DC Potential Drop Crack Monitor Software

DC Potential Drop Crack Monitor Software

DC Potential Drop Crack Monitor Software

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>DC</strong> <strong>Potential</strong> <strong>Drop</strong> <strong>Crack</strong> <strong>Monitor</strong> <strong>Software</strong><br />

For MTS TestStar and FlexTest Controllers<br />

Benefits<br />

Automated Testing<br />

� Allows you to automate your<br />

fatigue or creep crack growth<br />

testing on a wide variety of<br />

specimens.<br />

More Convenience<br />

� Works with other standard MTS<br />

products to accelerate your<br />

learning curve.<br />

More Versatility<br />

� In conjunction with TestWare ®—<br />

SX or MultiPurpose TestWare<br />

applications*, MTS <strong>DC</strong>PD CM<br />

allows you to run spectrum<br />

fatigue crack growth, creepfatigue<br />

crack growth, or fatigue<br />

crack growth with overloads.<br />

Faster, Repeatable Test Setup<br />

� <strong>Monitor</strong> Settings can be stored<br />

and retrieved allowing setups to<br />

be reused for different specimens.<br />

* MTS <strong>DC</strong>PD CM is typically used with<br />

TestWare SX or MTS Fatigue <strong>Crack</strong> Growth<br />

application SW on the TestStar II platform,<br />

or Multipurpose Test Ware or MTS Fatigue<br />

<strong>Crack</strong> Growth application on the TestStar IIs/<br />

IIm/FlexTest SE & GT platform.<br />

MTS <strong>DC</strong> <strong>Potential</strong> <strong>Drop</strong> <strong>Crack</strong> Length<br />

