REVEN air cleaning food industry 3.2 – english - Rentschler Reven ...

REVEN air cleaning food industry 3.2 – english - Rentschler Reven ...

REVEN air cleaning food industry 3.2 – english - Rentschler Reven ...

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

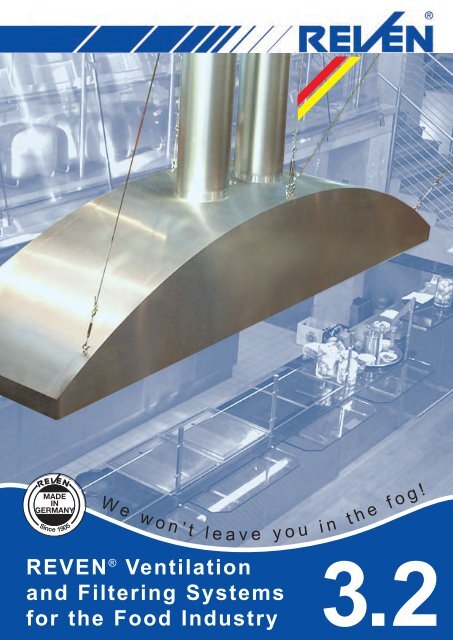

We won’tleave you in<strong>REVEN</strong> ® Ventilationand Filtering Systemsfor the Food Industrythe fog!<strong>3.2</strong>

<strong>REVEN</strong> ®ContentsINTRODUCTION p. 2 - 171Basic element X-Cyclone ® p. 18 - 33The separators made by <strong>Rentschler</strong> <strong>REVEN</strong> ® Lüftungssysteme GmbHefficiently separate oils, emulsions and other fluids.2COOKER EXTRACTION HOODS p. 34 - 2592.1. REVEX ® <strong>–</strong> Induction hood with condensationseparation and automatic separator <strong>cleaning</strong> p. 34 - 992.2. EVN <strong>–</strong> Inducing extraction hood p. 100 - 1212.3. RECOJET ® RCJ <strong>–</strong> Inducing extraction hood p. 122 - 1472.4. REJET ® <strong>–</strong> Airdiffusing extraction hood p. 148 - 1732.5. RGJ <strong>–</strong> Induction grill hood p. 174 - 1812.6. RGS <strong>–</strong> Exhaust <strong>air</strong> grill hood p. 182 - 1892.7. RVS Restar <strong>–</strong> Exhaust <strong>air</strong> extraction hood p. 190 - 2172.8. RAS Airstar <strong>–</strong> Exhaust <strong>air</strong> extraction hood p. 218 - 2412.9. Dispensing area hood X-Cyclone ® <strong>–</strong> Glass hood/design hood made of glass p. 242 - 2452.10. Extraction hood RGN recirculation p. 246 - 2593LOW-VELOCITY SUPPLY AIR DIFFUSER ECOJET ® p. 260 - 263Suitable for perforationtype integration into existing ceilings4VENTILATING KITCHEN CEILINGS p. 264 - 3234.1. REVEX ® D <strong>–</strong> Exhaust <strong>air</strong> extraction ceiling with automatic filter <strong>cleaning</strong> p. 264 - 2734.2. REDE <strong>–</strong> Induction ceiling exhaust <strong>air</strong> / REDE <strong>–</strong> supply <strong>air</strong> p. 274 - 2854.3. RLD <strong>–</strong> Exhaust <strong>air</strong> p. 286 - 2914.4. RGH <strong>–</strong> Largescale kitchen hood p. 292 - 2994.5. RFD-SSP <strong>–</strong> Flat ceiling p. 300 - 3034.6. RSD-SSP <strong>–</strong> Soundabsorbing ceiling p. 304 - 3114.7. RQA low-velocity supply <strong>air</strong> diffuser <strong>–</strong> Supply <strong>air</strong> system with p. 312 - 315high penetration depth of fresh <strong>air</strong>4.8. RAK box filter <strong>–</strong> including a grease separator and an exhaust <strong>air</strong> filter box p. 316 - 3232

Experience and progressProgressIn the year 1980, <strong>Rentschler</strong> <strong>REVEN</strong> ® LüftungssytemeGmbH evolved from the familyowned company thatwas founded in 1905. Right from the beginning, <strong>REVEN</strong> ®has specialized in the manufacturing of stainless steelventilating ceilings and cooker extraction systems forcommercial largescale kitchens. Today, <strong>REVEN</strong> ® alsomanufactures industrial oilmist separators and highperformancefilters.Drei Generationen der Familie <strong>Rentschler</strong>The goal of the company’s marketing and corporate activitieshas always been “clean <strong>air</strong>” in all of the three sectors inaccordance with our slogan “We won't leave you in the fog".A lack of clean, fresh <strong>air</strong> can cause illness, tiredness and abad working atmosphere and have a lot of negative consequences.High costs result from oil deposits on equipment,sensitive devices and even buildings. The proverbial<strong>REVEN</strong> ® quality is assured by inhouse manufacturing inthe companyowned factory in the German town ofSersheim. Virtually all components are made of stainlesssteel, which makes them easy care and unrivalled withregard to their functionality and appearance.This catalogue gives an overview of our kitchenventilation systems. You can find more information atwww.reven.de<strong>REVEN</strong> = RENTSCHLER VENTILATION4

Efficient manufactureManufactureOur production in Sersheim is automated to a great extent.We process coiled chromiumnickel steel and aluminiumalloys. Copper and other materials are used on request.Computercontrolled processing machines cut the metalsheets to size, straighten, emboss and punch them anddrill the necessary holes into the standardized preshapedparts. The high degree of automation guarantees perfectlyreproducible quality on a high level.Our production is organized in line with the principle oflean manufacturing: the teamoriented manner of workingmotivates the workforce in each “cell”, encourages decisionmakingand improves quality. Potential failure sources areeliminated in advance rather than after assembly on site.Online networking of CAD workplaces and processingsections is the standard today at <strong>REVEN</strong> ® ."Heutzutagekennen die Leutevon allem den Preisund von nichtsden Wert."Oscar Wilde5

The “modular systemconcept” above all elseSystemThe series components of our highrise warehouse formthe skeleton of our entire product range. The combinationof these components with individually shaped parts and thedesired accessories constitutes the final product.In order to reduce assembly expenditure on site, we deliverour systems in preassembled condition to the greatestpossible extent. It goes without saying that we apply themost stringent quality control procedures and final testsbefore assembly and delivery of the components. Thismeans that our customers receive a high-end productfrom quality-assured production.The standardized semifinished products are stored in ourCAD system where our construction staff has direct accessto them. This helps to reduce project handling times considerably.Even complex projects are realized using standardcomponents to a degree of 75 % in the meantime.The modular system concept governs our corporatephilosophy <strong>–</strong> in construction, production, orders handlingand customer service.6

Clean <strong>air</strong> with the highperformanceRXZ separatorRXZOne of the most important components among the <strong>REVEN</strong> ®ventilation range is the XCyclone ® separating system. Themechanical separating system, which was developed by<strong>REVEN</strong> ® , works without auxiliary energy or material and isinternationally patented. Air pollutants such as grease, oil,vapour, emulsions or other fluids that occur in the formof aerosols are separated to a very high extent. Furtherdevelopment produced the <strong>REVEN</strong> ® Ultra Cleaner, a compactseparating system, ready for connection, which offers a veryhigh degree of efficiency and decisive benefits to thecustomer.<strong>REVEN</strong> ® X-Cyclone ® type RXZ:High-efficient <strong>air</strong> <strong>cleaning</strong> formechanical applications - nowalso available in kitchentechnology. The maintenancefree XCyclone ® separator, type RXZ No extra costs due to throwaway separators No grease deposits on kitchen equipment,appliances and floors No more laborious <strong>cleaning</strong> operations<strong>REVEN</strong> ® Ultra Cleaner,maintenance-free <strong>air</strong><strong>cleaning</strong> equipmentwith high-performanceRXZ separators readyfor connection. Reduced sick rate and fatigueamong kitchen staff due to clean <strong>air</strong>Functional principle ofthe high-performance RXZseparator:Oil and emulsion mist isejected by small cycloneswith a diameter of 3 mm.The name X-Cyclone ® comesfrom the x-shaped profilesand the cyclone-liketurbulences in the <strong>air</strong>flow.Although the test stand is flooded with <strong>air</strong>from a fan, the flames are blocked by the highperformanceRXZ separator. This means thatthe <strong>REVEN</strong> ® separator has passed the mostimportant test without any problems.Certified SafetyWe give high priority to safety and accident prevention. This isthe reason why we have our high-performance RXZ separatortested for compliance with UL 1046 (UnderwritersLaboratories ® ). The equipment passed the tests successfully.UL 1046 is an American standard comparable to a DINstandard or the requirements of the German TÜV. It isconsidered to be the only standard anywhere in the worldthat describes a testing procedure for the flamearrestingcapability of oilmist separators.7

Individual and always the rightfit: Cooker extraction hoods!CookerInhouse design and production are the best preconditionsfor customized solutions with an appealing look andperfect technology that adapt to any space requirements.Our single hoods are available in various lengths up to6 m, in divided or singlepiece, wall or ceilingmountedversions.Our compact grill hoods with high extraction capacity area specialty for small kitchens particularly in the systemcatering.The combined supply and exhaust hoods REJET ® andRECOJET ® are more and more in demand for kitchenswith a low room height. The large <strong>air</strong> diffusers producea smooth, lownoise and draughtfree flow of the supply<strong>air</strong> into the kitchen.8

