Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

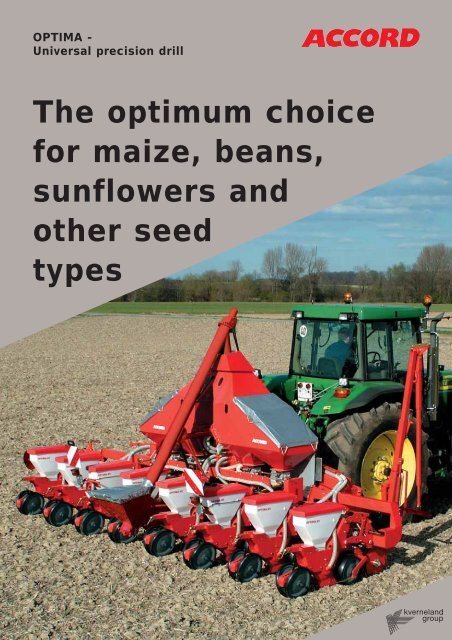

<strong>OPTIMA</strong> -<br />

Universal precision drill<br />

The optimum choice<br />

for maize, beans,<br />

sunflowers and<br />

other seed<br />

types

Accurate sowing<br />

maximising profit<br />

For all tillage and row crop establishment methods, ACCORD offers<br />

proven technology meeting all precision drilling requirements.<br />

ACCORD is the Kverneland Group's specialist in drilling technology.<br />

Since the 1960's, ACCORD has been the number one for pneumatic<br />

grain drills together with mechanical and pneumatic precision<br />

drills.<br />

The Optima is once again setting new standards with the<br />

introduction of the new HD sowing unit and the trailed frame concept.<br />

2

Precision establishment<br />

of maize, beet, beans,<br />

sunflowers, etc.<br />

The <strong>OPTIMA</strong> can be used for<br />

standard, mulch and direct<br />

seeding. (Depending on optional<br />

equipment)<br />

3<br />

The <strong>OPTIMA</strong> is available with working<br />

widths from 3 to 9m, with infinitely<br />

adjustable row widths and a wide range<br />

of additional equipment.<br />

Frame sizes<br />

<strong>OPTIMA</strong> telescopic 6-row<br />

page<br />

4-5<br />

<strong>OPTIMA</strong> folding 8-16row 4-5<br />

<strong>OPTIMA</strong> rigid 8 and 12-row 4-5<br />

"Optima HD"<br />

The sowing units 8-9<br />

The <strong>OPTIMA</strong> seeding heart 10<br />

"e-drive" electric drive<br />

page<br />

<strong>OPTIMA</strong>, e-drive 11<br />

Additional equipment<br />

page<br />

Optima HD and trailed frame 6<br />

Trailed frame concept 7<br />

HD- sowing unit 7<br />

Sowing with the <strong>OPTIMA</strong><br />

page<br />

page<br />

"Close row" sowing 12<br />

Fertilising, Micro granule application 13<br />

Electronics 14

8-row PH sowing machine<br />

with central fertilizer hopper<br />

and filling auger<br />

<strong>OPTIMA</strong> - suitable for all farm sizes<br />

From 4 - 16 rows, with telescopic,<br />

rigid, trailed and folding toolbar<br />

ACCORD <strong>OPTIMA</strong> HD:<br />

6-row telescopic,<br />

4.5m working width,<br />

fertiliser hopper<br />

capacity 770 litres<br />

4<br />

<strong>OPTIMA</strong> 6-row telescopic<br />

The ideal machine for contractors, with a<br />

working width up to 4.8m and a fertiliser<br />

capacity up to 900 litres.<br />

The hydraulically operated telescopic tool bar converts<br />

the machine to its transport width of 3m<br />

within seconds. Hydraulic vertical folding track<br />

markers are standard equipment.<br />

• Row distance range from 35 to 80cm<br />

• HP requirement 85kw (115 HP)

