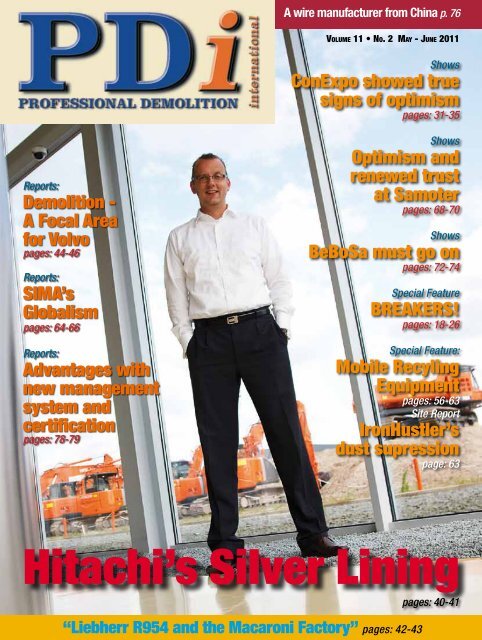

Hitachi's Silver Lining - Pdworld.com

Hitachi's Silver Lining - Pdworld.com

Hitachi's Silver Lining - Pdworld.com

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

FRD-HYDRAULIC BREAKERS ANDDEMOLITION ATTACHMENTSIn cooperation with the Technical University of Tokyo, FRD could tremendously reduce the new breakers noiselevels. A <strong>com</strong>plete new development of impact mechanism minimizes the discharge of vibration to the excavator,as well reduces the operators vibration stress drastically. In relation with this new developed breaker body,the fully closed frame with rubber plugged service points and a new worldwide patented rod arrangement,gives a considerable reduction in noise levels of 7db. Because of FRD optimized the applied materials with anew hardness process, a higher efficiency at same operation weight is guaranteed.DURABLE AND RELIABLENEW FX-LINEHigh PowerReduced VibrationReduced NoiselevelReduced MaintenanceFor each job, the right toolFurukawa Rock Drill Europe BVProostwetering 29, 3543 AB Utrecht, The NetherlandsPhone +31-(0)30-2412277, Fax +31-(0)30-2412305www.frd.eu, frd@frd.euXS XTRA SILENCEPATENTED ROD ARRANGEMENTC CO S

“One step forwardand two steps back”Dear ColleaguesSummer has finally arrived after another difficult winter that caused additional problemsfor an already suffering construction economy in many markets. But in Europe thepicture is quite mixed. Some countries are doing very well, some are picking up whilea few others have reach the bottom, but not yet seen signs of recovery. But still andoverall it is a little bit like “one step forward and two steps back”.The Iberian Peninsula is a good example of this situation. But in this case weare not talking about any steps forward yet. But Spain is believed to have reached thebottom, even though some say that the real estate prices need to go down a bit furtherfor Spain really to start to turn. Spanish manufacturers are struggling to find new waysof making money. And they are good at it, good at adapting and creating new productconcepts that are very beneficial to their customers. A very good example is the Andalusiabased <strong>com</strong>pany Sima in Granada, which I visited in March this year. There is moreinformation about Sima on pages 64-66 in this issue.This issue of PDi is full of news for demolition and recycling contractors. Thereare two interesting special features, one about new hydraulic breakers and another onnew mobile recycling equipment. We are also publishing details of new and interestinghigh reach demolition excavators.This spring has been very hectic and interesting with many changes and events.In Europe we have seen a clear recovery in many markets and others show signs ofpicking up, such as the UK. The situation is perhaps not <strong>com</strong>pletely satisfactory, butit is going in the right direction. Also in the US the recent ConExpo event showed aclear optimism in the US market.PDi was at ConExpo as well as the Samoter show in Verona and the Germanconcrete sawing and drilling show BeBoSa. In this issue we are publishing reports fromall of these shows. We also attended the IACDS annual meeting, which was held inBruges and the European Demolition Association’s convention in London. These weretwo very interesting events, providing a lot of news and details of these meetings willbe featured in detail in the next issue of PDi.At the IACDS meeting in Bruges Jose Blanco from Spain was elected new Presidentof IACDS. I would like to take the opportunity to wel<strong>com</strong>e this young, vibrant andvery efficient man to head the IACDS. I also thank the past IACDS President PeterWhite for his great work during the two periods he was the President. Peter has anenormous experience of the industry with more then 50 years working with concretesawing and drilling and he has also a fresh and inspiring wind for this industry. I canpromise you will see more of Peter in this magazine.At the IACDS meeting it was also decided that next year’s IACDS meeting willbe held in conjunction with the CSDA meeting in Hawaii. For those who would liketo join tickets need to be reserved to get to the island of Maui.I would also like to inform you that PDi has employed an additional editor inPetra Linderoth. Petra will mainly workwith our rental magazine, but also supportthe editorial work on PDi. See 16 formore details. And last I would like to wishyou all a wonderful summer with a goodmix of work and relaxation; somethingwe all need.Words from the new IACDS President“From White to Blanco”It is just a coincidence, but up to thismeeting of IACDS the president of theInternational Associations of ConcreteDrillers and Sawers was Peter White, andit is now my turn, Jose Blanco, to leadthis wonderful group of professionals.The funny part is that in Spanish Whitemeans Blanco, as the English translationfor Blanco is White.Allow me to have my very firstwords on this column to acknowledgethe work of Peter White, not just asPresident of IACDS for the past twoyears, but mainly for the work done onhis <strong>com</strong>pany (D-Drill) as a sawing anddrilling specialist, and also as President ofthe UK Sawing and Drilling association.Peter is a true man of this industry. Oneday he decided to be<strong>com</strong>e an employer,instead of being an employee working forthe electricity business; he started his own<strong>com</strong>pany on a new field: cutting concretewith diamond tools. Peter did well anddespite the difficulties on the constructionindustry (where is never easy to workas a specialist contractor) he managed toget on. Today his daughter, Julie, runsthe <strong>com</strong>pany D-Drill and Peter takescare of other business (helping out withthe national association, playing golf,…).Well done Peter. You deserve tobe on IACDS “hall of fame”, togetherwith other well-known professionals ofthis industry: Otto Alte-Teigeler, HorstWapler, Kaspar Disch,… and many others.If you look at the picture illustratingthis column you may find Peter lettinggo his duty as President, and telling thenew guys to take good care of it. Fromleft to right, you may find NorikazuShibuya, IACDS Vice president, myself,Jose Blanco, now assuming the role ofIACDS president, Peter White, IACDSpast president, and Lars Sandstrom,IACDS Vice president.When Jan Hermansson(editor of PDi) asked me fora picture for this first column, I reallywanted to emphasize that IACDS is bothinternational and team oriented.It is also interesting to note thatPeter is the only contractor on the picture.Mr. Shibuya runs a manufacturer<strong>com</strong>pany in Japan, well known for theirmachines for the sawing and drilling industry.Mr. Sandstrom runs the SwedishSawing and Drilling association, as generalmanager. And myself, Jose Blanco, Iwork with enterprise associations relatedwith the construction industry. It is asgeneral manager of the Spanish Sawingand Drilling association, AEDT, that Iwas called to be<strong>com</strong>e the new presidentof IACDS.AEDT is a very young association,created on 2006. It became a realitythanks to the support of the IACDS. Justso you know, the Presidency of IACDSchanges every two years, and before Spain,it was held by the United Kingdom, andtwo years before by the United States ofAmerica. But the Spanish Association isnot the newest member; this honor goesto SNED-SCBD, the French Associationof the Demolition Industry (SyndicatNational des Entreprises de Démolition).In this very unique case this association(SNED) represents together the demolition<strong>com</strong>panies (manual, mechanical,explosives,…), the diamond experts (sawingand drilling) and the asbestos removalspecialists. SNED became a member ofIACDS on our last meeting in Brugge,Belgium. Our meeting was held in May7th with a very good attendance fromdifferent continents (Asia, Europe andAmericas). On top of our market reports,networking and other activities, we hadtwo guest speakers to talk about grooving:Philip Zuzelo, from Cardinal Grooving(USA), and John Willis, from Tyrolit UK.Thanks to their presentations wehad the chance to get into more detailsof this specific technique, grooving, usedon airports, highways and other surfaces,for better friction and noise reduction.Next year, 2012, we will have ourannual convention with the CSDA,the Concrete Sawing and Drilling Association(USA), celebrating their 40thanniversary.And the meeting will be in: Hawaii!!Ok, let’s face it! Hawaii is a bit farfor most of us. But think about it: internationalconvention, concrete cutting,and Hawaii. Are you going to miss it?Best regardsJose BlancoPresident IACDSJan HermanssonEditor-in-Chiefjan.hermansson@pdworld.<strong>com</strong>6 PDi • Issue 2 • May - June 2011

