Distinctively - CENTRIA

Distinctively - CENTRIA

Distinctively - CENTRIA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>CENTRIA</strong><br />

<strong>Distinctively</strong><br />

Product Catalog

Contents<br />

4 Formawall® Dimension Series ®<br />

6 Formawall® Graphix Series<br />

8<br />

12<br />

15<br />

Smart-R Wall Solution<br />

Formavue Integrated Window System<br />

MetalWrap Insulated Composite Backup Panel<br />

16 Versawall® and Versapanel ®<br />

Wall & Roof Panel Systems<br />

18 FormaBond® Metal Composite Wall System<br />

19 FormaBond® II Metal Composite Wall System<br />

20<br />

22<br />

24<br />

25<br />

Profile Series Concept Series®<br />

Profile Series IW Series<br />

Profile Series Exposed Fastener Panels<br />

Profile Series Liner Panels<br />

26 EcoScreen® and Profile Series Design Options<br />

28<br />

Profile Series Load Tables<br />

32 SRS® Structural Standing Seam Roof Systems<br />

34<br />

SolarCrest Solar Roof Systems<br />

35 Ventilation Systems<br />

36<br />

Coating Systems<br />

38 Kolorshift Series<br />

39<br />

Product Finish Availability<br />

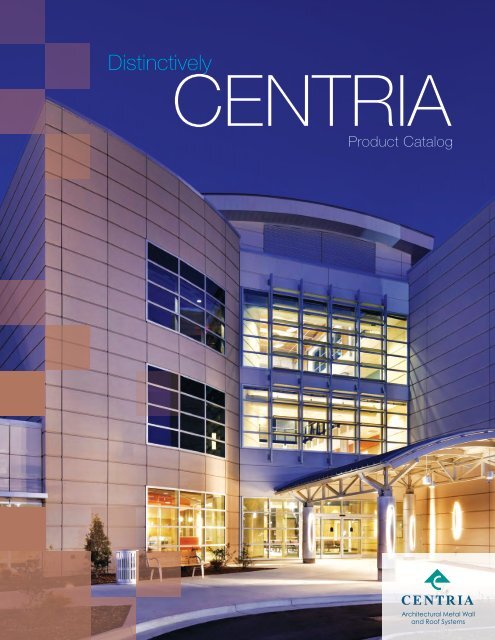

Cover and Pg 3 Image:<br />

Cumberland County<br />

Public Health Center<br />

Fayetteville, NC<br />

CJMW<br />

<strong>Distinctively</strong><br />

INNOVATIVE.<br />

<strong>Distinctively</strong><br />

SUSTAINABLE.<br />

<strong>Distinctively</strong><br />

INSTALLED.<br />

<strong>CENTRIA</strong> is the place where owner and architect visions<br />

are realized, contractor challenges are conquered and<br />

discoveries are made for greener ways to build with metal.<br />

Through continuous pursuit of excellence and innovation in<br />

the design, engineering and manufacturing of exterior wall<br />

and roof systems, no other company does more to improve<br />

the aesthetics, durability and performance of our world’s<br />

commercial buildings than <strong>CENTRIA</strong>.<br />

As a sustainability leader with the first Cradle-to-Cradle ®<br />

certified exterior building product, we continue to push<br />

“green” beyond the standard to provide aesthetic,<br />

environmentally-friendly solutions as well as tangible,<br />

immediate and long-term economic advantages over<br />

alternative systems.<br />

Our national and international sales and distribution networks<br />

will guide you from the design process through quality, ontime<br />

installation. Get the distinct advantage of <strong>CENTRIA</strong>’s<br />

expertise through:<br />

• Architectural and detailing services at any phase<br />

of your project<br />

• Sales service teams committed to total customer satisfaction<br />

• Product selection and cost estimating<br />

• Detail and design assistance for standard<br />

and custom applications<br />

• Development of specifications<br />

• Consulting on substrates, coatings and colors<br />

• Comprehensive in-house coil coating services<br />

• Thermal and structural analysis<br />

We are … distinctively <strong>CENTRIA</strong>.

04<br />

Formawall®<br />

Dimension Series ®<br />

The Complete Wall System<br />

<strong>Distinctively</strong> Efficient.<br />

<strong>CENTRIA</strong> Formawall Dimension Series, is the only wall system that provides both advanced<br />

thermal efficiency and moisture control in a single panelized component.<br />

This extraordinary performance, combined with integrated wall components – such as<br />

windows, louvers and sunshades – and the system’s ability to provide designers virtually<br />

unlimited possibilities in form, color and texture, make Formawall Dimension Series today’s<br />

preferred metal wall system.<br />

Compared to traditional multi-component wall construction – typically requiring seven separate<br />

components including: a rainscreen, an air barrier, exterior gypsum sheathing, fiberglass<br />

insulation and a vapor barrier – Formawall Dimension Series only requires one component<br />

to create a wall with superior thermal efficiency and moisture control in any environment.<br />

FORMAWALL<br />

DIMENSION SERIES<br />

1 Integrated rainscreen with<br />

pressure-equalized and<br />

vented dry sealed joinery<br />

provides long-term protection<br />

with minimal maintenance.<br />

2 Concealed clip installation<br />

provides fast close-in and<br />

eliminates the need for<br />

exterior gypsum sheathing.<br />

3 Integrated 2" [51mm] or<br />

3" [76mm] rigid closed-cell<br />

insulation cannot wet<br />

like batt insulation and is<br />

located outboard of studs for<br />

maximum thermal efficiency.<br />

4 Integrated air & vapor barrier<br />

comprised of steel liners and<br />

unexposed and protected<br />

sealant eliminates building<br />

wraps and vapor barriers,<br />

and takes the guesswork out<br />

of designing walls for specific<br />

climates.<br />

Formawall Dimension Series<br />

1<br />

2<br />

3<br />

4<br />

FORMAWALL<br />

DIMENSION SERIES<br />

VS.<br />

TRADITIONAL<br />

Stud insulated<br />

multi-component<br />

wall construction<br />

TRADITIONAL<br />

1 component required 7 components required<br />

1 installer required Up to 3 installers required<br />

Works for all climates Climate specific design required<br />

Superior thermal efficiency Thermally inefficient<br />

Total air & moisture control Questionable air & moisture control<br />

Contains no mold food sources May contain mold food sources<br />

Integrated windows, louvers<br />

and sunshades<br />

No integrated components<br />

Proven systematized long-term Unknown – dependant on<br />

performance<br />

installation quality

Cumberland County<br />

Public Health Center<br />

Fayetteville, NC<br />

CJMW<br />

Description<br />

Factory foam-insulated architectural<br />

wall panel system<br />

SUBSTRATE & CORE<br />

• Standard – 22/26 gage G-90 galvanized steel face and<br />

liner with HCFC-free polyurethane or polyisocyanurate<br />

foam-insulated core<br />

• Optional gages available – consult <strong>CENTRIA</strong><br />

• Optional stainless steel face sheet, 304 stainless steel,<br />

22 or 20 gage, smooth, embossed or striated<br />

• Optional .040" [1mm] Aluminum Face (2" [51mm]<br />

thick only), flat embossed or smooth striated**<br />

JOINERY<br />

• Horizontal oriented panel – Rainscreen, pressureequalized<br />

and drainable joinery, 1/2" [13mm] nom.<br />

joint – standard<br />

• Vertical oriented panel – Double tongue-and-groove,<br />

1/8" [3mm] nom. joint – standard<br />

• Optional Pressure Equalized Vertical Seal Plate<br />

• Optional Formawall IMV insulated metal vertical joint<br />

5/8" [16mm] joint – standard<br />

SURFACE FINISH<br />

• Exterior – Non-directional embossed flat or striated<br />

– Smooth flat or striated<br />

• Interior – Non-directional embossed planked or flat<br />

– Smooth planked<br />

COATINGS & COLORS<br />

• Advanced Fluorofinish PVDF, metallic and mica color<br />

coatings in standard & custom colors<br />

• Duragard & Duragard Plus premium high build<br />

architectural coatings<br />

• Duracast ® – a natural appearing textured finish<br />

• Versacor ® Ultra Premium Multi-Layered Coating System<br />

• Kolorshift Iridescent Coating System<br />

PANEL WIDTH<br />

• Available from 10" [254mm] to 40" [1016mm]<br />

PANEL LENGTH<br />

• Smooth – 16' [4.88m] max.<br />

• Embossed striated – 37' [11.28m] max.<br />

• Embossed – 37' [11.28m] max.<br />

• Smooth striated – 20' [6.10m] max.<br />

• Duracast – 28' [8.53m] max.<br />

PANEL THICKNESS/DEPTH OF REVEAL<br />

• 2" [51mm] with 1-3/16" [30mm] deep reveal – standard<br />

• 3" [76mm] with 2-3/16" [56mm] deep reveal<br />

• 3"-T [76mm] with 1-3/16" [30mm] deep reveal<br />

“R” VALUE<br />

• 2" [51mm] panel with 1/2" [13mm] reveal – R14<br />

• 3" [76mm] panel with 1/2" [13mm] reveal – R21<br />

• 3"-T [76mm] panel with 1/2" [13mm] reveal – R23<br />

R-Values are based on ASTM C1363 testing.<br />

Air films are included.<br />

* All data shown for flat panels only.<br />

* Patent No.: US 6,253,511; 6,627,128; 6,968,659<br />

Canada 2,351,846<br />

** Length restrictions apply, please consult <strong>CENTRIA</strong>.<br />

Consult <strong>CENTRIA</strong> for profiled panel information.<br />

<strong>CENTRIA</strong>.com<br />

Formawall<br />

Dimension Series<br />

Features & Benefits<br />

• May be installed horizontally or vertically<br />

• Available in a variety of interchangeable reveals,<br />

thickness and profile configurations<br />

• Concealed clips, fasteners and sealants plus vertical<br />

dry gaskets and insulated metal vertical joints provide<br />

a clean, uninterrupted appearance<br />

• Factory foamed-in-place core to ensure no insulation<br />

gaps within the panel<br />

• Panels integrate with <strong>CENTRIA</strong> Formavue window<br />

systems and are compatible with most other glass<br />

wall and window systems<br />

• Pressure-equalized horizontal joinery to help prevent<br />

water infiltration<br />

• Optional Pressure Equalized Vertical Seal Plate<br />

• Extruded aluminum or factory-formed metal<br />

trim available<br />

• Panels can be easily curved<br />

• Mitered panels permit clean, sharp corners, beam<br />

and column wraps<br />

• Trimless ends eliminate overlapping trim at panel<br />

end details<br />

• Thermal break between face and liner offers efficient<br />

panel R-values<br />

• High strength panels offer increased span capability<br />

and save support costs with less framing required<br />

• Lightweight – as low as 2.7 psf – easy to handle and<br />

install and minimizes foundation load<br />

• Aluminum, stainless, striated, variable striated,<br />

smooth, embossed and precast-like surface<br />

treatments available<br />

• Cradle-to-Cradle Silver Certification<br />

• Integrated louvers and sunshades available<br />

Aesthetic Options<br />

2" [51mm]<br />

thick panel<br />

Over 3"<br />

[76mm]<br />

thick panel<br />

3" [76mm]<br />

DS-59-T Profile<br />

3" [76mm]<br />

DS-60-T Profile<br />

Reveals<br />

from 1/2"<br />

[13mm] to 6"<br />

[152mm] in<br />

1/2" [13mm]<br />

increments,<br />

may be<br />

colorized<br />

3" [76mm]<br />

Steep Shelf-T Profile<br />

05

06<br />

Formawall®<br />

Graphix Series ®<br />

<strong>Distinctively</strong> Adaptable.<br />

Imagine a single wall panel, made to look like 12 smaller panels.<br />

<strong>CENTRIA</strong>’s Graphix Series offers unique segmented construction<br />