ACCORD Optima<br />

Eight-row maize sowing machine<br />

with 6.1m rigid tool bar<br />

High work rates:<br />

8-row PH sowing maize<br />

combined with an ACCORD<br />

DF-1 fertiliser hopper<br />

5<br />

<strong>OPTIMA</strong> 8 to 16 rows,<br />

hydraulic folding<br />

The 8-row parallel hydraulic folding model is designed<br />

for a high output.<br />

With the centrally mounted fertiliser hopper (optional),<br />

the machine is ideal for contractor use.<br />

Working width 6.0m<br />

Row distances from 37.5 to 80cm<br />

Transport width 3.0m<br />

Fertiliser hopper capacity up to 900 litres with filling<br />

auger (optional) or front hopper capacity DF1 and DF2<br />

Front hopper capacity: DF2 1650l (2200l with ext),<br />

DF1 1150l (1700l with ext)<br />

HP requirement from 110kw (150 HP)<br />

<strong>OPTIMA</strong> HD, 8 row trailed with central<br />

fertilizer hopper 1200 litres<br />

Reduced tractor power requirement and increased hopper<br />

capacities for maximum operating efficiency.<br />

The Optima trailed frame with 6 or 8 rows can be equipped<br />

with various sowing units for conventional seeding or mulch<br />

seeding (NT-2 or HD).<br />

<strong>OPTIMA</strong> 8 and 12 rows, rigid<br />

For high work rates, with easy end tow conversion for<br />

road transport.<br />

Working widths of 6.1 and 9.3m available<br />

Row widths: 35-80cm<br />

Transport width: 2.5m (lengthwise)<br />

HP requirement: 85kw (115 HP) for 8-rows, 100kw<br />

(136 HP) for 12-rows<br />

9.3m 12-row fertiliser placement with DF-2 front<br />

hopper system only

Optima HD and trailed frame -<br />

Professional equipment for<br />

maximising profit<br />

<strong>OPTIMA</strong> 8-row HD with trailed frame and<br />

central fertilizer hopper<br />

<strong>OPTIMA</strong> 6-row telescopic frame in<br />

working position<br />

6<br />

<strong>OPTIMA</strong> 6-row telescopic frame in<br />

transport position

Trailed frame concept<br />

- avaible in working widths of 4.5 metres and<br />

6 metres with 6 or 8 rows<br />

- mechanical folding to transport position<br />

_(3m), hydraulic folding as option<br />

- strong and reliable 180x180mm hollow<br />

section tube<br />

- optional fertiliser hopper with a capacity of<br />

1,200 litres<br />

- the trailed Optima, especially the<br />

hydraulically folding version, offers an<br />

interesting alternative for contractors and<br />

professional farmers who want to increase<br />

the machine output with minimum horse<br />

power requirement.<br />

HD- sowing unit<br />

- Optima HD (Heavy duty) for conventional,<br />

direct and mulch sowing<br />

- exact depth control is maintained through<br />

the front oscillating depth control wheels<br />

- seeding heart located above double disc<br />

system for excellent depth control<br />

- individual row weight of 129kg. The down-<br />

ward weight on the unit can be increased<br />

by 100kg<br />

- V-press wheels can be adjusted in 3 steps<br />

from 0 to 40kg as to loading with additional<br />

angle adjustment<br />

- e-drive as option<br />

7

<strong>OPTIMA</strong> sowing elements for<br />

conventional seeding<br />

The sowing units - like the whole machine - are<br />

modular in design. The basic element always<br />

remains the same and the equipment can be<br />

varied according to individual<br />

requirements.<br />

Press wheels<br />

The press wheels run on maintenance free ball bearings. The<br />

sowing depth can be infinitely adjusted by means of a screw<br />

jack. A scale ensures even depth adjustment over all rows.<br />

Standard on all sowing units:<br />

- Stable parallelogram<br />

- All parallelogram pivot points with maintenance-free bonded<br />

bushes<br />

- All press wheels with maintenance-free ball bearing<br />

- Chill cast coulters with quick release clamping to the coulter<br />

housing<br />

Sowing unit for conventional<br />

seeding<br />

The standard equipment for sowing in<br />

prepared conditions.<br />

