Dillimax tl-e- 05-01 - Dillinger Hütte GTS

Dillimax tl-e- 05-01 - Dillinger Hütte GTS

Dillimax tl-e- 05-01 - Dillinger Hütte GTS

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

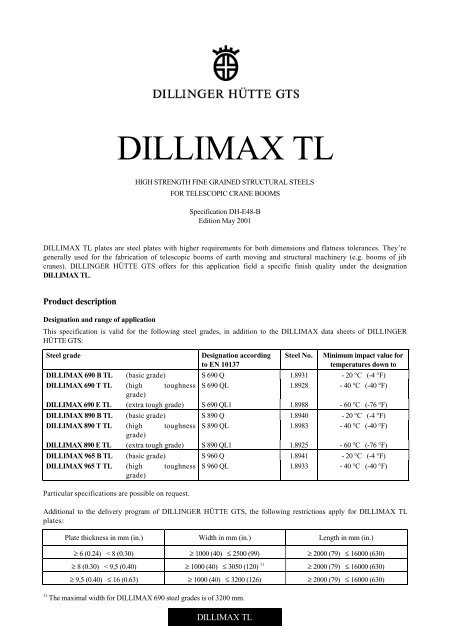

DILLIMAX TL<br />

HIGH STRENGTH FINE GRAINED STRUCTURAL STEELS<br />

FOR TELESCOPIC CRANE BOOMS<br />

Specification DH-E48-B<br />

Edition May 20<strong>01</strong><br />

DILLIMAX TL plates are steel plates with higher requirements for both dimensions and flatness tolerances. They’re<br />

generally used for the fabrication of telescopic booms of earth moving and structural machinery (e.g. booms of jib<br />

cranes). DILLINGER HÜTTE <strong>GTS</strong> offers for this application field a specific finish quality under the designation<br />

DILLIMAX TL.<br />

Product description<br />

Designation and range of application<br />

This specification is valid for the following steel grades, in addition to the DILLIMAX data sheets of DILLINGER<br />

HÜTTE <strong>GTS</strong>:<br />

Steel grade Designation according<br />

to EN 1<strong>01</strong>37<br />

DILLIMAX TL<br />

Steel No. Minimum impact value for<br />

temperatures down to<br />

DILLIMAX 690 B TL (basic grade) S 690 Q 1.8931 - 20 °C (-4 °F)<br />

DILLIMAX 690 T TL (high<br />

grade)<br />

toughness S 690 QL 1.8928 - 40 °C (-40 °F)<br />

DILLIMAX 690 E TL (extra tough grade) S 690 QL1 1.8988 - 60 °C (-76 °F)<br />

DILLIMAX 890 B TL (basic grade) S 890 Q 1.8940 - 20 °C (-4 °F)<br />

DILLIMAX 890 T TL (high<br />

grade)<br />

toughness S 890 QL 1.8983 - 40 °C (-40 °F)<br />

DILLIMAX 890 E TL (extra tough grade) S 890 QL1 1.8925 - 60 °C (-76 °F)<br />

DILLIMAX 965 B TL (basic grade) S 960 Q 1.8941 - 20 °C (-4 °F)<br />

DILLIMAX 965 T TL (high<br />

grade)<br />

toughness S 960 QL 1.8933 - 40 °C (-40 °F)<br />

Particular specifications are possible on request.<br />

Additional to the delivery program of DILLINGER HÜTTE <strong>GTS</strong>, the following restrictions apply for DILLIMAX TL<br />

plates:<br />

Plate thickness in mm (in.) Width in mm (in.) Length in mm (in.)<br />

≥ 6 (0.24) < 8 (0.30) ≥ 1000 (40) ≤ 2500 (99) ≥ 2000 (79) ≤ 16000 (630)<br />

≥ 8 (0.30) < 9,5 (0.40) ≥ 1000 (40) ≤ 3<strong>05</strong>0 (120) 1)<br />

≥ 2000 (79) ≤ 16000 (630)<br />

≥ 9,5 (0.40) ≤ 16 (0.63) ≥ 1000 (40) ≤ 3200 (126) ≥ 2000 (79) ≤ 16000 (630)<br />

1) The maximal width for DILLIMAX 690 steel grades is of 3200 mm.

Order example<br />

DILLIMAX 890 E TL<br />

General technical delivery requirements<br />

Unless otherwise agreed, the general technical delivery requirements in accordance with EN 10021 apply.<br />

Tolerances<br />

Tolerance for plate thickness<br />

Nominal thickness in mm (in.) Tolerance in mm (in.) 1)<br />

≥ 6 (0.24) ≤ 12 (0.47) -0.2 / +0.5 (-0.008 / +0.02)<br />

> 12 (0.47) ≤ 16 (0.63) -0.2 / +0.8 (-0.008 / +0.03)<br />

1) Another tolerance distribution around the nominal thickness can be agreed upon request.<br />

The difference in thickness along the bending line of a plate does not exceed 0,3 mm (0.<strong>01</strong>2 in.).<br />

Tolerance for plate width and length<br />

Unless otherwise agreed, the tolerances will be in accordance with EN 10029 .<br />

Flatness<br />

• 3 mm / 1m (0.12 in/1.09 yd) for a corrugation ≤ 1m (≤ 1.09 yd)<br />

• 4 mm / 1m (0.16 in/1.09 yd) for a corrugation > 1 ≤ 2 m (> 1.09 ≤ 2.19 yd)<br />

• 5 mm / 2m for a corrugation > 2 m (> 2.19 yd)<br />

A maximum of 2 ripples or corrugations per m of plate length is allowed. A ripple or corrugation is defined as a flatness<br />

deviation > 1 mm (> 0.04 in.). The flatness control is carried out on a flat support according to EN 10029 using a 1m- or<br />

2m- levelling staff.<br />

Surface quality<br />

Unless otherwise agreed, the specification will be in accordance with EN 1<strong>01</strong>63, class B2.<br />

Protection against corrosion<br />

A coating according to EN 10238 (primered plate) may be applied upon request.<br />

Identification of plates<br />

The plates are stamped with the following information at least:<br />

• heat number<br />

• rolled plate number<br />

• steel designation (for instance : DILLIMAX 890 E TL)<br />

• the manufacturer’s trademark<br />

General note<br />

If for application or manufacturing reasons, particular requirements are demanded of the steel which are not covered in<br />

this data sheet, please contact us for special agreement prior to ordering.<br />

The values in brackets are only for information.<br />

DILLIMAX TL

Sales organisations: Germany<br />

Vertriebsgesellschaft<br />

<strong>Dillinger</strong> <strong>Hütte</strong> <strong>GTS</strong><br />

Postfach 104927<br />

D-70036 Stuttgart<br />

Tel: +49 711 61 46-300<br />

Fax: +49 711 61 72 02<br />

AG der <strong>Dillinger</strong> <strong>Hütte</strong>nwerke<br />

Postfach 1580<br />

D-66748 Dillingen/Saar<br />

For your local representative<br />

please contact our coordination<br />

office in Dillingen<br />

Tel: +49 6831 47 23 85<br />

Fax: +49 6831 47 33 50<br />

e-mail: info@dillinger.de<br />

http://www.dillinger.de<br />

DILLIMAX TL<br />

France<br />

DILLING-<strong>GTS</strong> Ventes France<br />

Immeuble Pacific<br />

TSA 20002<br />

F-92070 La Défense CEDEX<br />

Tel: +33 1 41 25 87 28<br />

Fax: +33 1 41 25 86 77<br />

Tel. : +49 6831 47-21 46<br />

Fax : +49 6831 47-30 89