Words from the past IACDS President“Thank You Friends!”We had our International Associationof Concrete Drillers and Sawers annualgeneral meeting on 7 May, 2011 inBruges, Belgium and on the Friday wewere all wel<strong>com</strong>ed by Mrs H Decleer acity councillor of Bruges at the city hallin their 800 year old council chamberand then treated to a tour of city hall.We were given an overwhelming wel<strong>com</strong>eto the city.At the meeting there were 14countries represented from all aroundthe world. We also wel<strong>com</strong>ed newmembers from France Mr M. Hiblotand Mr F. David representing SCDS/SNED.There were some important subjectsdiscussed besides minutes of lastmeeting accounts for the year andbudgets for next year namely additionsto the world tolerances for drilling andsawing with the hard work being put inby the association in Germany, Austria,Switzerland and the Netherlands withthe draft to be finalised by 13 May,2011. We also done a market update oncountries around the world which canbe obtained from the IACDS website.www.iacds.org.We did have reports from theEuropean Demolition Association andfrom Federation of European Producersof Abrasives for more co-operationsbetween the three Associations, whichcan only improve relationships betweenthe various industries.Mr A Kossolapov from Russiais going to create a concrete drillingand sawing expressions directory i.e.a list of various words or sayings inour industry translated into otherlanguages. He has also done a paperon promotion of concrete drilling andsawing for planners and for the trainingof people in universities and colleges.This is budgeted to go ahead in thenext couple of years. He is also goingto produce a book about all aspect ofdrilling and sawing which is in Russianat the moment and to be translated inEnglish for worldwide distribution inconjunction with the IACDS.New activities include gettingemployees to be aware of internationalexchange scheme.Also raised was the argumentabout standardization of connectingtools and whetherIACDS should supportmanufactures or contractors.We had two excellentspeakers one beingMr Phillip Zuzelo ofCardinal Grooving ofthe USA on importancegrooving on run- ways8 PDi • Issue 2 • May - June 2011at airports which helps grip on landingwhich stops aqua planning which is<strong>com</strong>pulsory in the US but not the restof the world and a new grooving method;Utilization of trapezoidal shapedgrooves. Further information contacthim at www.cardinalgrooving.<strong>com</strong>.Our other speaker was Mr JohnWillis of Tyrolit UK on a new methodof diamond grinding of concrete roadsto increase their life span. Contact himat www.tyrolit.<strong>com</strong>.IACDS diamond awards congratulationsto the three winners Gold AwardTondin S.r.l Italy <strong>Silver</strong> award Thayr S.LSpain Bronze award D-Drill England.The next awards will be presented atBauma 2013 so contractors need to gettheir entries ready for submission byOctober 2012 for contracts <strong>com</strong>pletedfrom now to October2012.The IACDS intends to hold aseminar in the similar lines as we did inthe 2010 at Bauma 2013 topics to befinalised nearer the date.I as the outgoing president wouldlike to thank the following people Annaand Daniel Trachsel for their hard workas secretary and of running the internationalassociation, and the two speakersfor the excellent talk and last of all thedelegates and international memberswho attended.It was a shame that our HonoraryPresident Mr Otto Alte-Telglercould not attend due unforeseen healthreasons.Last thing I would like to say iswel<strong>com</strong>e to the new president MrJose Blanco and I hope he has a goodpresidency as I have had.Best regardsPeter WhiteOutgoingPresident IACDSBrokk delivers robots toFukushima in JapanBrokk is delivering robots to Fukushima nuclearplant in Japan. The first task for the machines isto provide access to highly contaminated areasand clean up contamination. “One key differencebetween Brokk’s demolition robots and otherrobots currently on site is that our machines arecapable of carrying out multiple different andtougher tasks, such as tearing down concretestructures and take care of heavier contaminatedmaterials” says Brokk CEO Martin Krupicka.The first contact with Brokk and its Japanesepartner BGE Company Ltd was taken soon afterthe accident at Fukushima, as Brokk demolitionrobots are known globally for de<strong>com</strong>missioningand material handling in radioactive environments.Brokk has since then had staff in place in Japan tobetter understand the situation and the challengesin detail. The first Brokk machine, delivered inmiddle of April, will be used to get inside one ofthe most damaged reactors. The last month hasbeen a very intense time for Brokk’s staff and itssubcontractors in order to be able to deliver themachines in a very short period of time. With theongoing crisis at Fukushima, every day saved hasbeen of high value. Brokk staff is currently presentin Japan to provide training on the machines andtheir capabilities to the local operators.Brokk has successfully delivered robots fordemolition, de<strong>com</strong>missioning and disposal ofradioactive material to the nuclear industry forover twenty years, including to the USA, France,Great Britain, Russia and Japan. Brokk machineshave for example been used for de<strong>com</strong>missioningand cleanup at Chernobyl in Ukraine. “Brokkwas chosen for this extremely challenging workby Taisei Corp, which works for TEPCO at Fukushima,because of our extensive experience in thenuclear industry. Today we have over two hundredmachines at various nuclear sites worldwide”, saysMike Evans, Head of Nuclear at Brokk.Brokk has proven and tested products andsolutions after having delivered more than 5,000demolition robots worldwide for the past 30 years.The Brokk machines can also be equipped with avariety of tools, making them the real multipurposemachines.A second shipment of three Brokk machinestook place using a specially chartered flight fromLuleå Airport in northern Sweden. These machineswere all designed and modified to handle theextreme situation and the high radiation at theFukushima site. Among other things, the machineswill be operated from a control room located asfar as one kilometre fom the reactors. Currently,the machines are expected to be working onsiteat Fukushima within the next few weeks.Some of the Brokk staff. A trained eyewill recognize that there is somethingdifferent with this picture. Pictureabove, Brokk CEO Martin Krupicka.

We get yourbusiness going.The separation and movement of inert materials arestrategic activities on every worksite.The PMG series grabbers can be used for demolishingmedium consistency structures and buildings and forthe targeted selection of all the resultant materials forenvironmental cleanup. Flexible, robust and reliable, theymove your work up another gear.From Trevi Benne, your reliable partner.Certified CompanyCert. N° 501005936Trevi Benne s.p.a.Tel. +39 0444 760773info@trevibenne.itwww.trevibenne.itLICENSE TO DEMOLISHTVB_PDI_aprile.indd 1 15-02-2011 14:54:44

Words from O’BrienProactiveLeadershipOne of the key responsibilities for an associationexecutive is to constantly stayinformed about the state of the industryand the future opportunities and to keepmembers informed so that their businessescan survive and thrive. As executivedirector of CSDA, I am involved in a numberof industry association meetings thatprovide a broad outlook for the industry.Many of these meetings over the yearshave resulted in changes for CSDA whichhas made the association stronger andbetter positioned to serve member needs.The most recent of these meetingswas the Concrete and Masonry RelatedAssociations (CAMRA) annual meeting.CAMRA membership includes CSDA and35 leading concrete and masonry associationsin North America such as AmericanConcrete Institute, National ReadyMixed Concrete Association and thePortland Cement Association. Key topicsfor discussion from this meeting includedaddressing increased regulations fromthe US Environmental Protection Agency,coordination of certification programsand promoting the inherent safety ofconcrete and masonry structures that cansave lives in the face of severe weatherevents that have taken so many lives inrecent events. CAMRA is coordinatingand leveraging its collective strengthsto benefit all members.The International Association ofConcrete Drillers & Sawers (IACDS) annualmeeting in Belgium continued itsmission to provide international cooperationof trade associations to supportthe development of professional sawingand drilling contracting. This umbrellaspecial surveyorganization of sawing and drilling associations,formed in 1995, includesassociations from Australia, Austria,France, Germany, Japan, Spain, Sweden,Switzerland, the United Kingdom andthe United States. IACDS sponsors theDiamond Award <strong>com</strong>petition to educatethe industry on the benefits sawing anddrilling offers the construction industry.The January award ceremony was madeduring the World of Concrete in Las Vegas.IACDS also conducted a one-day series oftechnical seminars at Bauma in supportof its mission.CSDA is also active and helped startthe Small Association Group Executives(SAGE) which recently met during theWorld of Concrete Cosponsor meeting inLas Vegas. SAGE membership includessmaller associations and addressesissues of <strong>com</strong>mon urgency. A majorfocus of this group will be to collectivelypromote individual association certificationefforts through joint print advertising,websites and at trade shows. The formationof a Concrete Industry CertificationGroup is in the planning stages to promotecertification to specifiers.Through our involvement in theseand other groups, CSDA is proactivelylooking to protect the current interestsof sawing and drilling contractors whilealso exploring the long term directionand opportunities for the industry.SPE Group investsin the futureThe SPE Group in the UK has recently <strong>com</strong>pleteda further extension to their head office in Lincoln.The 350m 2 purpose built facility represents a£250,000 investment in the existing site toensure the <strong>com</strong>pany remains in a strong positionas the economy begins to improve. The new buildprovides additional storage for machinery, fabricated<strong>com</strong>ponents and a dedicated practical area.The official opening ceremony for the WackerNeuson used equipment centre in Gotha washosted on 6-7 April 2011. “We got off to a greatstart,” says Head of Wacker Neuson Used Ralph-Jörg Gruber. “Our first-ever equipment auctionproved a particular hit with visitors.” Fritz Huber,a leading name in the industrial auctioneeringbusiness, held the auction. Prospective buyershad the opportunity of viewing the items forauction online before the event. A wide rangeof machines went under the hammer, includinginternal vibrators, pumps, rammers, plates and<strong>com</strong>pact equipment weighing up to 15 tons.With its central location and excellenthighway connections, the Wacker Neuson usedequipment centre is easy to reach. SpanningThis facility will be used for new equipmentdemonstrations and for practical modules as partof a number of training courses. A decorativefloor surface was required for equipment displaypurposes and the <strong>com</strong>pany opted for Resdev’sPumazzo TZ epoxy terrazzo in mid grey. Theconcrete subfloor was shot blasted using anSPE9ES Autoblast Machine, primed and materialapplied in a two day period. The terrazzowas then finished using the DFG700 planetarygrinding system working through metal gradeddiamond tools to a 100grit resin tool. Edgeworkwas also prepared and finished using SPE’s rangeof hand tools and diamond products. The areawas then grouted, reground with 100grit toolsand then sealed with Pumadur DD Gloss Clear.The main walkways were again preparedusing dust free shot blasting, primed and Resdev’sPumadur RT Polyurethane system applied. The<strong>com</strong>bination of steel, concrete and screededpractical demonstration pads, together with astunning decorative display and viewing areas,have provided the <strong>com</strong>pany with a state of artfacility for use by visitors from around the world.www.spe-int.<strong>com</strong>Wacker Neuson opensused equipment centre16,000 m 2 , it provides an ideal platform for thesale of used light and <strong>com</strong>pact equipment. Thecentre also offers used <strong>com</strong>petitor models from<strong>com</strong>parable segments. The centre’s website, isthe hub of its sales concept and all products canbe viewed online at www.used.wackerneuson.<strong>com</strong>.Best regardsPatrick O’BrienExecutive Director CSDA,US Concrete Sawing& Drilling Association10 PDi • Issue 2 • May - June 2011

EDAWords fromthe EDA President“Three valubledays in London”Recently, the European Demolition Association(EDA) celebrated its annual SpringConference. This time, the event was heldin London, being always a very interestingvenue for its perfect <strong>com</strong>munications andother facilities but specially now as thecity is getting ready for the 2012 OlympicGames.During these three days, we wereable to attend to a very professional and<strong>com</strong>plete program, which we hope wasinteresting for our associates and alsothe whole industry, as we think it has. AsPresident of the association, I would liketo thank all the people who have helpedEDA, in one way or another, to make thisConference succeed. Of course, much ofthe responsibility for the quality of theevent falls on the speakers, whom wewould like to thank very much.Mr. Howard Button, NFDC GeneralManager, shared very detailed informationabout how NFDC is preparing the HighReach training. Just after Mr. Button, wecould listen to Mr. Steve Jack, MAGNOXD&D Programme Manager, who gave ussome interesting clues about an interestingmarket with lots of possibilities: PowerStation Demolition.Mr. Iñigo Vegas came from Spain tospeak about the IRCOW Project, relatedto Innovative Strategies for High-gradematerial recovery C&D and waste.Ms. Katherine Adams, BRE PrincipalConsultant, shared some experiences onwaste management, focusing on the actualsituation and what shall it be in the future.Mr. Steve Bleninsop, Pre-constructionManager at ERITH, showed a urban demolitionproject in a crowded area, downtownLondon.Coming from France, Mr. Daniel Riebergave a presentation about the updatedFerrari demolition technique, using jacking,showing us the process and includingvery illustrative examples with photosand videos.Mr. David Sinclair, EDA Past President,associated with SAFEDEM Limited and alsoMember of NFDC spoke about the history ofEDA, how the association was created andhow these years of history are also a pathto success of many entrepreneurs. It wasa very interesting speech for many of theyoung faces attending the EDA conference.Specially invited to this event, directlyfrom the USA, we had the opportunity tohear Mr. Tom Stahr, ROBINETTE EmergencyResponse Division Manager, sharing insighton how to carry out a Crisis Strategyfor our <strong>com</strong>panies.Mr. Tom Stahr shared also interestingpossibilities for demolition <strong>com</strong>panies workingon Emergency Response, based onthe experience of the <strong>com</strong>pany RobinetteDemolition Inc. (founded and managed byThomas A. Robinette).After a very interesting history, EDAkeeps moving forward, and this year withthe change of Secretariat, we wanted toknow first-hand the opinion and expectationsof EDA members for the future. Forthis reason, we run questionnaires aboutthe present and future of the association,to collect the feedback of the membersand I am sure they will give us lots ofgood ideas.There was also time to make newcontacts and meet acquaintances fromthe demolition industry in an easier way,through the diverse leisure activitiesoffered this year, being one of the niceropportunities the Gala Dinner, which venuewas really remarkable (London RoyalCourts of Justice).During the dinner, we announced theClub of Honor and introduced its members,who delighted each guest with their wordsand presence. This initiative is born torecognize the activity of certain peoplewho have been and are very important forboth EDA and the entire demolition sector.EDA would like to recognize them, fortheir service to the demolition industry: Mr.H. van Eck, Mr. David Sinclair, Mr. Gerardvan Vliet, Mr. Walter Werner, Mr. SergePerdrieu, Mr. Howard Button, Mr. Jan Brandis,Mr. Yves Canessa, Mr. Celso Anka, Mr.Domenico Ferrari, Mr. Dietrich Korth, Mr.Daniel Midavaine and Mr. Philippe Sellier.All of these gentlemen are a greatsource of know-how for the new demolitiongenerations. It is remarkable for me toobserve how generational change is takingplace all over our industry and especiallyin the National Associations in Europe, andI was very pleased to see lots of new andyounger faces all through the audience,eager to learn and work in this industry.The Club of Honor will be open toreceive more members in the future, aswe have to recognize the work and abilityof professionals that dedicate their life tothe demolition business.Last, but not least, I would like to thankall of our associates, National Associationsand International Committee, for all theirhelp and support during this Conferencebut also through the whole year.GiuseppePresident of the EuropeanDemolition AssociationGiuseppe Panseri, EDA President, founderand chairman of Despe S.p.A, Italy.Julie set for MountEverest base campA female construction leader is set to prove she ismade of the White stuff later this year. Julie White,who runs the UK concrete diamond drilling andsawing specialists D-Drill (Master Drillers) Ltd inCoventry, will be taking on the 11-day walk toMount Everest Base Camp in Nepal.The base camp is at an altitude of 5.5 kmand will provide the managing director of D-Drillwith one of her greatest ever challenges. JulieWhite agreed to take on the challenge aftersponsoring explorer Mark Wood in his bid to bethe first person to walk to the South Pole andNorth Pole back-to-back.“If anyone buys and takes on and runs abusiness in the construction sector in the largestrecession the UK has ever seen, they clearly enjoya challenge. But this walk is going to be a reallytough physical and mental challenge but one thatI am really looking forward to,” says Julie White.Generation shiftat EdiconsultPDi’s Italian sales agent Ediconsult is announcingthe appointment of Ida De Mari as its new CEO.“I am genuinely pleased to make this appointmentafter Ida’s long standing service to this<strong>com</strong>pany”, said the former CEO, Vittorio Negrone.“Her proven track record of business leadership,passion for media and trade fairs and her highprofile within the market sectors that we operatein, make this a natural choice”.Commenting on her new role Mrs De Marisaid, “ I am really delighted to be taking on this newrole at such an exciting time of Ediconsult’s evolution.The <strong>com</strong>pany has a very strong team and I amreally looking forward to working with them, withMr Negrone’s advice, to help grow the business ina continually challenging economic environment”.New Holland’s EnergySaving Grand PrixNew Holland’s Grand Prix is back, kicking off withthe first event near Bologna, Italy in April. This year’sedition of the popular <strong>com</strong>petition took the brand’slatest models to construction equipment operatorsaround Europe, giving them the opportunity to testtheir skills while experiencing the exceptional fuelefficiency these machines deliver.Participants tackled a series of challenges onNew Holland’s latest models, including the newC Series wheel loaders and crawler excavatorsfeaturing the brand’s Tier 4 interim SCR technology,the new 200 Series skid steer loaders andthe upgraded backhoe loaders. In <strong>com</strong>pleting theirchallenges, the operators experienced the boostin productivity and the savings in fuel consumptionthese machines deliver. The Grand Prix willMark Wood with Julie Whitemove around Europe, with events taking place ina variety of locations in Germany, Spain, Franceand Italy. They will run throughout the summer,building up to the final event, which will take placein Italy in October.JCB’s Steve Simcoxbows out after 44years’ serviceJCB Senior Group Leader Steve Simcox recentlybid farewell to his colleagues at JCB after spendingalmost his entire working life at the <strong>com</strong>pany.Steve, 60, of Cheadle, Staffordshire, trained as aplumber when he left school, but spent just fourdays in the job before joining JCB as a welder.He said an emotional farewell to friends and colleaguesat the world headquarters at Rocesterwhere he has worked for his entire 44 year JCBcareer. Steve said: “It’s been a real roller-coasterworking here and never a dull moment. JCB andthe people who work here have a real can doattitude and that’s what sets the <strong>com</strong>pany apart.There is nothing we can’t do as a team.”12 PDi • Issue 2 • May - June 2011

We are looking for retailers in GermanyNews!ScanCombiflex 1000 radio controlled with six grinding discs ScanCombiflex 700 radio controlled with 3 grinding discs ScanCombiflex 650 with three grinding discsScanCombiflex 500PD withwatertank and three grinding discsScanCombiflex 500i with three grinding discsScanCombiflex 450 NS withwatertank and three grinding discsScanCombiflex 450 withthree grinding discsMADE IN SWEDENScanCombiflex 330with one grinding discNews!With a simple maneuverScan CombiFlex 330be<strong>com</strong>es an edge grinder!REAL GRINDERS FOR REAL GRINDINGRemoval - Grinding - PolishingConcrete Natural Stone WoodScanmaskin Sweden AB Box 187 S-437 22 Lindome Phone: +46-31 99 49 70Scanmaskin Sweden AB Box 187 S-437 22 Lindome Tel: +46-31 99 49 Fax: 70 Fax: +46-31 +46-31 99 99 48 487070 www.scanmaskin.<strong>com</strong>

Words fromthe IDE President“A Lack ofForesight”As part of the new National DemolitionTraining Group Demolition Managercourse, candidates visit the BuildingResearch Establishment headquarters.The purpose of the visit is to seewhat materials are being used in theenergy efficient houses of the future,how those houses might be demolished,and what the proposed demolitionwould cost at today’s prices.In terms of energy efficiency andenvironmental impact, the house designsare cutting edge. And yet theconstruction methods and materialsemployed, such as <strong>com</strong>posite panels,cassettes and foam insulations, meansthat demolition is costly and timeconsuming.These houses of the future maysave thousands of pounds in energycosts over the lifetime of the house,but when they are due for demolitionall of those energy saving costs willbe negated by the higher costs ofdemolition.At the moment, demolition of theseunquestionably innovative houseswould cost 10 times more than demolitionof a similar-sized, traditionallybuilt house. And the arisings from thatdemolition, such as the cassettes and<strong>com</strong>posites, are all destined for landfillrather than reuse.Steve Tomlin of Masco Walcott is apassionate advocate of recycling andreuse and he has ready customers forthe brick, stone, slate, timber and glassused in traditional British housingstock. But I doubt very much thathe would have such a ready marketfor <strong>com</strong>posite panels, roof and floorcassettes and polystyrene.Architects must realise that mosthouses must one day be demolishedand that their designs should, therefore,take into account demolitioncosts and techniques. As it standstoday, the houses of the future maywell meet the government’s environmentaland energy efficiency targets,but in doing so they will prevent thedemolition industry from realising itswaste minimisation goals.The motor industry has beenmade to consider the recycling of<strong>com</strong>ponents via the end of life vehicledirective. So is the time right to introducean end of life building directiveto ensure that recycling and wastemanagement is considered within thedesign process?John WoodwardPresident of the Institute ofDemolition EngineersYoung Swiss cutting specialistsvisit Hilti in LiechtensteinSwitzerland is one of the countries where thejob of cutting concrete is an official and authorisedprofession. The apprenticeship takes threeyears; the young people learn their job in theirdiamond service contracting <strong>com</strong>pany on jobsites, the practical training in the training centreof the Swiss association SVBS (www.svbs.ch)and the theoretical education at the professionalschool BWZ (www.bwzofingen.ch).Recently the apprentices of class BT08,who will finish their apprenticeship in June,visited the Hilti headquarters in Schaan, Liechtenstein.The visitation was exclusively for thediamond products. The youngsters got a lot ofinformation about the Hilti diamond business,the production of diamond core bits, wall sawblades and assembly lines for core drills andwall saws and how their working tools areproduced. Discussions in repair and testing,Doosan rises to sixth placeDoosan Infracore Construction Equipment, theglobal alliance of construction brands that includesDoosan, Bobcat and Doosan Moxy, has risento 6th place in a newly published global leagueof the world’s leading construction equipmentmanufacturers.Much of the growth at DICE has been overseenby new Chief Executive Officer, Anthony C Helsham,who was appointed in April 2010. “2010 was anexcellent year for DI CE with a turnover of US$5.232 billion, <strong>com</strong>pared to a 2009 figure of US$3.288 billion,” says Helsham. “Doosan was alsothe only <strong>com</strong>pany in the top six manufacturers toproduce 2010 sales figures that were larger thanthose recorded for 2008. The <strong>com</strong>pany is well onthe way to achieving our goal of being a top playerin the global construction equipment industry.”The DICE global alliance brings togetherthe strengths of Doosan’s Heavy and Compactconstruction equipment operations, maximisingsynergies, efficiencies and cost savings in a unifiedbusiness by leveraging previously separate functionssuch as engineering, sourcing, sales, marketing andback office activities.In 2010, DICE recorded a 59% increase insales, the increase being due not only to a greateras well as demonstrations of special dry coringof reinforced concrete got full attention ofthe BT08 team.During the day the class received a refresherof what they have learnt in the last twoand a half years. Hilti in Schaan is one of the fewplaces where it is possible to see productionand <strong>com</strong>petence for diamond consumables anddiamond drilling, sawing and cutting machinesin the same place.contribution from profitable markets such as Chinaand Korea, but also from improvements throughoutthe business around the globe.Unit sales of Doosan heavy equipmentincluding excavators, wheel loaders and articulateddump trucks in China leapt 72% in 2010 when<strong>com</strong>pared to 2009.An even more dramatic increase was seen inthe joint Asia Pacific and Emerging Markets sector,where the number of heavy equipment productssold in 2010 was more than 86% higher than thefigure for 2009.Sales of heavy equipment also increased in theEMEA region, where business expanded by morethan 55% <strong>com</strong>pared to 2009 and in the heavyexcavator market, in particular, the <strong>com</strong>pany’s shareof the market grew by 16%.Unit sales of <strong>com</strong>pact equipment <strong>com</strong>prisingboth Doosan and Bobcat branded products alsogrew across the globe with the biggest increasesbeing seen in EMEA, where sales were boostedyear on year by 45% and in the Asia Pacific andEmerging Markets sector where there was a 42%increase in unit sales. Similar growth was seen inthe North America/Oceania region where unit salesgrew by 41% and China, where a 33% increasewas achieved.14 PDi • Issue 2 • May - June 2011

Hilti DST 10-Ewall saw systemMore sawing jobsper day.Hilti. Outperform. Outlast.The new Hilti DST 10-E wall saw,featuring unique design, simply takesefficiency to new heights.As all electronics are incorporated inthe saw head, no separate electricalbox is required so the saw is easier totransport and quicker to set up.Make your life easier and <strong>com</strong>pletemore jobs per day!DST 10-Eelectric wall sawDS TS 20-Eelectric wall sawDD 350 / DD 500coring systemDS WS 10-E<strong>com</strong>pact wire sawDS WS 15wire sawHilti Corporation I 9494 Schaan I Liechtenstein I www.hilti.<strong>com</strong>

Yanmar-So<strong>com</strong>ec collaborationproduces new breaker modelsYanmar has teamed up with So<strong>com</strong>ec to producea new nine model DMS range of hydraulic breakersto <strong>com</strong>plement its mini-excavator range from700 kg to 9.5 t.The new DMS breakers are built in a monoblockstructure, eliminating traditional tie rod boltsthat often break. The only part that needs to beassembled to the body of the breaker by screwsis the accumulator, which doubles as a cap toseal the top of the breaker. By simply removingthe accumulator, all bushings and the piston areimmediately accessible. In its silenced version,the mono-block structure of the DMS series isvulcanized in a unique body with the external caseby means of a patented polyurethane solution.Noise is reduced to a minimum and the miniexcavator’sarm is protected from micro vibrations.The unique stepped piston design deliversmaximum energy to the chisel and minimumrecoil to the breaker body.The DMS breakers have an advancedmodular hydraulic brake on the piston to preventthe hammer from harmful blank firing. When thetool is not in contact with the rock, the oil supplyis automatically recycled and pressure strokesare avoided. A flow diverter valve is placed insidethe mono-block to stabilize the working pressureregardless of the oil flow, resulting in a constantenergy stroke.Technical specificationsModel Energy for Max Max Oil Max Operating Tool Height Min. Max Back MiniStroke Freq Flow Working Weight Dia Width Pressure ExcavatorpreassureCategoryjoule c/min lt/min bar kg mm mm mm bar tDMS 50 120 1 200 17-25 120 60 38 750 125 20/30 0.7–1.2DMS 95/2 240 1 200 27-40 12 95 45 100 130 20/30 1.2–1.8DMS 165 330 1 200 35-50 120 165 55 1 050 165 20/30 1.9–2DMS 210 500 1 200 40-55 120 210 62 1 200 160 20/30 2.8–3.8DMS 260 630 1 100 50-70 120 260 68 1 300 195 20/30 3.0–5.5DMS 310 750 1 000 60-80 120 310 72 1 450 205 25 5–7DMS 410 900 900 70-95 120 410 80 1 550 225 25 8.5–9.5DMS 510 1 080 900 80–110 120 510 85 1 700 230 25 8–11.5DMS 850 1 450 900 100–130 120 850 95 1 830 280 25 9.5–13.5Chicago Pneumatic breakersboost performanceChicago Pneumatic has added 13 new modelsto its new RX line of hydraulic breakers, eachdesigned to work with a specific range of carrier.For example, the 746-joule RX-4 is designedfor 2 to 6t carriers, while the 1,017 joule modelis tailored for skid steers. Models RX14 and upfeature a Power Stop function that reduces blankfiring, protecting the breaker and carrier andincreasing the working life of the <strong>com</strong>ponents.The larger models in the RX line, RX25-RX53,feature a power control valve to increase productivity.This enables the operator to set the breakercharacteristics according to the application forhigher productivity. The RX25-RX53 modelsalso feature a fastening system that uses headbolts and insert threads to distribute the threadstrain equally.Designed with fewer <strong>com</strong>ponents andfewer moving parts, RX line breakers are easierto maintain and repair, a critical considerationfor contractors who want to reduce the risk ofjob-site downtime. All RX breakers also include apower boost feature that achieves higher breakingperformance in tougher applications withoutrequiring additional hydraulic input.Stanley’s MBO5 isthree breakers in oneStanley Hydraulic Tools’ new lightweight MB05concrete breaker features a single four-positionbracket that spins into position, allowing skid steerloaders to operate from multiple angles without interruptionsfor back plate changes when breakingdown walls or sidewalks. The proprietary bracketexpands skid steer work areas and sight lineswith angles ranging from 18 to 36° downward,settings that normally require use of separate backplates for each position.By <strong>com</strong>bining three bracket assemblies intoone <strong>com</strong>ponent, MB05 brings major increasesto skid steer productivity and substantial reductionsin operating costs and dealer inventories.A side-plated model easily attaches to miniexcavatorswith two pins or through a bolt-onquick coupling process. “MB05’s three-piece,modular construction is the least <strong>com</strong>plex, easiest,and most cost-effective to maintain, and amongthe most powerful in its segment,” says StanleyHydraulic Tools president Martin Schnurr. “It’s aone-size-fits-all tool that eliminates the need forextra skid steer brackets and side plates in dealerinventory stocks.”With an operating weight of 367.4 kg, andone of the lightest in its class and 20% lighter thanthe MB356 breaker it replaces, the MB05 bringsincreased stability to 3t skid steers and 3.6t miniexcavators.Flow rates range from 38 to 83l/m,powered through direct acting nitrogen, delivering1,550b/m, almost 50% more than MB356 andwell above most <strong>com</strong>parable models. The MB05<strong>com</strong>es with exclusive features that reduce servicetime and operating costs, including bushings thatlast longer than their conventional counterparts.Worn portions of upper bushings rotate 90° tothe side, and lower bushings are flipped four timesbefore replacement. A sleeve around the pistonallows quick and low-cost replacement of partsdamaged by contaminated oil.So<strong>com</strong>ec heavy breakersizes up for reliabilityAlso setting a personal best for heavy rangehammers is So<strong>com</strong>ec, which debuted its MDO4000 TS at the 2011 Samoter fair. Designed tomeet the needs of the users of excavators in the45 to 65 t range, the 4t, 3m high MDO 4000TS shows off all the technical advantages thatSo<strong>com</strong>ec has be<strong>com</strong>e known. An innovative systemallows users to easily tailor the frequency andpower of the hammer’s blows to the resistanceof the material it is working on. This makes theoperator’s job easier and ensures optimal resultsfrom one job to another.Because tie rods in conventional hammerstructures require frequent maintenance, So<strong>com</strong>ecdevelopment a new system that allowstie rods on the MDO 4000 TS to be tightenedwithout threading, resulting in more elasticityand durability.So<strong>com</strong>ec heavybreakerIssue 2 • May - June 2011 • PDi 19

Technical specificationsHB 2 000 HB 3 100 HB 4 700Service weight (kg) 2 000 3 100 4 700Carrier weight class (t) 22–38 32–52 45–80Oil flow (l/min) 150–190 210–270 260–340Operating pressure (bar) 160–180 160–180 160–180Number of blows (bpm) 300–600 280–560 280–520Doosan hydraulic breakers guardagainst pressure reductionsDoosan has launched its DXB hydraulic breakersfor the European demolition, construction, andmining market. The DXB30, DXB100, DXB170,DXB190, and DXB260 models cover carriersfrom mini-excavators and skid steer loaders tolarge excavators.DXB technology ensures the carrier isprotected from the effects of reduction in pressurepeaks. The breakers include an energyrecovery system and a patented valve system,increasing overall performance. The piston andcylinder are manufactured to precise tolerances,resulting in lower maintenance costs. In addition,an advanced dampening system protects thebreakers against blank firing.The Doosan DXB170 is suitable for 18 to28t excavators, while the DXB260 is designedfor use on 27 to 37t excavators. The superiorpower-to-weight ratios of these breakers providevery efficient reduction of rock, boulders,concrete and other demolition waste, as well asexcellent excavation work.Atlas Copco heavy breakers feature PowerAdapt,optimized power-to-weight ratioAtlas Copco’s heavy hydraulic breaker models,HB 2000 HB 3100, and HB 4700, are designedto allow smaller attachments and carriers toprovide the same kind of performance as theirlarger counterparts. All three deliver significantlymore power than their predecessor models.The breakers are equipped with the Power-Adapt system, which shuts down the breaker incase the oil pressure is too high. “This is usefulwhen the hydraulic breaker is used on differentcarrier units,” says Atlas Copco medium andheavy breaker product manager Torsten Treger.“Hydraulic breakers can generally be hydraulicallyoverloaded if the carrier’s oil pressure hasthe wrong setting. In order to ensure that ourcustomers can make full use of the equipment interms of efficiency and power, we have equippedthe entire range of heavy-duty hydraulic breakerswith PowerAdapt.”With an improper carrier oil pressure setting,conventional pressure relief valves, as the onesfrequently used in hydraulic breakers, continu-ously drain oil into the tank and therefore wasteprecious energy. This affects the efficiency andprofitability of the equipment.The improved guide system of the hydraulicbreakers provides a better stability and resistance.“After all hydraulic breakers are subject totough operating conditions,” says Treger. “A newretaining bar provides better protection especiallyin the lower part of the hydraulic breaker, whichhas to take a lot of wear and tear. Both the Dustand Non-Dust versions of the three new modelsare furnished with the same all-round wearprotection.” The HB Series also feature the VibroSilencedSystem to protect operators againstnoise and vibrations, AutoControl to adapt theblow frequency and impact energy to the rockhardness, and the ContiLube II integratedautomatic lubrication system. The StartSelectfeature allows the operator to influence thebreaker’s starting and shutdown behaviour, whilean optional DustProtector prevents penetration oflower parts by dust and rock particles.Technical specificationsModel Carrier Operating Tool Operating Hydr. Flow. Max Energy perWeight Weight Dia Pressure Req. Frequency Blowt kg mm bar l/mm bpm jouleDXB30 3.5–7 250 68 140 35–50 700 1 000DXB100 10–20 900 106 170 80–140 800 2 350DXB170 18–28 1620 137 180 100–150 600 3 400DXB190 20–30 1750 142 180 120–180 600 4 000DXB260 27–37 2450 156 180 150–240 600 5 000Okada breakerstresses versatilityOkada has designed its TOP 280 breaker for awider range of applications than the <strong>com</strong>pany’sprevious 20t class model. Matched with an 18to 30t class carrier machine, the TOP 280’shydraulic circuit breaker provides a 12% higherimpact frequency with similar blow impact power.In addition, new <strong>com</strong>ponent materials and a newchisel set pin fixing system extends the life ofthe chisel by 35%. The TOP 280 also does notrequire an accumulator, and is easily maintainedwith only a few spare parts.Wacker Neuson breaker letsyou gas and go…Wacker Neuson’s new generation of gasolinebreaker, the BH 65, offers improved reliability,serviceability, and ergonomics features to increaseproduction in a variety of applications,including breaking concrete floors, walls, sidewalks,stones, brickwork, frozen ground, heavyclay and similar materials.Powered by Wacker Neuson’s own EPAcertified2-cycle engine, the tool can also beused for cutting and breaking asphalt pavements,soil probes, ground rod stakes, and tampingsmall backfill areasWeighing in at only 26 kg and hitting with asingle stroke impact of 65 joules/blow at a rate of1250 blows/min, the BH 65 offers an excellentpower-to-weight ratio. The self-contained unitdoes not require a generator or <strong>com</strong>pressor,making it convenient and ideal for use in remote20 PDi • Issue 2 • May - June 2011areas. An improved cooling system, the heart ofthe user-friendly design, uses an air deflector totransfer cool air to the percussion system. Thisdecreases the BH 65’s overall temperatureand increases the operator <strong>com</strong>fort, safety andservice life of the breaker.Improved ergonomic features include anew <strong>com</strong>pact design with redesigned hood andhandles that make it easier to operate the unit.Along with the unit’s patented air percussionsystem and vibration dampening housing, thisfeature enables operators to work for longerperiods of time under more <strong>com</strong>fortable conditionswithout <strong>com</strong>promising performance andincreasing productivity. To improve handling andmaintenance, a repositioned fuel cap is easier toaccess from any position. This allows the operatorto refill the tank with the unit upright or lying onthe ground. An integrated purge bulb removes airfrom the fuel line and improves starting. Anothernew product entry from Wacker Neuson is the EH75/240, the only 240V electric breaker availablein the United States. Using any construction grade3.8kW portable generator, the EH 75/240, withan integrated inverter, converts single phase tothree-phase power ensuring that each time thetool hits the concrete it delivers a consistent hardblow. Because of the inverter, the EH 75 canbe powered by a brushless three-phase motorand offers consistent power supply even whenusing a long extension cord. The inverter alsoprotects the tool with an automatic shut off ifinput voltage is too low or too high, providing forlong life and unmatched durability. By eliminatingthe traditional rotor and carbon brushes foundon <strong>com</strong>petitive models, Wacker Neuson haseliminated the need for maintenance on this tool.With no brushes to replace or winding failures tocontend with contractors can be assured that thistool will provide the best uptime in the industry.The EH 75 weighs only26 kilo, and hits with 75joules. With the high percussionrate of 1275blows/min, the EH 75offers the highest power-to-weightratio ofany breaker inthis size class.Because the EH75 and a small portable generator can easily fitin the back of a pickup truck, the new tool canmeet the performance of 27 to 32kg pneumatichammers, while eliminating the need to tow a<strong>com</strong>pressor. The EH 75’s outstanding performanceand extremely high breaking output is theresult of a new hollow piston percussion systemwith a rod striker and patented shockwaveoptimizedpercussion system along with the highsingle stroke energy.

- Stronger than ever!Pentruder MDU3065 Drill Motor -Soon to be introduced in your market!Discover Pentruder MCCS!Tractive AB I Gjutargatan 54 I 78170 Borlänge I SwedenTel: +46 (0)243 221155 I Fax: +46 (0)243 221180E-mail: info@tractive.se I www.pentruder.<strong>com</strong>Please visit our homepage www.pentruder.<strong>com</strong> for moreinformation about our products and contact details tothe Pentruder distributor in your country.

Caterpillar’s new H25D hydraulic hammerCaterpillar has introduced the H25D hydraulichammer, which <strong>com</strong>bines simplicity and costeffectivenesswith a class leading power toweight ratio that is optimized for demolitionand recycling.“The release of the H25D hammer is anotheraddition to the successful line of D-series hammersdesigned with the customer’s satisfactionin mind,” says Caterpillar Work Tools EAME salesmanager Scott Graham. “We look forward toproviding our customers with improved value insupport of their demolition and recycling tasks.”The H25D includes a number of newand improved features designed to maximizeproductivity and minimize downtime. The H25Dhas been designed with focus on reliability andease of serviceability. The simple design has astreamlined shape that provides good accessto narrow places. Also it features just two movingparts to minimise maintenance. The H25Dhas no tie rods, an integrated accumulator andintegrated lower tool busing.The H25D has a high blow rate, whichtranslates into high productivity. Also it featuresconstant blow energy regardless of the oil flowadjustment within the specifications.No periodical gas recharging is required forthe H25D, whilst servicing or resealing. The replacementof the single lower tool busing can bedone in a matter of minutes enhancing minimaldown time and better productivity.The hammer <strong>com</strong>es with a <strong>com</strong>plete mountinggroup for the HEXMN 300.9D machine. Thesingle bushing can be replaced in 10 minutes.Technical SpecificationsH25DCarrier Weight Kg 800–1 100Acceptable Oil Flow L/min 15–25Operating Pressure Bar 100–120Impact Frequency Bpm 1 000–1 900**Operating Weight Kg 70Tool Diameter mm 36Noise level dB (A) 121** Operating weight includes hammer, standard tool, and average mounting group.GlobramHydraulic BreakersIn 2010, hydraulic equipment expert Euroram-Rockmaster BV was approached by HenconMobile Equipment BV, which at the time wasworking on the development of a crust breaker,and needed a supplier of a hydraulic breakersuitable to the specific needs of their project.As a worldwide supplier of custommade mobile equipment for the heavyindustries, Hencon BV specialisesin the development of solutions forsituations where conventional vehiclescannot operate satisfactory. For this particularproject the crust breaker, used forbreaking slag on liquid aluminium, was tobe fitted with a hydraulic hammer that canperform under extreme circumstances.Based on the technical requirementssupplied, Euroram Rockmaster BV set towork on the modification of its Globram RM45breaker. Changes were made to its hydraulicand mechanical properties to guarantee optimumperformance in this specific, tough application.With both <strong>com</strong>panies satisfied with the out<strong>com</strong>eof the project, several more modified breakershave been delivered over the past six months.Following this first successful project, thetwo Dutch <strong>com</strong>panies are continuing theircooperation in new projects. Both are confidentthe cooperation will expand into the future, andwill allow both Hencon Mobile Equipment andEuroram Rockmaster to maximise their flexibilityand improve their respective product ranges.Atlas Copco’s newCC4700 CombiCutterThe new CC 4700 demolition cutter for 45–65tcarrier units <strong>com</strong>pletes Atlas Copco’s range.Stability, reliability and low operating costs are thekey criteria for the development of this crushermodel. “With the CC 4700 we are respondingto the trend towards larger demolition equipment,”says Silent Demolition Tools product linemanager Wolfgang Hohn, “And we are closingthe gap that existed between our CC 3300 andthe CC 6000, which was presented at Bauma2010.” The CC 4700 follows the design of theentire hydraulic demolition cutter range of AtlasCopco. The system of two articulated arms andtwo lifting cylinders has been tried and testedand it offers a constant high crushing forcethroughout the entire closing process. And the<strong>com</strong>bination of one single and one twin bladearm enables maximum stability even underextreme loads. Universal arms and Steel cuttingarms versions are available for the CC 4700.The crusher arms are stably mounted on acentral main pin, reducing the time required forchanging crusher arms by up to 75%, <strong>com</strong>paredto separate mountings. Both crusher arms canbe fitted and removed as a unit, because thecoupling and positioning system, continues tolink the two together even after removal.Crusher arms can be changed on site,thereby avoiding time-consuming and costlytransport to the workshop. And the practicalconcept for wearing parts also saves time.Crusher teeth and cutting blades can be turnedor changed quickly and easily on site. “We foundthat about two-thirds of the operating cost of anattachment arise from factors such as energy,operator costs, service and maintenance, andonly one-third from the investment costs,” addsWolfgang Hohn. “With the CC 4700 we arefocusing on these consequential costs.”Technical data: CC 4700 U* CC 4700S*Carrier weight class t 45-65 45-65Operating weight kg 4,750 4,500Cutting force t 198Crushing force, front crusher teeth t 155Oil throughflow l/min 350–450 350–450Operating pressure bar 350 350Jaw width mm 1 300 710Jaw depth mm 1 080 860*Jaw version “U” = Universal jaw, “S” = Steel cutting jaw26 PDi • Issue 2 • May - June 2011