Extraction Hoods9

Integral solution:Ventilating kitchen ceilingsVentilatThe most stylish and cleanest solution for largescalekitchens is a ventilating ceiling from <strong>REVEN</strong> ® . It spansfrom wall to wall and offers the highest level of hygieneand maintenance convenience. You can easily relocateany grease separator when you supplement or modifyyour kitchen equipment.Metal ceilings are increasingly used in sculleries too.They are easier to maintain and protect the building fromthe effects of moisture.The periodical painting of the ceiling and the disturbancethis causes can be dispensed with too. <strong>REVEN</strong> ® soundabsorbingceiling elements are being installed more andmore to reduce noise.<strong>REVEN</strong> ® ventilating kitchen ceilings can be fitted withthe following optional equipment on request. <strong>REVEN</strong> ® OMAT automatic fireextinguishing system REVEX ® separator washing facility Lighting Sound absorbing core LoudspeakersLowvelocity <strong>air</strong> diffusers are a proven solution for supplyingrooms with fresh <strong>air</strong>. The <strong>air</strong> flows slowly into the roomsthrough perforated ceiling strips without any draughtproblems. Furthermore, the ceiling remains clean for longerbecause no greasy <strong>air</strong> is distributed inside the room.10

ing Kitchen Ceilings11

Show kitchensShow KitchensSystem catering kitchens are becoming increasingly smaller,despite their higher productivity. The space gained isadded to the service area where the turnover is realized.<strong>REVEN</strong> ® complies with this development and offers powerfulmodules which produce hood and ceiling solutions thatare compatible with the structural dimensions even in mostconfined spaces.We deliver extraction hoods and mini ventilating ceilings forstylish show kitchens or grill rooms, true to dimensions andin any shape and size.These include asymmetrical versions and corner solutions,which set completely new optical accents.12

Tested high techcomponentsHigh TechThe vapourdependent speed control of the fans contributesto energy saving, even though the ventilation runs continuouslyoutside of the main cooking times. The sensorcontrolledspeed control system can be fitted subsequently.The acoustic ceiling elements with adjustable noisereduction were tested by the Fraunhofer Institute. Weoffer an odour neutralizer for the removal of smellsfrom the extracted <strong>air</strong>. REVEX ® autoclean extractionhoods and ventilating ceilings clean their separatorsautomatically at defined intervals or according to acomfort program. The doublesided <strong>cleaning</strong> system isprotected by patent rights.<strong>REVEN</strong> ® highperformance XCyclone ® separators complywith VDI Directive 2052 and are flamearresting (tested acc.to UL 1046).SPEED CONTROL SCHEMENEW VERSIONThe “brain” of theRSC hoodSpeed controlOdour neutralizerThe <strong>REVEN</strong> ® -O-MAT extinguishing system provides for preventive fire protection.It prevents the spreading of flames through the <strong>air</strong> duct network of the building inthe event of a fire.Acoustic ceiling elementsFire-extinguishing systemsRSC sensorSeparator <strong>cleaning</strong>13

Worldwide references:Ships, ship yards:MU „Gruziya“, Nils Holgerson,Peter Pan Homeric, Seabourn Pride,Ville de Jupiter, Ville de Mercure,Ville de Pluto, Ville de Saturn,Western LegendN, Western MonarcN,Western PrideN, Western RegentNNorway:Ulstein shipyardMTW Schiffswerft GmbH:Atlantic Trader, Elbe Trader, Macaro,Mercur Cloud, Ocean Trader, Pazific Trader,Ping Chuan, Tai Chuan, Warnow Trader,Xiang Xue Lan, Zi Yu LanThyssen Nordseewerke(Germany):Fresena, San Christobal, San Clemente,San Felipe, Fernando, San FranciscoHDW Kiel(Germany):China:APL China,Japan:APL JapanThailand:APL ThailandKröger Shipyard:Barbara, Jin Man Hai, Jin Man Hu,Jin Man Jiang, Juliusplate, Uta JohannaAirports:FeinkostKäfer Munich Airport,Frankfurt/Main, Hannover,LSG Sky Chefs Frankfurt Airport,LufthansaService Company, Düsseldorf,MönchenGladbach,Mövenpick Airport Leipzig,RheinMain Air Base Frankfurt, StuttgartNetherlands:AmsterdamDänemark:CopenhagenRussia:MoscowDaewoo:Korea:APL KoreaSingapore:APL SingaporePhilippines:APL PhilippinesGreat Britain:Royal Air ForceSweden:StockholmAustria:ViennaNato-Airports:Germany, UK, Greece, Italy, TurkeyCompanies, banks a.o.:AEG Ulm,Altana Pharma KG Konstanz,AOKDresden,Audi Ingolstadt,BASF Ludwigshafen,Building and Loan Association Schwäbisch Hall,Bayer Leverkusen,Bertelsmann Publishing House,BMW in Regensburg,Böhringer Mannheim,Bosch Stuttgart,Bundeshaus Bonn,Carl Zeiss Oberkochen,Commerzbank AG Düsseldorf,Daimler Distribution Center StuttgartSindelfingen,German Bank,Deutsche Bundesbank LZB Weimar,Dresdner Bank Leipzig,Druckmaschinenfabrik,Farbwerke Hoechst,FordWerke Köln,DaimlerChrysler Research Center Ulm,FSG Heilbronn,Gildemeister Drehmaschinen Bielefeld,Gruner und Jahr Publishing House,Henkel Düsseldorf,Hermle Maschinenfabrik Gosheim,HüllerHille,Hugo Boss Metzingen,INASchaeffler KG Herzogenaurach,Jenoptik Jena,John Deere Mannheim,Karstadt AG Essen,Klemme AG Nordhausen,Kreissparkasse Ludwigsburg,Landtag meeting hall Stuttgart,LBBW Karlsruhe,Maizena Heilbronn,Maybach Center Böblingen,Mercedes Benz Stuttgart,Merck Darmstadt,Merck Gernsheim,Miele Gütersloh,Opel Rüsselsheim,SELAlcatel,SEWEurodrive,Siemens Erlangen,Springer Publishing House,SüddeutscherVerlag Munich,Südwest LB Stuttgart,Traub Drehmaschinen Reichenbach,Trumpf Ditzingen,Voigt Heidenheim,Volksbank Pforzheim,VW Wolfsburg,Ministry of Trade and Commerce Stuttgart,Würth Künzelsau,ZF Sachs SchweinfurtSweden: Ericsson Components, VolvoItaly: Fiat TurinAustria: General Motors ViennaPublic and cultural facilities,halls, casinos, cafes,barracks etc:Public authorities canteen Leipzig,Boulevard Berlin,BTZChamber of Crafts Kaiserslautern,Federal Office for Employment Nürnberg,Drehscheibe Frankfurt,Technical University Koblenz,Guildhall Dresden,Guildhall Erfurt,Gründen Barracks Sonthofen,Zwickau prison,Congress Center Stuttgart,Arts and Leisure Center Bad Langensalza,State authorities centre Oldenburg,Federal Social Welfare Tribunal Stuttgart,Rosenheim Agricultural School,Liederhalle Stuttgart,MercedesBenzMuseum Stuttgart,Operncarree Berlin,Orangerie Fulda,Panzer Barracks Böblingen,Parkcafé Blühendes Barock Ludwigsburg,REWE canteen Köln,Town Hall Sonderhausen,City Hall Stuttgart,Ratskeller Chemnitz,Ratskeller Munich,RobertBreuningStift Besigheim,SAPArena Mannheim,Snow Dome Bispingen,Sportgymnasium Leipzig,Stadion Kaiserslautern,Municipal Hall Kiel,Municipal Hall Offenburg,TSG Arena Hoffenheim (Sinsheim),University of Leipzig,University of Saarbrücken,Waldstadion FrankfurtAustria:Casino Graz,Casino Velden Wörthersee,Penal institution Josefstadt ViennaStiftsBarracks ViennaLuxembourg:Cour de Justice Européenne,Lycée RedangeSwitzerland:Theatre ZugHighway service areas:Germany:Bruchsal Ost + West,Bühl,Frankenhöhe,Hamburg,Holzkirchen,Leipheim,Pforzheim,SiegburgWest,Spessart Nord,Weiskirchenand others14

