Berco Complete Track Systems - Berco S.p.A

Berco Complete Track Systems - Berco S.p.A

Berco Complete Track Systems - Berco S.p.A

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

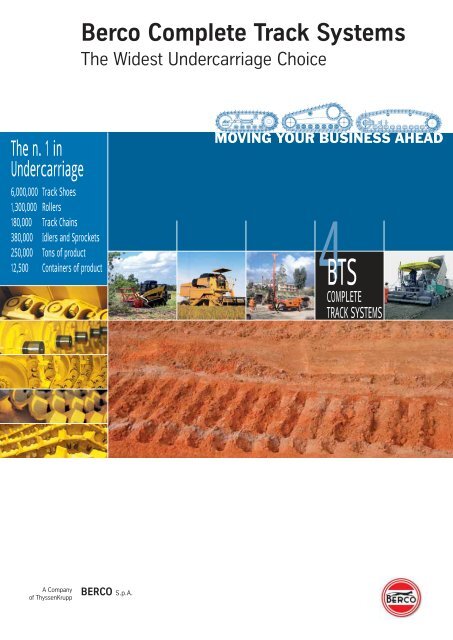

<strong>Berco</strong> <strong>Complete</strong> <strong>Track</strong> <strong>Systems</strong>The Widest Undercarriage ChoiceThe n. 1 inUndercarriage6,000,000 <strong>Track</strong> Shoes1,300,000 Rollers180,000 <strong>Track</strong> Chains380,000 Idlers and Sprockets250,000 Tons of product12,500 Containers of productMOVING YOUR BUSINESS AHEAD4 BTSCOMPLETETRACK SYSTEMSA Companyof ThyssenKruppBERCO S.p.A.

MOVING YOURBUSINESS AHEADWE CAREYOUR BEST UNDERCARRIAGE VALUESince 1920 <strong>Berco</strong> has offered an innovative,reliable and economical solution to anyundercarriage need. Whether for the originalequipment manufacturers (OEM) or theaftermarket, for a special machine or a miniexcavator,for a bulldozer or a miningexcavator, <strong>Berco</strong> can offer you the right answerto your specific requirement.Superior engineering, innovative technology,comprehensive know how and state-of-the-artmanufacturing guarantee the total quality of theproducts and services offered to you.“Original Equipment Quality, Aftermarket Value”AN EXPERT PARTNER YOU CAN RELY ONCustom made solutions and projectengineering support is available upon request.Our team of engineers can help you choose ordesign the most effective and efficient solutionto your specific undercarriage need.They can help you reduce development andengineering time, tooling expenses and facilitycosts, while adding value to your business.“<strong>Berco</strong>, The choice of the leading OEMs”CUSTOMER SERVICEWe have a large dealer network covering morethan 90 countries in the world. They have been inbusiness for decades, they know the business andthey know it from their customers’ point of view.They understand customers’ needs and theyknow that their success is tied to their customers’successes.We support our dealers with our professionalsales force. We train them, and provide them withthe right marketing tools and advancedtechnological systems. We have developed acomputer based integrated system BOPIS (<strong>Berco</strong>Online Product Information System) enabling adealer technician to use a laptop computer fromthe field to consult our database and easily findthe right answer.We back you, wherever you are. We work withour dealers to establish a parts and servicepresence near you, in order to always have theright product at the right time in the right place. Itis customer satisfaction that has built our <strong>Berco</strong><strong>Track</strong> Record.CUSTOMER SATISFACTIONConsidering that more than 50% of yourmaintenance costs will go into maintaining theundercarriage, it is not surprising that <strong>Berco</strong>represents the best choice when the time comesfor the replacement. And the best choice isconfirmed by the large number of SatisfiedCustomers that Keep Choosing <strong>Berco</strong>