- Maize coulter and Farmflex depth wheel<br />

370mm (500mm optional)<br />

- Coverer, spring-loaded fitted on both<br />

sides of the unit<br />

- Lifting device as standard<br />

Sowing coulters<br />

The sowing coulters are designed with a high attachment point.<br />

This enables them to work deeply when sowing beans or on dry<br />

soil, without the housing being subject to wear.<br />

Precise depth placement<br />

Precise depth control is achieved via the tandem design of the<br />

sowing units for beet.<br />

- Infinite depth adjustment by screw jack<br />

- 30 litres seed hopper<br />

- 55 litres hopper capacity as option<br />

- Seeding heart without seals<br />

8<br />

Tandem sowing unit<br />

Optimum sowing and precise placement<br />

of small seeds (beet).<br />

- Precise depth control due to front<br />

and rear press wheels<br />

- Rubber front wheel 300x100<br />

- Beet coulter<br />

- Intermediate press wheel<br />

- Adjustable coverer<br />

- Monoflex press wheel

<strong>OPTIMA</strong> NT2 and HD elements for<br />

direct, mulch, and conventional<br />

seeding<br />

<strong>OPTIMA</strong> HD, the universal<br />

sowing unit for all conditions<br />

Optima HD<br />

- The heavy basic weight of the sowing unit coupled with the possibility to add additional<br />

pressure (up to 100kg) onto each individual sowing unit via a spring loaded system<br />

allows optimum seeding even under extreme conditions.<br />

- Effective ground contour following, due to the large lateral depth control wheels<br />

(ø 400mm, width 120mm), precise seed placement and seed covering by means of the intermediate<br />

press wheel and the multi adjustable V-press wheel, ensure maximum field emergence.<br />

- The sowing unit Optima HD can be mounted on all Optima frames (3-point linkage or trailed).<br />

NT2 - Beet sowing unit<br />

Suitable for direct, mulch and conventional seeding.<br />

- Twin independent rubber depth control wheels<br />

- Double cutting disc<br />

- Beet coulter<br />

- Intermediate press wheel<br />

- Multi adjustable V-press wheel adjustable from 0 - 40kg<br />

- 2 Tension springs in parallelogram for increasing or decreasing<br />

unit pressure.<br />

NT2 - Maize sowing unit<br />

- Twin independent rubber depth control wheels<br />

- Double cutting disc<br />

- Maize coulter<br />

- Multi adjustable V-press wheel adjustable from 0 - 40kg<br />

- 2 tension springs in parallelogram for increasing or decreasing<br />

unit pressure<br />

9

The seeding heart:<br />

No friction. No wear.<br />

The patented seeding heart by Accord is the result of futuristic<br />

development which has reduced maintenance costs to a minimum.<br />

Easy access to the seeding heart<br />

for changing the seed disc without<br />

tools.<br />

Changing seed discs without tools<br />

Quick and easy seed disc change without tools minimizes<br />

down time.<br />

All the important rotating parts run on maintenance free ball<br />

bearings. Special washers are used at the parallelogram bushes<br />

to protect against dust.<br />

Only top quality components are used to ensure extremely low<br />

maintenance costs.<br />

Seed disc with opto transmitter Easy emptying<br />

10<br />

Seeding heart without seals<br />

Precise separation<br />

of small, large, round<br />

elongated and flat<br />

seeds.<br />

No friction, no wear, low drive torque, minimum maintenance: The<br />

seed disc rotates in the seeding heart together with the vacuum<br />

chamber. This seeding drum is connected to the vacuum fan via a<br />

hollow shaft.<br />

This seed heart principal results in no loss of vacuum, and therefore<br />

a low vacuum requirement.<br />

The upper toothed scraper singulates the seeds on the seed disc. It<br />

can be infinitely adjusted to suit seed size and type by means of a<br />

scale.<br />

The adjustable lower scraper centralises difficult seeds (sunflowers)<br />

over the holes on the seed discs. During calibration the correct loading<br />

of the seed disc can be checked via a window.