References:Hotels and Restaurants:Adlon Residenz Berlin,Airporthotel Mövenpick Stuttgart,Dom Hotel Köln,Egener Hof Tegernsee,Golfhotel Steigenberger Bad Tatzmannsdorf,GrafZeppelin Stuttgart,Herrenküferei Markgröningen,Intercontinental Stuttgart,Kölner Hofbräu,Spa Hotel Bareis BaiersbronnMitteltal (Black Forrest),Maritim Hotel Berlin,Maritim Hotel Dresden,Mövenpickhotel Düsseldorf,Steigenberger Hotel Frankfurt,Speckmeier München,Traube Toerbach,Wielandshöhe Stuttgart,Wiesbadener HofAustria:Clubhotel Robinson Nassfeld,Feldmayergründe Schwechat,Kanzelwandbahn Kleinwalzertal,Mövenpick PENTAHotel Salzburg,ÖBB Bahnhofsrestaurant Villach,Omesberg Lech/Arlberg,PENTAHotel Vienna,Restaurant Rainer Wörthersee,Royer Schladming,Sacher Baden (near Vienna),Seehotel Jägerwirt Turracher Höhe,Sporthotel Modul Wien,Stubaier Gletscherbahn,Weitzer Graz,ZugspitzenbahnRussia:Grand Hyatt MoskauSweden:Grand Hotel StockholmGeorgia:Tiflis HotelCzech Republic:Holiday Inn Brno,PENTAHotel PragSwitzerland:Jungfraujoch Zugspitzenrestaurant,Via ClaudiaNorway:Oslo CateringItaly:Restaurant Kandahar/Sestriere,Sitea TurinTurkey:Steigenberger Hotel IstanbulCastle hotels/restaurants:Mövenpickhotel Berlin,Schloss Aulendorf,Schloss Bühler Höhe,Schloss Heidelberger Königssaal,Schloss Kleinheubach,Schloss Schweinsburg,Schloss Wasserburg BodensseNorway: Diplomats’ Hotel OsloNetherlands: Knight’s Hall,Royal House The HagueSwitzerland: Schloss SchwandeggAustria: Schlosshotel Velden WörtherseePalace hotels:Nigeria: AjaohutaSaudi Arabia: Al KobahTurkey: NCO Club AnkaraKuwait: Palace of the Prince of KuwaitUnited Arab Emirates: Ruwais Oilfield,Special Residontal Complex AT Rifa BarainService area and f<strong>air</strong>grounds restaurants:Trade F<strong>air</strong> Frankfurt, Trade F<strong>air</strong> Hannover,Trade F<strong>air</strong> Köln, Trade F<strong>air</strong> NürnbergSwitzerland: Station restaurant Basel,F<strong>air</strong> Hotel BasleSweden: Le BuffetA6Center JönköpingAustria: F<strong>air</strong> restaurant Klagenfurt,service area MondseeNorway: Service area OsloDenmark: Service area SlagelsLapland: Service area TärnabyIT sector etc.:EPlus Main Office Hauptverwaltung Düsseldorf,Post Office 1 Frankfurt,Post Office Stuttgart,Telecom Hannover,Telecom Holzhausen Leipzig,Telekom StuttgartSweden: Gullstrandskolan Landskrona MalmöNetherlands: Moneyservice AmsterdamSpain: Telefonica MadridHospital, clinics etc.:ARCUS Sportklinik Pforzheim,Military Hospital Ulm,Military Hospital Wiederitzsch,Dr. Betzer Heidelberg,Dr. Gerecht Kempen,Dr. Heintzen Aalen,Dr. Kugler Coburg,KKH SchmalkaldenDistrict Hospital Crimmitschau,District Hospital Forst,District Hospital Füssen,District Hospital Neumarkt,District Hospital Schmölln,District Hospital Starnberg,Regional Hospital Schleswig,Med Com Tech SchopfheimProf. Dr. Jacobi Köln,Rheuma Clinic Bad Liebenwerda,Rhön Clinic,RobertBosch Hospital Stuttgart,Sanatorium HohenfreudenstadtUniversity Hospital Complex Bonn,University Hospital Complex Kiel,Canteen, University of Saarbrücken,Catering center / hospitals BonnSwitzerland:Hospital Bellinzona Tessin,Hospital BrisagoSaudi Arabien:King Abdulaziz University Hospital Jeddah,Medina Hospital,Riyadh HosptialNetherlands: Hospital Maria TilburgSweden: Stockholm HospitalAustria:Hospital Complex Bad Gleichenberg,Hospital Rohrbach,Special Regional Hospital Graz,Canteen, University of GrazDenmark: Rikshospital KopenhagenAntenna and televisiontowers, radio stations:Antenna Tower Berlin,Antenna Tower Bremen,RTL Cologne,Südwestfunk,WDR CologneSaudi Arabia:Television Tower RiyadhAustria:ORF Vienna15

<strong>REVEN</strong> ®Delivery ProgramProgramHigh tech for commercial kitchens:High-performanceseparators:High-performance RXZ separator,the first separator worldwide thatwas tested in accordance withVDI 2052 and DIN 18869-5Automaticfilter <strong>cleaning</strong>:Accessory for extractionsystemsCooker extraction hoods:Since 40 yearsVentilatingkitchen ceilings:Since 30 yearsOdour neutralization:Odour neutralization <strong>–</strong>high-performance granular filterUV systems:Pure exhaust <strong>air</strong> systemsDuct separators forkitchen ventilation:Suitable for installation induct systemRBS block units:Compact fan units for combined<strong>air</strong> supply and exhaustRSC systems:Energy-saving sensorsfor hoods and ceilingsFire-extinguishingsystems:Fire-extinguishing systemsfor hoods and ceilingsAir cleaners:Air cleaners for commercialkitchens, industrial applications,offices and private homes16

Extraction HoodsGeneral description:Cooker extraction hoods <strong>–</strong> execution and accessoriesThe synthesis of design and quality in manufacturingin combination with the required accessories determinesthe quality of cooker extraction hoods. The decadesof experience we have gained in the manufacture ofventilation components and our specialization instainless steel processing have borne rich fruits andguarantee the high manufacturing quality of a <strong>REVEN</strong> ®cooker extraction hood and its accessories. The<strong>REVEN</strong> ® systems combined from these componentssatisfy the highest demands.<strong>REVEN</strong> ® cooker extraction hoods are produced fromdeburred sheets to prevent any risk of injury to kitchenstaff during <strong>cleaning</strong> and maintenance work. The qualityseal and functional expertise by the German TÜV alsovouch for the high manufacturing quality of our hoods.1. Execution of the hoodsa.) MaterialsThe exhaust elements and top units of cooker extractionhoods are made of stainless steel, material no. 1.4301,process IIIC, coldrolled according to DIN 59382,grinded surface with 180 grain, sheet thickness upto 1.5 mm. Components made of other highgradesteels (chromium steel no. 1.4016) and materialssuch as aluminium, galvanized steel sheet, coppersheet or glass are available on request. Colourlacqueredor coated stainless steel hoods are alsoavailable on request.b.) ProcessingIn order to avoid any damage to the surface andgrinding pattern, the sheets are film coated prior toprocessing. You should remove the film coat aftercompletion of assembly and clean the hoods fromresidue.Although we handle the thin stainless steel sheetswith utmost care during processing, a slight surfacewaviness due to material tensions cannot alwaysbe avoided.17

Basic elementX-Cyclone ® separator, type RXZBASIC ELEMENT X-CYCLONE ® · BASIC ELEMENT X-CYCLONE ®X-Cyclone ® basic elementTESTEDIAWDIN 18869-518

X-Cyclone ® RXZTechnical dataBasic element X-Cyclone ® separator, type RXZSystem description1. Type RXZRXZ basic elementX-Cyclone ® separating systemThe separators made by <strong>Rentschler</strong> <strong>REVEN</strong> ® -Lüftungssysteme GmbH efficiently separate oils,vapours and other fluids.➜ Effective separation of oils, vapoursand other fluid mists (aerosols).The mechanical separators include patented specialprofile sections, spacers and a patented two-partframe. The special profile sections are arrangedin two separable plate levels. The self-<strong>cleaning</strong>effect is due to the special shape of the profilesections, the smooth surfaces and the easy-carelayout.➜ All basic elements can be cleaned and reused <strong>–</strong>no throwaway separators!Width W Height H Thickness Tin mm in mm in mm610 610 50500 500 50450 400 50450 300 50450 250 50410 410 50330 330 50Special sizes are available on request!➜ The delivery period for specialsizes is approximately four weeks!TÜV-tested ➜ flame-arresting capabilityin accordance with the UL Directive 1046 of the USUnderwriters Laboratories ® and DIN 18869-5.19

Technical dataBasic element X-Cyclone ® separator, type RXZ1. Separating efficiency RXZPressure loss in PaApproach velocity in m/sPressure loss* depending on the <strong>air</strong>flow velocitywhen approaching the basic element (pressure lossmeasured and confirmed by the German TÜV-Süddeutschland).The illustration shows the pressure loss curve of abasic module in a state of medium pollution.* IMPORTANT:➜ The specified pressure losses arealways based on the assumptionof a straight, steady approach!The diagram shows the separating efficiency of abasic element depending on the <strong>air</strong>flow velocity andthe particle size.The mass proportion should be considered whenevaluating separating efficiency and compliance withapplicable WELs (in mg pollutants per m 2 exhaust<strong>air</strong>).To calculate the surface of approach, a perimeterframe of 20 mm should be deducted from the elementsurface, i. e. a basic element of 450 x 450 mmin size has an effective separating surface of 410 x410 mm!➜ The measurements were carried out bythe Fraunhofer Institute for Toxicologyand Aerosol Research.Efficiency in %Flow velocity m/s10 µm particles 1.0 µm particles 0.8 µm particles5.0 µm particles 3.0 µm particles 0.5 µm particles20

X-Cyclone ® RXZTechnical dataBasic element X-Cyclone ® separator, type RXZ1. System comparison RXZSeparation with the basic element -a system comparison- Particle range: : 3 µm to 10 µm- Velocity of approach: max. 1.2 m/s(<strong>REVEN</strong> ® recommends an <strong>air</strong>flow velocity of 0.8 to 1.2 m/s!)- Media to be separated:vapour, fume, steam and combustion gases- 6-channel system (0.3 µm bis 10.0 µm)(particle counter)- Electronic impeller anemometerSeparation in %Type 1Type 2Type 3Type 4Type 5FrontRear+Type 1: X-Cyclone ®X-Cyclone ® separatorDefined <strong>air</strong>flowType 4: combination of type 3 and 5(Optimized baffle plate + aluminium mesh)Type 2: baffle plateBaffle plate separatorUndefined <strong>air</strong>flowType 5: aluminiummesh➜ Mesh filters are notpermissible accordingto VDI 2052!Type 3: optimizedbaffle plate21

Technical dataBasic element X-Cyclone ® separator, type RXZ1. Flame penetration test RXZUL 1046 is an American standard for the testing ofthe flame-arresting capability of equipment, which iscomparable to DIN standards or the requirements ofthe German TÜV. The standard describes a procedureto test the flame-arresting performance of kitchenseparators set up by the US Underwriters Laboratories ® .Why does <strong>REVEN</strong> ® test their high-performance RXZseparators for compliance with UL? The answer isvery easy: UL 1046 is the only standard anywhere inthe world that describes a testing procedure for theflame-arresting performance of devices. To date, theflame-arresting capability of hardly any separatorsnormally used in kitchens has ever been tested orproven in any way.Thanks to this test, we will be able to evaluateexactly the flame-arresting capability of our highperformanceRXZ separators in the future, becausethe required test result is clearly defined by UL 1046:The filter must resist exposure to a flame with aparticular intensity for three minutes at least withoutmelting or deforming and no break-through flame norany flying sparks may be visible at a short distancebehind the filter.It has always been maintained that these filters hada good flame-arresting performance because theydid not absorb grease or oil in the same way thatmesh filters did, for instance. How efficient this flamearrestingprotection really is was hardly ever testedor proven, however. We considered this situation tobe quite unsatisfactory and finally decided to haveour high-performance RXZ separators tested forcompliance with the above-mentioned standard.We are therefore one of the few manufacturers inEurope to use kitchen separators with certified flamearrestingcapability in their ventilation systems.22