to make this effect easy and economical. Best of all, you get to<br />

choose how a wall panel is segmented along its length for unlimited<br />

combinations of design possibilities.<br />

4<br />

5<br />

6<br />

7<br />

8<br />

9<br />

1<br />

Durable metal skins<br />

provide impact resistance,<br />

strength for increased span<br />

capability and a built-in vapor barrier<br />

Actual joint<br />

4<br />

Placement of segments are specified by designer<br />

Optional reveals of varying widths<br />

Segmented joints are treated to match actual joint<br />

Rainscreen vented, pressure-equalized and drainable joinery with<br />

concealed sealant prohibits water penetration<br />

Formawall Graphix Series<br />

2<br />

5<br />

3<br />

1<br />

2<br />

3<br />

High performance coatings offer long-term performance, minimal<br />

maintenance and excellent color selection for your building’s exterior<br />

Insulating foam core, factory foamed-in-place, provides a thermally<br />

efficient exterior wall in either 2" [51mm] or 3" [76mm] thickness<br />

Concealed clips and fasteners provide a sleek exterior appearance<br />

with proven long-term performance<br />

6<br />

7<br />

8<br />

9

National Corvette Museum<br />

Bowling Green, KY<br />

Sherman Carter Barnhart<br />

Features & Benefits<br />

• Graphix Series panels can be segmented as<br />

frequently as every 12" [305mm] and can be<br />

installed both vertically and horizontally<br />

• Distinguish your design further by adding panel<br />

to panel reveals of varying widths – from 1/2"<br />

[13mm] to 6" [152mm]<br />

• Customization continues as you select panel<br />

finishes, with enough options that your Graphix<br />

Series design may never be duplicated<br />

• <strong>CENTRIA</strong> offers advanced coating systems that<br />

provide outstanding durability and corrosion<br />

resistance – available in over 70 standard colors,<br />

including micas and metallics, and unlimited<br />

custom colors<br />

• Formawall Graphix Series is a single-component<br />

wall system – a steel face and liner, using<br />

foamed-in-place CFC-free foam insulation.<br />

Panels are joined with <strong>CENTRIA</strong>’s proven vented<br />

and dry-sealed rainscreen joinery. The result<br />

is the most advanced thermal and moisture<br />

protection available<br />

• Combined with Formawall’s integrated<br />

components including windows, louvers and<br />

sunshades, it’s all you need to build the complete<br />

wall in any climate<br />

• Optional Pressure Equalized Vertical Seal Plate<br />

<strong>CENTRIA</strong>.com<br />

Formawall<br />

Graphix Series<br />

Description<br />

Factory foam-insulated architectural wall panel system<br />

SUBSTRATE & CORE<br />

• Standard – 22/26 gage G-90 galvanized steel face and liner<br />

with HCFC-free polyurethane or polyisocyanurate foaminsulated<br />

core<br />

• Optional gages available – consult <strong>CENTRIA</strong><br />

• Optional .040" [1mm] Aluminum face (2" [51mm] thick<br />

only), embossed and smooth<br />

JOINERY<br />

• Horizontal oriented panel – Rainscreen, pressure-equalized<br />

and drainable joinery, 1/2" [13mm] nom. joint – standard<br />

• Vertical oriented panel – Double tongue-and-groove,<br />

1/8" [3mm] nom. joint – standard<br />

• Segmented joint – 5/8" x 3/4" [16mm x 19mm] deep<br />

embossment with factory applied black gasket, standard<br />

–Max. segments per panel – 12<br />

–Min. length of segment – 1' [305mm]<br />

• Optional Formawall IMV insulated metal vertical joint<br />

5/8" [16mm] joint – standard<br />

SURFACE FINISH<br />

• Exterior – Non-directional embossed<br />

–Smooth flat<br />

• Interior – Non-directional embossed planked or flat<br />

–Smooth planked<br />

COATINGS AND COLORS<br />

• Advanced Fluorofinish PVDF, metallic, and mica color coating<br />

systems are available in standard and custom colors<br />

• Duragard ® & Duragard ® Plus premium high build<br />

architectural coatings<br />

• Duracast ® a natural appearing textured finish<br />

• Versacor ® Ultra Premium Multi-Layered Coating System<br />

• Kolorshift Iridescent Coating System<br />

PANEL WIDTH<br />

• Available from 10" [254mm] to 40" [1016mm]<br />

PANEL LENGTH (Steel Face)<br />

• 20' [6.10m] max.<br />

PANEL LENGTH (Aluminum Face)<br />

• Embossed, Flat – Overall Max. Length – 12'6" [3.81m]<br />

-Max. Length of Segment – 11'6" [3.51m]<br />

-Min. Length of Segment – 12" [305mm]<br />

-Max. Number of Segments – 12<br />

• Smooth, Flat – Overall Max. Length – 12'6" [3.81m]<br />

-Max. Length of Segment – 4' [1.22m]<br />

-Min. Length of Segment – 12" [305mm]<br />

-Max. Number of Segments - 12<br />

PANEL THICKNESS<br />

• 2" [51mm] standard<br />

• 3" [76mm] consult <strong>CENTRIA</strong><br />

• 3"-T [76mm] standard<br />

“R” VALUE<br />

• 2" [51mm] panel with 1/2" [13mm] reveal – R14<br />

• 3" [76mm] panel with 1/2" [13mm] reveal – R21<br />

• 3"-T [76mm] panel with 1/2" [13mm] reveal – R23<br />

R-Values are based on ASTM C1363 testing.<br />

Air films are included.<br />

07

Smart-R<br />

<strong>Distinctively</strong> Smart-R.<br />

Wall Solution<br />

Introducing <strong>CENTRIA</strong>’s most efficient and aesthetic approach<br />

to metal wall systems. Smart-R combines seamless integration<br />

of panels, windows, louvers and sunshades with enhanced thermal<br />

performance to deliver an unmatched combination of aesthetics,<br />

performance and sustainability.<br />

Features & Benefits<br />

DESIGN<br />

• Systems approach to high-performance<br />

architectural cladding<br />

• Seamless integration of panels, windows, louvers<br />

and sunshades provides sleek sightlines at<br />

component joinery intersections<br />

• All-metal joinery provides unrivaled architectural foam<br />

panel aesthetics<br />

• Design flexibility with 3" [76mm] thick Formawall<br />

Dimension Series DS-59 and DS-60 profiles and<br />

Formawall Graphix Series panels<br />

08 Smart-R Wall Solution<br />

PERFORmANCE<br />

• Improved 3" [76mm] FWDS-T panel and new<br />

FV-600 window thermal performance<br />

• Addresses air infiltration, a critical issue in overall<br />

wall performance<br />

• Formawall IMV metal vertical joint features improved<br />

thermal performance and superior defense against<br />

water intrusion<br />

• Shop-assembled windows reduce risk during field<br />

installation and increase the speed of construction<br />

SUSTAINABILITY<br />

• Integrated wall system reduces the amount of material<br />

used (no receptors or exposed sealants)<br />

• Engineered composite foam panel, integrated<br />

accessories and factory-assembled windows<br />

reduce jobsite waste<br />

• High-performance wall system improves the overall<br />

air, water and thermal performance

Maple Grove Hospital<br />

Maple Grove, MN<br />

BWBR Architects, Inc.<br />

<strong>CENTRIA</strong>.com<br />

Formawall<br />

3" [76mm] Formawall-T insulated<br />

metal panel<br />

• Available with all popular<br />

Formawall profiles<br />

• Seamlessly integrates with louvers,<br />

sunshades and FV-600 windows<br />

• Enhanced thermal performance<br />

• R23<br />

FV-600 Formavue window<br />

• Shop-assembled, integrated punched<br />

or strip window system<br />

• Available on studs or thru-tube supports<br />

• Seamlessly integrates with 3" [76mm]<br />

Formawall-T<br />

• Enhanced thermal performance<br />

• R3.5<br />

Formawall IMV insulated metal vertical joint<br />

• The only foam panel product offering<br />

a 4-sided metal joint option<br />

• Added aesthetic flexibility<br />

• Enhanced thermal performance<br />

• R4<br />

09

The Complete Wall System<br />

Integration Options<br />

FORMAVUE <br />

WINDOWS<br />

Six distinct styles of<br />

Formavue windows<br />

integrate seamlessly with<br />

Dimension Series panels<br />

and accommodate a<br />

variety of fenestrations and<br />

construction types.<br />

10 Formawall Dimension Series<br />

C/S SUNSHADES<br />

<strong>CENTRIA</strong> and Construction<br />

Specialties, Inc. (C/S Group)<br />

join forces to provide a wide<br />

selection of sunshades,<br />

engineered for seamless and<br />

thermally isolated integration<br />

with Formavue windows and<br />

Dimension Series panels.<br />

C/S LOUVERS<br />

<strong>CENTRIA</strong> and C/S Group<br />

also provide a full line of<br />

fixed, drainable and stormresistant<br />

louvers engineered<br />

for seamless integration with<br />

Dimension Series panels.<br />

KALWALL ®<br />

TRANSLUCENT<br />

WINDOWS<br />

<strong>CENTRIA</strong> and Kalwall<br />

Corporation have<br />

co-designed this Formawall<br />

Dimension Series Integrated<br />

Translucent Window System.<br />

Designed to install easily with<br />

<strong>CENTRIA</strong> original 3" [76mm]<br />

Formawall Dimension Series<br />

panels, these lightweight<br />

and strong window systems<br />

combine the beauty and good<br />

sense of diffused, natural interior<br />

lighting with the functional<br />

qualities of high insulation,<br />

shatterproof construction and<br />

low maintenance.