<strong>OPTIMA</strong> e-drive - electronic drive<br />

e-drive - complete control and monitoring of the machine from the tractor<br />

cab in accordance with ISOBUS standard.<br />

Tellus - the new<br />

Kverneland Group<br />

ISO-standard<br />

solution<br />

-One single terminal for all<br />

machines which work at<br />

ISO 11783 standard<br />

certified by DLG<br />

- Control and adjustment<br />

directly from the tractor cab<br />

- Automatic identification<br />

of the machine via ISOBUS<br />

communication (plug and<br />

play) with the job control<br />

unit fitted at the machine.<br />

With e-drive, each sowing unit is driven<br />

individually via an electric motor.<br />

The low-maintenance drive is connected<br />

directly to the seeding heart via a<br />

toothed belt in an encapsulated dust<br />

proof housing. This enables an extremely<br />

compact design and smooth drive<br />

characteristics with low current consumption.<br />

All the data is entered and read out via the<br />

new "Tellus" ISOBUS terminal. The sowing<br />

distances are infinitely adjustable and can<br />

be changed during sowing. All the sowing<br />

units can be switched off individually.<br />

In conjunction with "close row" sowing<br />

widths of 37.5cm a further benefit of the<br />

e-drive comes into play: Individual tramline<br />

switching. Tramlines can be set up for any<br />

spray width.<br />

The e-drive features complete electronic<br />

monitoring of all machine functions, including<br />

seed monitoring via an opto sensor.<br />

11<br />

Technical<br />

specifications<br />

-High-resolution colour monitor<br />

- Robust plastic housing<br />

- Data-card port (64MB)<br />

- RS232 port (GPS and service<br />

interface)<br />

- Based on CAN bus system<br />

- Menu prompting via icons<br />

(independent on language)<br />

FOCUS - Terminal<br />

The FOCUS terminal can<br />

control all ISOBUS compatible<br />

machines manufactured<br />

by Kverneland<br />

Group Ltd.

Close row sowing: Increase yield!<br />

<strong>OPTIMA</strong> for close row sowing. 16-row parallel<br />

hydraulic folding toolbar combined with DF-2<br />

front fertiliser hopper, working width 6m<br />

How does close row sowing work?<br />

Efforts aiming at the optimum utilisation<br />

of growing space, even when<br />

sowing a wide variety of crops,<br />

have always been the farmers<br />

objective.<br />

With regards to maize, the harvesting<br />

process previously required a distance<br />

between rows of 75cm. Close rows<br />

have only been possible since the introduction<br />

of chopping and picking<br />

attachments, which are not dependent<br />

on the standard row widths. Tests performed<br />

at various locations and over<br />

several years with distances between rows<br />

ranging from 30 to 37.5cm have demonstrated<br />

that with a more even growing<br />

space the resulting photosynthesis rate<br />

12<br />

A wide range of <strong>OPTIMA</strong> models can be<br />

converted or retrofitted for close row sowing<br />

applications.<br />

37,5 cm<br />

achieved in yield increases by up to<br />

10%.<br />

In practice, close row sowing with a<br />

distance between rows of 37.5cm provides<br />

the ideal conditions for growth,<br />

with all plants developing at the same<br />

rate.

Optimum<br />

Fertiliser placement<br />

Harmonised fertilising and sowing<br />

Stable design, modular system, low<br />

maintenance costs, high degree of<br />

wear resistance and optimum depth<br />

placement are the<br />

characteristic features of the<br />

ACCORD fertilising coulters.<br />

For fertiliser placement<br />

ACCORD supplies hoppers for<br />

different applications.<br />

Each hopper is equipped with two metering<br />

devices, each featuring 1 or 2 cell<br />

wheels. The hopper capacity ranges<br />

from 2 x 220l and 4 x 220l through to 2 x<br />

475l.<br />

The chain drive for metering can be<br />

adjusted from 106 to 39kg per hectare at<br />

a distance between rows of 75cm.<br />

The fertiliser applicator is driven centrally<br />

by an easily accessible side mounted<br />

gear box.<br />

Precise metering by volume<br />

through cell wheel metering<br />

system with sealing lip<br />

Fertilising coulter,<br />

standard seeding<br />

- Narrow coulter design<br />

- Stable reliable construction<br />

- Coil spring protection<br />

from sideways forces<br />

- Minimal disruption of<br />

soil adjacent to rows<br />

Micro- granule applicators<br />

For the application of micro-granules<br />

Mulch seeding<br />

notched double-disc<br />

coulter<br />

- Blockage-free and<br />

precise fertiliser<br />

placement through<br />

ø 350mm notched<br />

double-disc coulter<br />

- Maintenance-free<br />

roller bearings<br />

- Overload protection via<br />

tension spring<br />

- Optimum fertiliser placement<br />

in mulch seeding<br />

conditions<br />

Knife-type coulter,<br />

direct seeding<br />

- Ideal for stone-free<br />

soils<br />

- The tip profile enables<br />

the coulter to<br />

be drawn automatically<br />

into the soil in<br />

hard ground.<br />

All Optima models can be equipped with micro granule applicators. The hoppers are made of special grade plastics and have a capacity of 35<br />

litres. Depending on the working width the hoppers supply 2 or 3 seeding units.<br />

Alternative sizes and material type metering wheels are available to suit most application requirements. Most types of micro-granules can be<br />

applied.<br />

13

Additional equipment<br />

FGS tramlining control unit<br />

ESC monitor<br />

OEC monitor<br />

Tellus<br />

FOCUS - Terminal<br />

Kverneland Group Spare Parts<br />

Kverneland Group spare parts are designed to give reliable,<br />

safe and optimal machinery performance - whilst<br />

ensuring a low cost life-cycle. High quality standards<br />

are achieved by using innovative production methods<br />

and patented processes in all our production sites.<br />

The Kverneland Group has a very professional network<br />

of partners to support you with service, technical<br />

knowledge and genuine parts. To assist our partners,<br />

we provide high quality spare parts and an efficient<br />

spare parts distribution worldwide.<br />

Kverneland Group Spare Parts... A part of your day!<br />

FGS electronic tramlining control<br />

system<br />

With the FGS electronic tramlining control<br />

system, various tramlining rhythms<br />

can be selected. When placing the<br />

tramlines, the operator receives visual<br />

The ESC provides comprehensive<br />

information, simple data entry, a<br />

variety of functions and precise<br />

control.<br />

For precise machine guidance during<br />

spraying or fertilising, tramlines are set<br />

The in-cab mounted OEC, Opto<br />

Electronic Control, constantly monitors<br />

the operation of the machine<br />

alerting the operator of any malfunction<br />

within the sowing heart.<br />

The OEC counts seeds as they are<br />

sown. If there is an interruption in seed<br />

delivery, an audible and visual alarm is<br />

TELLUS, the standardised ISOBUSenabled<br />

tractor terminal system<br />

from the Kverneland Group, offers a<br />

control unit for the <strong>OPTIMA</strong> which<br />

is also suitable for other ISO-compatible<br />

machines.<br />

Via the ISOBUS connection, TELLUS<br />

automatically identifies the job control<br />

The FOCUS Terminal is the entry<br />

level ISOBUS controller.<br />

The FOCUS terminal can ONLY control the<br />

ISOBUS compatible machines manufactured<br />

by the Kverneland Group. The monitor<br />

14<br />

information. The current pass of the drill<br />

is always displayed, this can be corrected<br />

manually if required.<br />

up and displayed visually by means of<br />

the electronic ESC control box. The<br />

ESC also offers many other functions.<br />

immediately triggered. The OEC indicates<br />

the area worked, working time and<br />

forward speed.<br />

Suitable for all seed types. High degree<br />

of operational reliability for contractors<br />

and farmers alike.<br />

unit, which is located on the machine.<br />

The Tellus terminal displays the data<br />

received from the job control unit and<br />

via a series of "soft keys" allows programming<br />

for complete set-up, monitoring<br />

and control of the machine.<br />

TELLUS has an RS 232 port for GPS,<br />

which is also used as the service interface.<br />

presentation is black and white. The terminal<br />

offers the same functions for the<br />

adjustment and control of equipment as<br />

the TELLUS.

<strong>OPTIMA</strong> Frame 3.00m 4.00m 4.50m 6.00m 6.10m 9.30m 4.50m 6.00m 4.50m<br />

rigid telesc. rigid PH rigid rigid trailed trailed rigid<br />

Tyres 7.00-12 AS (track width 1.45-1.74) 2.0 bar � � � — — — — — —<br />

Tyres 26x12.00 STG 1.4 bar � � � � � � — — —<br />

Tyres 11.5/80 - 15.3 — — — — — — � � �<br />

Drive 540 RPM � � � � � � — — —<br />

Drive 1000 RPM� � � � � � — — — —<br />

PTO (Walterscheid) � � � � � � — — —<br />

PTO with freewheel � � � � � � — — —<br />

Hydraulic fan drive � � � � � � � � �<br />

External hydraulic fan drive — — — — — — � � �<br />

Gear box with standard gear set � � � � � � � � �<br />

Optional chain wheels for additional sowing distances � � � � � � � � �<br />

6-speed lever change gearbox � � � � � � — — —<br />

Integrated ACCORD machine triangle � � � — � � — — —<br />

ACCORD tractor triangle � � � — � � — — —<br />

Manually operated track marker � — — — — — — — —<br />

Hydraulically operated track marker � � � � � � � � �<br />

Track marker extension for central marking � � � — � � � � �<br />

Vertical hydraulical track markers — � � � � � � � �<br />

Additional weights for track markers � � � � � � � � �<br />

OEC (Opto Electronic Control) � � � � � � � � �<br />

e-drive � � — � (�*) — — � � �<br />

End tow attachment — — � — � � — — —<br />

Lighting set � � � � � � � � �<br />

Parking leg � � � � � � � � �<br />

Hydraulic folding — � — � — — � � —<br />

Frame extension to 9.30m — — — — � � — — —<br />

Row fertiliser<br />

Mechanical � � � � * � — � � �<br />

Pneumatic DF1 — � � � � — — — —<br />

Pneumatic DF2 — — — � � � — — —<br />

Hopper extension (390 liter) with filling auger — � — — — — — — —<br />

Hopper extension (330 Liter) � � — — — — — — —<br />

Micro granule applicator � � � � � � � � �<br />

Filling auger — — — — — — � � �<br />

Number of sowing units (depending on equipment) max. 10 9 12 16 15 15 6 8 6<br />

Row width (depending on equipment) cm 30-80 37.5-80 30-80 37.5-80 30-80 30-80 70-80 70-80 45-80<br />

Total weight (maize 75cm w/o row fertilizer) ca. kg 600 970 820 1530 1350 1820<br />

Empty weight fertilizer ca. kg 125 150 150 350** 250 300 DF-2<br />

Fertilizer hopper capacity in litres 440 440 440 900** 880 1650 1200 1200 1200<br />

<strong>OPTIMA</strong> sowing unit Normal Normal Tandem Tandem No Till No Till HD HD<br />

(without seed disc) seeding seeding e-drive seeding seeding e-drive e-drive e-drive<br />

Parallelogramm � � � � � � � �<br />

Integrated chain drive � — � — � — � —<br />

Electronic drive — � — � — � — �<br />

Opto-electronic senso � � � � � � � �<br />

Lifting device � � � —<br />

Double-sided coverer � � — —<br />

Sowing coulter with quick-connect coupling � � �+cutting- � cutting<br />

discs<br />

Various coulters, depending on versio � � — —<br />

Various seed discs, depending on seed type � � � �<br />

Press wheel � � � �<br />

Various coulter press wheels, depending on version � � � �<br />

Retrofit kit optional for standard seeding, beet seeding � � � �<br />

Single hopper, capacity in litres 30l (55l)**** 30l (55l)**** 30l (55l)**** 55l ****<br />

Sowing unit weight, approx. 60kg 75kg 100kg 129kg<br />

* 16 rows: close row sowing � Standard equipment<br />

** with filling auger � Additional equipment<br />

*** 4 rows — Not available<br />

**** not for close row sowing<br />

15

Kverneland Group is one of<br />

the leading international<br />

companies developing, producing<br />

and distributing agricultural<br />

and viticultural<br />

machinery.<br />

The Group’s family of strong<br />

brands allows us to provide<br />

professional farmers, contractors<br />

and dealers with a<br />

unique and complete range<br />

of high quality products for<br />

soil preparation, seeding,<br />

grass processing, spreading,<br />

spraying, vine conditioning<br />

and grape harvesting.<br />

www.kvernelandgroup.com<br />

The information and illustrations<br />

shown may include additional equipment<br />

that does not form part of the<br />

standard range of equipment. The<br />

right to technical revision is reserved.<br />

Dealer:<br />

Please ask for other brochures<br />

from the Accord range.<br />

Accord is the Kverneland Group's specialist in<br />

seeding technology.<br />

DA-X pneumatic<br />

seed drill<br />

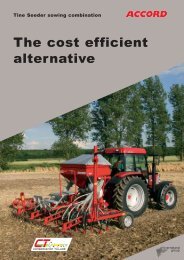

Tine Seeder<br />

sowing combination<br />

Monopill SE<br />

Producer:<br />

Kverneland Group Soest GmbH<br />

Coesterweg 42, D-59494 Soest, Germany<br />

Tel: +49 (0) 2921 / 974-0,<br />

Fax: +49 (0) 2921 / 77346<br />

Importers:<br />

Kverneland Group UK Ltd.<br />

Walkers Lane, Lea Green, St. Helens<br />

Merseyside WA9 4AF, UK<br />

Phone: +44 17 44 853 200, Fax +44 17 44 853 400<br />

Kverneland International BV<br />

Hoofdweg 1278, NL-2153 LR Nieuw-Vennep<br />

P.O. Box 1000, NL-2150 BA Nieuw-Vennep<br />

The Netherlands<br />

Phone: +31 252 662 244, Fax: +31 252 687 325<br />

E-mail: accord@kvernelandgroup.com<br />

www.kvernelandgroup.com/accord<br />

Pneumatic drills<br />

Semi-mounted, modular or tractormounted<br />

seed drills. Working widths<br />

range from 2.50m to 9.00m. Suffolk,<br />

Band, CX and CX-Plus disc coulters<br />

are available for use when using conventional<br />

and conservation sowing<br />

methods. For grass, rape, wheat, barley,<br />

beans and many other types of seed.<br />

Accord Tine Seeder<br />

The T-S Tine Seeder has been developed<br />

for cost efficient crop establishment.<br />

The hydraulic folding tine frame<br />

has three rows of spring tines protected<br />

by the Kverneland "Auto-reset" system.<br />

Depth control is via 4 floatation tyres and<br />

covering is achieved with 2 rows of following<br />

harrows working widths of 4.0 to 6.0 m.<br />

Monopill precision drill<br />

The Monopill precision drill is designed<br />

for sowing pelleted sugar beet, chicory<br />

and rape. The Monopill sowing units<br />

can be mechanically or electrically driven,<br />

with machines available from 6 to<br />

24 rows.<br />

AC758607 GB 01/07