X-Cyclone ® RXZTechnical dataBasic element X-Cyclone ® separator, type RXZ➜ Our high-performanceseparator easily satisfiedboth of these requirements.➜ The same test was applied to RFDceiling panels. They also passed thethe UL 1046 test without any problems!It resisted the flames for three minutes withoutany problems and without any deformation!Spontaneously occurring spark formation andflame penetration remained far below the maximumpermissible penetration length behind the separator.23

Technical dataBasic element X-Cyclone ® separator, type RXZ1. Air volume calculation RXZThe <strong>air</strong> volume calculation is basedon the separating surface:Sample calculation for a hood separator(W x H) 450 x 400 mm:Für RXZ-Abscheider: 450 x 400 x 50 mm ist die angeströmteFläche: (450-80 mm) x (400-60 mm) = 0.12 m 2The following <strong>air</strong> volumes result from this:Velocity of approach Airflow rate in in m 3 /h Pressure loss in Pa Separating efficiency* in %0.4 m/s 0.4 m/s x 0.12 m 2 x 3600 = 173 m 3 /h 25 Pa 50 %0.8 m/s 0.8 m/s x 0.12 m 2 x 3600 = 345 m 3 /h 80 Pa 78 %1.2 m/s 1.2 m/s x 0.12 m 2 x 3600 = 520 m 3 /h 140 Pa 88 %1.6 m/s 1.6 m/s x 0.12 m 2 x 3600 = 690 m 3 /h 200 Pa 98 %* referenced to a particle range from 3 to 10 µm. You can find detailed separating curves in our X-Cyclone ® documentation!➜ Optimum separation requires a velocity of approach above 1.0 m/s. You should takethe noise behaviour according to the illustrated curve into consideration, however!dB (A)*Noise behaviour with different approach velocities706050403020100Working areaHoods and Duct separatorceilingsagreeablenoise0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.0 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 2.0*measured at a distance of 1 metre from the separator.Approach velocity in m/s24

X-Cyclone ® RXZTechnical dataBasic element X-Cyclone ® separator, type RXZ1. Upgrade RXZEasy upgrade of older hoodsYou can easily upgrade older cooker extractionhoods or ventilating ceilings with flame-arrestinghigh-performance separators type RXZ from<strong>REVEN</strong> ® . This is particularly important in allkitchens where a lot of grease is used for cookingsuch as in steak grills or Chinese restaurants.Live-cell therapyOffer your customers a live-cell therapy for theirold hoods and ceilings with worn mesh filters ortraditional separators! Just ask for the <strong>REVEN</strong> ® -RXZ retrofit kit.Thanks to standardized dimensions,replacement of separators is quick and easy.By the way:ASSOCIATIONofGERMAN ENGINEERSVDI 2052If you are a system builder you will have to complywith the latest state of technology because it isyou who bears the acquisition risk. According toGerman legislation you still do so, even if thebuilder or engineer insists on unauthorized lowbudgetseparators. And it is you <strong>–</strong> and only you <strong>–</strong>who will be liable throughout a period of 30 yearsfor deficiencies that you have failed to disclose. Thecourt will assume that you are familiar with VDI 2052.RXZ AdapterThanks to standardized dimensions, the replacementof separators is quick and easy. If the separatorshould not fit because of an insufficient depth ofthe accommodating frame in the hood, <strong>REVEN</strong> ®offers a simple solution.➜ The separator is fitted into an adapter framethat is manufactured in the required size.Upgrade of an exhaust <strong>air</strong> extractionhood with an X-Cyclone ® basic elementAccommodating frame➜ When using X-Cyclone ® separators,you can save up to four duct <strong>cleaning</strong>interventions per year because up to98 % of the condensable particles areseparated!Adapter25

DIN 18869-5Technical dataTesting in accordance with DIN 18869-5Prüfung1. Flame-arresting in accordance with 18869-5To date we are the first and only company thathas their aerosol separator type RXZ, which isthe heart piece of our equipment, tested accordingto the German standard DIN 18869-5. When wedecided to do so, we found out that there was nosuitable test stand available for the test procedureprescribed by this DIN standard.What does DIN 18869-5 say?The standard states requirements concerning theconstruction of separators used in the ventilationsystems of commercial large-scale kitchens inaccordance with the state of the art and requires anefficiency test as well as a test of the flame-arrestingcapability for these separators.We therefore built a suitable test stand incooperation with the German TÜV SÜDProduct Service GmbH at our premises.➜ This standard applies to commercialkitchen ventilation hoods and ceilingsnot to separators in private kitchens.26

TestingTechnical dataTesting in accordance with DIN 18869-51. Flame penetration test and required equipmentFlame break-throughWith separators of type A, no flame penetrationmay occur according to DIN 18869-5 Item 8.2.Separators with which the flame breaks throughduring the test, or untested separators, areclassified as type B according to Item 8.2.➜ Type B separators must not be usedabove thermal equipment involvingan increased risk of fire!Test standThe test stand was fitted with a regulating facilitythat allows an adjustment of the <strong>air</strong>flow to theseparator between 70 m 3 /h and 1.500 m 3 /h.For the gravimetric measurement included in theefficiency test, removable rear walls and a collectingvessel for the separated condensate were providedfor. A gas surface burner was installed for theflame penetration test.RXZ <strong>–</strong> type ABaffle plate <strong>–</strong> type BThe burner must have a combustion surface of600 mm x 200 mm and emit a regular flame of800 mm height throughout one minute. Thedistance from the top edge of the gas surfaceburner to the bottom edge of the separator was500 mm. The gas surface burner was operatedwith propane.Absorbingmesh filterMesh filters are notpermissible accordingto VDI 2052!Areas of application for separators of type A and BPermissible kitchen areas for type A- Kitchen areas with thermal equipment(e.g. cooking areas, cook and chill)- Front cooking areasPermissible kitchen areas for type B- Food dispensing areas- Food storage areas- Sculleries27

DIN 18869-5Technical dataTesting in accordance with DIN 18869-51. Test stand1Gas surface burner2Collecting vessel3Separator type RXZto be tested28

TestingTechnical dataTesting in accordance with DIN 18869-51. Test standThe test was carried out at the <strong>REVEN</strong> ® factory inFebruary 2009. The flame was applied to the separatorfor one minute approximately.5Propane gas bottlesDuring this period, no flames weredetected behind the separator type RXZ!The entire test was recorded on video.We will send you the detailed test report inaccordance with the DIN standard on request.6Test stand withflame application4Continuouslyadjustable fan29

Kitchen hygiene1. Hygiene reportsDubious expert reports:Distributors of kitchen ventilation systems often referto hygiene reports in their advertisement in order topoint out the superiority of their grease separatorsand separator washing facilities. These expert reportsare often dubious, according to the Swabian systemsupplier <strong>Rentschler</strong> <strong>REVEN</strong> ® , because they are basedon measurements in rather sterile kitchens such asin hospitals or old people’s homes. The germ loadis much lower in these kitchens than in cateringkitchens and grill bars where much more greaseis involved in the cooking process. These expertreports are deceptive.Hygiene certificates can only be taken seriously,according to <strong>Rentschler</strong> <strong>REVEN</strong> ® , when the testinginstitute introduces various germs that occur inindustrial kitchens into the ventilation prior to themeasurement of the separators’ efficiency. Filterwashing systems must be able to kill bacteria andprevent their growth in addition to their <strong>cleaning</strong>performance. Proof can only be established when thecorresponding germs are released on the separatorelements and in the suction and exhaust area beforethe test. Any other measurements are worthless,<strong>REVEN</strong> ® points out.32

Kitchen hygiene<strong>Rentschler</strong> <strong>Reven</strong> <strong>–</strong>Lüftungssysteme GmbHLudwigstrasse 16-18Prof Dr. Ulrich JunghannßIn der Werre 1070619 StuttgartGermanyTel./Fax +49 (0)711 478726Office addressHochschule Anhalt (FH)Bernburger Str. 52-5706366 KochenGermanyTel/Fax +49 (0)3496 67-58374372 Sersheim 20. October 1999Expert examination of the hygiene status of the self-<strong>cleaning</strong> ventilation system type <strong>REVEN</strong> ®ExpertiseAt the request of <strong>Rentschler</strong> <strong>REVEN</strong> ® Lüftungssysteme GmbH, the Revex self-<strong>cleaning</strong>ventilation system was submitted to a bacteriological hygiene examination.System descriptionThe self-<strong>cleaning</strong> ventilation system of the type Revex consists of exhaust elements of stainlesssteel into which grease separators are integrated. The exhaust segments include a spraying facilityfor warm water that is intended to clean the grease separators periodically. The <strong>cleaning</strong> intervalscan be adjusted to the respective state of pollution by means of a control system included in theequipment. Cleaning agents are injected into the main washing cycle to support the <strong>cleaning</strong> ofthe grease separators. Inspection openings allow a removal of the grease separators if need be.The control of the self-<strong>cleaning</strong> ventilation system is ensured by a freely programmable modularprocess computer. This process control allows the setting of all desired values such as the starttime of the spraying cycle, the spraying time, the injection time of the <strong>cleaning</strong> agent as well asthe rinsing time.Testing procedureThe system was installed in a test room that was especially fitted out for this test series ( 3 x 2.50 m).Prior to the conducting of the microbiological hygiene tests, the system was cleaned (!40 sec.)with warm water and the <strong>cleaning</strong> agent Puronil (4.0 % Henkel) using the integrated sprayingfacility for warm water (60 °C) and subsequently dried with <strong>air</strong>. During the entire testing period,a <strong>cleaning</strong> operation as described above was performed once a day and the system was onlyshut-down during night-time by the process control.Dipl.-Ing. Sven <strong>Rentschler</strong>Expert reportWe will send you the entireexpert report on request.33