Finish Options Design Options<br />

DURACAST ®<br />

TEXTURED FINISH<br />

SYSTEM<br />

Dimension Series panels<br />

coated with <strong>CENTRIA</strong><br />

Duracast finish, which uses<br />

a silica aggregate, provides<br />

a rugged, natural look.<br />

Duracast is available in<br />

eight natural earthtones and<br />

comes with an exclusive<br />

20-year warranty.<br />

STAINLESS STEEL<br />

Choice of:<br />

• No. 2B – A bright, cold<br />

rolled, unpolished finish<br />

• No. 4 – A brushed finish<br />

• Embossed, smooth<br />

or striated<br />

ALUMINUM<br />

Tacoma Public Utilities<br />

Administration Building<br />

Tacoma, WA<br />

BCRA Architects<br />

• 0.040" [1mm] face<br />

• Available on 2" [51mm]<br />

Formawall Dimension<br />

Series<br />

• Non-directional<br />

embossed flat or smooth<br />

striated<br />

• Lengths up to 12'6"<br />

[3.81m]<br />

SoDo (South of<br />

Downtown Orlando)<br />

Orlando, FL<br />

Cupkovic Architecture LLC<br />

VARIABLE<br />

STRIATIONS<br />

• Striation bands are<br />

6" [152mm] wide<br />

• A minimum 1" [25mm]<br />

smooth band between<br />

striation bands<br />

• Striations can run out<br />

to both edges<br />

• Striations can be as far<br />

from the face edge as<br />

desired in 1/4" [6mm]<br />

increments<br />

<strong>CENTRIA</strong>.com<br />

Formawall<br />

Dimension Series<br />

Performance Options<br />

FORMAWALL<br />

DIMENSION SERIES<br />

PE<br />

<strong>CENTRIA</strong>’s new Formawall<br />

Dimension Series PE<br />

features an integral pressure<br />

equalized vent drainage<br />

channel for Formawall<br />

Dimension Series and<br />

Formawall Graphix Series<br />

exterior metal wall panels.<br />

The continuous air seal<br />

is not compromised by<br />

the seal plate venting and<br />

the plate transfers load to<br />

vertical support. This design<br />

creates two lines of defense<br />

against water intrusion.<br />

11

Formavue<br />

<strong>Distinctively</strong> Integrated.<br />

<strong>CENTRIA</strong> Formavue window systems are designed to integrate with Formawall Dimension Series<br />

and Formawall Graphix Series panels resulting in a high performance window/panel interface. These<br />

window systems are attractive, weather-resistant and feature a standard thermal break. They eliminate<br />

problems of coordinating window and metal panel intersections.<br />

FV-600 Formavue window<br />

System Window Descriptions Exterior Sightlines<br />

• Shop-assembled, integrated punched<br />

or strip window system<br />

FV 100 Vertical Panels with Spandrel<br />

3" [76mm]<br />

• Available on studs or<br />

Supports Strip window applications<br />

thru-tube supports<br />

and punched windows with single<br />

• Seamlessly integrates with 3" [76mm]<br />

lite and stacked glass options.<br />

Formawall-T<br />

Full and vertical structural glazed<br />

• Enhanced thermal performance<br />

mullions.<br />

• R 3.5<br />

FV 200 Horizontal Panels with Spandrel<br />

Supports Strip window applications<br />

and punched windows with single lite<br />

and stacked glass options. Full and<br />

vertical structural glazed mullions.<br />

FV 300 Horizontal Panels with Steel or<br />

Aluminum Thru-Tube Supports Strip<br />

window applications and punched<br />

windows with single lite and stacked<br />

glass options. Full and vertical<br />

structural glazed mullions.<br />

FV 400 Horizontal Panels with Steel or<br />

Aluminum Thru-Tube Supports Strip<br />

window applications and punched<br />

windows with single lite and stacked<br />

glass options. Full and vertical<br />

structural glazed mullions. Exterior<br />

pressure bar glazing with snap-on<br />

covers. Unique integral gutter at head<br />

is standard.<br />

FV 500 Horizontal Panels with Spandrel<br />

Supports for Punched Windows<br />

Horizontal Panels with Thru-Tube<br />

Supports for Strip Windows Shop<br />

assembled frames for faster<br />

installation. Single lite and stacked<br />

glass options, full mullions.<br />

12 Formavue<br />

3" [76mm]<br />

3" [76mm]<br />

2-1/2" [64mm]<br />

3" [76mm]<br />

All systems are designed to accept 1" [25mm] insulating glass.<br />

FV100-FV500 integrate with 2" [51mm] and 3" [76mm] Formawall Dimension<br />

and Graphix Series.<br />

FV600 integrates with 3"-T [76mm] Formawall Dimension Series only<br />

and 3" [76mm] Graphix Series.<br />

FV 600<br />

1<br />

2<br />

3<br />

1<br />

3<br />

2<br />

Window system eliminates receptor<br />

extrusions, provides easier and faster jobsite<br />

coordination and is system tested to ensure<br />

superior weather resistance<br />

Inside or outside glazing options allow easier<br />

access for installation or glass replacement<br />

Advanced, thermally-improved design<br />

features a thermal barrier that minimizes<br />

through-metal conductivity, while maintaining<br />

structural integrity tested CRF value of 65

Swedish Orthopedic<br />

Institute<br />

Seattle, WA<br />

NBBJ Design<br />

<strong>CENTRIA</strong>.com<br />

Formavue<br />

13

The Complete Wall System<br />

FORMAWALL SERIES<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

Insulating foam core, factory foamed-in-place, provides<br />

a thermally efficient exterior wall in either 2" [51mm]<br />

or 3" [76mm] thickness<br />

Durable metal skins provide impact resistance, strength for increased<br />

span capability and a built-in vapor barrier<br />

High performance coatings offer long-term performance, minimal<br />

maintenance and excellent color selection for your building’s exterior<br />

Concealed clips and fasteners provide a sleek exterior appearance<br />

with proven long-term performance<br />

Variable reveal sizes, 1/2" [13mm] to 6" [152mm]<br />

Rainscreen and pressure equalization design with concealed sealant<br />

protects against water penetration<br />

VERTICAL & HORIZONTAL PANEL ALLOWABLE SPANS Ft-In – 2" Thickness<br />

Module<br />

(in.)<br />

FWDS 3T Span Table - 3/16" Steel Supports<br />

w/structural, production & thermal limits for light & medium-colored building walls<br />

Panel Module Panel Gage<br />

36 22/26<br />

30 22/26<br />

24 22/26<br />

Gage<br />

F/L<br />

36 22/26<br />

30 22/26<br />

24 22/26<br />

No.<br />

Spans<br />

No.<br />

Maximum Span @ Load (psf)<br />

Spans 20 40 60 80<br />

1 12’- 0" (tb) 6’-6" (ec) 4’- 4" (ec) 3’- 3" (ec)<br />

2 12’- 0" (ts) 7’- 7" (if) 4’- 11" (ec) 3’- 6" (ec)<br />

3 10’- 0" (p) 7’- 10" (ec) 5’- 0" (ec) 3’- 8" (ec)<br />

1 12’- 0" (tb) 7’- 10" (ec) 5’- 2" (ec) 3’- 11" (ec)<br />

2 12’- 0" (ts) 9’- 0" (if) 6’- 1" (ec) 4'- 4" (ec)<br />

3 10’- 0" (p) 9’- 6" (ec) 6’- 2" (ec) 4’- 6" (ec)<br />

1 12’- 0" (tb) 9’- 9" (ec) 6’- 6" (ec) 4’- 11" (ec)<br />

2 12’- 0" (ts) 11’- 1" (ec) 7’- 7" (if) 5’- 8" (ec)<br />

3 10’- 0" (p) 10’- 0" (p) 7’- 10" (ec) 5’- 9" (ec)<br />

Based on the results of structural testing performed Feb 2010:<br />

TESTED PROPERTIES: GC=730 psi, FV=26.5 psi, FB= 20030 psi, REND=734 lb, RINT=2116 lb, FT=10000 psi<br />

PHYSICAL PROPERTIES: tF= 0.0299 in, tL=0.0179 in, total thk=3.000 in, AC=35.426 in 2 , y(BOT)=1.8706 in<br />

IC=1.190 in 4 /ft, Sb=0.6362 in 3 /ft, St=1.0537 in 3 /ft<br />

LENGTH LIMIT: Max Standard Length = 30'<br />

Limiting Modes: (b) - bending, (ec) - end clip, (ic) - interior clip, (ef) - end fastener, (if) - interior fastener, (p) - production,<br />

(tb) - thermal bow, (ts) - thermal stress<br />

Qualifications: 1. Fastener limitations were applied thru the use of (1) 1/4-14 screw into 3/16-inch steel supports with a<br />

pullout capacity of 2660 lb.<br />

2. Consult <strong>CENTRIA</strong> Design & Development for dark-colored panels and/or screenwall applications.<br />

14 Formawall Dimension Series<br />

20<br />

Load - psf<br />

30 40 50<br />

1 11-9 8-8 6-6 5-3<br />

2 12-0 9-9 7-5 6-1<br />

3 12-0 10-9 8-0 6-4<br />

1 11-9 9-11 7-10 6-3<br />

2 12-0 11-7 8-10 7-2<br />

3 12-0 11-8 9-8 7-8<br />

1 11-9 9-11 8-8 7-10<br />

2 12-0 11-8 10-3 8-10<br />

3 12-0 11-8 10-2 9-0<br />

1. Spans are based on a maximum 1/2" reveal.<br />

2. Spans are limited to a maximum deflection of L/180.<br />

3. Spans are based on one fastener per clip into 3/16" support steel.<br />

4. Spans may be further restricted dependent on color, thermal bow and thermal stress.<br />

5. Consult <strong>CENTRIA</strong> for conditions not conforming to these notes.<br />

1<br />

2<br />

3<br />

BUILDING CODE APPROVALS<br />

Fire Tests:<br />

• Tunnel Test, ASTM E84;<br />

a. Flame Spread 25 max.<br />

b. Smoke Developed 450 max.<br />

• UL Room Corner Test, UL 1715<br />

• Factory Mutual Approval: FM 4880<br />

• Factory Mutual Approval: FM 4881<br />

• SwRI: Multistory Fire Test, NFPA 285(ISMA)<br />

• ASTM D2015; BTU Content Test<br />

• ASTM D1929; Ignition Properties<br />

• UL Fire Wall Designs: 1 hr, 2 hr, 3 hr, U017,<br />

U617, U645, U605<br />

Special Approvals:<br />

• Dade County (Missile Impact Resistance)<br />

• New York City MEA 330-05-M<br />

Consult <strong>CENTRIA</strong> for test reports.<br />

4<br />

5<br />

6

MetalWrap<br />

1<br />

2<br />

3<br />

4<br />

5<br />

6<br />

7<br />

<strong>CENTRIA</strong>.com<br />

Insulated Composite Backup Panel System<br />

<strong>Distinctively</strong> Innovative.<br />

<strong>CENTRIA</strong> introduces the latest in metal wall technology. MetalWrap is an alternative thermal, air and<br />

moisture backup panel system designed specifically for <strong>CENTRIA</strong> non-insulated metal wall systems,<br />

such as FormaBond ® and Profile Series.<br />

With its integrated single-panel design, MetalWrap is the smart and economical backup panel choice. With<br />

