Process aids for the Chemical Industry. - Industrial Lubricants ...

Process aids for the Chemical Industry. - Industrial Lubricants ...

Process aids for the Chemical Industry. - Industrial Lubricants ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

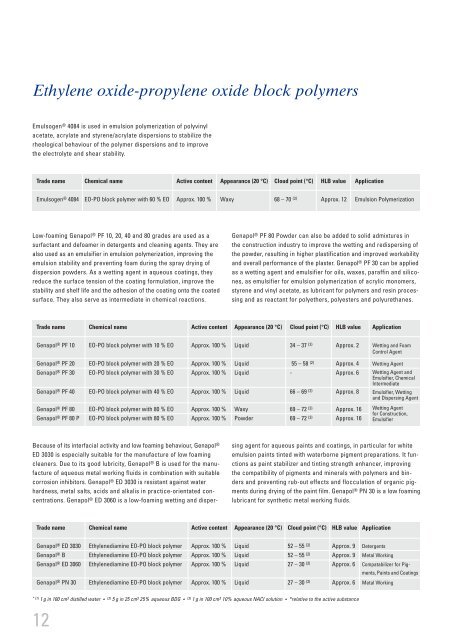

Ethylene oxide-propylene oxide block polymers<br />

Emulsogen ® 4084 is used in emulsion polymerization of polyvinyl<br />

acetate, acrylate and styrene/acrylate dispersions to stabilize <strong>the</strong><br />

rheological behaviour of <strong>the</strong> polymer dispersions and to improve<br />

<strong>the</strong> electrolyte and shear stability.<br />

Trade name <strong>Chemical</strong> name Active content Appearance (20 °C) Cloud point (°C) HLB value Application<br />

Emulsogen ® 4084 EO-PO block polymer with 60 % EO Approx. 100 % Waxy 68 – 70 (3) Approx. 12 Emulsion Polymerization<br />

Low-foaming Genapol ® PF 10, 20, 40 and 80 grades are used as a<br />

surfactant and defoamer in detergents and cleaning agents. They are<br />

also used as an emulsifier in emulsion polymerization, improving <strong>the</strong><br />

emulsion stability and preventing foam during <strong>the</strong> spray drying of<br />

dispersion powders. As a wetting agent in aqueous coatings, <strong>the</strong>y<br />

reduce <strong>the</strong> surface tension of <strong>the</strong> coating <strong>for</strong>mulation, improve <strong>the</strong><br />

stability and shelf life and <strong>the</strong> adhesion of <strong>the</strong> coating onto <strong>the</strong> coated<br />

surface. They also serve as intermediate in chemical reactions.<br />

Trade name <strong>Chemical</strong> name Active content Appearance (20 °C) Cloud point (°C) HLB value Application<br />

Genapol ® PF 10 EO-PO block polymer with 10 % EO Approx. 100 % Liquid 34 – 37 (2) Approx. 2<br />

Genapol ® PF 20 EO-PO block polymer with 20 % EO Approx. 100 % Liquid 55 – 58 (2) Approx. 4 Wetting Agent<br />

Genapol ® PF 30 EO-PO block polymer with 30 % EO Approx. 100 % Liquid - Approx. 6<br />

Genapol ® PF 40 EO-PO block polymer with 40 % EO Approx. 100 % Liquid 66 – 69 (2) Approx. 8<br />

Genapol ® PF 80 EO-PO block polymer with 80 % EO Approx. 100 % Waxy 69 – 72 (3) Genapol<br />

Approx. 16<br />

® PF 80 P EO-PO block polymer with 80 % EO Approx. 100 % Powder 69 – 72 (3) Wetting and Foam<br />

Control Agent<br />

Wetting Agent and<br />

Emulsifier, <strong>Chemical</strong><br />

Intermediate<br />

Emulsifier, Wetting<br />

and Dispersing Agent<br />

Approx. 16<br />

Wetting Agent<br />

<strong>for</strong> Construction,<br />

Emulsifier<br />

Because of its interfacial activity and low foaming behaviour, Genapol ®<br />

ED 3030 is especially suitable <strong>for</strong> <strong>the</strong> manufacture of low foaming<br />

cleaners. Due to its good lubricity, Genapol ® B is used <strong>for</strong> <strong>the</strong> manufacture<br />

of aqueous metal working fluids in combination with suitable<br />

corrosion inhibitors. Genapol ® ED 3030 is resistant against water<br />

hardness, metal salts, acids and alkalis in practice-orientated concentrations.<br />

Genapol ® ED 3060 is a low-foaming wetting and disper-<br />

Trade name <strong>Chemical</strong> name Active content Appearance (20 °C) Cloud point (°C) HLB value Application<br />

Genapol ® ED 3030 Ethylenediamine EO-PO block polymer Approx. 100 % Liquid 52 – 55 (2) Approx. 9 Detergents<br />

Genapol ® B Ethylenediamine EO-PO block polymer Approx. 100 % Liquid 52 – 55 (2) Approx. 9 Metal Working<br />

Genapol ® ED 3060 Ethylenediamine EO-PO block polymer Approx. 100 % Liquid 27 – 30 (2) Approx. 6<br />

Genapol ® PN 30 Ethylenediamine EO-PO block polymer Approx. 100 % Liquid 27 – 30 (2) Compatabilizer <strong>for</strong> Pig -<br />

ments, Paints and Coatings<br />

Approx. 6 Metal Working<br />

12<br />

Genapol ® PF 80 Powder can also be added to solid admixtures in<br />

<strong>the</strong> construction industry to improve <strong>the</strong> wetting and redispersing of<br />

<strong>the</strong> powder, resulting in higher plastification and improved workability<br />

and overall per<strong>for</strong>mance of <strong>the</strong> plaster. Genapol ® PF 30 can be applied<br />

as a wetting agent and emulsifier <strong>for</strong> oils, waxes, paraffin and silicones,<br />

as emulsifier <strong>for</strong> emulsion polymerization of acrylic monomers,<br />

styrene and vinyl acetate, as lubricant <strong>for</strong> polymers and resin processing<br />

and as reactant <strong>for</strong> polye<strong>the</strong>rs, polyesters and polyurethanes.<br />

sing agent <strong>for</strong> aqueous paints and coatings, in particular <strong>for</strong> white<br />

emulsion paints tinted with waterborne pigment preparations. It functions<br />

as paint stabilizer and tinting strength enhancer, improving<br />

<strong>the</strong> compatibility of pigments and minerals with polymers and binders<br />

and preventing rub-out effects and flocculation of organic pigments<br />

during drying of <strong>the</strong> paint film. Genapol ® PN 30 is a low foaming<br />

lubricant <strong>for</strong> syn<strong>the</strong>tic metal working fluids.<br />

* (1) 1 g in 100 cm 3 distilled water (2) 5g in 25cm 3 25% aqueous BDG (3) 1 g in 100 cm 3 10% aqueous NACI solution *relative to <strong>the</strong> active substance