COOKER EXTRACTION HOODS · COOKER EXTRACTION HOODSInduction hood REVEX ® -EH-W with condensation separationand automatic separator <strong>cleaning</strong> / wall-mounted versionREVEX ® -EH-W34

REVEX ® -EH-WTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / wall-mounted versionSystem description2.1. Type REVEX ® -EH-W + EH-NThe hood is made of a durable stainless steel structurewith welded corner joints. All cutting edges are envelopedand rounded free from burrs.The hood is equipped with grease- and waterproof exhaustsegments made of stainless steel. The grease separatorsare inserted in a slanted position into these segments inaccordance with VDI 2052. The hood canopy is suitablydesigned to retain even surge vapours. The special lightfixtures, type EB with polycarbonate cover, are splash andjet waterproof, with IP 54 protection and heat resistanceup to 110 °C. The polycarbonate cover offers highest transparencyand is breakproof and resistant to impact, oil andacid at the same time. The light fixtures are fully wired upto the connection box. The grease drain cock with internalthread is located in the deep-drawn drain area of thegrease collecting channel. The exhaust <strong>air</strong> chamber canaccommodate various types of grease separators that canbe inserted without tools. The hood is placed above thekitchen equipment block and should project sufficiently overthe outer edges of the appliances. A spraying facilityfor warm water is integrated in the exhaust <strong>air</strong> chamberand provides for the <strong>cleaning</strong> of the grease separators onboth sides at regular intervals. The control system includedin the washing facility allows the adjustment of the <strong>cleaning</strong>intervals to the actual level of contamination of the separators,which depends on the kitchen equipment used. In order tointensify the <strong>cleaning</strong> process, a grease remover is injectedduring the main washing cycle.The monitoring and automatic control of the self-<strong>cleaning</strong>extraction hood REVEX ® is ensured by a modular, freelyprogrammable process controller that offers variousadjustment options. Among other things, you can set alldesired values, such as the start time of the sprayingcycle, the spraying time, the injection time of the <strong>cleaning</strong>agent as well as the rinsing time. The maintenance intervalsare also indicated by the controller. The solenoidvalves that control the <strong>cleaning</strong> units are located on topof the hood roof. They are completely wired and pipedand are ready for connection to the on-site water supply.The strainer and the pipe network insulating valve are tobe delivered by customer.The hood is fitted with a patented Venturi supply <strong>air</strong>nozzle that can handle unheated fresh <strong>air</strong> of up to 20to 70 % of the exhaust <strong>air</strong> volume. The round nozzleblows inducing <strong>air</strong> into the hood. This <strong>air</strong>flow picks upthe pollutant particles from the rising cooking vapoursand transports them to the aerosol separators wherethey are captured immediately. In pure exhaust <strong>air</strong>hoods without induction, the thermal <strong>air</strong>flow containingthe pollutants is not immediately captured by the aerosolseparators because the suction effect is relatively low.The contaminated <strong>air</strong> mixes to a very high extentwith the ambient room <strong>air</strong> and produces an undefinedinduction! <strong>REVEN</strong> ® induction hoods completely preventany negative undefined induction because they transportthe pollutant particles directly to the separatorsvia the inducing <strong>air</strong>flow (push & pull principle). Anotherpositive effect is the additional condensation separationthat is due to the temperature difference between theinducing <strong>air</strong>flow and the rising thermal <strong>air</strong>flow. Whenusing <strong>REVEN</strong> ® induction hoods with condensationseparation you can easily comply with the minimum<strong>air</strong> exchange rate of 90 m 3 /h per m 2 kitchen surfacerequired by VDI 2052. In many kitchens, the exchangerate still falls considerably below this limit.The stainless steel structure of the hood is fitted witha thermal insulation for temperatures down to -50 °C inthe supply <strong>air</strong> area.The hood and its components are TÜV-tested in accordancewith VDE and UL regulations. A hygiene report is availabletoo. All versions of this hood comply with regulation VDI2052 issued by the Association of German Engineers andthe workplace health and safety regulation BGR 111 issuedby German Trade Associations.Material: chromium nickel steel(material no. 1.4301)Surface finish: fine sanding, 180 grainincl. protective film35

COOKER EXTRACTION HOODS · COOKER EXTRACTION HOODSPipe system with spray cansDosing pump for the injectionof the <strong>cleaning</strong> agent36

REVEX ® -EH-WSwitch cabinet with microprocessor for operating and <strong>cleaning</strong> processesFunctional sketchSwitch cabinet with microprocessor foroperating and <strong>cleaning</strong> processes37

Technical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / wall-mounted version2.1. Schematic wiring diagram REVEX ® EH-WNot included in the scope of delivery!Not included in the scope of delivery!38

REVEX ® -EH-WTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / wall-mounted version2.1. Cleaning intervals REVEX ® EH-WBasic setting:Pre-filter:4 min. total <strong>cleaning</strong> time:1 min. warm rinsing2 min. washing with <strong>cleaning</strong> agent1 min. warm rinsingInjection of <strong>cleaning</strong> agent once per second.Consumption per cycle is 1.11 ml x 120 cycles =13<strong>3.2</strong> ml total consumptionAfter-filter:30 sec. total <strong>cleaning</strong> time:10 sec. washing with <strong>cleaning</strong> agent20 sec. warm rinsingInjection of <strong>cleaning</strong> agent once per second.Consumption per cycle is 1.11 ml x 10 cycles =11.1 ml total consumptionWater consumption:1.5 litres and more per minute and metre of hood. The bestcompromise between water consumption and <strong>cleaning</strong>performance is 3 litres per minute and metre approximately.Consumption can be adjustedto suit project requirements!39

Technical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / wall-mounted version2.1. Technical equipment REVEX ® -EH-WSwitch cabinetFor the monitoring and control of the self-<strong>cleaning</strong>REVEX ® hoods, completely wired in accordance withVDE directives. The monitoring and control tasks arehandled by a modular, freely programmable processcontroller consisting of the following components:Display unit❑ Desired/actual values❑ Alarm❑ Operator guidance❑ Help functionsProgram controlInput keyboard for the digitaland menu-guided input ofDisplay unit❑ Status messages from the individualspraying cycles and indication of thetotal and remaining spraying time❑ Monitoring of the <strong>cleaning</strong> agent reservoirand alarm when the agent runs short (optional)❑ Monitoring of the solenoid valves and locking ofthe system in case of undefined flow (optional)❑ Zero potential single-poledouble-throw for centralized alarmConnection to the central control board❑ One input for on/off switching ofthe system via the central control board❑ Zero potential centralized alarm❑ desired values, such as- the start time of the spraying cycleseparately for each solenoid valve- the spraying cycle time (freely selectable)for each solenoid valve depending on the cookingactivity and grease load to be expected- the injection time for the <strong>cleaning</strong> agent or greaseremover for two defined groups and the rinsing time(both freely selectable)- the lock-up of the ventilation systemduring <strong>cleaning</strong> operations- the system configuration (basic data)- a weekly program with real-time control40

REVEX ® -EH-WTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / wall-mounted version2.1. Installation of REVEX ® -EH-WThe following should be observed wheninstalling the <strong>REVEN</strong> ® REVEX hood:1. The switch cabinet should belocated near the kitchen area.2. The pipelines by customer from theswitch cabinet to the hood should bemade of stainless steel or copper.N. B.:Do not use galvanized pipes!3. The <strong>cleaning</strong> agent for the washing systemis to be delivered by customer.4. The solenoid valves should be easilyaccessible after the installation.5. The exhaust <strong>air</strong> ducts mustbe grease- and oilproof.6. You must not drill any holes into theexhaust segments of the REVEX ® hood(to fasten an intermediate ceiling, for instance).41

Technical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / wall-mounted version2.1. Detailed drawings REVEX ® -EH-W: length 1000 <strong>–</strong> 1400 mm42

REVEX ® -EH-WTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / wall-mounted version2.1. Dimensions, wattage etc. REVEX ® -EH-WType REVEX ® -EH-W 90 100 110 120 130 140 150Width W (mm) 900 1000 1100 1200 1300 1400 1500Height H (mm) 450 450 450 450 450 450 450Type REVEX ® -EH-WLength No. of Number of separators/ Light fixtures No. of Supply <strong>air</strong> Exhaust <strong>air</strong> Dimensionsin mm grease exhaust <strong>air</strong> volume suspen- dampers sockets in mmdrain in m 3 /h (approximately) sionscocks Number Wattage Length Number Type Type Number E D Ain W in mm VKD ESG1000 1 2/up to 1000 m 3 /h 1 18 640 4 1 50/25 50/25 1 500 250 5001200 1 2/up to 1000 m 3 /h 1 18 640 4 1 75/25 75/25 1 600 225 7501400 1 3/up to 1500 m 3 /h 1 36 1250 4 1 100/25 100/25 1 700 200 1000N. B.:Make sure that you add the necessary projection!*N. B.:Other sizes on request!Hood dimensions to be selected:*Width = cooking equipment width + 450 mmLength = cooking equipment length + 400 mm* The specified dimensions apply to REVEX ® -EH-W hoods exclusively!43

Technical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / wall-mounted version2.1. Detailed drawings of REVEX ® -EH-W: length 1600 <strong>–</strong> 3000 mm44

