View Brochure - Cintas

View Brochure - Cintas

View Brochure - Cintas

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

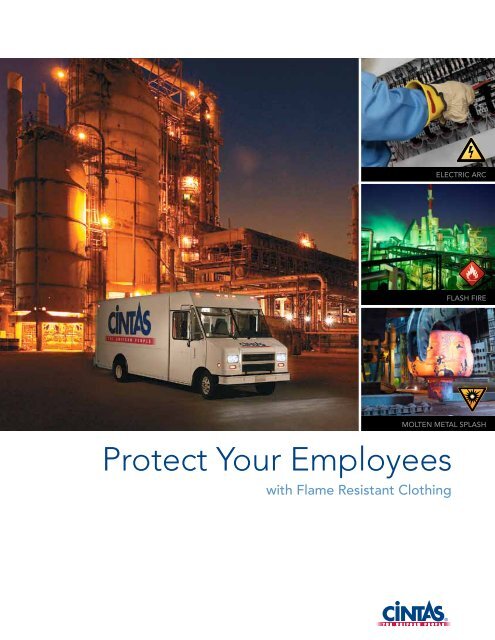

Protect Your Employees Against Electric Arc FlashDo your employees…o 4 work on energized parts,including voltage testing?o 4 remove or install CB’s orfused switches?o 4 work on control circuitswith energized partsgreater than 50 volts?If you answered Yes to any of these,NFPA 70E applies to you.<strong>Cintas</strong> will help you by providing:• Comprehensive Personal ProtectiveEquipment Programs• Specialists dedicated solely toprotective apparel• Proper care and maintenance of flameresistant garments• Appropriate protective apparel basedupon your hazard/risk category• Over 400 <strong>Cintas</strong> facilities throughoutNorth America• Rental, lease, purchase or combinationprogramsThe 2012 edition of NFPA 70E,Standard for Electrical Safety inthe Workplace, is a portion of theNational Electric Code and addresses,in part, personal protective clothingfor workers exposed to momentaryelectric arc.NFPA 70E*130.7 Personal and Other Protective Equipment(C) Personal Protective Equipment(1) General – When an employee is working within the Flash Protection boundary, he/she shall wearprotective clothing and other personal protective equipment in accordance with 130.3.(6) Body Protection – Employees shall wear Arc-rated clothing wherever there is possible exposure to an electric arcflash above the threshold incident-energy level for a second-degree burn, 5 J/cm2 (1.2 cal/cm2).(13) Care and Maintenance of Arc-rated Clothing and Arc-rated Flash Suits(a) Inspection. Arc-rated apparel shall be inspected before each use. Work clothing or flash suits that are contaminated,or damaged to the extent their protective qualities are impaired, shall not be used. Protective items that becomecontaminated with grease, oil, or flammable liquids or combustible materials shall not be used.(b) Manufacturer’s Instructions. The garment manufacturer’s instructions for care and maintenance of Arc-rated apparelshall be followed.*Reprinted with permission from NFPA 70E-2012 Standard for Electrical Safety in the Workplace © 2012. National Fire Protection Association, Quincy, MA 02269.This reprinted material is not the complete and official position of the NFPA on the referenced subject, which is represented only by the standard in its entirety.

A Simplified Approach to ComplianceElectrical safety is one of the most overlooked work hazards employees face, with electricarc flash being the most prevalent risk when working around energized parts.According to NFPA 70E – the Standard for Electrical Safety in the Workplace:• Arc flash sends 2,000 people to burn centers per year• Electrical injuries in general ranked fourth in workplace fatalities• Most of these fatalities occurred when working with less than 600vNFPA 70E – What is it?NFPA 70E, an industry consensus standard, outlines how to properly protect youremployees and create a safe working environment, as well as help your companycomply with government regulations.In 29 CFR 1910.132, OSHA requires employers to conduct hazard assessments andprovide the Personal Protective Equipment (PPE) for employees. OSHA stated,“Employers who select and require their employees to use protective clothingas stated in the NFPA 70E standard...are deemed in compliance.” OSHA hasreferenced NFPA 70E before to issue fines.NFPA 70E applies to all personnel working on energized equipment greater than50 volts or equipment that could produce an arc flash – which means virtuallyevery industry has employees at risk.NFPA 70E Protective Clothing CharacteristicsHazard/RiskCategory(HRC)0Clothing Description(Typical number of clothing layers is given in parentheses)Non-melting, flammable materials (i.e. untreatedcotton, wool, rayon or silk, or blends of these materials)with a fabric weight of at least 4.5oz/yd 2 (1)Required MinimumArc Rating of PPE[J/cm 2 (cal/cm 2 )]1 Arc-rated FR Shirt and FR pants or FR coverall (1) 16.74 (4)2 Arc-rated FR Shirt and FR pants or FR coverall (1) 33.47 (8)3Arc-rated FR Shirt and FR pants or FR coverall,and arc flash suit selected so that the system104.6 (25)arc rating meets the required minimum (1)4Arc-rated FR Shirt and FR pants or FR coverall,and arc flash suit selected so that the systemarc rating meets the required minimum (3 or more )167.36 (40)N/ASimplified, Two-Category,Flame-ResistantClothing SystemElectric Arc

Limit Flash Fire InjuriesUnderstanding Flash Fire RiskMany companies are faced with the challenge of protecting their employees fromthe hazards associated with a flash fire. Specifically, on March 19, 2010, OSHAreleased a new enforcement policy for citing 29 CFR 1910.132(a), the generalindustry standard for Personal Protective Equipment (PPE), clarifying its positionfor the failure to provide and use Flame-Resistant Clothing (FRC) in oil and gaswell drilling, servicing and production-related operations.Flash fire is defined as a fire that spreads rapidly through a diffuse fuel, such asdust, gas, or the vapors of an ignitable liquid, without the production of damagingpressure. Temperatures attained by a flash fire are capable of igniting or meltingregular clothing, which in contact with the skin, can then continue to burn untilthe fuel source (clothing) has been exhausted. Burning clothing is the cause of themost severe flash fire injuries.Flame resistant clothing is constructed of fibers and fabrics specifically designedto withstand extreme temperatures, resist ignition, self-extinguish, and not melt.These features work together to dramatically reduce the severity of flash fire injuries.Industry Expertise<strong>Cintas</strong> offers a wide range of FRC garment options and industry experience tohelp employers protect their workers against injuries due to flash fire.Industries Served• Chemical Manufacturing• Gas Utilities• Petroleum• PetrochemicalLet <strong>Cintas</strong> help you develop a flame resistant clothing program that keeps yourcompany compliant and your workers safe.Flash Fire

Guard Against Molten Metal Splash InjuriesUnderstanding Molten Metal Splash RiskMetals heated to a molten state can ignite regular clothing and lead to severeburns or even death. The causes of a molten metal splash incident can range fromhuman error to equipment failure. The secondary protective apparel we provide— FR pants and shirts, often worn under primary protective clothing such asjackets, aprons or capes — is designed to shield the skin and help prevent thermalburns by shedding molten metal droplets.<strong>Cintas</strong> is experienced in the risks facing molten metal workersServing the FRC needs of aluminum and steel manufacturers, foundries and otherindustrial metal working operations, <strong>Cintas</strong> understands the risks facing moltenmetal workers. Our industry involvement — as participants in collaborative fabricevaluation projects as well as other industry initiatives and associations —is ongoing. We understand the importance of achieving the appropriate level ofprotection against molten metal splash while being mindful of worker comfort.Molten Metal Aluminum Splash Protection — Fabrics• Oasis• VinexMolten Metal Steel Splash Protection — Fabrics• Indura ® UltraSoft ® • Indura ® • Indura ® WhipcordIndustries Served• White, non-ferrous metals, such as aluminum, magnesium, titanium andassociated alloys• Red, ferrous metals such as steel, iron and associated alloysLet us show you what fabric options are available and develop a program that fitsyour needs, while keeping your workers safe.Molten Metal Splash

Protective Clothing from <strong>Cintas</strong>60694 Indura ® Ultra-Soft ® ShirtTailored sleeve plackets and a lined, topstitchedbutton-down collar ensure a neat appearance.Fire-resistant properties endure hard work andwashing. 88% FR treated cotton/12% high-tenacitynylon. Domestic fabric/Manufactured import.Available in Navy (20) and Light Blue (80).Sizes: S-3XL. ATPV 8.7 HRC 27733 Tecasafe Plus 7 oz. ShirtEngineered as a more durable andcomfortable alternative to manyindustrial flame-resistant fabrics, thislightweight fabric is the coolest optionavailable, offering the most comfort forthe wearer when compared to other FRgarments on the market. Available inDark Khaki (62) and Light Blue (80).Sizes: RG: S-3XL, LN: M-2XL.ATPV 8.4 HRC 27733Light Blue (80) 80309Navy (20)60694Navy (20)60694Light Blue (80)7733Dark Khaki (62)70644 Indura ® Ultra-Soft ® PantsThese pants and their protective properties withstand eventhe most rigorous wear and washing. Inner lined waistbandgives lasting body and shape. Full-cut and flexible witha tapered fit. 88% FR treated cotton/12% high-tenacitynylon. Domestic fabric/Manufactured import. Available inNavy (20). Sizes: 28, 29, 30, 31, 33, 34-50 waist (even sizes),specify inseam. ATPV 12.4 HRC 28803 Tecasafe Plus 8.5 oz. PantTecasafe Plus fabric delivers protection,comfort and durability, giving customers moreoptions for their FRC Uniform program. Thislightweight fabric is the coolest option whencompared to other FR garments on the market.Available in Navy (20). Sizes: 25-39 waist(odd sizes), specify inseam. Sizes: 24-54 waist(even sizes), specify inseam. ATPV 9.3 HRC 28803Navy (20)70644Navy (20)280Denim (83)<strong>Cintas</strong>Exclusive280 Carhartt Flame Resistant JeanRelaxed fit for comfort; 14.75 oz fabric provides both protection andcomfort; 100% FR treated cotton. Available in Denim (83). Sizes: 30-54waist (even sizes), specify inseam. ATPV 23.8 HRC 2