<strong>Monitor</strong> (<strong>DC</strong>PD CM) application software<br />

calculates crack length on a loaded specimen<br />

using the reversing <strong>DC</strong> potential drop<br />

method. <strong>Monitor</strong>ing load and potential<br />

(voltage) data from both a loaded and reference<br />

specimen, it calculates crack length<br />

by calculating ratios of potential on both<br />

the reference and loaded specimen. The<br />

current is switched on and off, or reversed,<br />

to correct for thermal couple effects. An<br />

appropriate calibration equation is then<br />

applied to the ratios resulting in the specimen<br />

crack length. The calculated crack<br />

length is provided to other application<br />

programs and any external data acquisition<br />

devices that can read a high level (0-10<br />

Volt) analog output. Using other programs<br />

on MTS digital control platforms, you can<br />

periodically store the crack length data to<br />

disk for further analysis.<br />

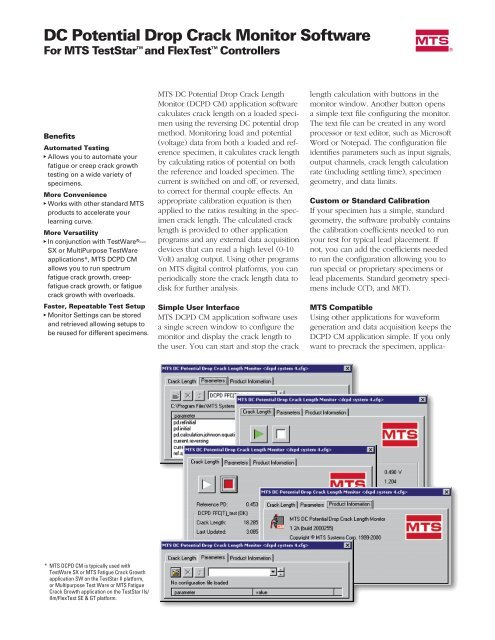

Simple User Interface<br />

MTS <strong>DC</strong>PD CM application software uses<br />

a single screen window to configure the<br />

monitor and display the crack length to<br />

the user. You can start and stop the crack<br />

m<br />

length calculation with buttons in the<br />

monitor window. Another button opens<br />

a simple text file configuring the monitor.<br />

The text file can be created in any word<br />

processor or text editor, such as Microsoft<br />

Word or Notepad. The configuration file<br />

identifies parameters such as input signals,<br />

output channels, crack length calculation<br />

rate (including settling time), specimen<br />

geometry, and data limits.<br />

Custom or Standard Calibration<br />

If your specimen has a simple, standard<br />

geometry, the software probably contains<br />

the calibration coefficients needed to run<br />

your test for typical lead placement. If<br />

not, you can add the coefficients needed<br />

to run the configuration allowing you to<br />

run special or proprietary specimens or<br />

lead placements. Standard geometry specimens<br />

include C(T), and M(T).<br />

MTS Compatible<br />

Using other applications for waveform<br />

generation and data acquisition keeps the<br />

<strong>DC</strong>PD CM application simple. If you only<br />

want to precrack the specimen, applica-

Accessories<br />

Cables for TestStar II<br />

� Powered switching cable for<br />

older Fracture Technology<br />

Associates hardware<br />

� Un-powered switching cable<br />

(used with newer Fracture Technology<br />

Associates hardware)<br />

� Analog input cables, BNC<br />

connectors<br />

Cables for TestStar IIs<br />

� Powered switching cable for<br />

older Fracture Technology<br />

Associates hardware<br />

� Un-powered switching cable<br />

(used with newer Fracture Technology<br />

Associates hardware)<br />

� Analog input cables, BNC<br />

connectors<br />

� MTS Model 793.45 A/D daughter<br />

card (required)<br />

Cables for TestStar IIm/<br />

FlexTest GT<br />

� Powered switching cable for<br />

older Fracture Technology<br />

Associates hardware<br />

� Un-powered switching cable<br />

(used with newer Fracture Technology<br />

Associates hardware)<br />

� Analog input cables, BNC<br />

connectors<br />

� MTS Model 793.45 A/D daughter<br />

card (required)<br />

� MTS Model 793.46 D/A daughter<br />

card (required for full functionality)<br />

� MTS 793 Digital I/O (required for<br />

full functionality)<br />

Cables for FlexTest SE<br />

� Power or unpowerd switching<br />

cable<br />

� Analog input cables, BNC<br />

connectors<br />

� MTS Model 793.45 A/D daughter<br />

card (required)<br />

Suggested <strong>DC</strong>PD Electronics<br />

� Fracture System Research <strong>DC</strong>PD<br />

electronics including<br />

• Model PD 510 current amplifier<br />

• Model PD 502 Dual PD Amplifier<br />

• Modified Tektronix TM506A<br />

chassis<br />

MTS Systems Corporation<br />

14000 Technology Drive<br />

Eden Prairie, MN 55344-2290 USA<br />

Toll Free: 800·944·1687<br />

Phone: 952·937·4555<br />

Fax: 952·937·4515<br />

E-mail: info@mts.com<br />

www.mts.com<br />

ISO 9001:2000 CERTIFIED QMS<br />

tions such as MTS Function Generator or<br />

Station Exerciser provide simple waveforms.<br />

The control platform’s limit detectors<br />

can be used to detect a specified crack<br />

length and shut down waveform generation.<br />

For more complicated waveforms, generalpurpose<br />

applications like MTS TestWare-<br />

SX or MultiPurpose TestWare must be used.<br />

General-purpose applications can provide<br />

complicated wave shapes including hold<br />

times, overloads, and spectrum file playback.<br />

These applications can also be used<br />

to store data, including crack lengths, to<br />

disk at various crack length increments or<br />

time intervals. You can analyze this crack<br />

length data after the test using Microsoft<br />

Excel or other standard analysis tools.<br />

Use MTS or Existing Hardware<br />

MTS <strong>DC</strong>PD CM allows you to continue to<br />

use any <strong>DC</strong> potential drop equipment you<br />

already have in your lab. You can configure<br />

the <strong>DC</strong>PD in a variety of ways to take<br />

advantage of your previous investment.<br />

For labs with an existing “black box” <strong>DC</strong><br />

potential drop measurement system, thermally<br />

corrected potentials can be presented<br />

to the <strong>DC</strong>PD CM and a crack length will<br />

be calculated. In this instance, the <strong>DC</strong>PD<br />

CM will not switch the current. For labs<br />

that do not use reference potentials, the<br />

<strong>DC</strong>PD CM can be configured to calculate<br />

an appropriate crack length with no corrections<br />

for possible current drift or mate-<br />

m<br />

rial resistance. The <strong>DC</strong>PD CM software can<br />

also be configured to work on systems with<br />

long settling times or systems requiring digital<br />

filtering or averaging.<br />

Simultaneous Multiple<br />

Specimen <strong>Monitor</strong>ing<br />

Because MTS <strong>DC</strong>PD CM runs on Windows<br />

NT, Windows 2000, and Windows XP multiple<br />

copies of the application can be run<br />

to monitor the crack length of multiple<br />

specimens in the load train. This allows<br />

you to increase your testing efficiency<br />

by running multiple load-controlled specimens<br />

at once.<br />

The <strong>DC</strong> <strong>Potential</strong> <strong>Drop</strong> <strong>Crack</strong> Length<br />

<strong>Monitor</strong> application program provides a<br />

simple method to calculate, acquire and<br />

make decisions during your test using<br />

crack length data calculated using the<br />

reversing <strong>DC</strong> potential drop method.<br />

Availability<br />

MTS <strong>DC</strong>PD CM is an optional application<br />

available on new MTS FlexTest SE and<br />

FlexTest GT controllers. It is also available<br />

as an add-on feature for existing TestStar<br />

and FlexTest controllers on Windows NT,<br />

Windows 2000, or Windows XP.<br />

Requirements<br />

The TestStar IIs/IIm/FlexTest SE & GT<br />

version of the <strong>DC</strong>PD CM application<br />

requires the 793.45 6-channel A/D option.<br />

The TestStar IIm/FlexTest GT version also<br />

requires the 793.46 6-channel D/A option<br />

for full functionality. The Model 793 version<br />

of <strong>DC</strong>PD CM requires system software<br />

793.00 V3.2 or greater. The Model<br />

790 version of <strong>DC</strong>PD CM requires system<br />

software 790.00 V4.0D or greater. All versions<br />

require some simple cables, and<br />

<strong>DC</strong>PD electronics.<br />

For More Information<br />

Contact your local MTS sales engineer for<br />

more information on MTS CCM software.<br />

Or, e-mail us (info@mts.com) Visit MTS<br />

on the web at www.mts.com<br />

Specifications subject to change without notice.<br />

MTS and TestWare are registered trademarks and<br />

TestStar and FlexTest are trademarks of MTS<br />

Systems Corporation. RTM No. 211177. Microsoft,<br />

Microsoft Word, Windows NT, and Windows 2000<br />

and are trademarks of Microsoft Corporation.<br />

© 2004 MTS Systems Corporation.<br />

100-056-971a <strong>DC</strong><strong>Potential</strong> Printed in U.S.A. 5/04