Long Coupled End Suction Pumps Series 4030 - Tomlinson Hall

Long Coupled End Suction Pumps Series 4030 - Tomlinson Hall

Long Coupled End Suction Pumps Series 4030 - Tomlinson Hall

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

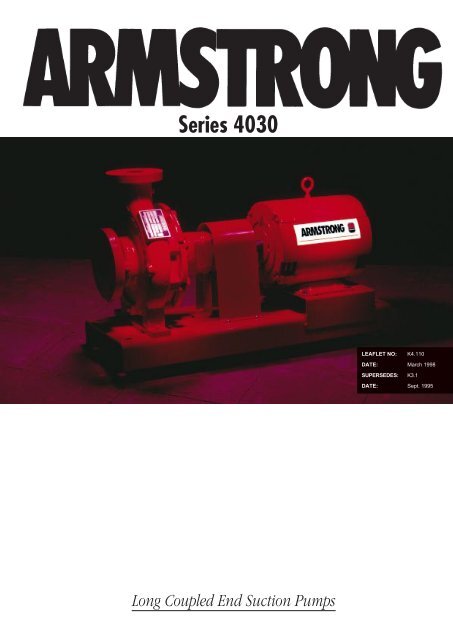

<strong>Series</strong> <strong>4030</strong><br />

<strong>Long</strong> <strong>Coupled</strong> <strong>End</strong> <strong>Suction</strong> <strong>Pumps</strong><br />

LEAFLET NO: K4.110<br />

DATE: March 1998<br />

SUPERSEDES: K3.1<br />

DATE: Sept. 1995

SERIES SERIES <strong>4030</strong><br />

ARMSTRONG PUMPS - HALLMARK OF QUALITY<br />

TRADITIONAL FEATURES:<br />

❑ Back Pull Out Design<br />

❑ One Piece Baseplate<br />

❑ Armstrong - Manufacturer of pumps since 1934<br />

❑ Base mounted pump designs continuously updated<br />

❑ Traditional features combined with cutting edge concepts<br />

❑ Base Supported Radially Split Casing<br />

❑ Flexible Coupling, with Guard<br />

❑ Drain and Gauge Connections<br />

❑ Cast Iron Housing, Bronze Fitted Construction<br />

❑ All Iron and Ductile Iron Construction available<br />

❑ Designed, Manufactured, and<br />

Tested to Exacting Standards<br />

CURRENT DESIGN CONCEPTS:<br />

❑ Centerline Discharge Casing<br />

❑ Large Flow Range<br />

❑ DIN Flanged Casing<br />

❑ Pre-Lubricated and Sealed Ball Bearings<br />

❑ Confined Casing Gasket<br />

❑ Mechanical Seal with O-Ring Mounted Seat<br />

❑ Stainless Steel Shaft Sleeve

Pressure<br />

BASE MOUNTED CENTRIFUGAL PUMPS<br />

Coupling Guard<br />

Provided on all pumping units<br />

Drilled and Tapped connections<br />

for Gauges and Drain<br />

DIN flanges<br />

Radially Split Casing provides Pull Out design<br />

Allows removal of bearing assembly and<br />

impeller without disturbing pipe connections<br />

Top centerline discharge<br />

casing, self-venting to<br />

eliminate pump vapor lock<br />

Gasket, non-asbestos, confined<br />

Cast Bronze or Iron Impeller<br />

Dynamically Balanced<br />

Stainless Steel Shaft Sleeve<br />

Bearing Assembly<br />

Two anti-friction bearings,<br />

permanently lubricated, carry design<br />

loads with minimum maintenance<br />

(Oil Lube on larger sizes) Base supported casing.<br />

Eliminates need to support casing<br />

when bearing assembly is removed<br />

A heavy fabricated steel baseplate, rigidly constructed,<br />

provides for proper alignment of pump and motor<br />

Single spring Mechanical Seal<br />

leak-proof operation throughout pump range<br />

SERIES <strong>4030</strong> – SIMPLY THE BEST BASE MOUNTED PUMP<br />

DESIGN IN TODAY’S HVAC INDUSTRY!<br />

PRESSURE ➁ /TEMPERATURE CHART ➀ SERIES <strong>4030</strong><br />

250<br />

psig<br />

200<br />

psig<br />

150<br />

psig<br />

100<br />

psig<br />

50<br />

psig<br />

-18°C 10°C 38°C 66°C 93°C 121°C<br />

1724<br />

kPa<br />

B<br />

A<br />

0°F 50°F 100°F 150°F 200°F 250°F<br />

Temperature<br />

1380<br />

kPa<br />

1034<br />

kPa<br />

690<br />

kPa<br />

345<br />

kPa<br />

A - CAST IRON - PN16 flanges<br />

Standard Seal<br />

B - DUCTILE IRON - PN16 flanges to 1600 kPa<br />

PN25 1600-2500 kPa<br />

➀ - All values are based on clear, clean water<br />

Values may change with other liquids.<br />

➁ - Hydrostatic test pressure at ambient temperature<br />

is 150% maximum working pressure.

