BS1501-430A - Macsteel

BS1501-430A - Macsteel

BS1501-430A - Macsteel

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NORMAL STRENGTH CARBON & CARBON MANGANESE PRESSURE VESSELSTEEL PLATEB.S.1501: 430 MPa GradesDESCRIPTIONB.S.1501-161-<strong>430A</strong>/B is a British Standard Specified steel which has now been superseded bythe Euro Norm Specification EN 10028.As reference is still being made to this material by prospective clients, we have includeddetails of B.S.1501-161-<strong>430A</strong>/B on this referencefor information purposes.The steel is used in the fabrication of welded pressure vessels and boilers.There are two types of <strong>BS1501</strong>-161-430 available which are as follows:Type A:Denotes specified min. room temperature tensile propertiesType B: As per Type A but with elevated temperature properties.A wide range of steel plate specifications may be used for Pressure Vessels designed andbuilt to the British construction code PB 5500.These steels are specified in BS 1501: Parts 1,2 and 3.Part 1 refers to carbon and carbon manganese steels, Part 2 to alloy steels and Part 3 tostainless Steel.This data sheet deals with one steel in Part 1,’Specification for carbon and carbonmanganese steels’, namely:BS 1501-161 grade 430, a fully killed carbon steel available in thicknesses up to andincluding 100mm.These steels are designated by the specification number, steel type number and a gradenumber which represents the minimumtensile strength e.g. BS 1501-161 grade 430.In addition, the suffix A or B is added to the grade number, ‘A’ being used if tensileproperties are guaranteed at room temperature onlyand ‘B’ being used when characteristic elevated temperature properties are guaranteed inaddition to the room temperature properties.The suffix RT is applicable when impact tests are to be performed at room temperature.The suffix LT is added if sub-zero impact tests are to be carried out, the temperature beingincluded, e.g. LT30 for impact testing at -30°C.Hence a full designation will be as follows: BS 1501-161 grade 430B, LT30.

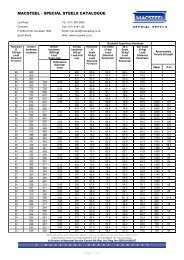

Steel MakingSteel is normally supplied from a basic oxygen furnace but could also be supplied fromelectric arc furnaces using clean internal scrap and direct reduced iron.All steel is desulphurised to maintain a high degree of cleanliness and is made fully killedand fine-grained from continuously cast slabs.Full shrouding techniques and automatic mould level control are applied to ensure superiorinternal and surface quality.Chemical compositionTable 1 shows the chemical composition as specified by BS 1501: Part 1: 1980.Table 1. Chemical composition (ladle analysis, percent) as specified in BS 1501: Part 1: 1980Type161Grade430CmaxMn Si PmaxSmaxAlminCrmaxCumaxMomaxNimaxNmaxCEmax0.25 0,60- 0,10- 0,030 0,030 - 0,25 0,30 0,10 0,30 0,012 0,411,40 0,35Heat treatment conditionPlates up to and including 40mm are supplied as rolled unless normalizing isrequested by the purchaser.Where cold forming of plate thicknesses thinner than or equal to 40mm is intended,normalizing is a prerequisite.Plates over 40mm thick are supplied normalized unless supply in the as rolledcondition is required, in which case the test pieceswill be normalized.Plates up to and including 40mm are supplied as rolled unless normalizing isrequested by the purchaser.Where cold forming of plate thicknesses thinner than or equal to 40mm is intended,normalizing is a prerequisite.Plates over 40mm thick are supplied normalized unless supply in the as rolledcondition is required in which case the test pieces will benormalizedMechanical PropertiesRoom temperature tensile propertiesTable 2. Mechanical properties at room temperature as specified in BS 1501: Part 1: 1980TypeNominalthickness t(mm)161 grade 430 t ≤ 1616 < t ≤ 4040 < t ≤ 6363 < t ≤ 80TensileStrength(MPa)430 – 550430 – 550430 – 550430 - 550Minimum yieldStrength(MPa)250240230220MinimumElongation(%)23232221Note:1. Gauge length 5,65√S₀. Refer to paragraph 20.1 in the specification.

Impact resistanceNote:1. The specification has no impact test requirements for steel type 161.Elevated temperature yield strength or proof stressIn appendix D (for steel types 151 and 161) and appendix F (for steel type 224). Thespecification shows the yield strength or proof stress valuesof the respective grades at elevated temperature.These values may be used for design purposes, but if a user requires verification of thestrength at any particular temperature, a tensile testat this temperature must be stipulated on the order. The high temperature yield strengthvalues for these steels are summarized in thetable below.Table 3. Minimum yield strength or 0,2% proof stress at elevated temperatureType151and161NominalThickness t(mm)t ≤1616 < t ≤ 4040 < t ≤ 6363 < t ≤ 80Minimum yield strength or proof stress (MPa) at temperature150°C 200°C 250°C 300°C 350°C 400°C222210200186215202192181192181178172161161161161153153153153148148148148DimensionsPlates to BS 1501: Part 1 are supplied to the dimensional tolerances specified in BS EN 10029, unless otherwise agreed at the time of theenquiry and order.Surface inspectionPlates are inspected and defects repaired in accordance with specification BS EN10 1063:Part 2, Class B, Subclass 2, unless otherwise agreedat the time of the enquiry and order.CertificationAll material described in this data sheet is supplied with test and analysis certificates.

WeldabilityThe normal strength pressure vessel steels to BS 1501 are all readily weldable by the usualmetal arc welding processes.When welding plates thicker than 20mm, reference should be made to BS 5135: ‘Metal arcwelding of carbon and carbon manganese steels’,to establish possible preheat requirements, especially at low heat inputs.Values of the carbon equivalent used to generate welding procedures should be calculatedfrom the values for chemical composition on thetest certificates for the plates concerned, not from the tables on this data sheet.Attention is drawn to paragraph 7.4.4 of the specification, regarding maximum carbonequivalent requirements in the event that post weldheat treatment is specified.Note: This data sheet merely gives some important commonly used parameters.It is strongly recommended that users of steel to BS 1501: Part 1: 1980 should study thespecification in full.