Dr. Schulze launches new dry coring system at BeBoSaDr. Schulze GmbH used BeBoSa to unveila new system designed for dry coringin heavily reinforced concretes. The newsystem consists of a rugged drill stand,electric drill motor and drill bits DCD-SPdeveloped specifically for dry drilling. Oncustomers’ requests, the system may <strong>com</strong>ewith an industrial vacuum cleaner and otheraccessories.The system is designed for 28-130mmdrilling to a maximum depth of up to 500mm.To achieve the maximum drilling depth, a260mm long bit can be extended by usinga 300mm extension shaft. The new set-upis said to revolutionize concrete coringbecause it allows for drilling in a very denseand heavily reinforced material at a speed,which is equal to that of the wet process.But unlike wet drilling, the machine generatesvirtually no slurry and dust. Anothergreat benefit of the new system is that itdoes not require any additional cooling whichmakes it the perfect choice for jobs at nuclearpower plants or newly-remodeled premises.The system is also well suited for overheadapplications. The crucial part of the ruggedstand is a column with the steel tooth rake,which is designed to withstand high drillingloads. The roller guides ensure smooth andprecision operation.The electric motor is equipped with atwo-speed reducer and an input for vacuumcleaner. One of the motor’s key functions isautomatic shutdown at overload that helpsprevent damage to the core bit. The core bitis installed on the motor’s spindle by a trapezoidalthread that protects the bit from dustand ensures its quick assembly or dismantling.The custom-made modular drill bits DCD-SP remain the most important element of theentire set-up. Due to their modular construction,the core can be easily removed frominside the bit by screwing off one of the twomodules. The changeable module can be usedrepeatedly and save the cost of buying newcore bits. During multiple tests on different jobsites, the system has shown very high drillingperformances even on extremely reinforcedconcrete. It is true that tools for dry drilling andsawing put a bigger strain on the user’s budgetthan regular diamond consumables. But it salso true that on sites where the use of wateris off-limits, such as nuclear power plants,server rooms and new offices, dry coring isthe only viable option. And even where wateris allowed, the time-consuming process ofwater connection and collection eats up thesavings of purchasing cheaper tools.http://goo.gl/6K5bKhttp://goo.gl/kSgXvVTN’s new FB 150Crusher BucketFollowing the encouraging response at theBauma preview, VTN Europe recently <strong>com</strong>pletedits new series of Crusher Buckets by introducingthe FB 150 model at Samoter in March. The newFB series is not the result of a simple restyling ofthe previous range, first introduced in 2004, butthe result of the <strong>com</strong>pany’s <strong>com</strong>mitment to produceequipment that increasingly distinguishesitself for its quality and reliability.By taking into account both the experiencegained over time and tests conducted followingfeedback from our users, VTN’s technicaldepartment focused on a new job with the aimof creating models that have been improvedin terms of structure, as well as performance,<strong>com</strong>fort and safety.The new version of VTN’s Crusher Bucket ismore attractive thanks to its more uniform design.The jaws are again made with precasting techniquesand retain their reversibility and can beused at least twice as long before replacement.To make it easier to adjust the mobile jaw, VTNhas introduced direct access from outside, makingit easier to extract or insert the special linings,which in turn determine the range of movement.FB 150 <strong>com</strong>pletes VTN Europe’s range andcan be used on excavators between 10 and16t. The mouth measures 600 mm in widthand 450 mm in height and has a capacity ofapproximately 0.5m 3 .ALLU’s newproducts at ConExpoAt ConExpo the Finnish <strong>com</strong>pany ALLU presentedits D–series in a series of demonstrationsfor visitors. These were the ALLU DNS 3-12fine screening attachment, ALLU DH 4-17 forscreening and crushing with changeable bladesand ALLU DNS 2-09 fine screening attachmentmounted on a small skid steer loader.At the ALLU stand there was a large numberof visitors to the demonstrations and a positivefeeling of better times ahead. “The exhibition wasa huge success and there is an obvious changetowards better times in sight. In some countriesthe movement is faster and in some the start isa little bit slower, but the direction is right,” saysALLU Finland managing director Kauko Pylväs.The demonstrations ran all day and everyday of the exhibition and received a lot of positivefeedback. Material used in the demonstrationswas very harsh and made many visitors returnto watch again how ALLU screened the hugerocks from the gravel. ConExpo visitors werealso first to see the new ALLU PMX Power Mixer,officially launched at ConExpo. The new mixeris a part of the ALLU Mass Stabilisation Systemmeant for stabilising soft or contaminated soilsand processing dredged sludge. The new PMXmixer has many new innovations, includinginclined drums that minimize the dead area ofthe bottom frame. This ensures easy penetrationthrough hard crust soil layers.28 PDi • Issue 2 • May - June 2011

What ever your needs for demolition, decontamination or sanitation…We deliver! The right solutions!Test our best expertise in:Wire cutting / Dry sawing / Wet cutting / Drilling / SurfacingCarbodiam Areas of Excellence.· Nuclear de<strong>com</strong>missioning and maintenance.· Asbestos Removal.· Clean demolition of old buildings, bridges, highways,factory chimneys …· Elimination of lead containing coatings.· Environmental soil audit drilling.· Dismantling of shipwrecks, oilrigs, underwater cutting…· Any surfacing, sawing and drilling operationNew and Unique on the market:Carbodiam’s Green Tools and Camel Tools!More details about Carbodiam’s Environmental Developments?YourWorld-YourFuture@carbodiam.<strong>com</strong>Carbodiam s.a.Rue Général Mellier 27 · B-1495 Tilly · BelgiumPhone : + 32 71 87 76 40 · Fax : + 32 71 87 92 32www.carbodiam.be

32 PDi • Issue 2 • May - June 2011of demolition and recycling attachments developed forthe US market. Quite a big number of new demolitionattachments were launched at the show and several ofthem feature in this issue of PDi. There was also quite agathering of mobile crushing and recycling manufacturers.Several new recycling units were launched and arecovered in our special recycling feature on pages 56-63.Atlas Copco took the chance to introducetheir new Powercrusher range on the USmarket. And Rockster Recycler launchednew machinery. It was also a clear trendthat <strong>com</strong>pact and mobile recycling unitsare be<strong>com</strong>ing more popular on the USmarket, which also has been taken upby domestic producers.Tons of newsThere was also a big number ofnew <strong>com</strong>pact loading equipmenton display with many new modelssuitable for loading demolitiondebris on narrow indoor renovationand demolition projects as well as outdoorheavy demolition projects. There were very few specialdemolition rigs on show for heavy duty and high reachdemolition. The large demolition machines with long