REVEX ® -EH-WTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / wall-mounted version2.1. Dimensions, wattage etc. REVEX ® -EH-WType REVEX ® -EH-W 90 100 110 120 130 140 150Width W (mm) 900 1000 1100 1200 1300 1400 1500Height H (mm) 450 450 450 450 450 450 450Type REVEX ® -EH-WLength No. of Number of separators/ Light fixtures No. of Supply <strong>air</strong> Exhaust <strong>air</strong> Dimensionsin mm grease exhaust <strong>air</strong> volume suspen- dampers sockets in mmdrain in m 3 /h (approximately) sionscocks Number Wattage Length Number Type Type Number E D Ain W in mm VKD ESG1600 1 3/up to 1500 m 3 /h 1 58 1550 4 2 50/25 50/25 2 400 150 5001800 1 4/up to 2000 m 3 /h 1 58 1550 4 2 50/25 50/25 2 450 200 5002000 1 4/up to 2000 m 3 /h 1 58 1550 4 2 50/25 50/25 2 500 250 5002200 1 4/up to 2000 m 3 /h 1 58 1550 4 2 50/25 50/25 2 550 300 5002400 1 5/up to 2500 m 3 /h 1 58 1550 4 2 75/25 75/25 2 600 225 7502600 1 5/up to 2500 m 3 /h 1 58 1550 6 2 100/25 100/25 2 650 150 10002800 1 6/up to 3000 m 3 /h 2 36 1250 6 2 100/25 100/25 2 700 200 10003000 2 6/up to 3000 m 3 /h 2 36 1250 6 2 100/25 100/25 2 750 250 1000N. B.:Make sure that you add the necessary projection!*N. B.:Other sizes on request!Hood dimensions to be selected:*Width = cooking equipment width + 450 mmLength = cooking equipment length + 400 mm* The specified dimensions apply to REVEX ® -EH-W hoods exclusively!45

Technical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / wall-mounted version2.1. Detailed drawings of REVEX ® -EH-W: length 3200 <strong>–</strong> 4600 mm46

REVEX ® -EH-WTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / wall-mounted version2.1. Dimensions, wattage etc. REVEX ® -EH-WType REVEX ® -EH-W 90 100 110 120 130 140 150Width W (mm) 900 1000 1100 1200 1300 1400 1500Height H (mm) 450 450 450 450 450 450 450Type REVEX ® -EH-WLength No. of Number of separators/ Light fixtures No. of Supply <strong>air</strong> Exhaust <strong>air</strong> Dimensionsin mm grease exhaust <strong>air</strong> volume suspen- dampers sockets in mmdrain in m 3 /h (approximately) sionscocks Number Wattage Length Number Type Type Number E D A L/2in W in mm VKD ESG3200 2 7/up to 3500 m 3 /h 2 58 1550 8 3 75/25 75/25 3 535 160 750 16003400 2 7/up to 3500 m 3 /h 2 58 1550 8 3 75/25 75/25 3 565 190 750 17003600 2 8/up to 4000 m 3 /h 2 58 1550 8 3 75/25 75/25 3 600 225 750 18003800 2 8/up to 4000 m 3 /h 2 58 1550 8 3 75/25 75/25 3 635 260 750 19004000 2 8/up to 4000 m 3 /h 2 58 1550 8 3 75/25 75/25 3 665 290 750 20004200 2 9/up to 4500 m 3 /h 2 58 1550 8 3 100/25 100/25 3 700 200 1000 21004400 2 9/up to 4500 m 3 /h 2 58 1550 8 3 100/25 100/25 3 735 235 1000 22004600 2 10/up to 5000 m 3 /h 2 58 1550 8 3 100/25 100/25 3 765 265 1000 2300N. B.:Make sure that you add the necessary projection!*N. B.:Other sizes on request!N. B.:For hoods with a length of 3600 mm and more,two solenoid valves and two drains are requiredfor each nozzle holder. There is one connectionon the right and one on the left!Hood dimensions to be selected:*Width = cooking equipment width + 450 mmLength = cooking equipment length + 400 mm* The specified dimensions apply to REVEX ® -EH-W hoods exclusively!47

Technical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / wall-mounted version2.1. Detailed drawings of REVEX ® -EH-W: length 4800 <strong>–</strong> 6000 mm48

REVEX ® -EH-WTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / wall-mounted version2.1. Dimensions, wattage etc. REVEX ® -EH-WType REVEX ® -EH-W 90 100 110 120 130 140 150Width W (mm) 900 1000 1100 1200 1300 1400 1500Height H (mm) 450 450 450 450 450 450 450Type REVEX ® -EH-WLength No. of Number of separators/ Light fixtures No. of Supply <strong>air</strong> Exhaust <strong>air</strong> Dimensionsin mm grease exhaust <strong>air</strong> volume suspen- dampers sockets in mmdrain in m 3 /h (approximately) sionscocks Number Wattage Length Number Type Type Number E D A G Iin W in mm VKD ESG4800 2 10/up to 5000 m 3 /h 3 58 1550 10 4 75/25 75/25 4 600 225 750 450 12005000 2 11/up to 5500 m 3 /h 3 58 1550 10 4 75/25 75/25 4 625 250 750 500 12505200 2 11/up to 5500 m 3 /h 3 58 1550 10 4 75/25 75/25 4 650 275 750 550 13005400 2 12/up to 6000 m 3 /h 3 58 1550 10 4 75/25 75/25 4 675 300 750 600 13505600 2 12/up to 6000 m 3 /h 3 58 1550 10 4 100/25 100/25 4 700 200 1000 400 14005800 2 12/up to 6000 m 3 /h 3 58 1550 10 4 100/25 100/25 4 725 225 1000 450 14506000 2 13/up to 6500 m 3 /h 3 58 1550 10 4 100/25 100/25 4 750 250 1000 500 1500N. B.:Make sure that you add the necessary projection!*N. B.:Other sizes on request!N. B.:For hoods with a length of 3600 mm and more,two solenoid valves and two drains are requiredfor each nozzle holder. There is one connectionon the right and one on the left!Hood dimensions to be selected:*Width = cooking equipment width + 450 mmLength = cooking equipment length + 400 mm* The specified dimensions apply to REVEX ® -EH-W hoods exclusively!49

Technical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / wall-mounted version2.1. Weights in kg REVEX ® -EH-WType REVEX ® -EH-W 90 100 110 120 130 140 150Length in mm1000 133 136 149 155 169 185 2011200 148 154 166 173 186 204 2211400 165 170 183 190 208 223 2411600 183 188 203 209 226 245 2651800 200 206 221 226 246 266 2862000 218 229 245 253 273 286 3182200 235 245 264 270 291 308 3392400 256 263 280 286 313 335 3612600 274 281 300 306 331 355 3812800 291 299 318 326 351 378 4043000 309 316 335 346 370 398 4253200 326 334 354 364 390 418 4483400 344 351 374 383 396 439 4693600 361 370 391 405 409 459 4913800 379 391 413 428 428 485 5144000 396 406 431 450 469 506 5414200 416 426 450 473 493 528 5634400 434 445 469 480 514 548 5844600 451 463 488 510 534 553 6064800 469 480 505 528 553 569 6295000 486 499 524 546 573 611 6505200 504 516 543 554 591 631 6735400 521 535 564 575 613 656 6955600 540 555 583 596 636 676 7215800 560 574 601 628 655 698 7416000 578 625 620 634 675 719 76950

REVEX ® -EH-WTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / wall-mounted version2.1. Accessories REVEX ® -EH-WStandard accessories:N. B.:Included in the scope of delivery:❑ Separators❑ Light fixtures EB1/18W, EB1/36W, EB1/58W❑ Supply <strong>air</strong> dampers VKD 50/25,VKD 75/25, VKD 100/25❑ Exhaust <strong>air</strong> sockets ESG 50/25,ESG 75/25, ESG 100/25Not included in the scope of delivery!❑ Cleaning agent❑ Piping up to the hood❑ Network isolating valve❑ Strainer❑ Electric wiring up to the connection box❑ Suspensions for threaded rods M10❑ Switch cabinet with microprocessorfor operating and <strong>cleaning</strong> processes❑ Dosing pump for the injectionof the <strong>cleaning</strong> agent❑ Pipe system with spray nozzles❑ Solenoid valve51

Induction hood REVEX ® -EH-M with condensation separationand automatic separator <strong>cleaning</strong> / ceiling-mounted versionCOOKER EXTRACTION HOODS · COOKER EXTRACTION HOODSREVEX ® -EH-M52