LEADERSHIPIN ENVIRONMENTAL DEVELOPMENTNot only do we care about our customerssupplying quality products manufactured underISO 9001:2000 certified processes, but, also, wecare about the Environment.Since Jan 2000 <strong>Berco</strong> is ISO 14001 certified andhas adopted Environmental Proceduresthroughout the entire manufacturing process. Wehave an Environmental Strategy and wecontinuously check on the progress made towardthe set objectives.Getting More out of Less. Reduction of energyconsumption, improved use of materials andminimization of waste, allows for a lower impacton the environment.We have given preference to environmentallyfriendly transportation like trains and boats and wehave begun redesigning our packaging in order touse recyclable materials. We have changed ourpainting processes and now use environmentallyfriendly water-based paint, with a reduction in theamount of pollutant emissions. We have adopteda closed loop cooling system that reuses the waterfrom our heat treatment processes instead ofemitting it into the environment.ISO 9001 - ISO 14001

BCOMPLETETRACK SYSTEMSSYSTEMS TAILOREDTO CUSTOMER NEEDSIn order to respond to the growing interestshown by OEMs in “turnkey” solutions,<strong>Berco</strong> now offers a series of completeundercarriage systems for a wide range ofapplications, such as pavers, drillingmachines, road planers, rice combineharvesters, etc…This new range of products is confirmationof <strong>Berco</strong>’s ability to provide integratedsolutions, working together with thecustomer from the initial design stage rightthrough to the supply of the fullyassembled undercarriage - the “completetrack system” - with undercarriagecomponents, frame, hydraulics andtransmission systems, ready for directinstallation on the machines on themanufacturer’s assembly line.<strong>Berco</strong> is proud of the services it can offerits customers, which include solutionsperfectly tailored to customers’ needs andspecifications, flexible engineering toachieve the best undercarriage solutionquickly and efficiently and comprehensiveproduct support that accompaniescustomers from the design stage rightthrough to installation in the field.A SPECIAL PRODUCTION UNITFOR COMPLETE TRACK SYSTEMSWith this goal in mind <strong>Berco</strong> hasdeveloped a specific production plant toguarantee the manufacturing capacitynecessary to meet customers’ needs - interms both of quality and quantity. A new<strong>Berco</strong> division has been organized toengineer, manufacture and assemble awide variety of different complete tracksystems: working according to thespecifications of both the designdepartment and the customer (coengineering),the products made by thisunit (specialized in the production of tracksystems complete with undercarriagecomponents, frame, reduction gear,etc…) are superb.The <strong>Complete</strong> <strong>Track</strong> <strong>Systems</strong> productionunit not only specializes in themanufacture and assembly of completeundercarriage systems (for manyapplications and many machine types andsizes), but is also capable of supplyingwelded parts for earth moving equipment(i.e. excavator arms and booms, loaderarms, drums, etc…).The new <strong>Berco</strong> <strong>Track</strong> System division iscapable of providing the customer with acomplete manufacturing solution, usingthe combined resources of its threefactories. CNC machining centers(workpieces up to 4 meters long), CNCrobotic welding systems, manual weldingcells and a wealth of experience in the fieldare the key factors in ensuring high levelsof quality and capability.