A NEW GENERATIONDEMOLITION MACHINESTHE RS SERIESMULTIPLE BOOMCONFIGURATION FORHEAVY DEMOLITIONWORKS• high reach, 45 meter and more• long reach• foundation ripperDUE NOVEMBER 2011Offshore ServicesKraantechniekP.O. Box 4128 • 1620 HC HoornThe NetherlandsPhone +31 (0)229 213372Fax +31 (0)229 211439 • rsp@rusch.toHijs- en HeftechniekSpecial ProductsWWW.RUSCH.TO

MORE PROFIT & ZERO EMISSIONwith <strong>com</strong>pact hydraulic equipmentDynasetsolutionHYDRAULIC GENERATORHigh power electricityalways at work:AC-powered tools, lights,heating, cooling, welding,pumps, microwaves,1or3~motors etc…Power set 3,5-200 kVAWelding generator180-400 Amps DCMagnet system3-40kW, 220 VDCHydraulic MagnetØ700-1500mmHandy unit for demolitionscrap handling.DynasetsolutionHYDRAULIC COMPRESSORAir in <strong>com</strong>pact size to allwork machines: pneumatictools, cleaning, quarry drillsflushing, pressurizing hydraulicbreakers against dust orwater, filling tires etc…Output 400-7500 l/min.(14-765 CFM), 7-12barHYDRAULIC KNOW-HOWEasy installation and guaranteedreliability. Hydraulic PTO,priority-, LS-valves, HVB-vibra,submersible pumps, etc..Ready installation data forevery machines.DynasetsolutionTake out of hydraulics to produce electricity, high pressure water,<strong>com</strong>pressed air, magnetism, vibration...HIGH PRESSUREWATER PUMPBest power-to-size ratioin the world: powerwashing at work site, street,pipeline, bin cleaning, dustsuppression, water cutting,hydro demolition, scaling,fire fighting, drilling fluidpumping, water hydraulic,washing robot, underwaterwork etc…Water pressure 90-1600bar. Flow 20-300lpm25 years world leader expands for added productivity andwork efficiency – simply and in <strong>com</strong>pact size – without extraengines. World’s best power-to-weight ratio guaranteeseasiest on-board installation on all work machines.Know more? DYNASET Oy, Menotie 3, FI-33470 Ylöjärvi, Finland. Tel +358 3 3488 200,Fax +358 3 3488 222, info@dynaset.<strong>com</strong>, www.dynaset.<strong>com</strong> or dealers around worldreach rigs in Europe have not yet had that break through inthe US. In terms of remotely controlled demolition robots,three manufacturers were represented. These were Brokk,Finmac and a new machine from Hong Kong based HDEngineering. Brokk showed their two latest additions theBrokk 260 and Brokk 400. Finmac showed their existingmodel F16 in the Stanley La Bounty booth. The Finmacrobot is, besides Stanley LaBounty, marketed by the US<strong>com</strong>pany Wrench. The <strong>com</strong>pany offers a wide and <strong>com</strong>prehensiverange of equipment for demolition, includingtwo dust cannon brands from Italy. Another US <strong>com</strong>panythat has increased its marketing efforts across the US boardersis Brunner & Lay. The <strong>com</strong>pany has a long and strongreputation of developing and manufacturing chisels forhydraulic breakers.The new demolition robot model from HD Engineering,HD-50 RB, is quite an interesting piece of equipmentdeveloped for heavy-duty remotely controlled demolition.The unit weighs about 5 t and has a reach of approximately8 m. HD Engineering was once a distributor in the Far EastAsia for Brokk.There were also plenty of models for demolition contractorsthat would like to do something radical about preventingdust from spreading on outdoor demolition sites. A big numberof manufacturers of dust cannons showed their latest models.Several of them are based in Italy but still the biggest in thisarea is US Dustboss, which introduced several years ago therevolutionary method of using water mist to bind dust particlesin the air.A show for heavy equipmentAs usual ConExpo-Con/Agg showed that it is an exhibitionmainly for heavy-duty equipment. Very few manufacturers ofdiamond tools and concrete sawing and drilling equipmentwere present as well as manufacturers of concrete floor grindingand polishing. These manufacturers mainly choose the Worldof Concrete to show their equipment. The 2011 edition ofConExpo-Con/Agg offered a fresh start of something verypositive on the US market, clear signs of a turn in the economy.Let us hope that the show turned out to be a boost for theeconomy that will help the US construction market to recover.Issue 2 • May - June 2011 • PDi 35

Updates for Komatsu Dash 8Demolition ExcavatorsNew JCB’sfor demolitionAt the forefront of its demolition offeringis JCB’s range of purpose-built trackedexcavators. JCB offers XD (Extra-Duty)versions of its JS220 and JS260 excavators,which feature alongside the successfulhigh reach demolition rig for the JS330XDmodel. Each features strengthened boomand dippers, rugged undercarriage guardingand covers, side rail protection systemsand FOPS cab guards with a host of furtheroptions.At the smaller end of the spectrum,Micro excavators are also invaluable forstripping out recyclable materials such asgypsum, plasterboard, and Artex. Smallenough to fit through a standard doorway,the JCB Micro can deliver powerfulperformance within a building. A 13.7kW(18.4hp) engine can handle the toughesttasks in the tightest environments, whilstthe undercarriage extends from 700 mmto 1000 mm giving excellent stability andlift capacity. Fitted with a bucket or breaker,the JCB 8014, 8016 and 8018 miniexcavators are perfect for bringing downinternal walls or for general clean up andloading out workKomatsu offers a <strong>com</strong>pleterange of Dash 8Demolition Excavatorsspecifically configuredfor demolition work,with options designedto meet the rigours oftough demolition applications.The highreach equipment is<strong>com</strong>plemented by conventionaldemolitionexcavators, availablewith mono, straight ortwo piece boom optionsthat can carryout site clearance andother essential taskson demolition sites.36 PDi • Issue 2 • May - June 2011The PC290LC/NLC-8 is the latest addition to the high reachdemolition range and was first presented at Bauma 2010. Followingthe European Demolition Associations safe workingrange guidelines, it is ideally suited for demolition of two tofive story buildings or buildings up to 15m height without theneed for a platform.Extra protectionIts size is advantageous, particularly in restricted areas; the relativelylight weight of this machine makes it easily transportable.It can work in areas where larger 60-70 tonnes machines withnormal boom configurations cannot.Recently Komatsu also added extra protection featuresto all the Dash 8 demolition excavators. These latest developmentsinclude:• An opening front guard: Already proven on High ReachDemolition, it is now available on all Komatsu demolitionexcavators. Operators can easily clean the whole windowspace regularly for maximum visibility.• An optional cylinder guard: Top and side protection of the cylinderrod ensures maximum protection against damage from fallingdebris. (Standard on HRD machines)• A reinforced side link: Demolition work is tough and continuoususe of heavy attachments can induce higher stresses thanconventional digging work.• A boom lamp guard : Extra protection from debris• Completing the range, Komatsu’s short tail excavators witha level II Operator Protective Guard (OPG) are ideal for thosespecial demolition jobs where work space is limited.The KOMTRAX systemThe Dash 8 demolition excavators are all fitted with KOM-TRAX, Komatsu’s Satellite Monitoring System. Machinedata is easily accessible over the internet and allows owners orfleet managers to view their machine’s location, performanceand service requirements. KOMTRAX can track transportmovements and also help to keep the machine secure by sendingan email notification to the owner or fleet manager in caseof an unauthorized engine start.

RELIABLEUsing our Multi-Processors means you can handle virtually any demolition and reduction job with confidence.Maximize productivity and stay flexible due to using the basic housing and a choice of up to six availablejaw sets. For more effective, efficient and sustainable operation, choose the world’s best-selling universaldemolition tool - just like proud owners before you!But that’s not all. You also have the reassurance of our unrivalled spare parts service and vast dealer network.And our work tools generally have a high resale value. What’s more, using them in <strong>com</strong>bination with Cat machinesgives you the perfect performance match. Uninterrupted productivity. And a single point of contact.For the ideal partner for all your demolition needs go to www.cat-worktools.<strong>com</strong>Scan the QR codewith help fromyour QR reader onyour Smartphoneto see the video.©2011 Caterpillar Inc. All rights reserved. CAT, CATERPILLAR, their respective logos, “Caterpillar Yellow” and the POWER EDGE tradedress, as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permissionAEXQ0759-00

38 PDi • Issue 2 • May - June 2011“When fully assembled,the TUHD 90-5 makes ajaw-dropping sight”;