MetalWrap, there is no need for conventional batt or board installation, exterior gypsum board, air barriers,<br />

vapor retarders or building wraps, which reduces the amount of waste at the worksite and decreases labor<br />

costs and coordination. Because MetalWrap makes use of ATMP ® building envelope science, it effectively<br />

controls moisture without sacrificing thermal efficiency, making it a highly superior product.<br />

Features & Benefits<br />

• Single-panel design allows for one-step<br />

installation and lower labor costs<br />

• Flexible design allows for application<br />

of <strong>CENTRIA</strong> horizontal and vertical<br />

exterior cladding<br />

• Faster close-in and dry-in for reduced<br />

building costs<br />

• High R-Values reduce energy costs<br />

1<br />

4<br />

5<br />

2<br />

3<br />

6<br />

7<br />

MetalWrap Panel<br />

• Superior water drain plane<br />

• Excellent moisture, air and<br />

thermal barriers<br />

• Unique foam insulated composite<br />

backup system<br />

• Minimal construction waste<br />

• Universal backup wall solution for all<br />

building types in any climate<br />

Description<br />

MetalWrap<br />

Durable Metal Drain Plane<br />

Vertical Subgirt for<br />

Exterior Cladding<br />

R14 or R21 System Thermal Value<br />

<strong>CENTRIA</strong> Exterior<br />

Rainscreen Cladding<br />

Unique Clip Design Allows for<br />

Integration of Exterior Cladding<br />

Pressure Equalized<br />

Horizontal Joinery<br />

Metal Liner Provides Air<br />

and Vapor Barrier<br />

Insulated composite backup panel<br />

THICKNESS<br />

LENGTH<br />

• 2" [51mm] or 3" [76mm] • 12' [3.66m] or 20' [6.10m]<br />

THERmAL SYSTEm<br />

standard lengths<br />

• 2" [51mm] – R14<br />

FACE AND LINER<br />

• 3" [76mm] – R21<br />

• 29GA AZ-50 Galvalume<br />

WIDTH<br />

FOAm INSULATION<br />

• 36" [914mm]<br />

• Minimum 2.4 PCF Urethane<br />

modified isocyanurate foam<br />

15

Versawall®<br />

& Versapanel®<br />

Wall & Roof Systems<br />

<strong>Distinctively</strong> Versatile.<br />

Versawall and Versapanel (Cradle-to-Cradle ® Certified)<br />

insulated metal composite panels install vertically to<br />

create a wall with advanced thermal and moisture<br />

protection properties.<br />

Architects enjoy the systems’ ability to provide long,<br />

uninterrupted sight lines – up to 48 feet [14.63m]. Plus,<br />

Versawall and Versapanel wall panels can be coated with<br />

<strong>CENTRIA</strong> Duracast to provide a natural textured look.<br />

The versatility of Versapanel allows this bold standing<br />

seam to double as a high-performance insulated roof<br />

when combined with its watertight snap-on batten cap.<br />

16 Versawall & Versapanel<br />

Versawall 2.75" [70mm]<br />

Planked<br />

Versawall 2.75" [70mm]<br />

Striated<br />

Versapanel 1.75" [44mm]<br />

Planked<br />

VERSAWALL 2.00 ALLOWABLE SPANS – FT-IN<br />

Module<br />

(in.)<br />

Features & Benefits<br />

• Lightweight panels lower installation costs<br />

• Outstanding weather resistance due to double<br />

tongue-and-groove joinery<br />

• Concealed fasteners provide a clean, uninterrupted surface<br />

• May be installed in any type of weather, faster and easier<br />

• Increased span capability reduces support steel<br />

requirements<br />

• CFC-free foam insulation<br />

• Thermal break between face and liner saves energy<br />

• Versawall can be used for interior partitions<br />

• Available with factory-formed sheet metal flashing<br />

or extruded aluminum trim<br />

• Versapanel’s snap-on cap conceals joint for a seamless<br />

appearance (required on roofs)<br />

• Cradle-to-Cradle Certification<br />

Coatings & Colors<br />

• Advanced Fluorofinish ® PVDF, metallic and mica color<br />

coatings in standard & custom colors<br />

• Duragard ® & Duragard ® Plus premium high build<br />

architectural coatings<br />

• Duracast ® – a natural appearing textured finish<br />

• New Versacor ® Ultra Premium Multi-Layered Coating System<br />

• Kolorshift Iridescent Coating System<br />

Gage<br />

F/L<br />

36 26/26<br />

36 22/22<br />

No.<br />

Spans<br />

1. L/120 deflection criteria.<br />

2. 3/16" steel supports with 1 fastener per clip.<br />

3. For dark colored panels, further panel length and restrictions<br />

may be required due to thermal stress. Consult <strong>CENTRIA</strong>.<br />

Load - psf<br />

20 30 40 50<br />

1 11-11* 8-0 6-0 4-9<br />

2 12-0* 9-9 7-5 5-9<br />

3 12-0* 9-9 7-3 5-9<br />

1 12-0* 10-3 7-8 6-2<br />

2 12-0* 9-10 7-7 6-2<br />

3 12-0* 10-10 8-2 6-7<br />

*Spans are restricted by thermal<br />

stress and bow considerations.

VERSAPANEL 2.50 WIND LOAD SPANS – FT-IN<br />

Gage<br />

Face/Liner<br />

26/26<br />

No.<br />

Spans<br />

Fast.†<br />

Clip<br />

Load - psf<br />

20 25 30 35 40 45 50 55 60<br />

1 1 12-0* 12-0 10-0 8-7 7-6 6-8 6-0 5-5 5-0<br />

2 1 12-0* 11-9* 10-0 8-7 7-7 6-10 6-3 5-9 5-3<br />

3 1 13-4 13-0 10-10 9-4 8-2 7-3 6-7 6-0 5-6<br />

1. †Fastener capacity is based on the use of minimum 3/16" support steel substrate.<br />

2. Spans are limited to a maximum deflection is L/120.<br />

3. Triple span of 13'-4" is limited by 40'-0" maximum panel length.<br />

4. Consult <strong>CENTRIA</strong> for additional allowable spans.<br />

*Spans may be increased dependent on color, thermal bow and thermal stress.<br />

VERSAPANEL FLAT<br />

VERSAPANEL PLANKED<br />

Sears Centre<br />

Hoffman Estates, IL<br />

Ryan Companies US, Inc.<br />

<strong>CENTRIA</strong>.com<br />

Versawall<br />

& Versapanel<br />

Description<br />

Factory foam-insulated wall and roof panel system<br />

SUBSTRATES<br />

• Standard – 26/26 G-90 galvanized steel face and<br />

liner with HCFC-free foam insulated core<br />

• Optional gages available, consult <strong>CENTRIA</strong><br />

JOINERY<br />

• Double tongue-and-groove joinery with<br />

factory-applied air and vapor seal<br />

SURFACE FINISH<br />

• Versawall Exterior – Non-directional embossing,<br />

flat, striated or planked. For non-embossed and<br />

non-striated, consult <strong>CENTRIA</strong><br />

• Versapanel Exterior – Non-directional embossing,<br />

planked or flat<br />

• Interior – Non-directional embossing, planked<br />

• Optional Duracast textured finish is available for<br />

Versawall and Versapanel wall applications, consult<br />

<strong>CENTRIA</strong> for panel length options<br />

PANEL WIDTH<br />

• Versawall – 30" [762mm], 36" [914mm]<br />

• Versapanel – 36" [914mm]<br />

PANEL LENGTH<br />

• 6' to 40' [1.83m–12.19m] standard<br />

• 48' [14.63m] max. consult <strong>CENTRIA</strong><br />

PANEL THICKNESS<br />

• Versawall – 2" [51mm], 2-3/4" [70mm],<br />

4" [102mm] nom.<br />

• Versapanel – 1-3/4" [44mm], 2-1/2" [64mm],<br />

4" [102mm]<br />

“R” VALUE<br />

Versawall<br />

• 2" [51mm] depth – R14<br />

• 2-3/4" [70mm] – R20<br />

• 4" [102mm] – R27<br />

Versapanel<br />

• 1-3/4" [44mm] – R14<br />

• 2-1/2" [64mm] – R19<br />

• 4" [102mm] – R27<br />

R-values are based on ASTM C1363 testing.<br />

Air films are included.<br />

VERSAWALL FLAT<br />

VERSAWALL PLANKED<br />

VERSAWALL STRIATED<br />

17

FormaBond®<br />

Metal Composite<br />

Wall System *<br />

<strong>Distinctively</strong> Superior.<br />

<strong>CENTRIA</strong> revolutionizes the thin aluminum composite panel<br />

industry with FormaBond. Unlike traditional ACM – that’s made<br />

through lamination, then fabricated into panels by a second<br />

party – FormaBond is manufactured entirely by <strong>CENTRIA</strong> using<br />

