple ESP completions which overcomethese constraints.CASING PROTECTION ESP SYSTEMSFor wells with casing integrity issues and corrosive fluids (fig. 1)The ESP system is housed in a pod which is stabbed into a lower packer. The pod and packerisolate the upper casing from the well fluid, protecting it from corrosive well fluids. Thepod enables the ESP to produce from below the packer by routing well fluid directly into theintake of the pump via the sealed pod unit. The pod has a penetrator system incorporated inthe pod hanger to allow the ESP cable to exit through a pressure-tight connection. Multiplepods may be deployed to provide redundancy in the event of ESP failure.PARALLEL ESP SYSTEMSFor wells that have high productivity indexes and therefore high potential rates (fig. 2)1.Pod AssemblyAuto Flow ValveThe parallel system uses two electrical submersible pumps to maximise flow rate where asingle ESP would not be capable of handling the well potential rate due to casing size, pumprate or power supply constraints. Production from two ESPs is combined at the Y-blockin the upper ESP bypass assembly. The bypass assembly suspends the lower ESP on itsbypass tubing.Each ESP can produce to the surface independently at a reduced rate in the event that apump should prematurely fail. This allows continued production, albeit at a lower rate, untilworkover is feasible.Upper ESP AssemblyDUAL BACK-UP ESP SYSTEMSFor wells with high workover costs or difficult access (fig. 2)In the event of an ESP failure, a back-up ESP already deployed in the well can be immediatelyturned on to maintain production. The second ESP is suspended below the upper ESPwith a bypass assembly. The bypass tubing provides a production path for the lower ESP.Normally the upper ESP is run first to prevent temperature effecting the backup systemrunlife. The lower ESP can be appropriately sized to accommodate changes in well performancesuch as decreasing reservoir pressure or increasing water cut.Replace the Y-block with the <strong>Zenith</strong> Auto Flow-Through tool for automatic switchingbetween upper and lower ESPs. The Auto Flow-Through also prevents circulation fromupper to lower ESP and vice-versa, and protects the pumps from descending solids onshut-down.E-Series SensorPackerDUAL BOOST ESP SYSTEMSFor wells that have lower productivity index values and require a large draw-down toovercome high back-pressure (fig. 3)Two ESPs are combined in series, sharing the number of stages and required horsepower.Pods are used to configure two ESPs in series, the lower ESP boosting the intake pressureof the ESP above it. The configuration enables two smaller ESPs to perform the job wherea single large ESP would normally be infeasible due to casing size, horsepower or shaftstrength limitations.If a single pump will not produce to surface then a third ESP can be included in the completionas a redundancy measure for the failed pump. The <strong>Zenith</strong> Auto Flow Valve ensures thatthe lower pumps can be run without having to produce through the upper pump stages. Thevalve opens and closes automatically depending on which ESP is running.