ERCO, THE COMPETENT LEADER YOU CAN RELY ONCOMPLETE TRACK SYSTEMDesigning the right undercarriagesolution is a very complex task. A lot ofvariables and constraints have to betaken into account, especially when theapplication is not standard and requiresad-hoc solutions and skills.Being sure to create the cheapest and,at the same time, most reliableundercarriage class for a givenapplication is not as simple as it mayappear: track rollers have to be scaledto be strong enough both to withstandconcentrated impulsive loads andsupport the machine in movement; theminimum dynamic performance of themobile equipment to install has to bedefined; the correct stiffness and strokeof the bearing assembly spring has tobe calculated accurately. These are justa few examples of the questions thathave to addressed and resolved whendesigning a complete crawler system.And finding the right answer and, mostimportant, a reliable and optimizedengineering solution, isn‘t always easy.<strong>Berco</strong> has been on the undercarriagecomponents and machine tools marketsince 1920. Thanks to its expertise inthe undercarriage field, developed overmany years of activity, <strong>Berco</strong> can offera vast range of complete solutions forcrawler system OEMs in widely differingindustrial areas (e.g. construction,mining, forestry, agriculture, roadmaintenance, drilling, etc...) and iscapable of maximizing performanceand optimizing costs and servicing.<strong>Berco</strong> has an extensive knowledge ofhow to produce undercarriagecomponents and is familiar with theway the parts actually perform in thefield when the machine is working. As aconsequence <strong>Berco</strong> has decided toapply its know-how to complete tracksystems that are treated as multibodies.Structural simulation is veryuseful for previewing machineperformance in the field. Using testequipment specially designed forundercarriage components,performance results can be obtainedfor single components (e.g. a trackroller test rig that relates machine load,application, speed, oil and lubrication,geometric properties and thermalstatus). Subsequently, complete multibodysimulation and prototyping makeit possible to test the system as awhole after the optimization of all theindividual parts.All the steps in the development, fromthe initial concept to the realization, areplanned together with the OEMcustomer to be sure that theundercarriage system will be able tocope with all the technical andoperational demands it will be subjectto.All this knowledge, together with themost advanced production facilities andISO9001:2000 quality standards, makeit possible to have a product thateverybody can rely on.<strong>Berco</strong> not only develops completeundercarriage systems capable ofsatisfying all customer needs but alsoprovides support throughout the entirelife of the product (from the first idearight through to field assistance) inorder to create a mobile equipment unitreally tailored to customerrequirements.<strong>Berco</strong> - the competent partner youcan rely on.We offer a wide range of applicationsand sizes. On the following pages youwill see just a few examples of ourproducts. Custom-oriented design ispossible. Our complete undercarriageoffer includes frames, track rollers,carrier rollers, track chains, final drivewith sprockets, front idlers with trackadjusters and shock absorbers.Frames are available both as sideframeonly and/or together with carbody.Sideframes can be oscillating or fixed.

4 BTSCOMPLETE TRACK SYSTEMSBGENERIC UNDERCARRIAGE FRAMES• Standard layout dimensions are presented.• Custom-tailored design on request.• Sideframe or carbody supply.• Wide choice of gear-boxes and hydraulic motors is available.• Optional swing bearing plate and swivel joints are available.• Various track shoe widths are available.UNDERCARRIAGE GEAR BOX TRACK CHAIN TRACK ROLLER CARRIER ROLLER SPROCKETREFW O H MT P QTY QTY Z(mm) (mm) (mm) (Nm) (mm) (n°) (n°) (n°)BEX125/1840/7 1840 2358 599 8000 125 7 1 21BEX125/1905/7 1905 2424 596 8000 125 7 1 21BEX140/2100/6 2100 2850 777 20500 140 6 1 27BEX140/2404/7 2404 2992 620 15000 140 7 0 21BEX140/2544/8 2544 3132 694 15000 140 8 1 21BEX140/2553/9 2553 3167 751,5 18000 140 9 2 21BEX140/2699/9 2699 3311 695 15000 140 9 1 21BEX140/2721/9 2721 3373 715 26000 140 9 2 23BEX160/2584/8 2584 3356,5 906 21560 160 8 1 27BEX160/2646/9 2646 3267 776 30000 160 9 2 19BEX160/2820/8 2820 3545 861 24000 160 8 1 23BEX160/2820/9 2820 3558 865 29866 160 9 1 23BEX160/3000/8 3000 3729 754 26000 160 8 0 23BEX160/3300/9 3300 4024 753 30000 160 9 0 23BEX160/3300/9 3300 4024 753 26000 160 9 0 23BEX171,45/2935/7 2935 3732 887 30000 171,45 7 2 23BEX171,45/3280/8 3280 4077 887 30000 171,45 8 2 23BEX171,45/3280/8 3280 4077 887 36000 171,45 8 2 23BEX171,45/3800/9 3800 4597 887 40000 171,45 9 2 23BEX190/3166/7 3166 3959 894 30087 190 7 2 21BEX190/3258/8 3258 4199 1051 60000 190 8 2 23BEX190/3707/9 3707 4517 938,5 60000 190 9 3 21BEX190/3707/9 3707 4517 938,5 60000 190 9 2 21BEX203,2/3790/10 3790 4651 1107 60000 203,2 10 2 21BEX203,2/4284/10 4284 5229 1032 70000 203,2 10 2 23BEX215,9/4350/10 4350 5350 1190 120000 215,9 10 2 23BEX215,9/4993/11 4993 6001 1282 120000 215,9 11 3 23BEX216/3608/7 3608 4590 1207 80000 216 7 2 23BEX216/4374/11 4374 5365 1059 80000 216 11 2 23BEX228,6/4014/7 4014 4757 886 71687 228,6 7 2 21BEX228,6/4350/8 4350 5093 886 71687 228,6 8 2 21BEX228,6/4442,5/9 4442,5 5532 1310 81170 228,6 9 3 23BEX228,6/5490/11 5490 6600 1387 130000 228,6 11 3 23BEX260,35/6375/12 6375 7618 1535 260000 260,35 12 4 23