a proprietary reaction injection molding process. The result is a<br />

patented, stronger, flatter and finished ACM panel, complete with<br />

pressure-equalized joinery.<br />

Patented dry joinery eliminates wet seals and provides optimum<br />

venting to allow wall cavities to dry effectively while prohibiting<br />

the entry of rainwater, thus reducing the chance of entrapped<br />

moisture, material degradation and mold. Specify FormaBond and<br />

elevate the quality and integrity of your next ACM wall system.<br />

*Patent no: US 7,007,433 B2<br />

18 FormaBond<br />

PRESSURE-<br />

EQUALIZED<br />

RAINSCREEN<br />

JOINERY<br />

SURFACE FINISH<br />

1 2<br />

3 4<br />

1 FUSION 2 EmBOSSED<br />

3 BRAIDED 4 HONEYCOmB<br />

Features & Benefits<br />

• Provides super-flat, sharp and crisp exterior sight lines<br />

• Value-added dry seal installation<br />

• Low maintenance and no costly re-caulking<br />

• Pressure-equalized rainscreen with no water entry<br />

behind the screen at 15 psf.<br />

• Ventilated cavity along each horizontal joint<br />

• Excellent bond strength and superior impact resistance<br />

• Proprietary polymeric core meets fire code<br />

requirements for all building heights<br />

• .315" [8mm] sheet thickness passes the large and<br />

small missile impact test required in many coastal<br />

regions with no plywood backing<br />

Description<br />

Pre-formed aluminum composite architectural<br />

wall panel system<br />

SUBSTRATE & CORE<br />

• Metal – 0.032" [.8mm] nominal aluminum face and liner<br />

• Core – Highly cross-linked polymer that meets fire core<br />

requirements<br />

• .315" [8mm] sheet thickness<br />

• Smooth – flat ACM panel system<br />

JOINERY<br />

• All dry construction that is pressure equalized and<br />

provides ventilation to the inner wall cavity<br />

SURFACE FINISH<br />

• Smooth, Embossed, Braided, Fusion or Honeycomb<br />

Surface Finish<br />

PANEL WIDTH<br />

• Up to 60" [1.52m] Smooth<br />

• Up to 45" [1.14m] for Fusion, Braided, Honeycomb and<br />

Embossed textures<br />

PANEL LENGTH<br />

• Up to 180" [4.57m]<br />

VARIABLE REVEALS<br />

• From 1/2" [13mm] to 6" [152mm]<br />

in 1/2" [13mm] increments.<br />

May also be colorized<br />

COATINGS<br />

• Available in micas, metallics, Fluorofinish ® and Kolorshift PERFORmANCE<br />

• High performance air and water testing<br />

• Pressure-equalized joinery<br />

• AAMA 508-05<br />

Lancaster Public Safety Building<br />

Lancaster, TX<br />

Perkins & Will

II<br />

FormaBond®<br />

<strong>Distinctively</strong> Efficient.<br />

<strong>CENTRIA</strong>’s complete installation-ready MCM panel system<br />

that delivers dependability, convenience and value to today’s<br />

building construction. As the only MCM wall system backed<br />

by a nationwide sales force, installer network, as well as expert<br />

design and engineering support, FormaBond II receives the<br />

start-to-finish service, which is <strong>CENTRIA</strong>’s hallmark.<br />

FormaBond II incorporates <strong>CENTRIA</strong>’s unique horizontal<br />

dry seal joinery to minimize water penetration and maximize<br />

ventilation. This innovative design improves the integrity of<br />

the application by reducing the chance of entrapped moisture<br />

behind the rainscreen, reducing the potential for material<br />

degradation and mold.<br />

<strong>CENTRIA</strong>.com<br />

FormaBond II<br />

Features & Benefits<br />

• Superior flatness<br />

• Sharp, crisp sight lines<br />

• Fire resistant core available<br />

• Lightweight<br />

• No maintenance dry seal joinery<br />

• High performance per AAMA 509-09<br />

• Metal spline or gaskets available at vertical joint<br />

Description<br />

Available in a variety of colors and coating<br />

systems, <strong>CENTRIA</strong> FormaBond II is a smooth<br />

panel with a sleek, flat design offering crisp<br />

corner transitions or soft, flowing curves.<br />

SUBSTRATE & CORE<br />

• Metal – 0.020" [.5mm] nominal thickness aluminum<br />

face and liner<br />

• Polyethylene and fire-rated cores available<br />

• 4mm panel thickness, 2 ½" [64mm] system<br />

• 6mm panel thickness, 2 ½" [64mm] system<br />

• Flat MCM panel<br />

JOINERY<br />

• All dry construction<br />

• High performance drained and back<br />

ventilated system<br />

• Open side joint allows ventilation behind<br />

the rainscreen<br />

• Drain shelf at top edge of panel minimizes<br />

water penetration<br />

• Metal spline and gasket vertical joint options<br />

SURFACE FINISH<br />

• Smooth<br />

PANEL WIDTH<br />

Panel Module – Up to 58" [1.47m]<br />

Panel Length – Up to 180" [4.57m]<br />

Panel Reveals – ½" [13mm] Horiz., ½" [13mm] Vert.<br />

*contact <strong>CENTRIA</strong> for other size options<br />

COATINGS<br />

• Fluorofinish ® – Durable PVDF coating system<br />

• Sundance MICA – 2-coat pearlescent PVDF<br />

coating system<br />

• Sundance AM – 3-coat metallic PVDF coating<br />

system<br />

• Also available in Kolorshift iridescent colors<br />

*contact <strong>CENTRIA</strong> for other coating options<br />

STANDARD COLORS AVAILABLE FOR RAPID<br />

SHIPmENT:<br />

• Silversmith #9946<br />

• Chromium Gray #971<br />

• Platinum #9989<br />

• Off-White #993<br />

• XL Silver #9957<br />

• Regal White #179<br />

19

20<br />

Harrah’s Chester Casino<br />

Chester, PA<br />

SOSH Architects<br />

Profile Series<br />

<strong>Distinctively</strong> Attractive.<br />

<strong>CENTRIA</strong> took a close look at how architects use traditional single-skin profile panels in<br />

contemporary design and re-engineered the Profile Series system to help them achieve the<br />

aesthetics they desire easily and economically.<br />

With <strong>CENTRIA</strong> Profile Series you get a full metal palette of both concealed and exposed<br />

fastener panels, including the six Concept Series concealed fastener panels based on a classic<br />

asymmetrical form. This broad selection provides thousands of combinations of articulation,<br />

shadows and sight lines, along with a complete line of design, finish, integration, special systems<br />

and detail options.<br />

Profile Series

Profile Series<br />

Concept Series ®<br />

Concealed Fastener Profiles<br />

<strong>CENTRIA</strong> Concept Series single-skin panels combine concealed<br />

fasteners with a wide range of profiles based upon a single<br />

theme – a dynamic asymmetrical form.<br />

Concept Series panels are available for insulated or uninsulated<br />

field-assembled wall applications.<br />

CS-200<br />

CS-210<br />

CS-260<br />

*Patent no: US D538,948; D527,834<br />

CS-610<br />

CS-620<br />

CS-660<br />

<strong>CENTRIA</strong>.com<br />

Profile Series<br />

Concept Series<br />

Features & Benefits<br />

• Panels may be installed vertically and horizontally*<br />

• Common lock joint allows panels to be mixed freely for<br />

custom-like aesthetics<br />

• Concealed clips and fasteners<br />

• Cost effective with a clean, unbroken appearance allowing<br />

for interesting visual effects<br />

• Excellent for new construction and retrofit projects<br />

• All-weather installation capability shortens installation time,<br />

permits fast-track scheduling<br />

• Panels are available with stucco-embossed or smooth<br />

finishes<br />

• Concealed extended leg option<br />

• EcoScreen for CS-260 and CS-660 profiles<br />

• Profile Louvers for CS-260 and CS-660 profiles<br />

*Horizontal applications require a backup with exterior sheathing,<br />

weather-resistent and air barrier.<br />

Description<br />

SUBSTRATES<br />

• Standard 24-18 gage G-90 galvanized steel<br />

• Galvalume ® steel, aluminum or stainless steel – optional<br />

• Smooth or embossed surface texture<br />

CONCEPT SERIES PROFILES<br />

• Lengths up to 30' [9.14m]<br />

• Concealed clips and fasteners<br />

• Stand-off clips provides ventilation cavity and continuous<br />

drain plane behind panel<br />

• Horizontal or vertical wall installation<br />

• Common joint design permits multiple profile integration<br />

• Concealed extended leg option<br />

“Oil canning” is an inherent part of light gage cold-formed metal<br />

products, particularly those with broad flat areas. <strong>CENTRIA</strong> takes<br />

every precaution, as defined by MCA, to minimize the effects of<br />

oil canning. Lack of flatness or waviness due to oil canning is not<br />

sufficient cause for rejection of material.<br />

Concealed<br />

Clip Fastener<br />

(standard)<br />

Concealed Extended<br />

Fastener Leg<br />

(optional)<br />

21

Profile Series<br />

IW Series<br />

Concealed Fastener Profiles<br />

Medical Center of the Rockies,<br />

North MOB, South MOB<br />

Loveland, CO<br />

HLM Design<br />

Vaught Frye Ripley Design, Inc.<br />

Hauser Architects, P.C.<br />

22 Profile Series IW Series

IW-10A<br />

IW-12A<br />

IW-14A<br />

IW-11A<br />

IW-13A<br />

IW-15A<br />

IW-20A IW-21A<br />

IW-30A<br />

IW-40A<br />

IW-41A<br />

IW-60A<br />

<strong>CENTRIA</strong>.com<br />

Profile Series<br />

IW Series<br />

Features & Benefits<br />

• No exposed panel fasteners<br />

• Cost effective, with a clean, unbroken appearance<br />

• All panels except IW-60A are interchangeable because of<br />

the common lock-joint design which allows for interesting<br />

visual effects<br />

• Excellent for new construction and retrofit projects<br />

• All-weather installation capability shortens installation<br />

time, permits fast-track scheduling<br />

• Panels are available with stucco-embossed or smooth<br />

finishes and in flush, ribbed, striated and stepped profiles<br />

NOTE: Swaged ends of 2" [51mm] length are available in<br />

20, 22, and 24 gages only. Not available in IW-12A, IW-14A,<br />

IW-15A and IW-60A.<br />

Description<br />

IW SERIES PROFILES<br />

• Lengths up to 30' [9.14m]<br />

• Horizontal or vertical wall installation<br />

• Lock-joint design of IW-10A through IW-41A makes<br />

panels interchangeable<br />

• Horizontal applications require a backup with exterior<br />

sheathing, weather-resistant and air-barrier<br />

• Now available with MicroSeam ® corners<br />

IW-31A<br />

“Oil canning” is an inherent part of light gage cold-formed metal<br />

products, particularly those with broad flat areas. <strong>CENTRIA</strong> takes<br />

