STRONGHOLD 902 - U-Pol

STRONGHOLD 902 - U-Pol

STRONGHOLD 902 - U-Pol

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

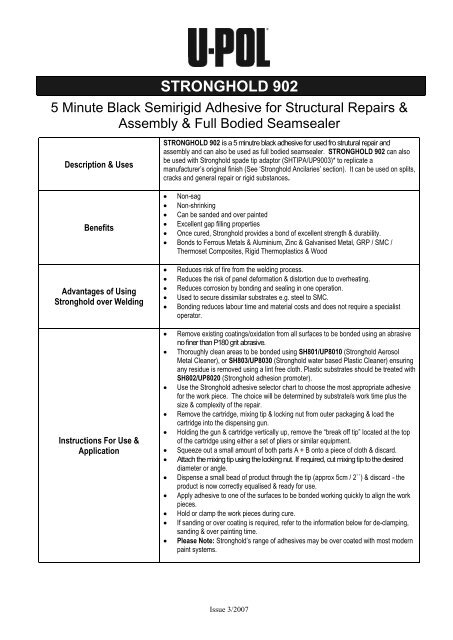

<strong>STRONGHOLD</strong> <strong>902</strong>5 Minute Black Semirigid Adhesive for Structural Repairs &Assembly & Full Bodied SeamsealerDescription & UsesBenefitsAdvantages of UsingStronghold over WeldingInstructions For Use &Application<strong>STRONGHOLD</strong> <strong>902</strong> is a 5 minutre black adhesive for used fro strutural repair andassembly and can also be used as full bodied seamsealer. <strong>STRONGHOLD</strong> <strong>902</strong> can alsobe used with Stronghold spade tip adaptor (SHTIPA/UP9003)* to replicate amanufacturer’s original finish (See ‘Stronghold Ancilaries’ section). It can be used on splits,cracks and general repair or rigid substances.Non-sagNon-shrinkingCan be sanded and over paintedExcellent gap filling propertiesOnce cured, Stronghold provides a bond of excellent strength & durability.Bonds to Ferrous Metals & Aluminium, Zinc & Galvanised Metal, GRP / SMC /Thermoset Composites, Rigid Thermoplastics & WoodReduces risk of fire from the welding process.Reduces the risk of panel deformation & distortion due to overheating.Reduces corrosion by bonding and sealing in one operation.Used to secure dissimilar substrates e.g. steel to SMC.Bonding reduces labour time and material costs and does not require a specialistoperator.Remove existing coatings/oxidation from all surfaces to be bonded using an abrasiveno finer than P180 grit abrasive.Thoroughly clean areas to be bonded using SH801/UP8010 (Stronghold AerosolMetal Cleaner), or SH803/UP8030 (Stronghold water based Plastic Cleaner) ensuringany residue is removed using a lint free cloth. Plastic substrates should be treated withSH802/UP8020 (Stronghold adhesion promoter).Use the Stronghold adhesive selector chart to choose the most appropriate adhesivefor the work piece. The choice will be determined by substrate/s work time plus thesize & complexity of the repair.Remove the cartridge, mixing tip & locking nut from outer packaging & load thecartridge into the dispensing gun.Holding the gun & cartridge vertically up, remove the “break off tip” located at the topof the cartridge using either a set of pliers or similar equipment.Squeeze out a small amount of both parts A + B onto a piece of cloth & discard.Attach the mixing tip using the locking nut. If required, cut mixing tip to the desireddiameter or angle.Dispense a small bead of product through the tip (approx 5cm / 2``) & discard - theproduct is now correctly equalised & ready for use.Apply adhesive to one of the surfaces to be bonded working quickly to align the workpieces.Hold or clamp the work pieces during cure.If sanding or over coating is required, refer to the information below for de-clamping,sanding & over painting time.Please Note: Stronghold’s range of adhesives may be over coated with most modernpaint systems.Issue 3/2007

<strong>STRONGHOLD</strong> <strong>902</strong>ApplicationsWork Time/Open TimeDe-Clamping Sanding& Over-Painting TimeOptimum Cure TimeProduct Code<strong>STRONGHOLD</strong> <strong>902</strong> is suitable for use on the following substrates:Ferrous Metals & AluminiumZinc & Galvanised MetalGRP/SMC/Thermoset CompositesRigid ThermoplasticsWood5 Minutes20 Minutes4 HoursAny remaining adhesive in the cartridge can be stored in a cool dry place with the mixingtip on. To re-use, remove and discard the old mixing tip and repeat the adhesivepreparation instructions as described above.Product Code50ML Cartridge200ML Catridge- SH<strong>902</strong>1 (UP<strong>902</strong>1)- SH<strong>902</strong>2 (UP<strong>902</strong>2)Disclaimer & Warranty:The results of tests carried out by us, are provided in good faith and are considered to be accurate. Recommendations for useof U-POL products, whether given by us in writing, verbally, or implied from test results are made upon the condition that theBuyer shall remain responsible for satisfying himself that the products as supplied by U-POL are suitable for his particular use.The intended purpose, application or processing of U-POL products are beyond our control, we cannot therefore acceptresponsibility for subsequent performance. We warrant that U-POL products are free from defects in accordance with andsubject to our general conditions of supply.Health & Safety Statement:FOR PROFESSIONAL USE ONLY. Read full instructions before use.IMPORTANT: This product contains hazardous materials and therefore appropriate personal protective equipment shouldalways be used. Please refer to the label and consult the material safety data sheet for full handling instructions and personalprotection information. These are available via your local stockist or via the U-POL website at WWW.U-POL.COM.U-POL disclaim any liability where the user does not wear the recommended personal protective equipment.U-POL, 1 TOTTERIDGE LANE, WHETSTONE, LONDON, N20 0EY, UKHome Sales T: +44(0)870 899 8200; F:+44(0)870 899 8211; E: sales@u-pol.com;Export Sales T: +44(0)870 899 8200; F:+44(0)870 899 8299; E: exportsales@u-pol.com;Technical T: +44(0)870 899 8310; F:+44(0)870 899 8351; E: technicaldepartment@u-pol.com;WEBSITE: WWW.U-POL.COMIssue 3/2007