ERCO, THE COMPETENT LEADER YOU CAN RELY ONDRILLING RIG FRAMES• Standard layoutdimensions are presented.• Custom-tailored design onrequest.• Wide choice of gear-boxesand hydraulic motors isavailable.• Various track shoe widthsare available.UNDERCARRIAGE GEAR BOX TRACK CHAIN TRACK ROLLER CARRIER ROLLER SPROCKETREFW O H MT P QTY QTY Z(mm) (mm) (mm) (Nm) (mm) (n°) (n°) (n°)BDR140/2100/6 2100 2850 777 20500 140 6 1 27BDR125/1840/7 1840 2358 599 10000 125 7 1 21BDR140/2560/8 2560 3324 847 21560 140 8 1 27BDR160/2584/8 2584 3356,5 906 21560 160 8 1 27BDR160/2820/8 2820 3545 861 24000 160 8 1 23BDR140/2544/8 2544 3132 694 15000 140 8 1 21BDR140/2553/9 2553 3167 751,5 18000 140 9 2 21BDR160/2820/9 2820 3558 865 29866 160 9 1 23BDR140/2699/9 2699 3311 695 15000 140 9 1 21BDR160/2646/9 2646 3267 776 30000 160 9 2 19BDR203,2/3790/10 3790 4651 1107 60000 203,2 10 2 21BDR216/3608/7 3608 4590 1207 80000 216 7 2 23BDR215,9/4993/11 4993 6001 1282 120000 215,9 11 3 23BDR260,35/6375/12 6375 7618 1535 260000 260,35 12 4 23