every precaution, as defined by MCA, to minimize the effects of<br />

oil canning. Lack of flatness or waviness due to oil canning is not<br />

sufficient cause for rejection of material.<br />

23

Profile Series<br />

Exposed Fastener Profiles<br />

NOLA DOTD Regional Transportation<br />

Management Center<br />

New Orleans, LA<br />

Sizeler Thompson Brown Architects<br />

ECONOLAP 1/2" ECONOLAP 3/4"<br />

TR4-36 STYLE-RIB BR5-36<br />

24 Profile Series Exposed Fastener Profiles<br />

mR3-36

SUPER-RIB<br />

Features & Benefits<br />

• Extremely versatile panels can be used as<br />

exterior or interior walls, roofs and soffits<br />

• Ribs can be run either horizontally* or vertically<br />

• May be insulated to meet many levels of<br />

thermal protection<br />

• Excellent negative wind load properties<br />

• All-weather installation capability minimizes<br />

delays, permits fast-track scheduling<br />

• Panels are available in stucco-embossed<br />

or smooth finishes<br />

* Horizontal applications require a backup with<br />

exterior sheathing, weather-resistant and air-barrier<br />

Description<br />

EXPOSED FASTENER PROFILES<br />

• Horizontal or vertical wall installation<br />

• Wall and roof installation<br />

• Lengths up to 40' [12.19m], consult <strong>CENTRIA</strong><br />

for longer lengths<br />

Profile Series<br />

Liner Panels Features & Benefits<br />

L-21<br />

L2<br />

L2-2<br />

L2-3<br />

L-21A<br />

Stratton ANG Maintenance<br />

& Fuel Cell Hangars<br />

Scotia, NJ<br />

Morris Architect: Burns &<br />

McDonnell<br />

<strong>CENTRIA</strong>.com<br />

Profile Series<br />

Liner Panels<br />

• Incorporate liner panel, subgirts, varying thicknesses of<br />

noncombustible fiberglass insulation and any <strong>CENTRIA</strong><br />

exposed fastener or concealed fastener panel<br />

• High “R” Values, depending upon insulation<br />

• Provides a flush appearance to building interiors<br />

• Perforated liner panels available for tested acoustical<br />

performance<br />

• Firewall systems<br />

Description<br />

Minimize heat loss or gain to conserve valuable<br />

energy with <strong>CENTRIA</strong> liner panels<br />

SUBSTRATE<br />

• 24-18 gage G-90 galvanized steel<br />

PANEL WIDTH<br />

• 24" [610mm]<br />

PANEL LENGTH<br />

• 30'-0" [9.14m] max.<br />

PANEL THICKNESS<br />

• L2 – 1-3/8" [35mm]<br />

• L2-2 – 2" [51mm]<br />

• L2-3 – 3" [76mm]<br />

• L-21 – 1-1/2" [38mm]<br />

• L-21A – 1-1/2" [38mm]<br />

L2<br />

L2-2<br />

L2-3<br />

L-21<br />

L-21A<br />

Finished Side<br />

25

1<br />

2<br />

EcoScreen®<br />

Perforated Screenwall<br />

<strong>CENTRIA</strong> offers exterior perforated screenwall panels using<br />

CS-260, CS-660, Econolap 3/4" [19mm], MR3-36, Style-Rib,<br />

and BR5-36 in 20 gage stainless steel and 0.040" [1mm]<br />

painted aluminum. This unique fabrication provides a 10%<br />

to 40% open area for the effect of a translucent screen to<br />

control light, air movement and provide safety and security.<br />

Perforated screenwalls can help blend industrial and other<br />

functional applications with the surrounding communities.<br />

Please consult <strong>CENTRIA</strong> for optional panels and perforation<br />

patterns. Paint finish not warranted on perforated panels.<br />

ECOSCREEN PERFORATION PATTERN OPTIONS<br />

Open/Free Area Pattern Diameter (in) Spacing (in)<br />

10 Reverse 1/8 3/8<br />

23 Staggered 1/8 1/4<br />

23 Reverse 1/4 1/2<br />

30 Staggered 1/8 7/32<br />

33 Staggered 3/16 5/16<br />

40 Staggered 1/8 3/16<br />

40 Staggered 3/8 9/16<br />

Bold lines are standard. For additional patterns, contact <strong>CENTRIA</strong>.<br />

Profile Series<br />

Design Options<br />

QUIETWALL SYSTEM<br />

The <strong>CENTRIA</strong> Quietwall system helps you select a wall system with<br />

specific sound absorption or transmission loss values that your<br />

design requires – more economically and more efficiently.<br />

OTHER SYSTEMS<br />

• Explosion Release<br />

• RF Shielding<br />

FIREWALL SYSTEM<br />

With the <strong>CENTRIA</strong> firewall system, layers of gypsum board<br />

between the exterior Profile panel and the insulation and liner<br />

panel create UL one-hour through four-hour firewalls based on<br />

ASTM E119 fire tests.<br />

26 Profile Series EcoScreen and Design Options<br />

BR5-36 CS-260<br />

CS-660 ECONOLAP 3/4"<br />

mR3-36 STYLE-RIB<br />

Images showing standard 40% open area staggered pattern, 3/8" [10mm]<br />

diameter, 9/16" [14mm] spacing.<br />

1<br />

2

MICROSEAM ® CORNERS<br />

<strong>CENTRIA</strong>.com<br />

Profile Series<br />

Design Options<br />

MicroSeam Corners use cutting edge structural bonding techniques<br />

to produce corners that appear virtually seamless. Manufactured<br />

from the same metal substrate coil as the panels, MicroSeam<br />

corners employ no welding and no pop rivets. Available in<br />

<strong>CENTRIA</strong>’s full palette of nearly 100 colors, including metallics<br />

and Versacor ® Ultra. Like all <strong>CENTRIA</strong> panels, they are fully tested<br />

for performance. MicroSeam Corners are available on BR5-36,<br />

Econolap 3/4", MR3-36, Style-Rib, Super-Rib, TR4-36, all Concept<br />

Series profiles and all IW Series profiles.<br />

MICROLINE EXTRUSIONS<br />

MicroLine details incorporate aluminum extrusions designed to<br />

integrate visually and mechanically with <strong>CENTRIA</strong> Profile Series<br />

Concept Series ® panels. Slim 2" [51mm] wide MicroLine extrusions<br />

make it a snap to trim and finish around windows and doors, inside<br />

or outside corners, and at the base of walls; or to create clean vertical<br />

joints. MicroLine details enable you to replace wide obtrusive flashing<br />

and exposed fasteners with narrower, crisper and cleaner finished<br />

lines, and can be finished to match or complement wall panels. Also<br />

available for horizontal IW Series, Style-Rib, BR5-36, Econolap 3/4"<br />

and TR4-36. MicroLine details are available for Concept Series<br />

profiles in horizontal and vertical applications. Separate MicroLine<br />

extrusions are available for horizontally erected IW-60A.<br />

PROFILE LOUVERS<br />

<strong>CENTRIA</strong> Profile Louvers come in gages, colors and finishes<br />

to match corresponding panels and blend invisibly into a wall,<br />

eliminating visual breaks in site lines. Profile Louvers are available<br />

for horizontal installation with BR5-36, Inverted BR5-36, MR3-36,<br />

CS-260, CS-660, Style-Rib or Super-Rib wall panels. Variable blade<br />

depths from 1-1/2" to 8" [38mm to 203mm] create free area from<br />

10% to 49% for air intake or exhaust.<br />

CURVED PANELS<br />

With <strong>CENTRIA</strong> curved panels you can add radius design elements<br />

to your projects. Available in a wide selection of exposed fastener<br />

profiles, finishes and colors to match virtually any architectural,<br />

commercial or industrial application, curved panels are ideal for<br />

canopies and awnings, roofing, fascia, walls, curved parapets,<br />

curved trim, column and beam wraps, where it can be used to<br />

add bold visual statements or innovative special effects.<br />

<strong>CENTRIA</strong> fabricates curved panels from a variety of architectural<br />

panel profiles and they are available in a number of finishes to<br />

match your application, and in the full <strong>CENTRIA</strong> color palette.<br />