SERIES SERIES <strong>4030</strong><br />

NEED TO REDUCE SPACE REQUIREMENTS AND INSTALLATION COSTS?<br />

Base mounted pump with <strong>Suction</strong> Vertical In-Line with <strong>Suction</strong> dualArm Vertical In-Line<br />

Guide and Flo-Trex valve. Guide and Flo-Trex Valve. Incorporates two pumps in a casing with<br />

Eliminates cost and space of: Eliminates cost and space of: single inlet and outlet connections. Enables<br />

<strong>Suction</strong>: Y-Strainer All the items listed under base standby or parallel operation with only one<br />

<strong>Long</strong> Radius Elbow mounted pump, also saves: set of piping. Casing design and port valves<br />

Min. Straight Pipe Run Inertia Base with spring mounts allow one pump to be removed for service<br />

Discharge: <strong>Long</strong> Radius Elbow Flexible Pipe Connectors with the second pump still operating.<br />

Check Valve Grouting When installed with <strong>Suction</strong> Guide and<br />

Isolating Valve Field Alignment Flo-Trex valve the dualArm represents<br />

Throttling Valve Split Couplings available for ease the greatest Life Cycle Value in today’s<br />

of mechanical seal replacement commercial HVAC market.<br />

Armstrong <strong>Pumps</strong> Limited S.A. Armstrong Limited Armstrong <strong>Pumps</strong> Inc. Armstrong Darling Inc.<br />

Peartree Road, Stanway 23 Bertrand Avenue 93 East Avenue 2200 Place Transcanadienne<br />

Colchester, Essex Toronto, Ontario Buffalo, New York Montreal, Quebec<br />

United Kingdom, C03 5JX Canada, M1L 2P3 U.S.A., 14120-6594 Canada, H9P 2X5<br />

Tel.: 01206-579491 Tel.: (416) 755-2291 Tel.: (716) 693-8813 Tel.: (514) 421-2424<br />

Fax: 01206-760532 Fax: (416) 759-9101 Fax: (716) 693-8970 Fax: (514) 421-2436<br />

AP960<br />

BASE MOUNTED PUMPS<br />

TYPICAL SPECIFICATION:<br />

1.1 CIRCULATING PUMPS<br />

.1 Furnish and install, as indicated on the plans and specifications, Armstrong <strong>Series</strong> <strong>4030</strong> base mounted<br />

centrifugal pumps.<br />

.2 The pump shall be single, end suction type with radially split, top center-line discharge, self-venting casing.<br />

The casing-to-cover gasket shall be confined on the atmospheric side to prevent blow-out possibility.<br />

.3 Pump construction shall be cast iron, bronze fitted (all iron, all bronze, ductile iron) and shall be fitted with<br />

a long-life, self lubricating, drip-tight mechanical seal, with O-ring seat retainer, designed for the specified<br />

maximum temperature and pressure.<br />

.4 The shaft shall be fitted with a Stainless Steel shaft sleeve and be supported by two heavy duty ball<br />

bearings. The design shall allow Back Pull Out servicing, enabling the complete rotating assembly to be<br />

removed without disturbing the casing piping connections.<br />

.5 The pump shall be mounted on a rigid, single piece baseplate, with grouting hole, and connected by flexible<br />

coupling, with guard, to a __kW, __Hz, _ph, __volts, __rpm, __enclosure squirrel cage, induction type<br />

motor of standard (premium, __%) efficiency and suitable for direct on line/star delta starting.<br />

.6 The housing shall be hydrostatically tested to 150% maximum working pressure.<br />

.7 The unit shall be suitable for the conditions shown on the pump schedule.<br />

Armstrong SG<br />

<strong>Suction</strong><br />

Guide<br />

with<br />

Strainer<br />

ARMSTRONG ARMSTRONGER ARMSTRONGEST<br />

Armstrong FTV-S<br />

Flo-Trex<br />

Combination<br />

Valve<br />

Armstrong SG<br />

<strong>Suction</strong><br />

Guide<br />

with<br />

Strainer<br />

Armstrong FTV-A<br />

Flo-Trex<br />

Combination<br />

Valve<br />

Armstrong SG<br />

<strong>Suction</strong><br />

Guide<br />

with<br />

Strainer<br />

Our policy is one of continuous improvement and we reserve the right to alter our dimensions, designs and specifications without notice.<br />

© S.A. Armstrong Limited, 1995,1998.<br />

Armstrong FTV-A<br />

Flo-Trex<br />

Combination<br />

Valve<br />

Armstrong<br />

dualArm<br />

Vertical<br />

in-Line<br />

Pump