REVEX ® -EH-MTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / ceiling-mounted versionSystem description2.1. Type REVEX ® -EH-MThe hood is made of a durable stainless steel structurewith welded corner joints. All cutting edges are envelopedand rounded free from burrs.The hood is equipped with grease- and waterproof exhaustsegments made of stainless steel. The grease separatorsare inserted in a slanted position into these segments inaccordance with VDI 2052. The hood canopy is suitablydesigned to retain even surge vapours. The special lightfixtures, type EB with polycarbonate cover, are splash andjet waterproof, with IP 54 protection and heat resistanceup to 110 °C. The polycarbonate cover offers highest transparencyand is breakproof and resistant to impact, oil andacid at the same time. The light fixtures are fully wired upto the connection box. The grease drain cock with internalthread is located in the deep-drawn drain area of thegrease collecting channel. The exhaust <strong>air</strong> chamber canaccommodate various types of grease separators that canbe inserted without tools. The hood is placed above thekitchen equipment block and should project sufficiently overthe outer edges of the appliances. A spraying facilityfor warm water is integrated in the exhaust <strong>air</strong> chamberand provides for the <strong>cleaning</strong> of the grease separators onboth sides at regular intervals. The control system includedin the washing facility allows the adjustment of the <strong>cleaning</strong>intervals to the actual level of contamination of the separators,which depends on the kitchen equipment used. In order tointensify the <strong>cleaning</strong> process, a grease remover is injectedduring the main washing cycle.The monitoring and automatic control of the self-<strong>cleaning</strong>extraction hood REVEX ® is ensured by a modular, freelyprogrammable process controller that offers variousadjustment options. Among other things, you can set alldesired values, such as the start time of the sprayingcycle, the spraying time, the injection time of the <strong>cleaning</strong>agent as well as the rinsing time. The maintenance intervalsare also indicated by the controller. The solenoidvalves that control the <strong>cleaning</strong> units are located on topof the hood roof. They are completely wired and pipedand are ready for connection to the on-site water supply.The strainer and the pipe network insulating valve are tobe delivered by customer.The hood is fitted with a patented Venturi supply <strong>air</strong>nozzle that can handle unheated fresh <strong>air</strong> of up to 20to 70 % of the exhaust <strong>air</strong> volume. The round nozzleblows inducing <strong>air</strong> into the hood. This <strong>air</strong>flow picks upthe pollutant particles from the rising cooking vapoursand transports them to the aerosol separators wherethey are captured immediately. In pure exhaust <strong>air</strong>hoods without induction, the thermal <strong>air</strong>flow containingthe pollutants is not immediately captured by the aerosolseparators because the suction effect is relatively low.The contaminated <strong>air</strong> mixes to a very high extentwith the ambient room <strong>air</strong> and produces an undefinedinduction! <strong>REVEN</strong> ® induction hoods completely preventany negative undefined induction because they transportthe pollutant particles directly to the separatorsvia the inducing <strong>air</strong>flow (push & pull principle). Anotherpositive effect is the additional condensation separationthat is due to the temperature difference between theinducing <strong>air</strong>flow and the rising thermal <strong>air</strong>flow. Whenusing <strong>REVEN</strong> ® induction hoods with condensationseparation you can easily comply with the minimum<strong>air</strong> exchange rate of 90 m 3 /h per m 2 kitchen surfacerequired by VDI 2052. In many kitchens, the exchangerate still falls considerably below this limit.The stainless steel structure of the hood is fitted witha thermal insulation for temperatures down to -50 °C inthe supply <strong>air</strong> area.The hood and its components are TÜV-tested in accordancewith VDE and UL regulations. A hygiene report is availabletoo. All versions of this hood comply with regulation VDI2052 issued by the Association of German Engineers andthe workplace health and safety regulation BGR 111 issuedby German Trade Associations.Material: chromium nickel steel(material no. 1.4301)Surface finish: fine sanding, 180 grainincl. protective film53

Technical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / ceiling-mounted version2.1. Schematic wiring diagram REVEX ® -EH-MNot included in the scope of delivery!Not included in the scope of delivery!54

REVEX ® -EH-MTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / ceiling-mounted version2.1. Cleaning intervals REVEX ® -EH-MBasic setting:Pre-filter:4 min. total <strong>cleaning</strong> time:1 min. warm rinsing2 min. washing with <strong>cleaning</strong> agent1 min. warm rinsingInjection of <strong>cleaning</strong> agent once per second.Consumption per cycle is 1.11 ml x 120 cycles =13<strong>3.2</strong> ml total consumptionAfter-filter:30 sec. total <strong>cleaning</strong> time:10 sec. washing with <strong>cleaning</strong> agent20 sec. warm rinsingInjection of <strong>cleaning</strong> agent once per second.Consumption per cycle is 1.11 ml x 10 cycles =11.1 ml total consumptionWater consumption:1.5 litres and more per minute and metre of hood. The bestcompromise between water consumption and <strong>cleaning</strong>performance is 3 litres per minute and metre approximately.Consumption can be adjustedto suit project requirements!55

Technical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / ceiling-mounted version2.1. Technical equipment REVEX ® -EH-MSwitch cabinetFor the monitoring and control of the self-<strong>cleaning</strong>REVEX ® hoods, completely wired in accordance withVDE directives. The monitoring and control tasks arehandled by a modular, freely programmable processcontroller consisting of the following components:Display unit❑ Desired/actual values❑ Alarms❑ Operator guidance❑ Help functionsProgram controlInput keyboard for the digitaland menu-guided input ofDisplay unit❑ Status messages from the individualspraying cycles and indication of thetotal and remaining spraying time❑ Monitoring of the <strong>cleaning</strong> agent reservoirand alarm when the agent runs short (optional)❑ Monitoring of the solenoid valves and locking ofthe system in case of undefined flow (optional)❑ Zero potential single-poledouble-throw for centralized alarmConnection to the central control board❑ One input for on/off switching ofthe system via the central control board❑ Zero potential centralized alarm❑ desired values, such as- the start time of the spraying cycleseparately for each solenoid valve- the spraying cycle time (freely selectable)for each solenoid valve depending on the cookingactivity and grease load to be expected- the injection time for the <strong>cleaning</strong> agent or greaseremover for two defined groups and the rinsing time(both freely selectable)- the lock-up of the ventilation systemduring <strong>cleaning</strong> operations- the system configuration (basic data)- a weekly program with real-time control56

REVEX ® -EH-MTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / ceiling-mounted version2.1. Installation REVEX ® -EH-MThe following should be observed wheninstalling the <strong>REVEN</strong> ® REVEX hood:1. The switch cabinet should belocated near the kitchen area.2. The pipelines by customer from theswitch cabinet to the hood should bemade of stainless steel or copper.N. B.:Do not use galvanized pipes!3. The <strong>cleaning</strong> agent for the washing systemis to be delivered by customer.4. The solenoid valves should be easilyaccessible after the installation.5. The exhaust <strong>air</strong> ducts mustbe grease- and oilproof.6. You must not drill any holes into theexhaust segments of the REVEX ® hood(to fasten an intermediate ceiling, for instance).57

Technical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / ceiling-mounted version2.1. Detailed drawings of REVEX ® -EH-M: length 1000 <strong>–</strong> 1400 mm, split version58

REVEX ® -EH-MTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / ceiling-mounted version2.1. Dimensions, wattage etc. REVEX ® -EH-MType REVEX ® -EH-M 180 200 220 240 260 280 300Width W (mm) 1800 2000 2200 2400 2600 2800 3000Height H (mm) 450 450 450 450 450 450 450Type REVEX ® -EH-MLength No. of Number of separators/ Light fixtures No. of Supply <strong>air</strong> Exhaust <strong>air</strong> Dimensionsin mm grease exhaust <strong>air</strong> volume suspen- dampers sockets in mmdrain in m 3 /h (approximately) sionscocks Number Wattage Length Number Type Type Number E D Ain W in mm VKD ESG1000 2 4/up to 2000 m 3 /h 2 18 640 8 2 50/25 50/50 1 500 250 5001200 2 4/up to 2000 m 3 /h 2 18 640 8 2 75/25 75/50 1 600 225 7501400 2 6/up to 3000 m 3 /h 2 36 1250 8 2 100/25 100/50 1 700 200 1000N. B.:Make sure that you add the necessary projection!*N. B.:Other sizes on request!Hood dimensions to be selected:*Width = cooking equipment width + 900 mmLength = cooking equipment length + 400 mm* The specified dimensions apply to REVEX ® -EH-M hoods exclusively!59

Technical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / ceiling-mounted version2.1. Detailed drawings of REVEX ® -EH-M: length 1600 <strong>–</strong> 3000 mm, split version60

REVEX ® -EH-MTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / ceiling-mounted version2.1. Dimensions, wattage etc. REVEX ® -EH-MType REVEX ® -EH-M 180 200 220 240 260 280 300Width W (mm) 1800 2000 2200 2400 2600 2800 3000Height H (mm) 450 450 450 450 450 450 450Type REVEX ® -EH-MLength No. of Number of separators/ Light fixtures No. of Supply <strong>air</strong> Exhaust <strong>air</strong> Dimensionsin mm grease exhaust <strong>air</strong> volume suspen- dampers sockets in mmdrain in m 3 /h (approximately) sionscocks Number Wattage Length Number Type Type Number E D Ain W in mm VKD ESG1600 2 6/up to 3000 m 3 /h 2 36 1250 8 4 50/25 50/50 2 400 150 5001800 2 8/up to 4000 m 3 /h 2 58 1550 8 4 50/25 50/50 2 450 200 5002000 2 8/up to 4000 m 3 /h 2 58 1550 8 4 50/25 50/50 2 500 250 5002200 2 8/up to 4000 m 3 /h 2 58 1550 8 4 50/25 50/50 2 550 300 5002400 2 10/up to 5000 m 3 /h 2 58 1550 8 4 75/25 75/50 2 600 225 7502600 2 10/up to 5000 m 3 /h 2 58 1550 10 4 100/25 100/50 2 650 150 10002800 2 12/up to 6000 m 3 /h 4 36 1250 10 4 100/25 100/50 2 700 200 10003000 4 12/up to 6000 m 3 /h 4 36 1250 10 4 100/25 100/50 2 750 250 1000N. B.:Make sure that you add the necessary projection!*N. B.:Other sizes on request!Hood dimensions to be selected:*Width = cooking equipment width + 900 mmLength = cooking equipment length + 400 mm* The specified dimensions apply to REVEX ® -EH-M hoods exclusively!61

Technical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / ceiling-mounted version2.1. Detailed drawings of REVEX ® -EH-M: length 3200 <strong>–</strong> 4600 mm, split version62