27

Profile Series Load Tables<br />

Wind Load Span – Ft-In – WALL PANELS<br />

CS-200<br />

CS-210<br />

CS-260<br />

CS-610<br />

CS-620<br />

CS-660<br />

Wind<br />

Load<br />

psf<br />

Design<br />

Limited<br />

By<br />

28 Profile Series Load Tables<br />

20<br />

30<br />

40<br />

50<br />

20<br />

30<br />

40<br />

50<br />

20<br />

30<br />

40<br />

50<br />

20<br />

30<br />

40<br />

50<br />

20<br />

30<br />

40<br />

50<br />

20<br />

30<br />

40<br />

50<br />

24 Gage 22 Gage 20 Gage 18 Gage<br />

No. Spans No. Spans No. Spans No. Spans<br />

1 2 3 1 2 3 1 2 3 1 2 3<br />

Stress n/a n/a n/a 5-10 5-10 6-6 6-8 6-8 7-6 8-4 8-4 9-3<br />

Defl. n/a n/a n/a 4-8 6-3 5-9 5-0 6-9 6-2 5-9 7-9 7-2<br />

Stress n/a n/a n/a 4-9 4-9 5-4 5-5 5-5 6-1 6-9 6-9 7-7<br />

Defl. n/a n/a n/a 4-1 5-5 5-0 4-5 5-11 5-5 5-1 6-9 6-3<br />

Stress n/a n/a n/a 4-2 4-2 4-7 4-9 4-9 5-3 5-10 5-10 6-7<br />

Defl. n/a n/a n/a 3-8 4-11 4-7 4-0 5-4 4-11 4-7 6-2 5-8<br />

Stress n/a n/a n/a 3-8 3-8 4-2 4-3 4-3 4-9 5-3 5-3 5-10<br />

Defl. n/a n/a n/a 3-5 4-7 4-3 3-8 5-0 4-7 4-3 5-8 5-3<br />

Stress n/a n/a n/a 8-3 8-3 9-3 9-3 9-3 10-5 11-2 11-2 12-5<br />

Defl. n/a n/a n/a 5-8 7-7 7-0 6-1 8-2 7-6 6-10 9-2 8-5<br />

Stress n/a n/a n/a 6-9 6-9 7-7 7-7 7-7 8-6 9-1 9-1 10-2<br />

Defl. n/a n/a n/a 5-0 6-8 6-2 5-4 7-2 6-7 6-0 8-0 7-4<br />

Stress n/a n/a n/a 5-10 5-10 6-7 6-7 6-7 7-4 7-10 7-10 8-10<br />

Defl. n/a n/a n/a 4-6 6-1 5-7 4-10 6-6 6-0 5-5 7-3 6-8<br />

Stress n/a n/a n/a 5-3 5-3 5-10 5-10 5-10 6-7 7-0 7-0 7-10<br />

Defl. n/a n/a n/a 4-2 5-7 5-2 4-6 6-0 5-7 5-0 6-9 6-3<br />

Stress 8-6 8-6 9-6 9-9 9-9 10-11 10-10 10-10 12-1 12-8 12-8 14-2<br />

Defl. 5-9 7-9 7-2 6-4 8-5 7-9 6-8 9-0 8-3 7-6 10-0 9-3<br />

Stress 6-11 6-11 7-9 8-0 8-0 8-11 8-10 8-10 9-10 10-4 10-4 11-7<br />

Defl. 5-1 6-9 6-3 5-6 7-4 6-9 5-10 7-10 7-3 6-6 8-9 8-1<br />

Stress 6-0 6-0 6-9 6-11 6-11 7-9 7-8 7-8 8-7 9-0 9-0 10-0<br />

Defl. 4-7 6-2 5-8 5-0 6-8 6-2 5-4 7-2 6-7 5-11 7-11 7-4<br />

Stress 5-4 4-11 5-7 6-2 6-2 6-11 6-10 6-10 7-8 8-0 8-0 9-0<br />

Defl. 4-3 5-8 5-3 4-8 6-3 5-9 4-11 6-7 6-1 5-6 7-4 6-9<br />

Stress n/a n/a n/a 7-5 7-5 8-3 8-4 8-4 9-4 9-10 9-10 10-11<br />

Defl. n/a n/a n/a 5-3 7-0 6-6 5-8 7-7 7-0 6-4 8-6 7-10<br />

Stress n/a n/a n/a 6-0 6-0 6-9 6-9 6-9 7-7 8-0 8-0 8-11<br />

Defl. n/a n/a n/a 4-7 6-2 5-8 4-11 6-7 6-1 5-7 7-5 6-10<br />

Stress n/a n/a n/a 5-3 5-3 5-10 5-11 5-11 6-7 6-11 6-11 7-9<br />

Defl. n/a n/a n/a 4-2 5-7 5-2 4-6 6-0 5-6 5-1 6-9 6-3<br />

Stress n/a n/a n/a 4-8 4-8 5-3 5-3 5-3 5-11 6-2 6-2 6-11<br />

Defl. n/a n/a n/a 3-10 5-2 4-9 4-2 5-7 5-2 4-8 6-3 5-10<br />

Stress n/a n/a n/a 7-5 7-5 8-3 8-6 8-6 9-6 10-0 10-0 11-2<br />

Defl. n/a n/a n/a 5-3 7-0 6-6 5-8 7-7 7-0 6-7 8-10 8-1<br />

Stress n/a n/a n/a 6-1 6-1 6-9 6-11 6-11 7-9 8-2 8-2 9-1<br />

Defl. n/a n/a n/a 4-7 6-2 5-8 5-0 6-8 6-2 5-9 7-8 7-1<br />

Stress n/a n/a n/a 5-3 5-3 5-10 6-0 6-0 5-10 7-1 7-1 7-11<br />

Defl. n/a n/a n/a 4-2 5-7 5-2 4-6 6-1 5-7 5-3 7-0 6-5<br />

Stress n/a n/a n/a 4-8 4-8 5-3 5-4 5-4 6-0 6-4 6-4 7-0<br />

Defl. n/a n/a n/a 3-10 5-2 4-9 4-2 5-7 5-2 4-10 6-6 6-0<br />

Stress 8-4 8-4 9-4 9-7 9-7 10-9 10-7 10-4 11-9 12-4 10-4 11-9<br />

Defl. 5-9 7-8 7-1 6-3 8-5 7-9 6-8 8-11 8-3 7-5 9-11 9-1<br />

Stress 6-10 6-10 7-8 7-10 7-11 8-9 8-8 8-8 9-8 10-1 10-1 11-4<br />

Defl. 5-0 6-9 6-2 5-6 7-4 6-9 5-10 7-10 7-2 6-5 8-8 8-0<br />

Stress 5-11 5-11 6-7 6-9 6-9 7-7 7-6 7-6 8-4 8-9 8-9 9-9<br />

Defl. 4-7 6-1 5-7 5-0 6-8 6-2 5-4 7-1 6-7 5-10 7-10 7-3<br />

Stress 5-3 5-2 5-10 6-1 5-8 6-5 6-8 6-1 6-11 7-10 7-1 8-0<br />

Defl. 4-3 5-8 5-3 4-7 6-2 5-8 4-11 6-7 6-1 5-5 7-3 6-9<br />

The maximum allowable spans in this<br />

table represent a significant update based<br />

on the latest IBC and ASCE7 codes,<br />

which no longer permit a 33% increase in<br />

allowable stress due to wind. Therefore,<br />

some values may be less than previously<br />

published by <strong>CENTRIA</strong>. Contact <strong>CENTRIA</strong> for<br />

additional information.<br />

1. Spans should be limited by the lower<br />

of stress, calculated as 0.6 Fy or<br />

deflection @ L/180.<br />

2. For deflection @ L/120, multiply the<br />

tabulated L/180 Defl. span by 1.144.<br />

3. Wind span tables are based on<br />

using 1/4"-14 fasteners with 5/8" –<br />

combination washers fastened into<br />

3/16" minimum thickness supports<br />

indicated on the tables.<br />

4. Wind span tables are based on single<br />

skin with 1 fastener per panel clip per<br />

support.<br />

5. *Consult <strong>CENTRIA</strong> for all 18 gage<br />

product lead times.<br />

6. Oil canning within industry standard<br />

guidelines as defined by MCA is not a<br />

cause for rejection.<br />

7. These tables apply to clip “CS” Panels.<br />

For Load Tables for Extended Leg<br />

Panels, consult <strong>CENTRIA</strong>.