4 BTSCOMPLETE TRACK SYSTEMSBMOBILE CRUSHING PLANT FRAMES• Standard layout dimensions are shown.• Custom-tailored design on request.• Wide choice of gear-boxes and hydraulic motors isavailable.• Various track shoe widths are available.UNDERCARRIAGE GEAR BOX TRACK CHAIN TRACK ROLLER CARRIER ROLLER SPROCKETREFW O H MT P QTY QTY Z(mm) (mm) (mm) (Nm) (mm) (n°) (n°) (n°)BCR125/1840/7 1840 2358 599 8000 125 7 1 21BCR125/1905/7 1905 2424 596 8000 125 7 1 21BCR140/2100/6 2100 2850 777 20500 140 6 1 27BCR140/2404/7 2404 2992 620 15000 140 7 0 21BCR140/2544/8 2544 3132 694 15000 140 8 1 21BCR140/2553/9 2553 3167 751,5 18000 140 9 2 21BCR140/2699/9 2699 3311 695 15000 140 9 1 21BCR140/2721/9 2721 3373 715 26000 140 9 2 23BCR160/2584/8 2584 3356,5 906 21560 160 8 1 27BCR160/2646/9 2646 3267 776 30000 160 9 2 19BCR160/2820/8 2820 3545 861 24000 160 8 1 23BCR160/2820/9 2820 3558 865 29866 160 9 1 23BCR160/3000/8 3000 3729 754 26000 160 8 0 23BCR160/3300/9 3300 4024 753 30000 160 9 0 23BCR160/3300/9 3300 4024 753 26000 160 9 0 23BCR171,45/2935/7 2935 3732 887 30000 171,45 7 2 23BCR171,45/3280/8 3280 4077 887 30000 171,45 8 2 23BCR171,45/3280/8 3280 4077 887 36000 171,45 8 2 23BCR171,45/3800/9 3800 4597 887 40000 171,45 9 2 23BCR190/3166/7 3166 3959 894 30087 190 7 2 21BCR190/3258/8 3258 4199 1051 60000 190 8 2 23BCR190/3707/9 3707 4517 938,5 60000 190 9 3 21BCR190/3707/9 3707 4517 938,5 60000 190 9 2 21BCR203,2/3790/10 3790 4651 1107 60000 203,2 10 2 21BCR203,2/4284/10 4284 5229 1032 70000 203,2 10 2 23BCR215,9/4350/10 4350 5350 1190 120000 215,9 10 2 23BCR215,9/4993/11 4993 6001 1282 120000 215,9 11 3 23BCR216/3608/7 3608 4590 1207 80000 216 7 2 23BCR216/4374/11 4374 5365 1059 80000 216 11 2 23BCR228,6/4014/7 4014 4757 886 71687 228,6 7 2 21BCR228,6/4350/8 4350 5093 886 71687 228,6 8 2 21BCR228,6/4442,5/9 4442,5 5532 1310 81170 228,6 9 3 23BCR228,6/5490/11 5490 6600 1387 130000 228,6 11 3 23BCR260,35/6375/12 6375 7618 1535 260000 260,35 12 4 23

MAKINGA SUPERIOR PRODUCTADDING VALUE TO YOUR BUSINESSState-of-the-art 3D modeling, Finite ElementAnalysis (FEM) and Rapid Prototyping enables todesign, optimize and evaluate a component beforeit is built.Artificial Intelligence techniques are currentlybeing developed to automatically inspect 100% ofcomponents. Reliability Test on components arecarried out to determine life and performance in avariety of field applications.<strong>Berco</strong> Metallurgy Laboratory employs advancedmachines such as an electron microscope withmicroanalysis, a spectrophotometer, tribometersfor wear tests, MTS presses for static and fatiguetests (also at extreme temperatures -70°C ÷250°C) on materials and components.Huge efforts are also devoted to the developmentof New Materials and improvement of the HeatTreating Processes, to guarantee longer productlife and superior products.Photo-elasticity and Strain Gauge techniquesare commonly used for stress and fatigue analysison individual and assembled components.<strong>Berco</strong> adds value not only to the products butalso to Your Business.

STATE OF THE ARTPRODUCTIONWith a capacity of over 250,000 tons of finishedproduct, <strong>Berco</strong> manufactures more than 180,000track chains, 6,000,000 track shoes,1,300,000 rollers and 380,000 idlers andsprockets per year.<strong>Track</strong> links are forged, quenched, tempered,machined and induction hardened on the railsurface. Bushings are turned and drilled in doublespindle lathes, case hardened, ground andsuperfinished (lapped) for longer seal life.<strong>Track</strong> shoes are either hot rolled or forged foroptimum internal grain flow and stronger coreresistance, through hardened and stress relievedfor perfect geometry and excellent resistance tobending.<strong>Complete</strong> track chains are then assembled in afully automatic transfer line (<strong>Berco</strong> Design) whereall important parameters (torque, lubrication, sealspositioning, etc.) are monitored.Rollers are forged in two halves, welded inautomated welding stations, through hardened,machined and finally assembled with shafts,hubs, collars and seal groups.Sprockets are forged for optimum internal grainflow and stronger core resistance, machined andinduction hardened on the entire tooth profile.Idlers are fabricated by automated welding of hotrolled rail rims (one piece) with heat treated forgedhub and high resistance side plates. Paintingcompletes the process while final inspection onthe finished products guarantees the Total Qualityof all components.AUTOMATED PROCESSESAUTOMATIC QUALITYThe entire production process is fully automatedand computer controlled via ComputerManufacturing Technology systems. Thisguarantees a highly reliable process and constantquality of the products.THE RIGHT PRODUCTAT THE RIGHT TIMEA vast variety of raw materials and flexiblemanufacturing give the competitive advantage ofshort lead times while matching your specificneed. That’s what we also call CustomerSatisfaction.HEAT TREATEDTO TREAT YOU EVEN BETTERQuality materials and state-of-the-artmanufacturing are not enough to guarantee thequality of the finished products. That’s why theheat treating processes are carried out makingsure that all process parameters (temperaturegradients, time, quenching temperature, etc.) areconstantly monitored online.Hardening and tempering upgrade mechanicalproperties for superior wear resistance, stressrelieving guarantees perfect geometry andexcellent resistance for longer product life.13