REVEX ® -EH-MTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / ceiling-mounted version2.1. Dimensions, wattage etc. REVEX ® -EH-MType REVEX ® -EH-M 180 200 220 240 260 280 300Width W (mm) 1800 2000 2200 2400 2600 2800 3000Height H (mm) 450 450 450 450 450 450 450Type REVEX ® -EH-MLength No. of Number of separators/ Light fixtures No. of Supply <strong>air</strong> Exhaust <strong>air</strong> Dimensionsin mm grease exhaust <strong>air</strong> volume suspen- dampers sockets in mmdrain in m 3 /h (approximately) sionscocks Number Wattage Length Number Type Type Number E D A L/2in W in mm VKD ESG3200 4 14/up to 7000 m 3 /h 4 36 1250 12 6 75/25 75/50 3 535 160 750 16003400 4 14/up to 7000 m 3 /h 4 58 1550 12 6 75/25 75/50 3 565 190 750 17003600 4 16/up to 8000 m 3 /h 4 58 1550 12 6 75/25 75/50 3 600 225 750 18003800 4 16/up to 8000 m 3 /h 4 58 1550 12 6 75/25 75/50 3 635 260 750 19004000 4 16/up to 8000 m 3 /h 4 58 1550 12 6 75/25 75/50 3 665 290 750 20004200 4 18/up to 9000 m 3 /h 4 58 1550 12 6 100/25 100/50 3 700 200 1000 21004400 4 18/up to 9000 m 3 /h 4 58 1550 12 6 100/25 100/50 3 735 235 1000 22004600 4 20/up to 10000 m 3 /h 4 58 1550 12 6 100/25 100/50 3 765 265 1000 2300N. B.:Make sure that you add the necessary projection!*N. B.:Other sizes on request!N. B.:For hoods with a length of 3600 mm and more,two solenoid valves and two drains are requiredfor each nozzle holder. There is one connectionon the right and one on the left!Hood dimensions to be selected:*Width = cooking equipment width + 900 mmLength = cooking equipment length + 400 mm* The specified dimensions apply to REVEX ® -EH-M hoods exclusively!63

Technical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / ceiling-mounted version2.1. Detailed drawings of REVEX ® -EH-M: length 4800 <strong>–</strong> 6000 mm, split version64

REVEX ® -EH-MTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / ceiling-mounted version2.1. Dimensions, wattage etc. REVEX ® -EH-MType REVEX ® -EH-M 180 200 220 240 260 280 300Width W (mm) 1800 2000 2200 2400 2600 2800 3000Height H (mm) 450 450 450 450 450 450 450Type REVEX ® -EH-MLength No. of Number of separators/ Light fixtures No. of Supply <strong>air</strong> Exhaust <strong>air</strong> Dimensionsin mm grease exhaust <strong>air</strong> volume suspen- dampers sockets in mmdrain in m 3 /h (approximately) sionscocks Number Wattage Length Number Type Type Number E D A G Iin W in mm VKD ESG4800 4 20/up to 10000 m 3 /h 6 58 1550 14 8 50/25 50/50 4 600 350 500 700 12005000 4 22/up to 11000 m 3 /h 6 58 1550 14 8 75/25 75/50 4 625 250 750 500 12505200 4 22/up to 11000 m 3 /h 6 58 1550 14 8 75/25 75/50 4 650 275 750 550 13005400 4 24/up to 12000 m 3 /h 6 58 1550 14 8 75/25 75/50 4 675 300 750 600 13505600 4 24/up to 12000 m 3 /h 6 58 1550 14 8 100/25 100/50 4 700 200 1000 400 14005800 4 24/up to 12000 m 3 /h 6 58 1550 14 8 100/25 100/50 4 725 225 1000 450 14506000 4 26/up to 13000 m 3 /h 6 58 1550 14 8 100/25 100/50 4 750 250 1000 500 1500N. B.:Make sure that you add the necessary projection!*N. B.:Other sizes on request!N. B.:For hoods with a length of 3600 mm and more,two solenoid valves and two drains are requiredfor each nozzle holder. There is one connectionon the right and one on the left!Hood dimensions to be selected:*Width = cooking equipment width + 900 mmLength = cooking equipment length + 400 mm* The specified dimensions apply to REVEX ® -EH-M hoods exclusively!65

Technical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / ceiling-mounted version2.1. Weights in kg REVEX ® -EH-MType REVEX ® -EH-M 180 200 220 240 260 280 300Length in mm1000 265 273 298 310 338 370 4031200 295 308 333 345 373 408 4431400 330 340 365 380 415 445 4831600 365 375 405 418 453 490 5301800 400 413 443 453 493 533 5732000 435 458 490 505 545 573 6352200 470 490 528 540 585 615 6782400 513 525 560 573 625 670 7232600 548 563 600 613 663 710 7632800 583 598 635 653 703 755 8083000 618 633 670 693 740 795 8503200 653 668 708 728 780 835 8953400 688 703 748 765 793 878 9383600 723 740 783 810 818 918 9833800 758 783 825 855 855 970 10284000 793 813 863 900 938 1013 10834200 833 853 900 945 985 1055 11254400 868 890 938 960 1028 1095 11684600 903 925 975 1020 1068 1105 12134800 938 960 1010 1055 1105 1138 12585000 973 998 1048 1093 1145 1223 13005200 1008 1033 1085 1108 1183 1263 13455400 1043 1070 1128 1150 1225 1313 13905600 1080 1110 1165 1193 1273 1353 14435800 1120 1148 1203 1255 1310 1395 14836000 1155 1250 1240 1268 1350 1438 153866

REVEX ® -EH-MTechnical data <strong>–</strong> Induction hoodwith condensation separation and autom. separator <strong>cleaning</strong> / ceiling-mounted version2.1. Accessories REVEX ® -EH-MStandard accessories:N. B.:Included in the scope of delivery:❑ Separators❑ Light fixtures EB1/18W, EB1/36W, EB1/58W❑ Supply <strong>air</strong> dampers VKD 50/25,VKD 75/25, VKD 100/25❑ Exhaust <strong>air</strong> sockets ESG 50/50,ESG 75/50, ESG 100/50Not included in the scope of delivery!❑ Cleaning agent❑ Piping up to the hood❑ Network isolating valve❑ Strainer❑ Electric wiring up to the connection box❑ Suspensions for threaded rods M10❑ Switch cabinet with microprocessorfor operating and <strong>cleaning</strong> processes❑ Dosing pump for the injectionof the <strong>cleaning</strong> agent❑ Pipe system with spray nozzles67

Conventional exhaust <strong>air</strong> hood REVEX ® -KH-Wwith automatic separator <strong>cleaning</strong> / wall-mounted versionCOOKER EXTRACTION HOODS · COOKER EXTRACTION HOODSREVEX ® -KH-W68

REVEX ® -KH-WTechnical dataConventional exhaust <strong>air</strong> hood with automatic separator <strong>cleaning</strong> / wall-mounted versionSystem description2.1. Type REVEX ® -KH-WThe hood is made of a durable stainless steelstructure with welded corner joints. All cuttingedges are enveloped and rounded free from burrs.The hood is equipped with grease- and waterproofexhaust segments made of stainless steel. Thegrease separators are inserted in a slanted positioninto these segments in accordance with VDI 2052.The hood canopy is suitably designed to retaineven surge vapours. The special light fixtures,type EB with polycarbonate cover, are splashand jet waterproof, with IP 54 protection and heatresistance up to 110 °C. The polycarbonate coveroffers highest transparency and is breakproof andresistant to impact, oil and acid at the same time.The light fixtures are fully wired up to the connectionbox. The grease drain cock with internal thread islocated in the deep-drawn drain area of the greasecollecting channel. The exhaust <strong>air</strong> chamber canaccommodate various types of grease separatorsthat can be inserted without tools. The hood isplaced above the kitchen equipment block andshould project sufficiently over the outer edges ofthe appliances. A spraying facility for warm wateris integrated in the exhaust <strong>air</strong> chamber and providesfor the <strong>cleaning</strong> of the grease separators on bothsides at regular intervals. The control systemincluded in the washing facility allows the adjustmentof the <strong>cleaning</strong> intervals to the actual levelof contamination of the separators, which dependson the kitchen equipment used. In order to intensifythe <strong>cleaning</strong> process, a grease remover is injectedduring the main washing cycle.The monitoring and automatic control of the self<strong>cleaning</strong>extraction hood REVEX ® is ensured by amodular, freely programmable process controllerthat offers various adjustment options. Among otherthings, you can set all desired values such as thestart time of the spraying cycle, the spraying time,the injection time of the <strong>cleaning</strong> agent as well asthe rinsing time. The maintenance intervals are alsoindicated by the controller.The solenoid valves that control the <strong>cleaning</strong>units are located on top of the hood roof. Theyare completely wired and piped and are ready forconnection to the on-site water supply. The strainerand the pipe network insulating valve are to bedelivered by customer.The hood and its components are TÜV-tested inaccordance with UL regulations. A hygiene report isavailable too. All versions of this hood comply withregulation VDI 2052 issued by the Association ofGerman Engineers and the workplace health andsafety regulation BGR 111 issued by German TradeAssociations.Material: chromium nickel steel(material no. 1.4301)Surface finish: fine sanding, 180 grainincl. protective film69

Technical dataConventional exhaust <strong>air</strong> hood with automatic separator <strong>cleaning</strong> / wall-mounted version2.1. Schematic wiring diagram REVEX ® -KH-WNot included in the scope of delivery!Not included in the scope of delivery!70

REVEX ® -KH-WTechnical dataConventional exhaust <strong>air</strong> hood with automatic separator <strong>cleaning</strong> / wall-mounted version2.1. Cleaning intervals REVEX ® -KH-WBasic setting:Pre-filter:4 min. total <strong>cleaning</strong> time:1 min. warm rinsing2 min. washing with <strong>cleaning</strong> agent1 min. warm rinsingInjection of <strong>cleaning</strong> agent once per second.Consumption per cycle is 1.11 ml x 120 cycles =13<strong>3.2</strong> ml total consumptionAfter-filter:30 sec. total <strong>cleaning</strong> time:10 sec. washing with <strong>cleaning</strong> agent20 sec. warm rinsingInjection of <strong>cleaning</strong> agent once per second.Consumption per cycle is 1.11 ml x 10 cycles =11.1 ml total consumptionWater consumption:1.5 litres and more per minute and metre of hood. The bestcompromise between water consumption and <strong>cleaning</strong>performance is 3 litres per minute and metre approximately.Consumption can be adjustedto suit project requirements!71