Profile Series Load Tables<br />

Wind Load Span – Ft-In – WALL PANELS<br />

IW-10A<br />

IW-11A<br />

IW-12A<br />

IW-13A<br />

IW-14A<br />

IW-15A<br />

IW-20A<br />

IW-21A<br />

IW-30A<br />

IW-31A<br />

IW-40A<br />

IW-41A<br />

IW-60A<br />

IW-10A<br />

IW-11A<br />

IW-12A**<br />

IW-13A†**<br />

IW-14A<br />

IW-15A<br />

IW-20A<br />

IW-21A†<br />

IW-30A<br />

IW-31A<br />

IW-40A<br />

IW-41A<br />

IW-60A†<br />

Wind<br />

Load<br />

psf<br />

20<br />

30<br />

40<br />

50<br />

20<br />

30<br />

40<br />

50<br />

20<br />

30<br />

40<br />

50<br />

20<br />

30<br />

40<br />

50<br />

20<br />

30<br />

40<br />

50<br />

Design<br />

Limited<br />

By<br />

24 Gage 22 Gage 20 Gage 18 Gage<br />

No. Spans No. Spans No. Spans No. Spans<br />

1 2 3 1 2 3 1 2 3 1 2 3<br />

Stress 7-2 7-2 8-0 8-6 8-6 9-6 9-10 9-10 11-0 12-5* 12-5* 13-10*<br />

Defl. 6-6 8-9* 8-0 7-3 9-9 8-11 7-11 10-7 9-9 9-0 12-1* 11-2<br />

Stress 5-10 5-10* 6-6* 6-11 6-11 7-9 8-0 8-0 8-11 10-2 10-2 11-4<br />

Defl. 5-8 7-7* 7-0* 6-4 8-6* 7-10 6-11 9-3 8-6 7-11 10-7 9-9<br />

Stress 5-1 5-1* 5-8* 6-0 6-0* 6-9 6-11 6-11 7-9 8-9 8-9 9-10<br />

Defl. 5-2 6-11* 6-5* 5-9 7-9* 7-1* 6-3 8-5* 7-9 7-2 9-7 8-10<br />

Stress 4-6 4-6* 5-1* 5-5 5-5* 6-0* 6-2 6-2 6-11 7-10 7-10 8-9<br />

Defl. 4-10 6-5* 5-11* 5-4 7-2* 6-7* 5-10 7-9* 7-2 6-8 8-11* 8-3<br />

Stress 7-0 7-0 7-10 8-4 8-4 9-3 9-6 9-6 10-8 12-0 12-0 13-5*<br />

Defl. 6-8 8-11* 8-3 7-5 9-11 9-2 8-1 10-10 10-0 9-4 12-6* 11-6<br />

Stress 5-9 5-9* 6-5* 6-9 6-9 7-7 7-9 7-9 8-9 9-9 9-9 10-11<br />

Defl. 5-10 7-10* 7-2* 6-6 8-8* 8-0 7-1 9-6 8-9 8-2 10-11 10-1<br />

Stress 4-11 4-11* 5-6* 5-10 5-10 6-7 6-9 6-9 7-6 8-6 8-6 9-6<br />

Defl. 5-4 7-1* 6-6* 5-11 7-11* 7-3* 6-5 8-8* 7-11 7-5 9-11 9-2<br />

Stress 4-5 4-5* 4-11* 5-3 5-3* 5-10* 6-0 6-0 6-9 7-7 7-7 8-6<br />

Defl. 4-11 6-7* 6-1* 5-6 7-4* 6-9* 6-0 8-0* 7-5* 6-11 9-3* 8-6<br />

Stress n/a n/a n/a 8-5 8-5 9-5 9-9 9-9 10-11 12-3* 12-3* 13-9*<br />

Defl. n/a n/a n/a 7-4 9-10 9-1 8-0 10-9 9-11 9-2 12-4* 11-4<br />

Stress n/a n/a n/a 6-11 6-11 7-8 7-11 7-11 8-11 10-0 10-0 11-3<br />

Defl. n/a n/a n/a 6-5 8-7* 7-11 7-0 9-4 8-8 8-0 10-9 9-11<br />

Stress n/a n/a n/a 6-0 6-0 6-8 6-11 6-11 7-8 8-8 8-8 9-9<br />

Defl. n/a n/a n/a 5-10 7-10* 7-2* 6-4 8-6* 7-10 7-3 9-9 9-0<br />

Stress n/a n/a n/a 5-4 5-4* 6-0* 6-2 6-2 6-11 7-9 7-9 8-8<br />

Defl. n/a n/a n/a 5-5 7-3* 6-8* 5-11 7-11* 7-3* 6-9 9-1* 8-4<br />

Stress n/a n/a n/a 8-5 8-5 9-5 9-9 9-9 10-11 12-4* 12-4* 13-9*<br />

Defl. n/a n/a n/a 7-3 9-9 9-0 7-11 10-8 9-10 9-1 12-3* 11-3<br />

Stress n/a n/a n/a 6-11 6-11 7-9 8-0 8-0 8-11 10-1 10-1 11-3<br />

Defl. n/a n/a n/a 6-4 8-6* 7-10 6-11 9-4 8-7 8-0 10-8 9-10<br />

Stress n/a n/a n/a 6-0 6-0 6-8 6-11 6-11 7-9 8-9 8-9 9-9<br />

Defl. n/a n/a n/a 5-9 7-9* 7-2* 6-4 8-5* 7-9 7-3 9-8 8-11<br />

Stress n/a n/a n/a 5-4 5-4* 6-0* 6-2 6-2 6-11 7-10 7-10 8-9<br />

Defl. n/a n/a n/a 5-4 7-2* 6-8* 5-10 7-10* 7-3 6-9 9-0* 8-3<br />

Stress 8-3 8-3 9-3 9-7 9-7 10-9 10-10 10-10 12-2 12-7 12-7 14-0<br />

Defl. 6-1 8-2 7-6 6-7 8-10 8-2 7-1 9-6 8-9 7-11 10-7 9-9<br />

Stress 6-9 6-9 7-6 7-10 7-10 8-9 8-10 8-10 9-11 10-3 10-3 11-6<br />

Defl. 5-4 7-1 6-6 5-9 7-9 7-2 6-2 8-3 7-8 6-11 9-3 8-6<br />

Stress 5-10 5-10 6-6 6-10 6-10 7-7 7-8 7-8 8-7 8-11 8-11 9-11<br />

Defl. 4-10 6-5 5-11 5-3 7-0 6-6 5-7 7-6 6-11 6-3 8-5 7-9<br />

Stress 5-3 5-3 5-10 6-1 6-1 6-10 6-10 6-10 7-8 7-11 7-11 8-11<br />

Defl. 4-6 6-0 5-6 4-10 6-6 6-0 5-3 7-0 6-5 5-10 7-9 7-2<br />

1. Spans are limited by the lower of of the two values listed for stress and deflection.<br />

Stress is based on 0.6 x Fy. Deflection is based on L/180.<br />

2. For deflection @ L/120, multiply the tabulated L/180 Defl.<br />

span by 1.144.<br />

3. Wind span tables are based on using 1/4"-14 fasteners with 5/8" ø combination<br />

washers fastened into 3/16" minimum thickness supports.<br />

4. Wind span tables for IW-60A are based on single skin with one clip with one screw<br />

per panel per support into 3/16" supports.<br />

<strong>CENTRIA</strong>.com<br />

Profile Series<br />

Load Tables<br />

The above tables for IW-10A through IW-41A apply to positive load only. For negative load analysis, consult <strong>CENTRIA</strong>. IW-60A tables apply to both<br />

positive and negative load.<br />

5. Oil canning within industry standard guidelines as defined by MCA<br />

is not a cause for rejection.<br />

† IW-13A, IW-21A and IW-60A are the only panels available in 24 gage.<br />

* Spans marked with an asterisk require negative load clips (part NLC-1)<br />

at each support.<br />

** IW-12A and IW-13A are not available in 18 gage.<br />

29

30<br />

Profile Series Load Tables<br />

Super-Rib Wind Load Span – Ft-In – Wall and Roof Panels<br />

Wall<br />

Roof<br />

Wind<br />

Load<br />

psf<br />

20<br />

Design<br />

Limited<br />

By<br />

MR3-36 Wind Load Span – Ft-In – Wall and Roof Panels<br />

Wall<br />

Roof<br />

30<br />

40<br />

50<br />

Wind<br />

Load<br />

psf<br />

20<br />

30<br />

24 Gage 22 Gage 20 Gage 18 Gage<br />

No. Spans No. Spans No. Spans No. Spans<br />

1 2 3 1 2 3 1 2 3 1 2 3<br />

Stress n/a n/a n/a 21-5 21-5 24-0 23-6 23-6 26-3 27-2 27-2 30-5<br />

Defl. n/a n/a n/a 20-4 27-2 25-1 21-8 29-0 26-9 23-11 32-1 29-7<br />

Stress n/a n/a n/a 17-6 16-0 18-2 19-2 18-11 21-5 22-2 22-2 24-10<br />

Defl. n/a n/a n/a 17-9 23-9 21-11 18-11 25-4 23-4 20-11 28-0 25-10<br />

Stress n/a n/a n/a 15-2 12-0 13-8 16-7 14-2 16-1 19-3 17-8 20-1<br />

Defl. n/a n/a n/a 16-1 21-7 19-11 17-2 23-0 21-2 19-0 25-5 23-5<br />

Stress n/a n/a n/a 13-7 9-7 10-11 14-10 11-4 12-10 17-2 14-2 16-1<br />

Defl. n/a n/a n/a 14-11 20-0 18-6 15-11 21-4 19-8 17-8 23-7 21-9<br />

Design<br />

Limited<br />

By<br />

BR5-36 Wind Load Span – Ft-In – Wall and Roof Panels<br />

Wall<br />

1-1/2"<br />

Exterior<br />

Roof<br />

40<br />

50<br />

Wind<br />

Load<br />

psf<br />

20<br />

30<br />

40<br />

50<br />

24 Gage 22 Gage 20 Gage 18 Gage<br />

No. Spans No. Spans No. Spans No. Spans<br />

1 2 3 1 2 3 1 2 3 1 2 3<br />

Stress 12-0 12-0 13-5 14-7 14-7 16-3 16-6 16-6 18-5 19-11 19-11 22-3<br />

Defl. 14-1 18-10 17-4 15-9 21-1 19-5 17-0 22-9 21-0 19-1 25-7 23-7<br />

Stress 9-9 9-9 10-11 11-11 11-11 13-3 13-6 13-6 15-1 16-3 16-3 18-2<br />

Defl. 12-3 16-6 15-2 13-9 18-5 17-0 14-10 19-11 18-4 16-8 22-4 20-7<br />

Stress 8-6 7-9 8-10 10-3 10-3 11-6 11-8 11-8 13-1 14-1 14-1 15-9<br />

Defl. 11-2 15-0 13-9 12-6 16-9 15-5 13-6 18-1 16-8 15-2 20-4 18-9<br />

Stress 7-7 6-3 7-1 9-2 9-2 10-3 10-5 10-5 11-8 12-7 12-7 14-1<br />

Defl. 10-4 13-11 12-10 11-7 15-6 14-4 12-6 16-9 15-6 14-1 18-10 17-4<br />

Design<br />

Limited<br />

By<br />

Style-Rib Wind Load Span – Ft-In – Wall and Roof Panels<br />

Wall<br />

Roof<br />

7.2"<br />

36"<br />

Wind<br />

Load<br />

psf<br />

20<br />

30<br />

40<br />

50<br />

Profile Series Load Tables<br />

24 Gage 22 Gage 20 Gage 18 Gage<br />

No. Spans No. Spans No. Spans No. Spans<br />

1 2 3 1 2 3 1 2 3 1 2 3<br />

Stress 9-6 9-6 10-8 10-9 10-9 12-1 11-11 11-11 13-4 14-0 14-0 15-8<br />

Defl. 8-5 11-4 10-5 9-4 12-6 11-6 10-2 13-7 12-6 11-7 15-6 14-4<br />

Stress 7-9 7-9 8-9 8-10 8-10 9-10 9-9 9-9 10-11 11-5 11-5 12-10<br />

Defl. 7-5 9-11 9-1 8-2 10-11 10-1 8-10 11-10 10-11 10-1 13-7 12-6<br />

Stress 6-9 6-9 7-7 7-7 7-7 8-6 8-5 8-5 9-5 9-11 9-11 11-1<br />

Defl. 6-8 9-0 8-3 7-5 9-11 9-2 8-1 10-9 9-11 9-2 12-4 11-4<br />

Stress 6-0 6-0 6-9 6-10 6-10 7-7 7-7 7-7 8-5 8-10 8-10 9-11<br />

Defl. 6-3 8-4 7-8 6-11 9-3 8-6 7-6 10-0 9-3 8-6 11-5 10-7<br />

Design<br />

Limited<br />

By<br />

24 Gage 22 Gage 20 Gage 18 Gage<br />

No. Spans No. Spans No. Spans No. Spans<br />

1 2 3 1 2 3 1 2 3 1 2 3<br />

Stress 9-3 9-3 10-4 10-9 10-9 12-1 12-2 12-2 13-7 14-9 14-9 16-6<br />

Defl. 8-7 11-5 10-7 9-4 12-7 11-7 10-1 13-6 12-6 11-4 15-3 14-1<br />

Stress 7-7 7-7 8-5 8-10 8-10 9-10 9-11 9-11 11-1 12-0 12-0 13-5<br />

Defl. 7-6 10-0 9-3 8-2 11-0 10-1 8-10 11-10 10-11 9-11 13-4 12-3<br />

Stress 6-7 6-7 7-4 7-7 7-7 8-6 8-7 8-7 9-7 10-5 10-5 11-8<br />

Defl. 6-9 9-1 8-4 7-5 9-11 9-2 8-0 10-9 9-11 9-0 12-1 11-2<br />

Stress 5-10 5-10 6-7 6-10 6-10 7-7 7-8 7-8 8-7 9-4 9-4 10-5<br />

Defl. 6-4 8-5 7-9 6-11 9-3 8-6 7-5 10-0 9-2 8-5 11-3 10-4<br />

The maximum allowable spans in this table represent a significant update based on the latest IBC and ASCE7 codes, which no longer permit a 33% increase in allowable stress due to wind. Therefore, some values<br />

may be less than previously published by <strong>CENTRIA</strong>. Contact <strong>CENTRIA</strong> for additional information.<br />

1. Spans are limited by the lower of of the two values listed for stress and deflection. Stress is based on<br />

0.6 x Fy. Deflection is based on L/120.<br />

2. For deflection @ L/180, multiply the tabulated L/120 Defl. span by 0.874.<br />

3. Two fasteners per panel for Super-rib. Three fasteners per panel for MR3-36, BR5-36 and Style-rib.<br />

4. All panels must be ordered as either “Roofing” or “Siding”.<br />

5. For more detailed load span information, consult www.centria.com.

Profile Series Load Tables<br />

TR4-36 Wind Load Span – Ft-In – Wall and Roof Panels<br />

Wind<br />

Load<br />

psf<br />

20<br />

30<br />

40<br />

50<br />

Design<br />

Limited<br />