Wartsila Brochure - Clean Shipping Technology

Wartsila Brochure - Clean Shipping Technology

Wartsila Brochure - Clean Shipping Technology

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

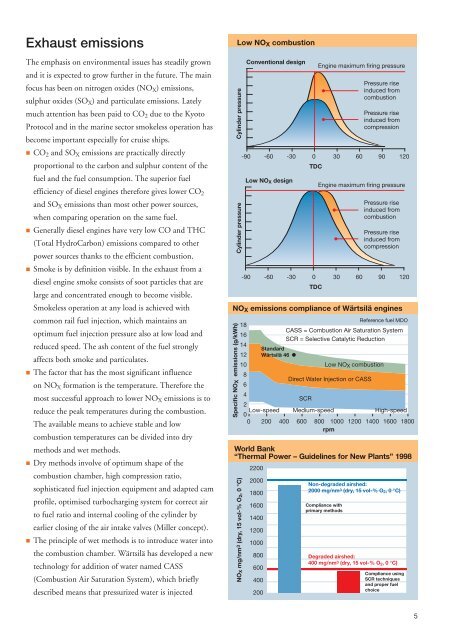

Exhaust emissionsThe emphasis on environmental issues has steadily grownand it is expected to grow further in the future. The mainfocus has been on nitrogen oxides (NO X ) emissions,sulphur oxides (SO X ) and particulate emissions. Latelymuch attention has been paid to CO 2 due to the KyotoProtocol and in the marine sector smokeless operation hasbecome important especially for cruise ships. CO 2 and SO X emissions are practically directlyproportional to the carbon and sulphur content of thefuel and the fuel consumption. The superior fuelefficiency of diesel engines therefore gives lower CO 2and SO X emissions than most other power sources,when comparing operation on the same fuel. Generally diesel engines have very low CO and THC(Total HydroCarbon) emissions compared to otherpower sources thanks to the efficient combustion. Smoke is by definition visible. In the exhaust from adiesel engine smoke consists of soot particles that arelarge and concentrated enough to become visible.Smokeless operation at any load is achieved withcommon rail fuel injection, which maintains anoptimum fuel injection pressure also at low load andreduced speed. The ash content of the fuel stronglyaffects both smoke and particulates. The factor that has the most significant influenceon NO X formation is the temperature. Therefore themost successful approach to lower NO X emissions is toreduce the peak temperatures during the combustion.The available means to achieve stable and lowcombustion temperatures can be divided into drymethods and wet methods. Dry methods involve of optimum shape of thecombustion chamber, high compression ratio,sophisticated fuel injection equipment and adapted camprofile, optimised turbocharging system for correct airto fuel ratio and internal cooling of the cylinder byearlier closing of the air intake valves (Miller concept). The principle of wet methods is to introduce water intothe combustion chamber. Wärtsilä has developed a newtechnology for addition of water named CASS(Combustion Air Saturation System), which brieflydescribed means that pressurized water is injectedLow NOXcombustionCylinder pressureCylinder pressureSpecific NO emissions (g/kWh)XConventional designTDCEngine maximum firing pressurePressure riseinduced fromcombustionPressure riseinduced fromcompression-90 -60 -30 0 30 60 90 120Low NOXdesignTDCEngine maximum firing pressurePressure riseinduced fromcombustionPressure riseinduced fromcompression-90 -60 -30 0 30 60 90 120NOXemissions compliance of Wärtsilä enginesReference fuel MDO18CASS = Combustion Air Saturation System16SCR = Selective Catalytic Reduction14Standard12 Wärtsilä 4610Low NOXcombustion86Direct Water Injection or CASS4SCR2Low-speed0Medium-speedHigh-speed0 200 400 600 800 1000 1200 1400 1600 1800rpmWorld Bank“Thermal Power – Guidelines for New Plants” 1998NO mg/nm (dry, 15 vol-% O , 0 °C)23X2200200018001600140012001000800600400200Non-degraded airshed:2000 mg/nm 3 (dry, 15 vol-% O , 0 °C)Compliance withprimary methodsDegraded airshed:400 mg/nm 3 (dry, 15 vol-% O , 0 °C)22Compliance usingSCR techniquesand proper fuelchoice5