NUBR J-z.qxd - Hewitt-impex.co.uk

NUBR J-z.qxd - Hewitt-impex.co.uk

NUBR J-z.qxd - Hewitt-impex.co.uk

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

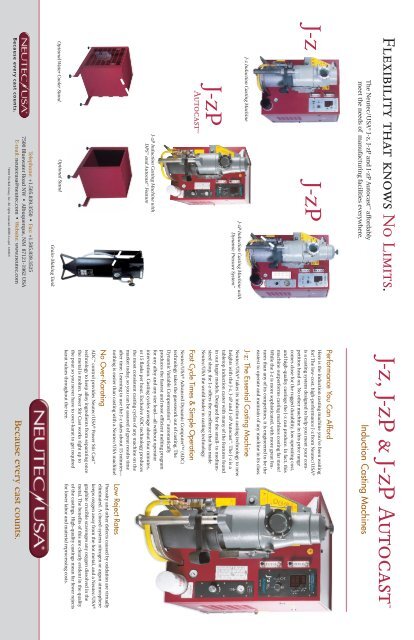

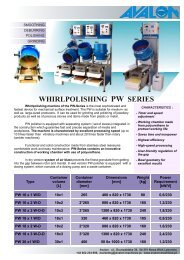

Flexibility that knows No Limits.The Neutec/USA ® J-z, J-zP and J-zP Autocast affordablymeet the needs of manufacturing facilities everywhere.J-zJ-zPJ-z Induction Casting MachineJ-zPAutocast J-zP Induction Casting Machine withDynamic Pressure System J-zP Induction Casting Machine withDPS and Autocast FeatureOptional Water Cooler Stand Optional StandGrain-Making TankBecause every cast <strong>co</strong>unts.Telephone: +1.505.839.3550 • Fax: +1.505.839.35257500 Bluewater Road NW • Albuquerque, NM 87121-1962 USAE-mail: neutecusa@neutec.<strong>co</strong>m • Website: www.neutec.<strong>co</strong>m©2003 The Bell Group, Inc. All rights reserved. <strong>NUBR</strong> J-z.<strong>qxd</strong> 1203LHJ-z, J-zP & J-zP AutocastInduction Casting MachinesPerformance You Can AffordHere is the induction casting machine you’ve been waitingfor! The low-<strong>co</strong>st, high-performance J-z from Neutec/USA ®is a casting system designed to help you meet your <strong>co</strong>mpetitionhead on. No other machine in this price range<strong>co</strong>mes close for the rugged durability, low operating <strong>co</strong>st,and high-quality castings the J-z can produce. In fact, thismachine outperforms casting machines <strong>co</strong>sting far more!While the J-z is more sophisticated, with more great featuresthan any of its <strong>co</strong>mpetitors, it is engineered to be theeasiest to operate and maintain of any machine in its class.J-z: The Essential Casting MachineNeutec/USA ® takes its induction casting technology to newheights with the J-z, J-zP and J-zP Autocast . The J-z is atabletop induction caster with many of the features foundin our larger models. Designed for the small- to mediumsizedshop, the J-z offers the excellence that has madeNeutec/USA the world leader in casting technology.Fast Cycle Times & Simple OperationNeutec/USA ® Advanced Dynamic Computer (ADC)technology takes the guesswork out of casting. TheDynamic Variable Compensation automaticallyproduces the fastest and most efficient melting programfor any alloy and any size load—all without operatorintervention. Casting cycles average about four minutes,or 15 flasks per hour. Exclusive ADC technology producesthe most <strong>co</strong>nsistent casting cycles of any machine on themarket today, so you can be assured of great results timeafter time. Learning to use the J-z takes about 15 minutes—nothing is easier than casting with a Neutec/USA machine!No Over-KaratingADC <strong>co</strong>ntrol provides Neutec/USA ® Power Stir Cast technology to keep alloy ingredients from separating oncethe metal is molten. Power Stir Cast works right up tothe pour so you never have to over-karat to get requiredkarat values throughout the tree.Low Reject RatesPorosity and other defects caused by oxidation are virtuallyeliminated. A closed-system nitrogen or argon atmospherekeeps oxygen away from the hot metal, and a Neutec/USA ®graphite crucible scavenges any oxygen dissolved in themetal. The benefits of this are clearly evident in the qualityof the castings. High-quality castings mean far fewer rejectsfor lower labor and material reprocessing <strong>co</strong>sts.Because every cast <strong>co</strong>unts.

Stone-in-Wax CastingThe accuracy of ADC temperature <strong>co</strong>ntrol has provensuccessful for stone-in casting because it allows you tocast at the lowest possible metal temperatures, reducingthermal shock to the stones. In addition to diamonds,CZs, sapphires and rubies, a whole new groupof stones is being successfully cast withNeutec/USA ® machines—Gilson ® createdopals, lab-grown emeralds and many othersonce <strong>co</strong>nsidered impossible to use with thistimesaving technique.Autocast Raises EfficiencyThe new Autocast feature delivers thetime-saving efficiency of an automatic castat the precise moment your metal reachesoptimal temperature—you cast at the righttime, every time—automatically!Pressure-Vacuum ImprovesFill and DetailNeutec/USA ® has <strong>co</strong>nducted extensiveresearch into pressure technology andhow best to implement it. The Neutec/USADynamic Pressure System developed forthe J-zP is a sophisticated two-stagesystem that increases fill rate at lowercasting temperatures and improvessurface detail—so you have fewerrejects and easier finishing. You willbe amazed at how well this system fillssmall details like prongs and the smallletters found on school rings.NeuSprue Couple the benefits of Neutec/USA ® casting machineswith the revolutionary NeuSprue sprue and sprue baseassembly to get the best quality castings possible. Thepatented NeuSprue system solves age-old castingproblems caused by the old sprue and base system.Contact your Neutec/USA dealer for more information.Built-in Vacuum PumpThe J-z includes a standard 15cfm vacuum pump builtinto the cabinet. This vacuum pump is a high-quality,oil-sealed, direct-drive pump that offers quiet durabilityand trouble-free operation.Grain-Making Accessory IncludedWith the J-z grain-making accessory, you can stock finegold and master alloy and mix the karat and <strong>co</strong>lor alloyyou need when you need it. This means you save moneyand increase service to your customers. Research showsthat casting quality improves when only casting grain isJ-zP inductioncasting machineon water <strong>co</strong>oler standused. The ability to recycle sprues by <strong>co</strong>nverting them tocasting grain saves you money and improves the qualityof your castings. Neutec/USA ® knows how important itis to take a systematic approach to casting; grain-makingin a <strong>co</strong>ntrolled atmosphere is an important part of thatsystem. And because grain-making is so vital to successfulcasting, we include the grain-making tank as standardequipment with the J-z. Ask yourNeutec/USA representative about thebenefits of recycling sprues in ourpatented Auto Valve crucible.Large CrucibleThe 184cc graphite crucible is surprisinglylarge for a machine in this class.You can alloy 2.7kg of 18K in a singlebatch and you can cast up to 1.6kg at atime. And don’t worry about being ableto cast small amounts—the exclusiveADC melt <strong>co</strong>ntrol automaticallyprovides the same precision on 100grams as it does on 1500 grams.Large Flask Capacity,When You Need ItThe first thing we did at the start ofthe J-z design project was to interviewjewelry casters to find out what theyneed. Most of the casters originallysaid they needed a maximum flask sizesomewhat smaller than the 5" diameter by9" height of the J-z . But we also heardabout missed job opportunities and thedesire to cast small sculptures. In otherwords, you wanted a larger crucible and flaskcapacity—if it didn’t <strong>co</strong>st more. Our engineering staff metthis challenge. Now you can have big-machine capacitytogether with a practical, reasonably-priced machine foreveryday work.Inert Gas SystemAll you need is a bottle of inert gas available from yourlocal gas supplier or welding supply house. We can supplythe <strong>co</strong>rrect gas regulator and the hose. We re<strong>co</strong>mmendyou use pure nitrogen gas in the J-z. If you prefer, you canuse argon gas—the same regulator will work with eithergas. We would be glad to talk to you about the pros and<strong>co</strong>ns of both gases.The J-z has two gas flow meters to the left of the <strong>co</strong>ntrolpanel. The crucible chamber gas and the flask chambergas are <strong>co</strong>ntrolled separately just as they are on ourlarger machines. This system makes the J-z moreflexible and less expensive to run. You get big-machineperformance at a small-machine price.Neutec/USA ® castingmachines help you castwith incredible detailand very few defects.© pendant <strong>co</strong>urtesy of Relios18-Turn Induction CoilLook at the <strong>co</strong>ils in <strong>co</strong>mpetitors’ induction castingmachines: you’ll see less than half the number of turnsthat we gave the <strong>co</strong>il in the J-z. The J-z has 18 turns on itsinduction <strong>co</strong>il, though you’ll have to take our word for it.You can’t see our <strong>co</strong>il—it’s encased in a heat-resistant,dielectric ceramic material. This keeps you safe fromelectrical shock and makes the <strong>co</strong>il extremely reliable.What you can see is the superior stirring that an 18-turn<strong>co</strong>il provides for your metal before you cast.No Compressed Air RequiredAnother thing we learned from the interviews we<strong>co</strong>nducted is that many shops have limited capacityto supply <strong>co</strong>mpressed air, so we designed the J-z towork without an air <strong>co</strong>mpressor.Single-Phase ElectricityEveryone said they had single-phase electricity in theirshop or studio, so we engineered the J-z to work on this.In fact, the J-z is designed to work almost anywhere inthe world, adjusting automatically for voltage between200V and 240V. Just tell your electrician to install a 50amp.high-inrush circuit breaker (the type <strong>co</strong>mmonly used formotors) and you’re ready to go!Water Cooling SystemAll induction casting machines need <strong>co</strong>oling water. Withthe J-z, you have two choices. You can <strong>co</strong>nnect the J-z toyour water line and let the water run through the machineto a drain or you can purchase our closed-loop <strong>co</strong>olingsystem that reuses water. The J-z fits on top of the J-zWater Cooler/Stand, saving space and putting the J-z atjust the right working height. If you don’t want a closedloopwater <strong>co</strong>oling system but still want the J-z at a<strong>co</strong>nvenient height, we offer the J-z Stand, a cabinetwith extra storage space instead of the water <strong>co</strong>oler.J-z SpecificationsCrucible capacity*: 184cc (1151g sterling, 1439g 14K)Perf. flask capacity: 127 x 229mm/5" x 9"Normal cycle time: 4 minutesMax. temperature: 1370°C/2500°FOverall dimensions: 89 x 56 x 97cm/35" x 22" x 38"Weight: 132kg/290 lbs.Shipping weight: 186kg/410 lbs.Power requirements: 200–240 volts, 50amps,single-phase, 50/60HzThermo<strong>co</strong>uple: type-K or type-S*Working capacity is 60% of liquid capacity, using casting grain.Optional AccessoriesNeutec/USA ® Flask TongsSpecially designed tongs meet your specific castingneeds and are available to fit individual flask sizes.Neutec/USA ® Crucible Cooling JarUse this airtight jar for quick cruciblechanges. It seals out oxygen and preventsdeterioration of crucibles due to acceleratedoxidation while hot. Use the jar whenchanging alloy crucibles or when goingfrom casting to grain-making. It holds allsizes of Neutec/USA ® crucibles.Crucible Removal TongsHolds hot or <strong>co</strong>ld crucibles safely and easily duringinsertion or removal from machine. Tongs can be usedwith the <strong>co</strong>oling jar (above) for quick crucible changes.The Neutec/USA ® <strong>co</strong>oling jarand crucible tongs help your<strong>co</strong>nsumables last even longer!