INPUT DATA SHEETIn order to design a correct crawler system, we require the following data from you:PRODUCT REQUESTED:Machine type / application: __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _Sideframe: YES NO<strong>Complete</strong> undercarriage frame: YES NOGENERAL INPUT DATA:Total machine weight (static / dynamic): ____ ____ ____ ____ ____ ____ ____ ____ ___KgWeight distribution (CG position): ____ ____ ____ ____ ____ ____ ____ ____ ___Power available for translation per side: ____ ____ ____ ____ ____ ____ ____ ____ ___kWUndercarriage size now used: ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ ____ __ __ __ __ __ __ __ __ __ _Soil conditions: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

REQUESTED PERFORMANCE:Total pull force: F __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _ kNMax vehicle translational speed: V __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _ Km/hGradeability: G __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _ %Max bending moment: M __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _ kN-mGround pressure: GP __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _ Kgf/cm 2Maneuvrability special requests, min turning radius: _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _mREQUESTED DIMENSIONS:Carriage pitch: A __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _ mmTotal length: B __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _ mm<strong>Track</strong> gauge: I __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _ mm<strong>Track</strong> shoe width, mm: C __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _ mmTotal width: W __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _ mmTotal carriage height: H ________________________________________________ mmTotal sideframe height: h _______________________________________________ mmClear span from ground (headroom): cs ________________________________________________ mmAVAILABLE POWER PLANT - HYDRAULIC PUMP:Number of pumps: __________________________________ -Pump displacement: Dp ____ ____ ____ ____ ____ ____ __ ccPump speed: n ____ ____ ____ ____ ____ ____ __ rpmHydraulic system max pressure: ρs __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _ barWorking pressure (max differential output): Δp __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _ barFlow rate per pump: Q __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ __ _ l/minREQUESTED FEATURES:Oscillating sideframes: YES NOWelded sideframes: YES NOBolted sideframes: YES NO<strong>Track</strong> type METAL TRACK RUBBER BELT<strong>Track</strong> shoes 1 GROUSER 2 GROUSERS 3 GROUSERSCLIPPED MUD SLOT PU RUBBERFixed / Variable displacement motors: Fixed VariableAre stabilizers / levelling jacks used during working cycle?: YES NOPlanned annual demand _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _Expected implementation time _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _Special application conditions _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

01111.WR433GB00CISO 9001 Cert. n. 0029/6ISO 14001 Cert. n. 0009A/3All manufacturers’s names, numbers, symbols and descriptions are used for reference purposes only. All parts listed are of<strong>Berco</strong> original production.The specifications and processes described in this brochure are subject to change without noticePublished by <strong>Berco</strong> Communications Dept.BERCO S.p.A.Via 1° Maggio, 23744034 Copparo (FE) ItalyTel. +39 0532 864 111Fax +39 0532 864 259info@berco.comwww.berco.comYour <strong>Berco</strong> Dealer: